Full-anchor partition pressure transferring grouting anchor rod and application method thereof

A technology for grouting bolts and bolts, which is used in the installation of bolts, earth-moving drilling, mining equipment, etc. Let pressure and other issues save manpower and material resources, simplify construction procedures, and ensure long-term stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

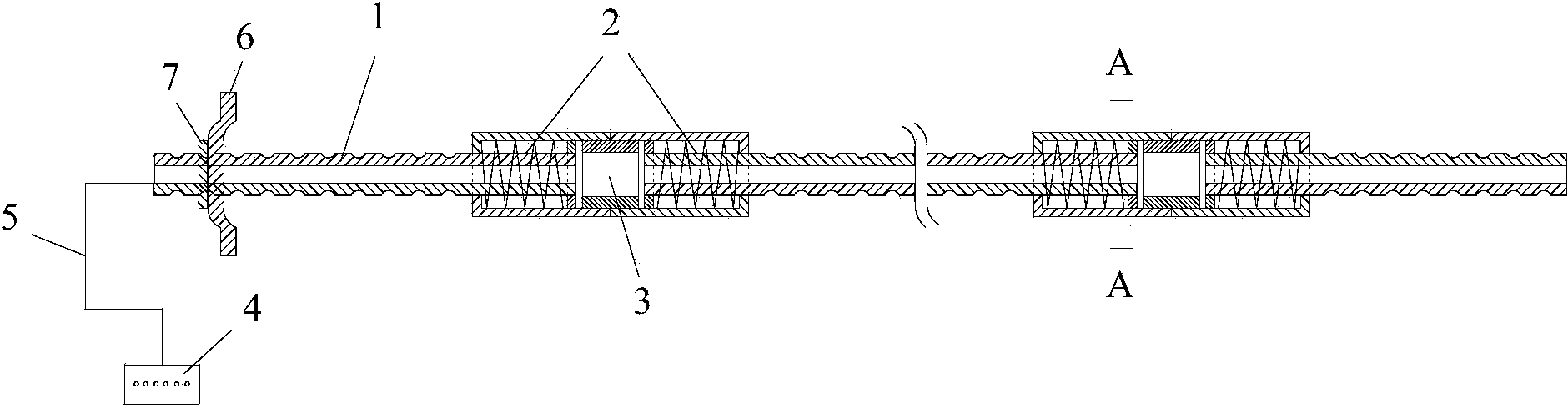

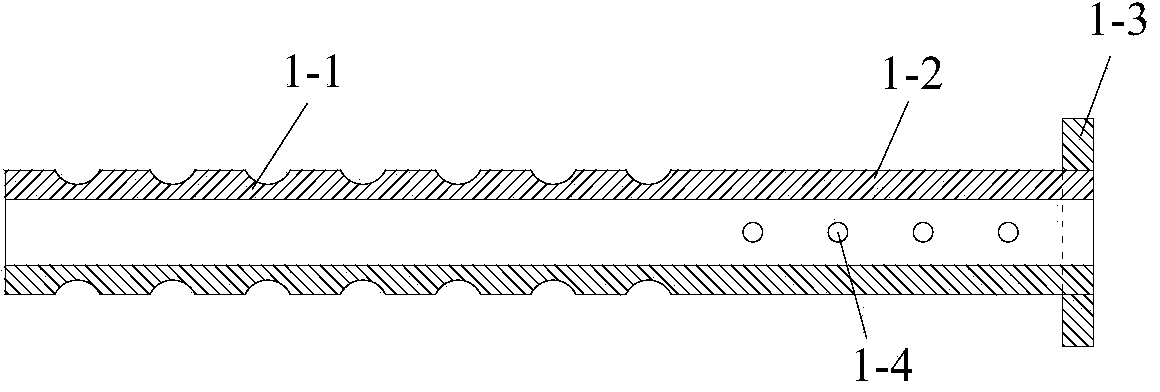

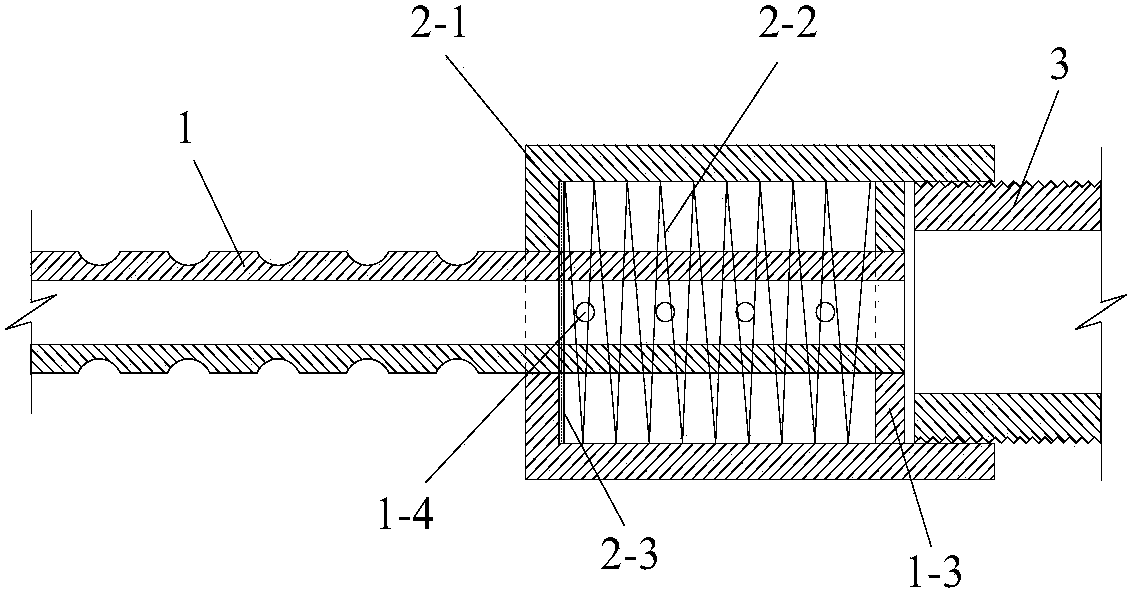

[0023] as attached figure 1 As shown, the full-anchor partition pressure grouting bolt of the present invention is mainly composed of a hollow bolt body 1, a rod body pressure relief device 2, a partition grouting indicator 4, an anchor tray 6 and a lock nut 7; the anchor tray 6 and the lock nut 7 are arranged on the hollow anchor body 1, and the hollow anchor body 1 is cut into 0.5-1.0m long body, and the hollow connecting bolts are arranged between the long body and the long body. 3 Rod body pressure relief devices 2 connected together; the zone grouting indicator 4 is provided with a plurality of indicator lights consistent with the number of rod body pressure relief devices 2, to reflect the pressure relief conditions at different fractured partitions inside the surrounding rock and the stress on the anchor rod body. Each section long body includes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com