Novel squeeze-expansion branch/plate forming device combined with post-grouting process and operation method thereof

A technology of squeezing and expanding the support plate and forming device, which is applied in the direction of foundation structure engineering, construction, sheet pile wall, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

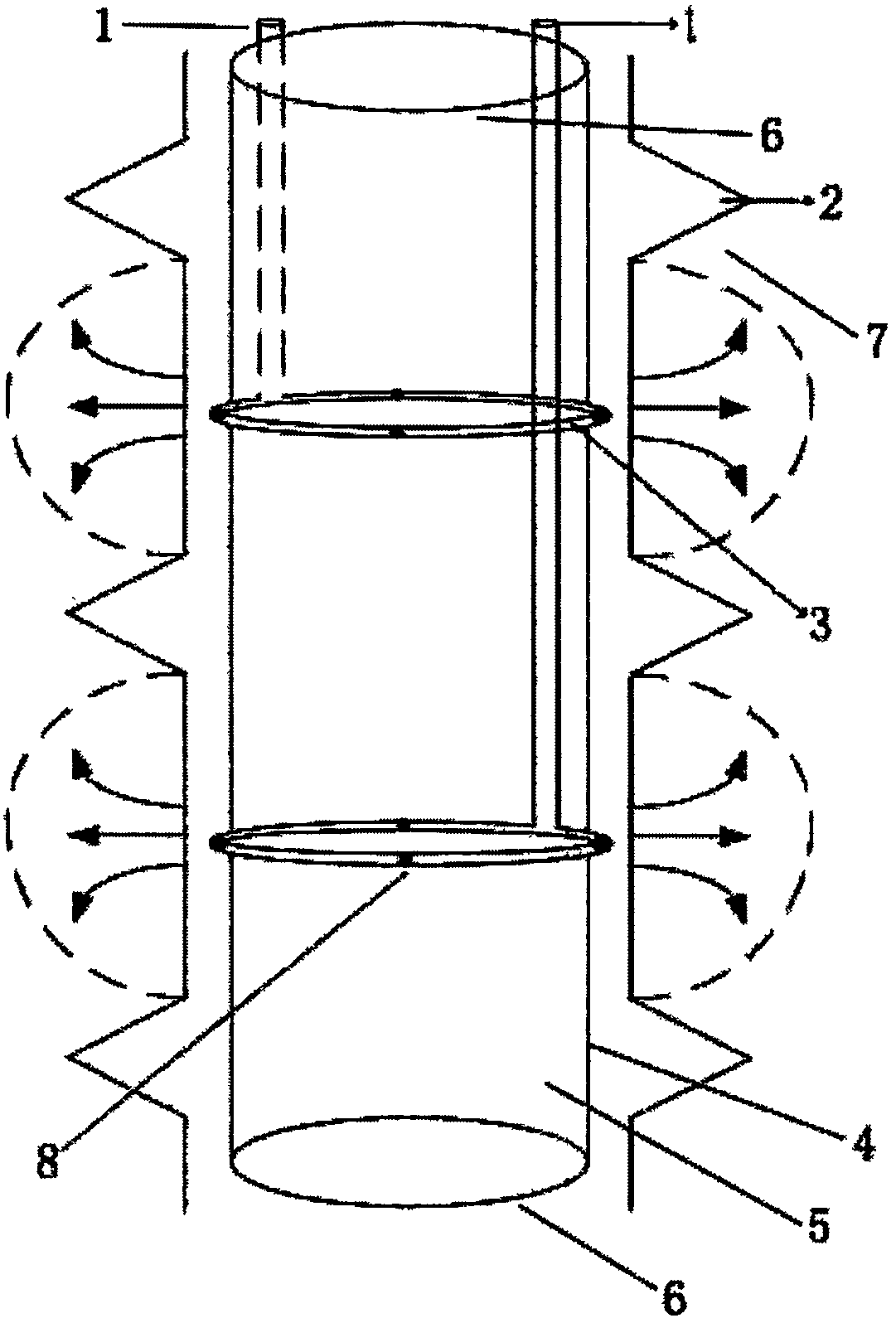

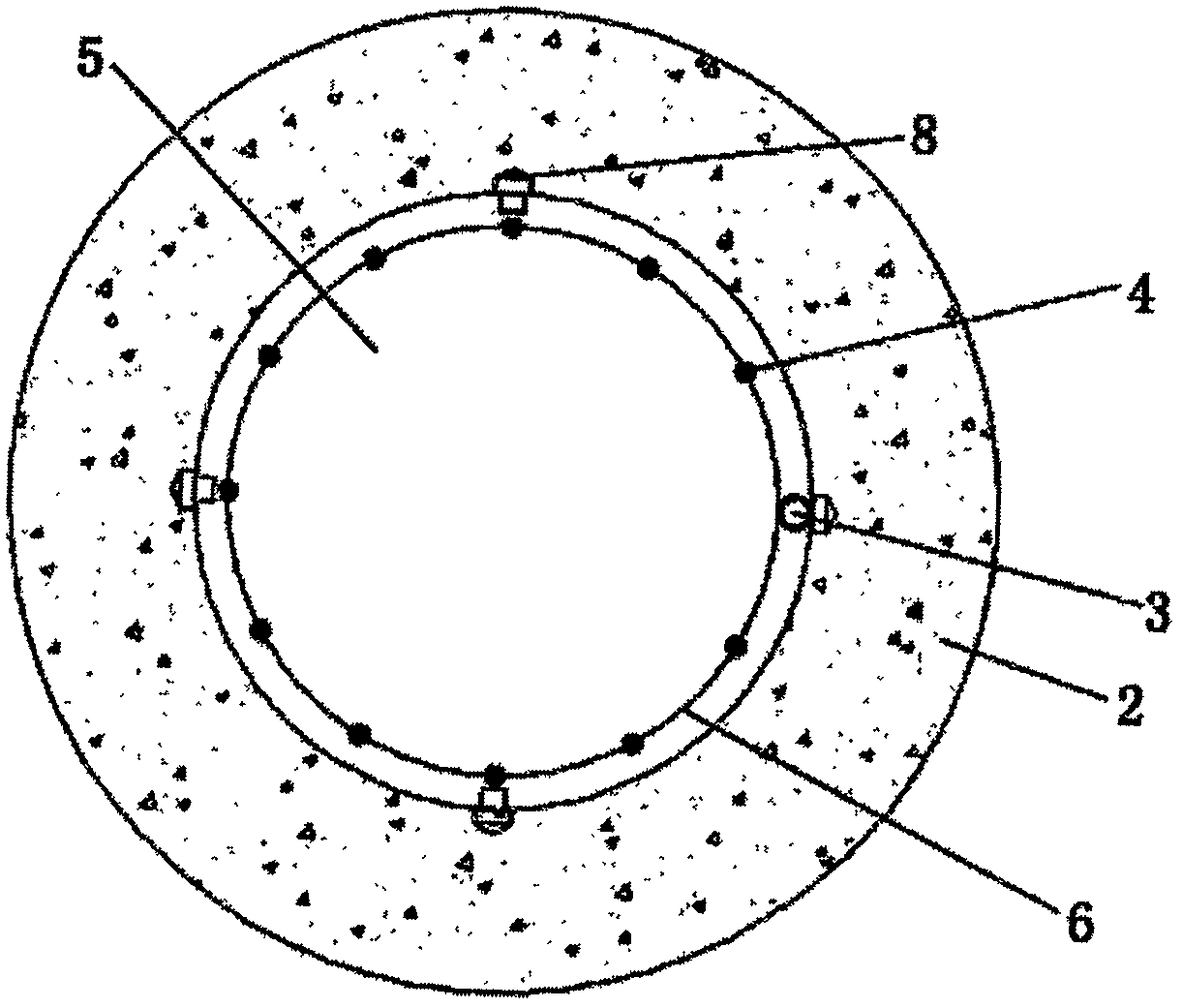

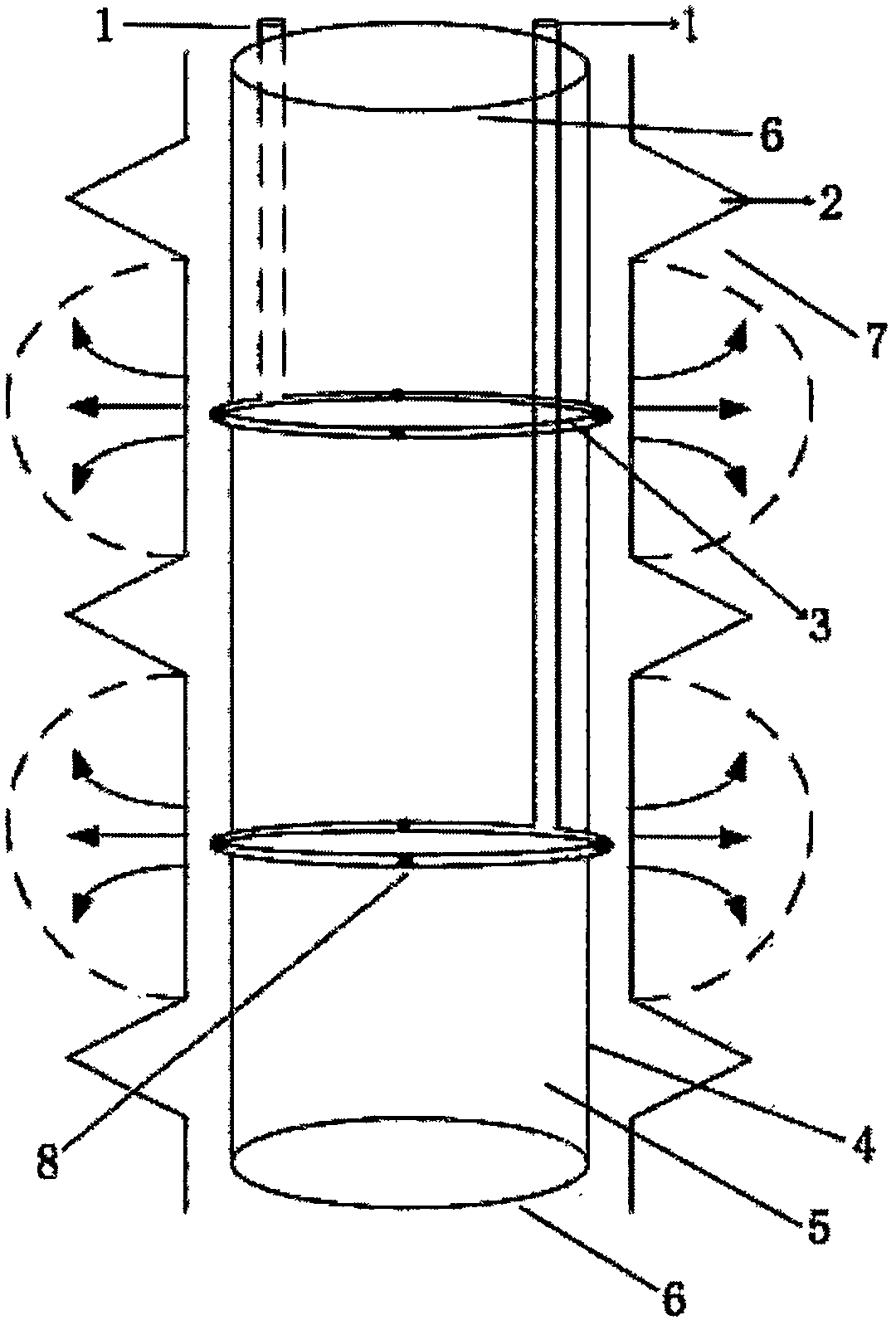

[0018] like figure 1 and figure 2 As shown, the novel extruding and expanding support plate forming device of the present invention in combination with the post-grouting process comprises a reinforcement cage 5, and the outer circumference of the reinforcement cage 5 is covered with a plurality of horizontally arranged annular grouting pipes 3 from top to bottom, so Four one-way throttling grouting valves 8 are uniformly arranged on the annular grouting pipe 3 . A plurality of spiral stirrups 6 are arranged on the side walls of the reinforcement cage 5, and a plurality of vertically arranged main reinforcements 4 cross-connected with the spiral stirrups 6 are evenly distributed on the side walls of the reinforcement cage 5. , the side wall of the steel cage 5 is also evenly distributed with a plurality of vertically arranged galvanized grouting pipes 1 fixed together with the spiral stirrup 6 and the main reinforcement 4, and the top is higher than the top surface of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com