Calcareous sand hollow cylinder sample in-situ curing sample preparation instrument and method

A hollow cylindrical sample, in-situ curing technology, applied in the preparation of test samples and other directions, can solve the problems of instruments and devices that have not yet been reported, and achieve the effects of large void ratio, strong controllability, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

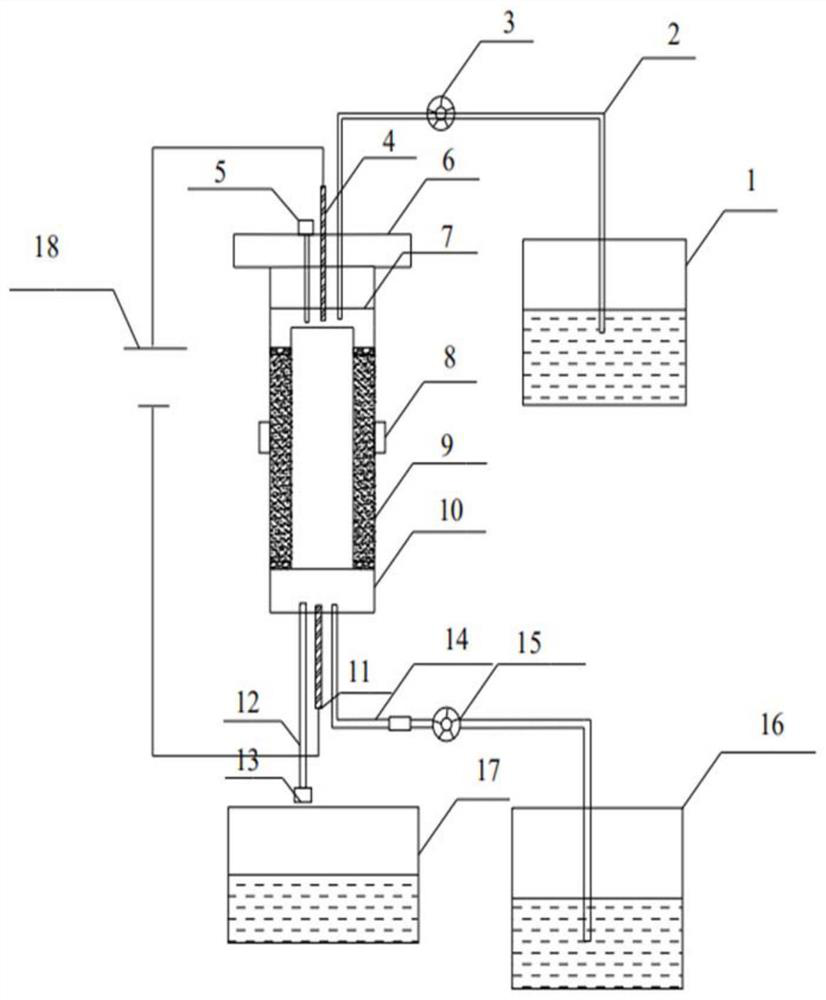

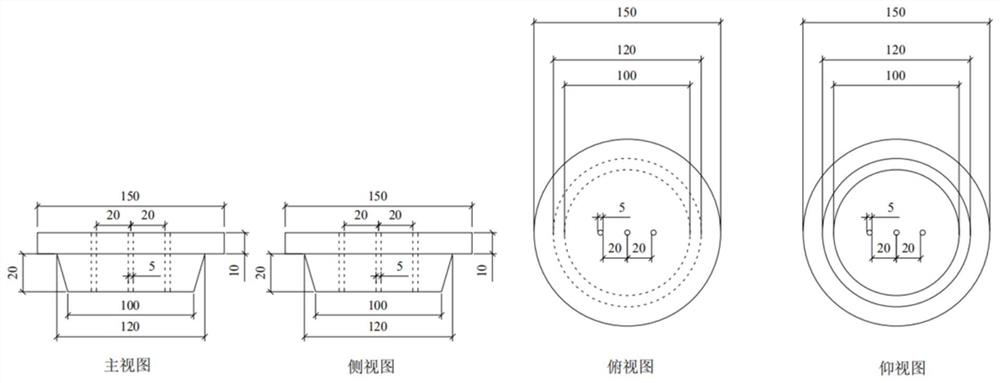

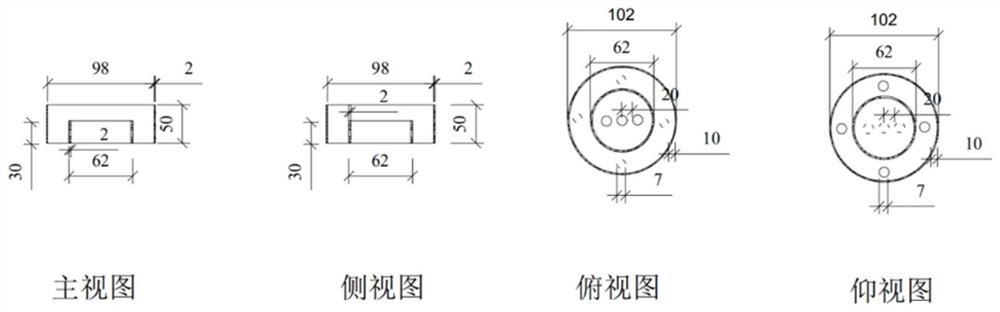

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] refer to Figure 1-Figure 4 , is a specific example of the in-situ solidification sample preparation instrument for calcareous sand hollow cylinder samples of the present invention, including No. 1 slurry storage vessel 1, No. 1 grouting pipe 2, No. 1 peristaltic pump 3, No. 1 graphite electrode 4, Waterproof breathable valve 5, rubber plug 6, grouting converter 7, pipe collar 8, plexiglass tube 9, cylinder assembly 10, No. 2 graphite electrode 11, exudate outlet pipe 12, outlet pipe plug 13, No. 2 grouting pipe 14, No. 2 peristaltic pump 15, No. 2 slurry storage dish 16, exudate collection dish 17, DC power supply 18;

[0028] The No. 1 slurry storage vessel 1 successively stored Ca-rich 2+ The gelling solution and the bacterial solution with its own anions, there are Ca-rich 2+The gelling solution; the No. 1 grouting pipe 2 is connected to the No. 1 grout s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com