Microbe reinforcing sand column grouting device and test method thereof

A technology of microorganisms and sand columns, which is applied in the direction of soil material testing, material inspection products, etc., to reduce the effect of unsatisfactory tests or even failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

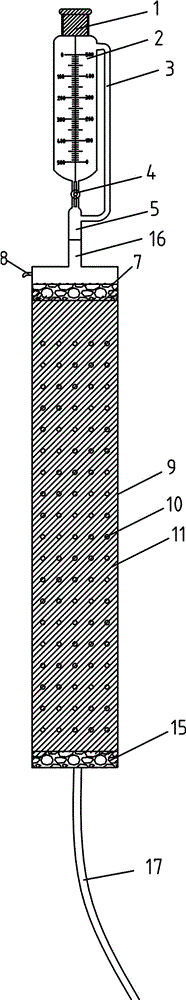

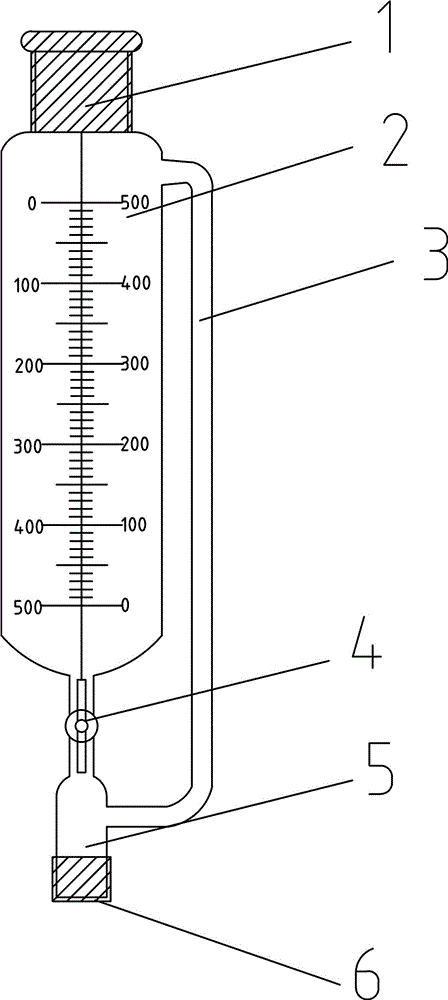

[0035] Such as Figure 1-12 As shown, a microbe-reinforced sand column grouting device includes a constant pressure funnel. The constant pressure funnel is in communication with a grouting nozzle 16 through a grouting hose, and the grouting nozzle 16 is in communication with the upper end of the glass sleeve 9;

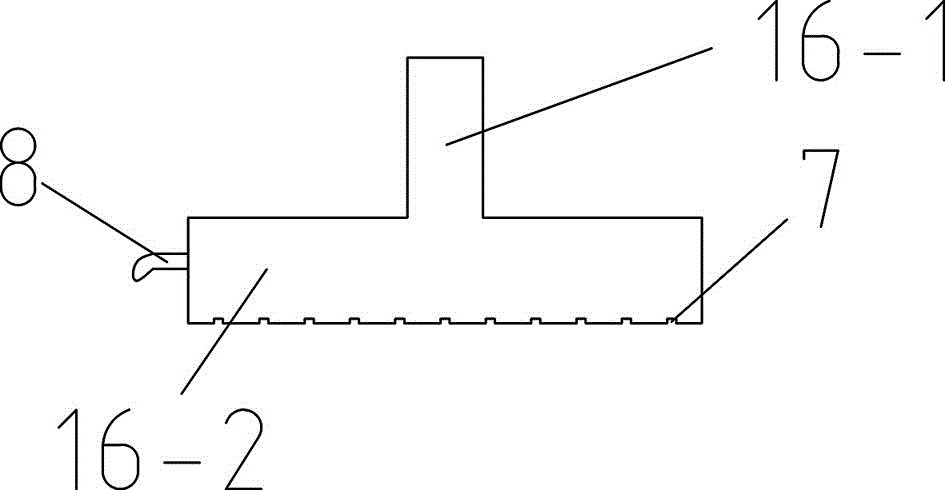

[0036] In the grouting nozzle 16, the liquid inlet pipe 16-1 is connected with the spray plate body 16-2, the spray plate body 16-2 is equipped with a water outlet adjustment switch 8, and the spray plate body 16-2 is evenly distributed with a plurality of water outlet holes 7 , The water outlet hole 7 has a diameter of 1 mm, which is evenly distributed on the nozzle surface according to the diameter of the nozzle;

[0037] The barrel wall of the glass sleeve 9 is evenly distributed with a plurality of sleeve wall holes 10, the diameter of the sleeve wall hole 10 is 0.5 mm, the hollow sleeve cover 12 is matched with the two ends of the glass sleeve, the sleeve cover 12 A ...

Embodiment 2

[0045] A method for grouting test using the above microorganism-reinforced sand column grouting device, the method includes the following steps:

[0046] Step 1: Place the permeable stone 15 on the bayonet plug 14, press the upper surface of the permeable stone 15 into the bayonet plug 14 to make the plane level, and then clamp the bayonet plug 14 on the lower end of the glass sleeve 9;

[0047] Step 2: Put the rubber sleeve 11 on the outside of the glass sleeve 9 so that all sleeve cover holes 13 on the glass sleeve 9 are covered to prevent sand samples and grouting liquid from leaking out of the sleeve wall holes 10 and affect the test effect ;

[0048] Step 3: Inject a sand sample into the glass sleeve 9. After injecting the sand sample, place the permeable stone 15 on the sand sample so that the upper surface of the permeable stone 15 coincides with the upper end surface of the glass sleeve 9, and then grouting with silicone rubber The nozzle 16 and the glass sleeve 9 are glued ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com