Novel pouring device for model test and application method

A technology of grouting device and model test, applied in soil material testing, material inspection products and other directions, can solve the problems of complex experimental device, can not meet the development of grouting engineering, etc., and achieve simple device, strong disassembly, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

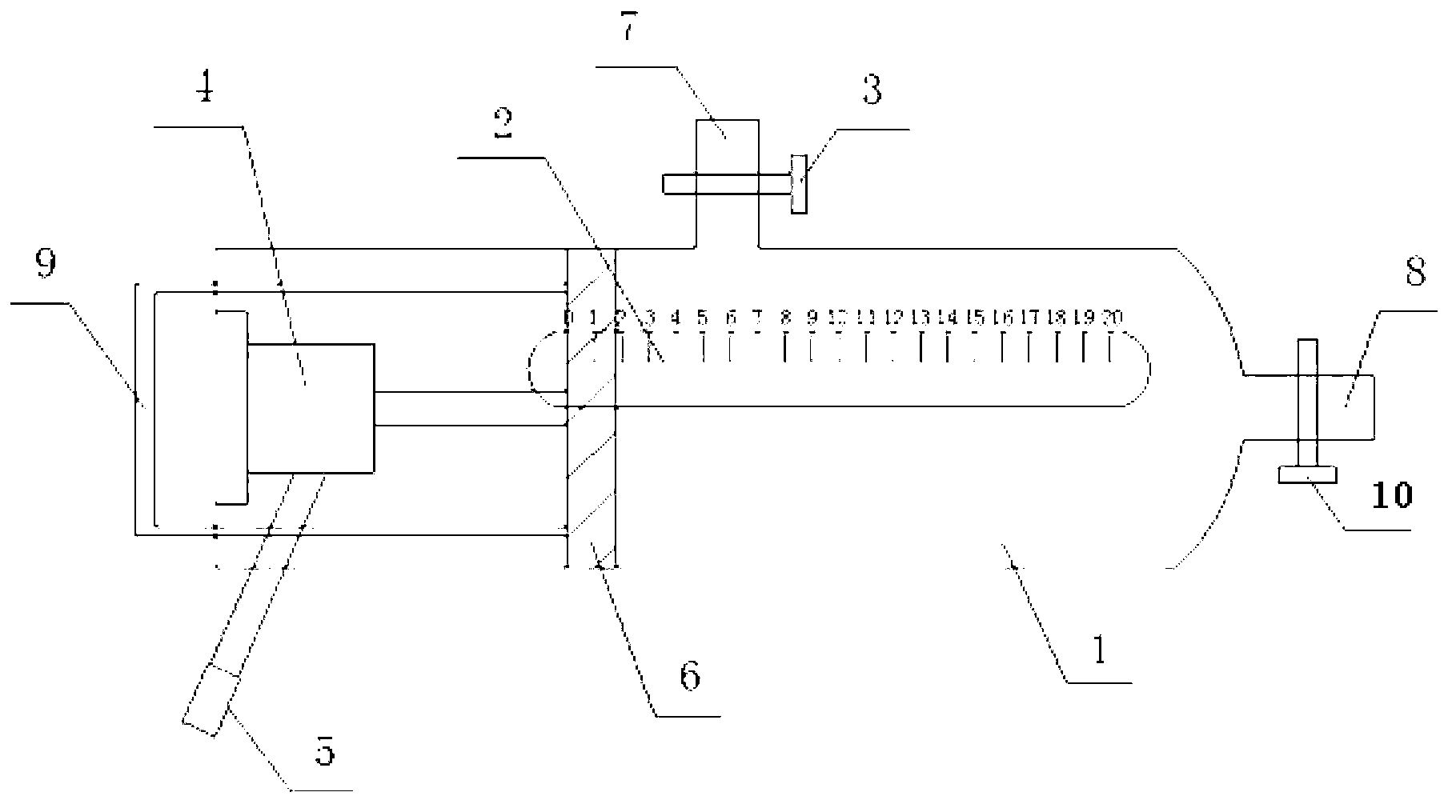

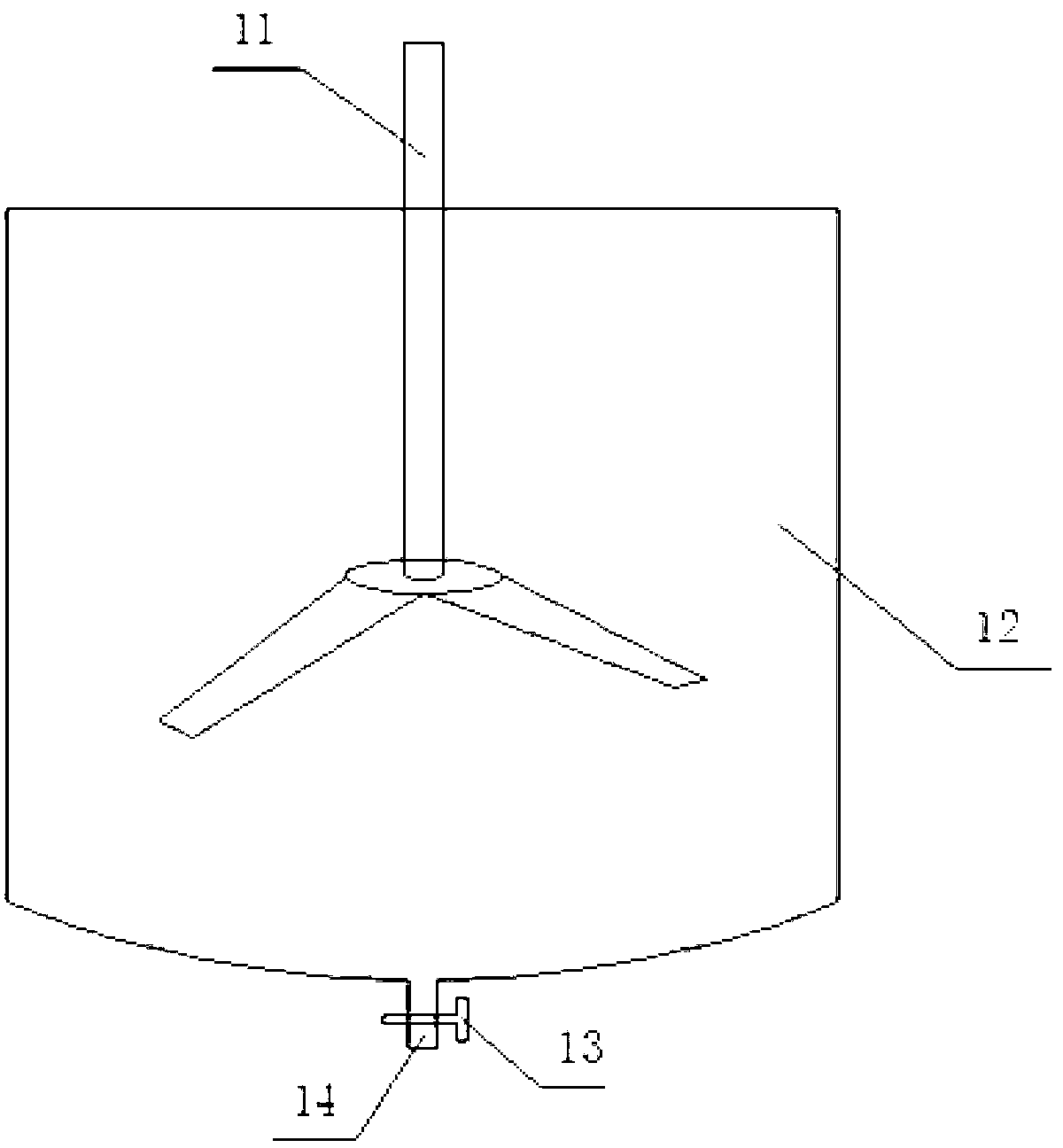

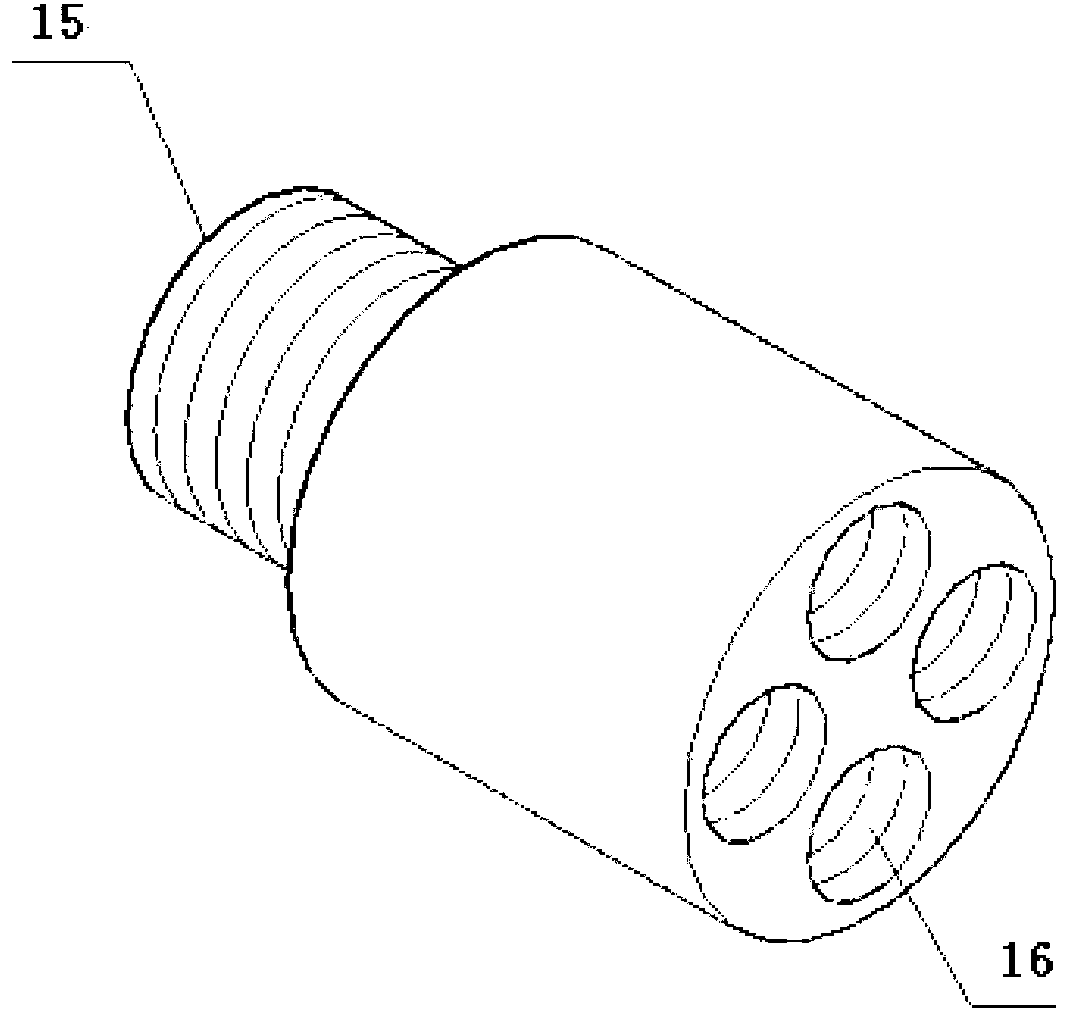

[0035] A new grouting device for model experiments, including: grout storage 1, glass dial 2, grout stop valve 3, hydraulic jack 4, lever 5, piston 6, grout inlet 7, grout inlet 8, pull rod 9. Anti-slurry valve 10, mixer 11, slurry mixing tank 12, slurry outlet valve 13, slurry outlet 14, #1 slurry delivery pipe connection port 15, #2 slurry delivery pipe connection port 16, grouting hole 17.

[0036] The slurry outlet 14 is threaded and can be connected to the slurry delivery pipe through bolts, and is provided with a slurry outlet valve 13;

[0037] The grout inlet 7 is threaded and can be connected to the grout delivery pipe through bolts, with a grout stop valve 3; the grout injection port 8 is equipped with an anti-slurry valve 10 to prevent the grout from flowing back; the glass dial 2 can control the amount of grout ;

[0038] The #1 grouting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com