Forming system for baked food

A technology for baking food and forming device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

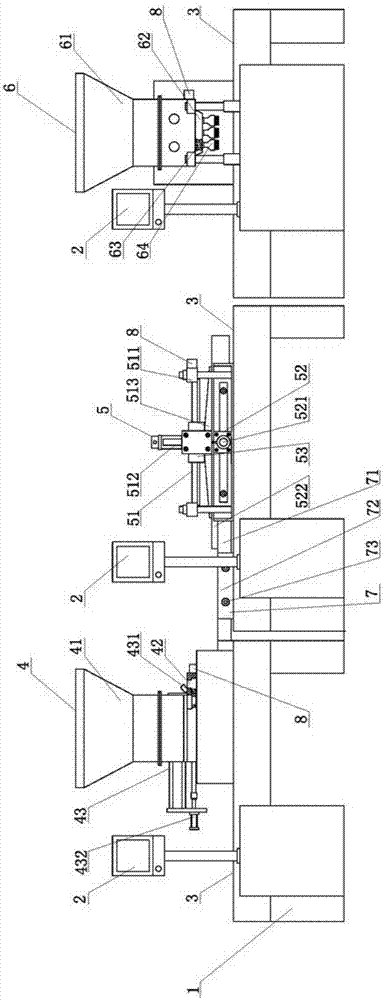

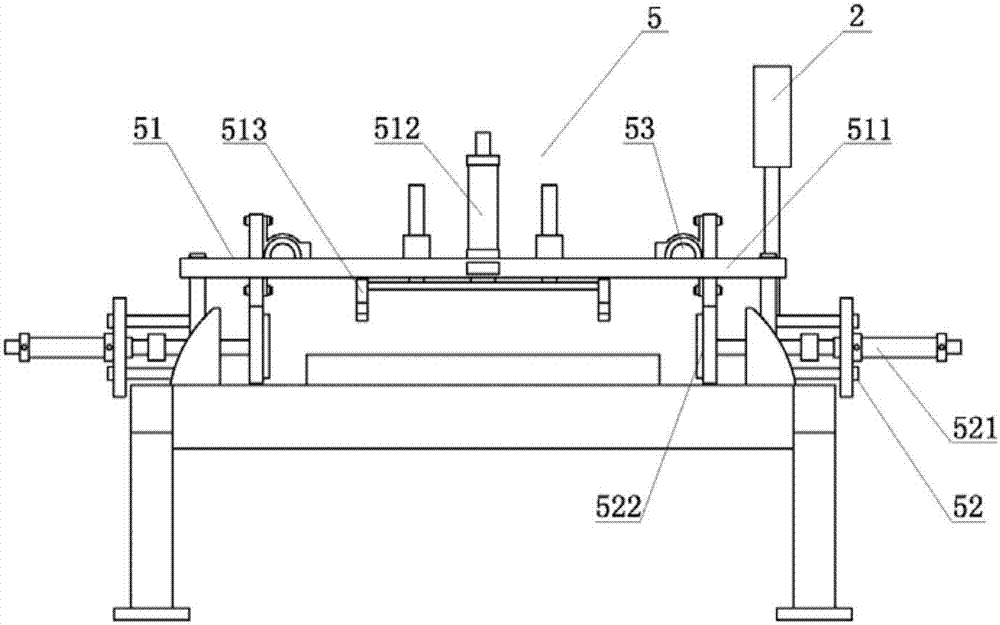

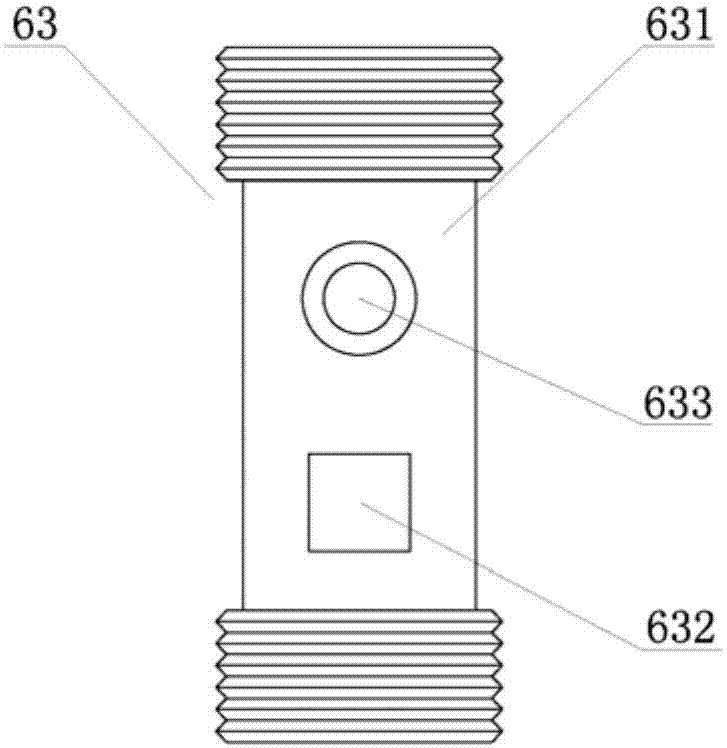

[0035] Embodiment: The working process of the baked food forming system is: before the work, firstly prepare the granular matter that needs to be added such as nuts and prepare the slurry required for production, and then respectively introduce the nuts and slurry into the quantitative feeding mechanism 4 in the storage hopper 41 and the grouting hopper 61 of the grouting mechanism 6, and then select a material tray with a suitable size containing the mold cavity, adjust the adjusting bolt 73 according to the size of the material tray, so that the distance between the movable guide plates 71 on both sides is the same as that of the material. Disk adaptation, complete the preparations before booting.

[0036]Then start the transmission mechanism 3, the transmission mechanism 3 is set to a belt drive or a chain transmission mechanism, under the transmission of the transmission mechanism 3, after the empty material tray is transported forward to the lower end of the storage hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com