Bridge crane-below multilayer laser scanning container truck and lifting appliance locking head aligning method

A laser scanning and laser scanner technology, applied in the direction of load hanging components, transportation and packaging, can solve the problem of unable to achieve the alignment of the pallet and the spreader lock, and achieve the effect of improving work efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

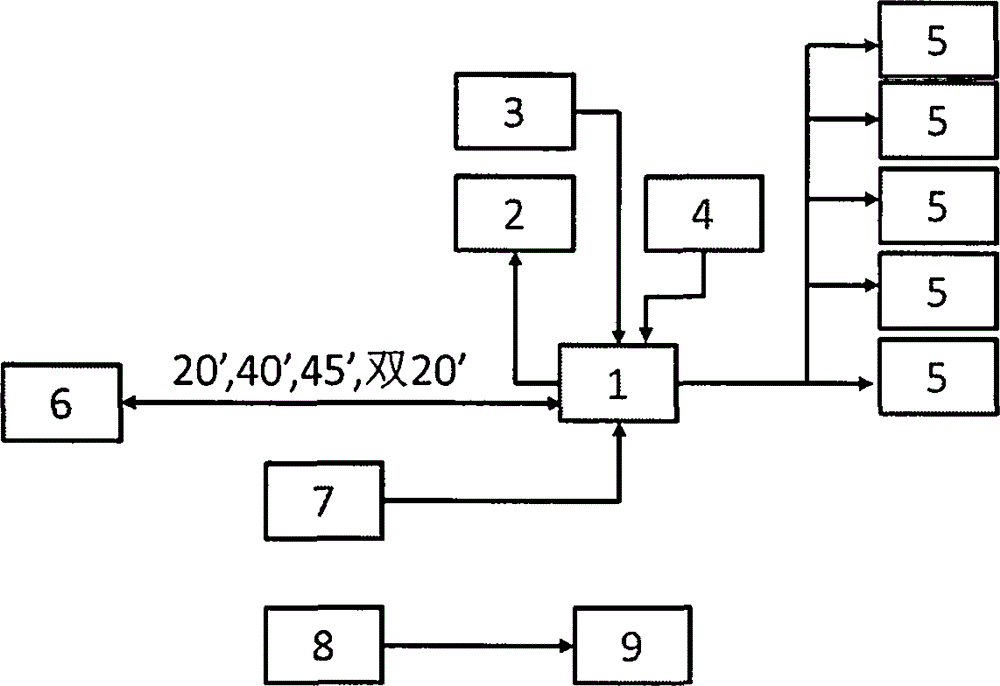

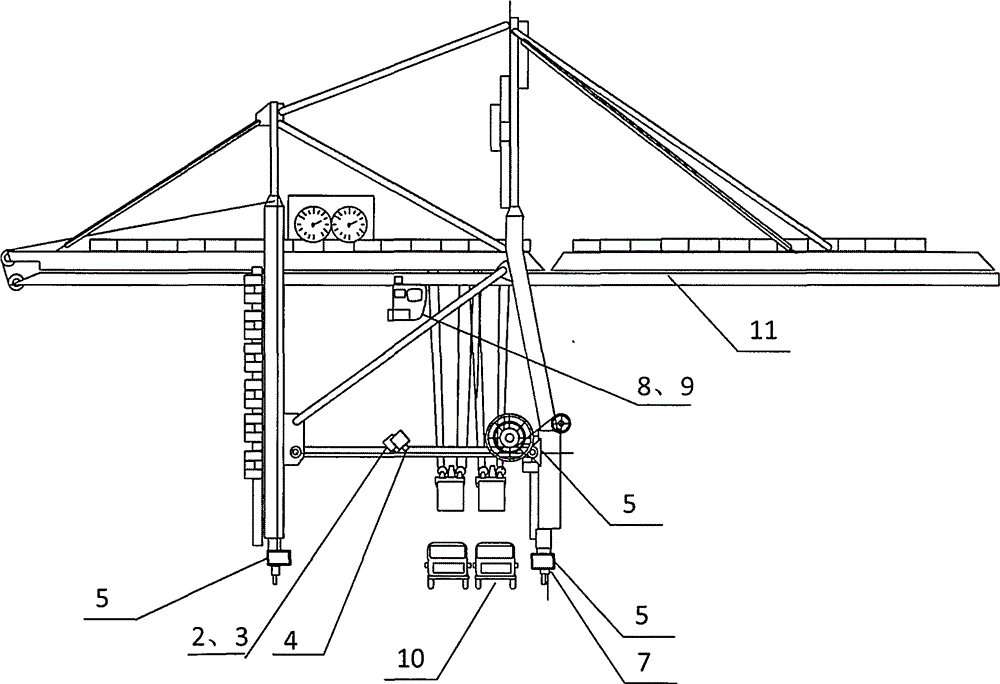

[0039] Such as figure 1 As shown, the microprocessor (1) is respectively connected with the electronically controlled rotating device (2), the multi-layer laser scanner 1 (3), the multi-layer laser scanner 2 (4), the high-brightness light-emitting diode display screen (5), the bridge Crane PLC (6) and bridgeside lane selector (7) are connected, and wherein multi-layer laser scanner 1 (3) is installed on the electronic control rotating device (2), can rotate with the electronic control rotating device rotation. The cab lane selector (8) communicates with the microprocessor (1) through the PLC communication module (9).

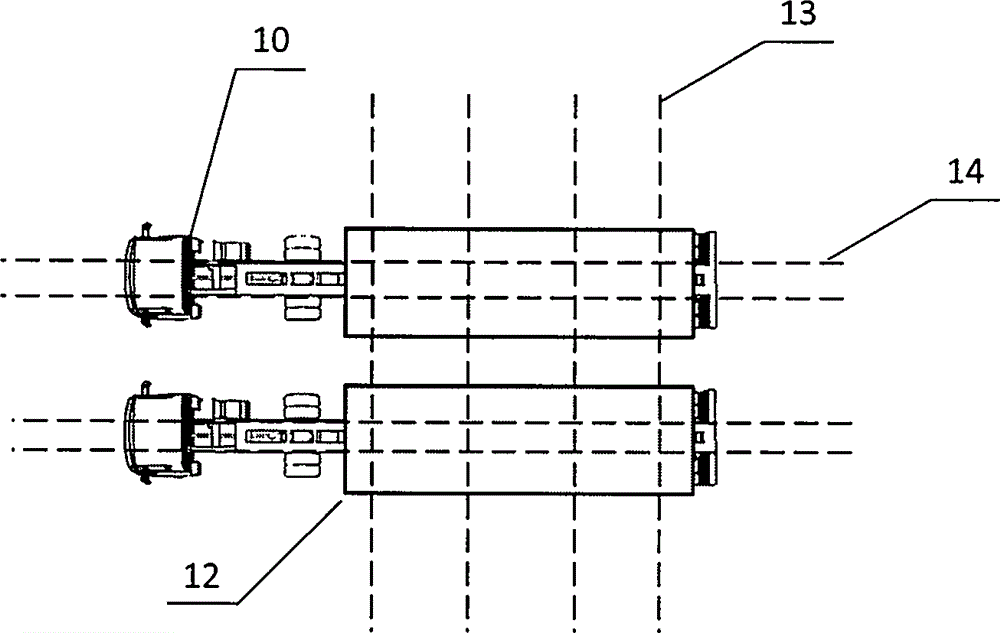

[0040] Such as figure 2 The high-brightness light-emitting diode display screen (5) shown is installed on the side of the crossbeam on both sides of the bridge crane (8) at sea and land. The installation height is consistent with or slightly higher than the horizontal line of sight of the truck driver. There are two display screens in the forward and reverse d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com