Inverse armature brazing machine with double feeding of brazing wire belts and welding technology thereof

A technology for feeding brazing wire and brazing machines, which is applied in welding equipment, tin feeding devices, metal processing, etc., and can solve problems such as low failure rate, short life, and reduced use of brazing material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

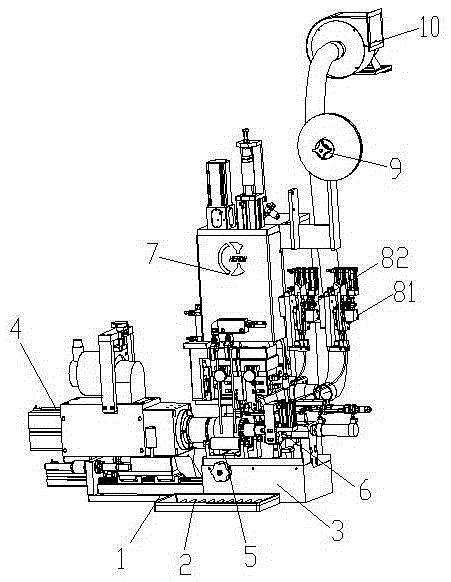

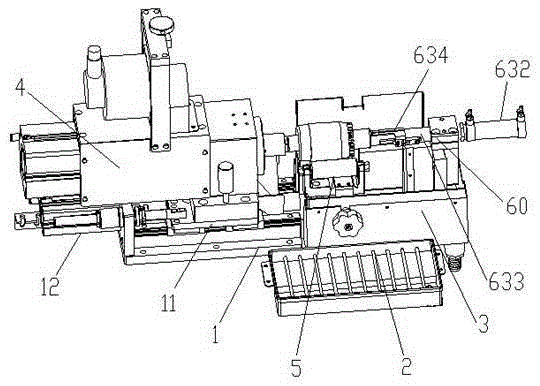

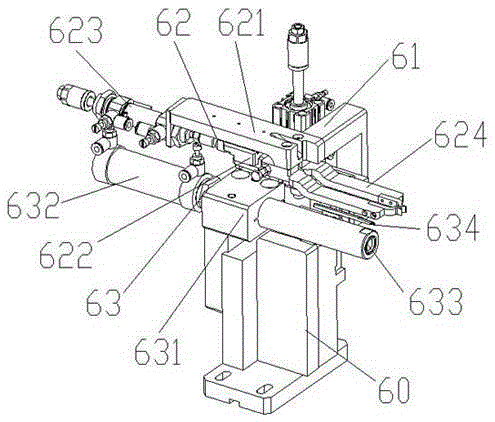

[0029] In this example, refer to figure 1 and Figure 6 As shown, an inverter double-feeding wire belt armature brazing machine of the present invention and its welding process include an armature stock tray 2, a machine base 1, a feeding support base 3, a servo clamping indexing mechanism 4, an electric Pivot feeding idler mechanism 5 , armature support deviation correction mechanism 6 , wire pressing welding mechanism 7 , first brazing ribbon mechanism 81 , second brazing ribbon mechanism 82 , solder pan 9 and smoking mechanism 10 .

[0030] In one of the embodiments, the machine base 1 is set on the left side of the feeding support base 3, the armature limit moving assembly 11 is set on the machine base 1, and the servo clamping index mechanism 4 is slidably set on the armature limit On the moving assembly 11, the armature feeding idler mechanism 5 and the armature support deviation correction mechanism 6 are arranged on the feeding support base 3 from left to right, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com