Large-span truss-type prefabricated member conveying and alignment assembly system

A technology of prefabricated components and assembly systems, which is applied in the direction of building construction, construction, and building materials processing. It can solve the problems of reducing labor intensity, potential safety hazards for operators, and high labor intensity of personnel, so as to reduce labor intensity and improve The effect of improving safety and alignment assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

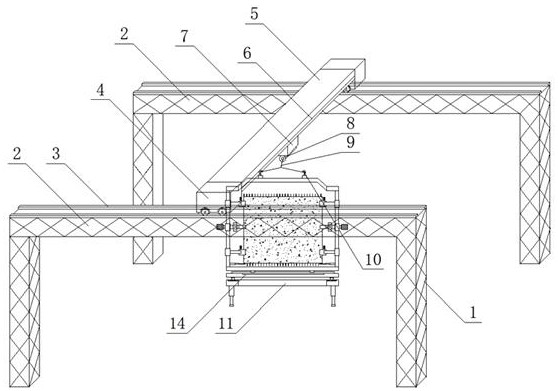

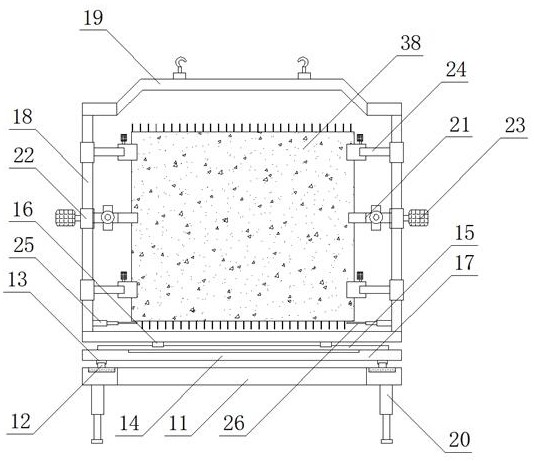

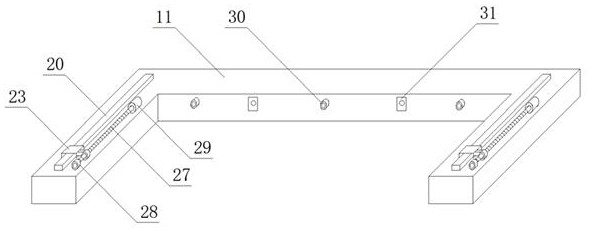

[0024] see Figure 1 to Figure 6, a large-span truss-type fabricated prefabricated component delivery and alignment assembly system of the present invention, including a vertical support tower 1, is characterized in that: the vertical support tower 1 is fixed on the outer four corners of the building, located on the same side Horizontal trusses 2 are arranged horizontally on the tops of the two vertical supporting towers 1, and track chutes 3 are arranged on the horizontal trusses 2, and track trolleys 4 are respectively set on the two parallel track chutes 3, and the two track trolleys 4 There is a hoisting truss 5 horizontally connected between them, the lower surface of the hoisting truss 5 is horizontally provided with a hoisting mobile trolley 7, and a winding machine 8 is installed on the bottom of the hoisting mobile trolley 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com