Intelligent alignment assembly equipment and alignment assembly method for prefabricated parts of assembly type shear wall

A technology of prefabricated components and assembly equipment, which is applied in the construction of buildings, construction, and the processing of building materials. , Reduce the labor intensity of personnel, and improve the effect of anti-fall self-locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

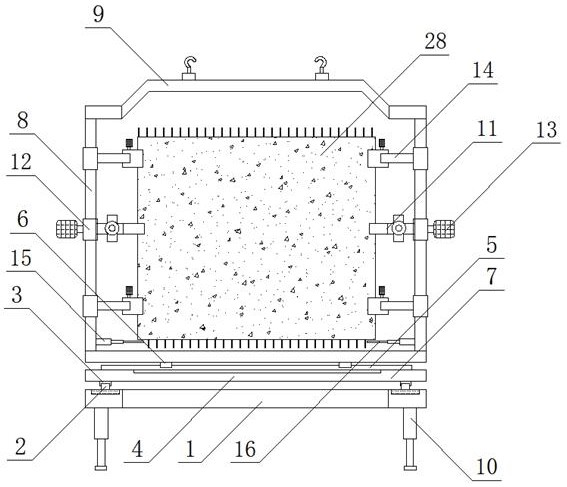

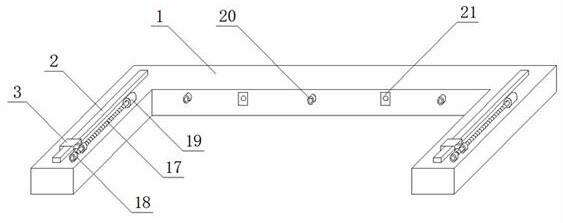

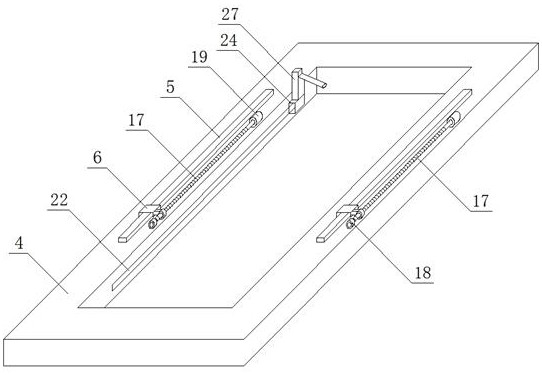

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] see Figure 1 to Figure 5 , an intelligent alignment assembly equipment for prefabricated shear wall prefabricated components of the present invention, including a lifting base 1, characterized in that: synchronous hydraulic cylinders 10 are respectively installed on the four corners of the lower surface of the lifting base 1, and the lifting base 1 A pair of longitudinal sliding rails 2 parallel to each other is longitudinally arranged on the upper surface, and longitudinal sliding blocks 3 are respectively installed on the longitudinal sliding rails 2, and a longitudinal moving platform 4 is fixed on the longitudinal sliding blocks 3, between the longitudinal moving platform 4 and the longitudinal sliding block 3 A longitudinal linear motion device is installed, and a pair of parallel transverse slide rails 5 are installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com