High-efficiency paver for hybrid type plastic runway

A plastic track and hybrid technology, which is applied to roads, pavements, roads, etc., can solve the problems of high price, reduced alignment accuracy, uneven thickness, etc., and achieves low manufacturing costs, saving manpower and material resources, and reasonable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

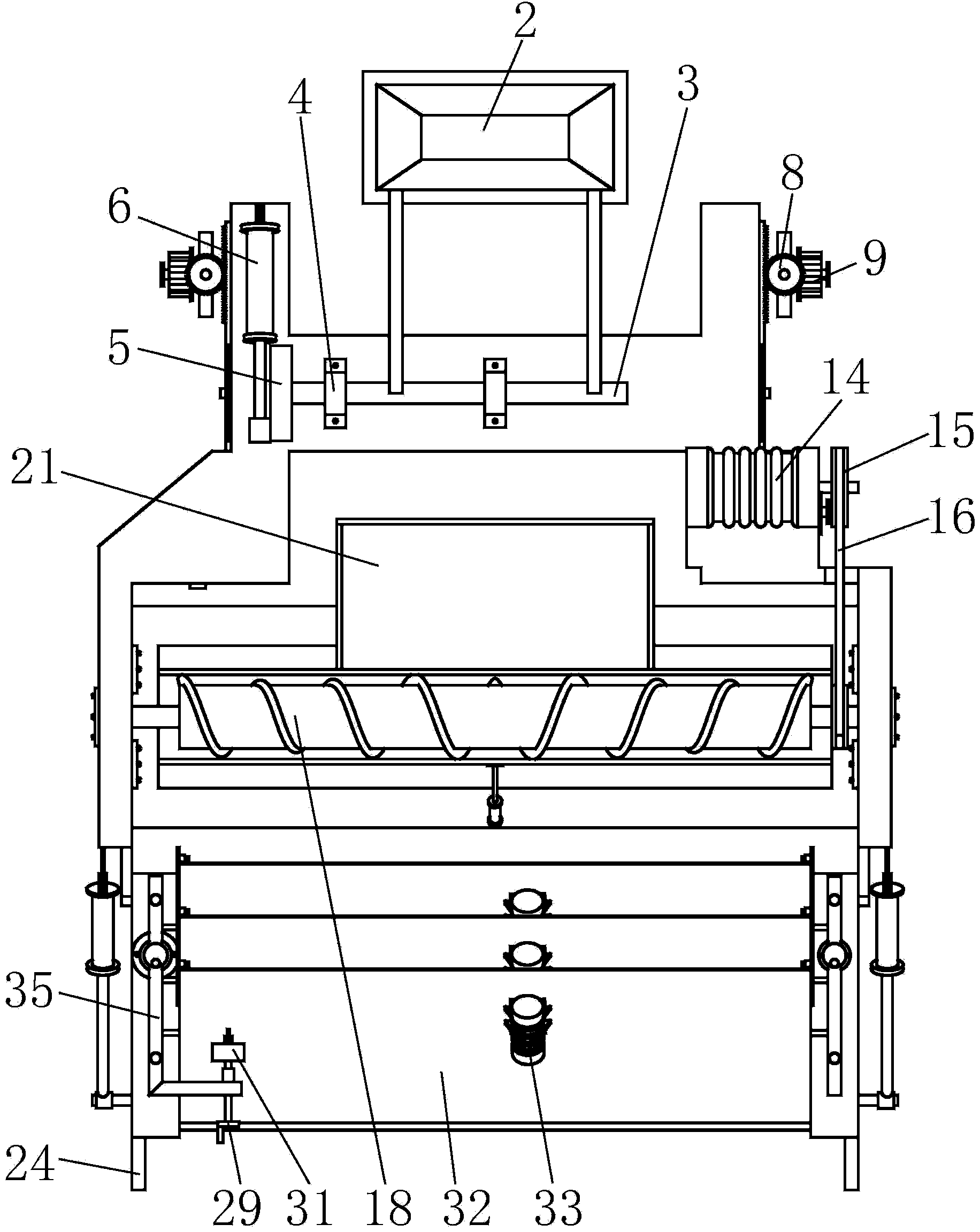

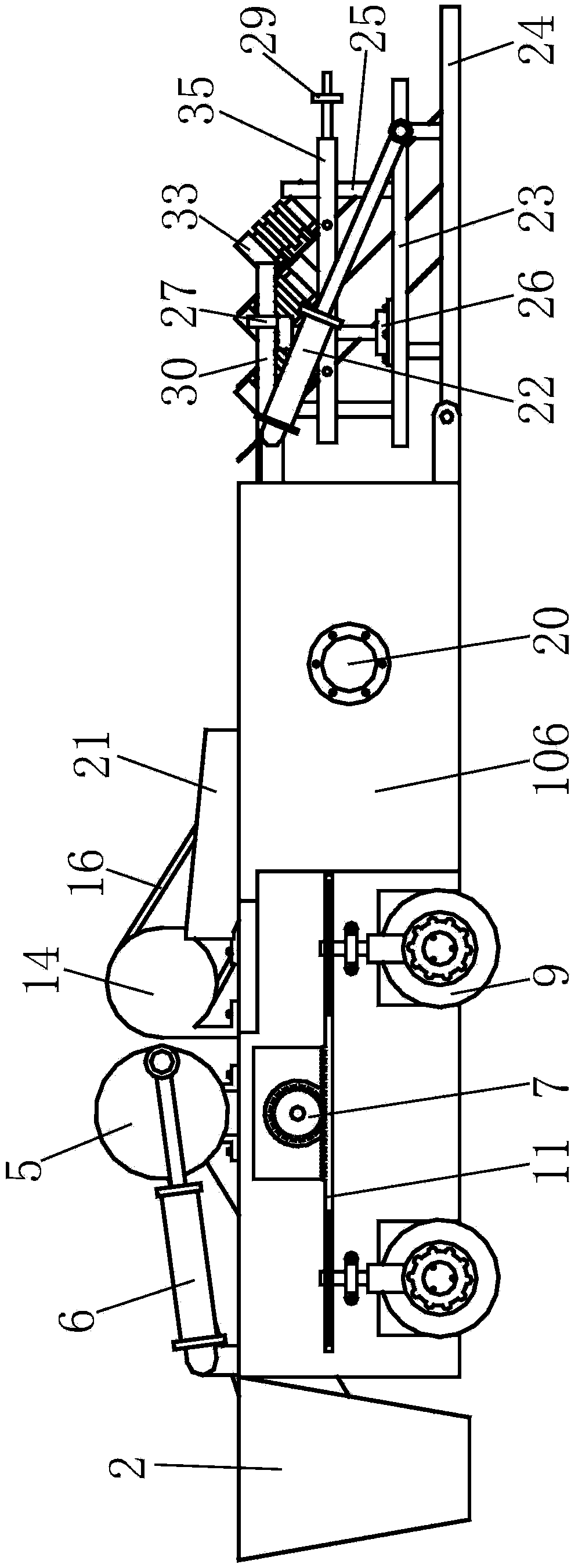

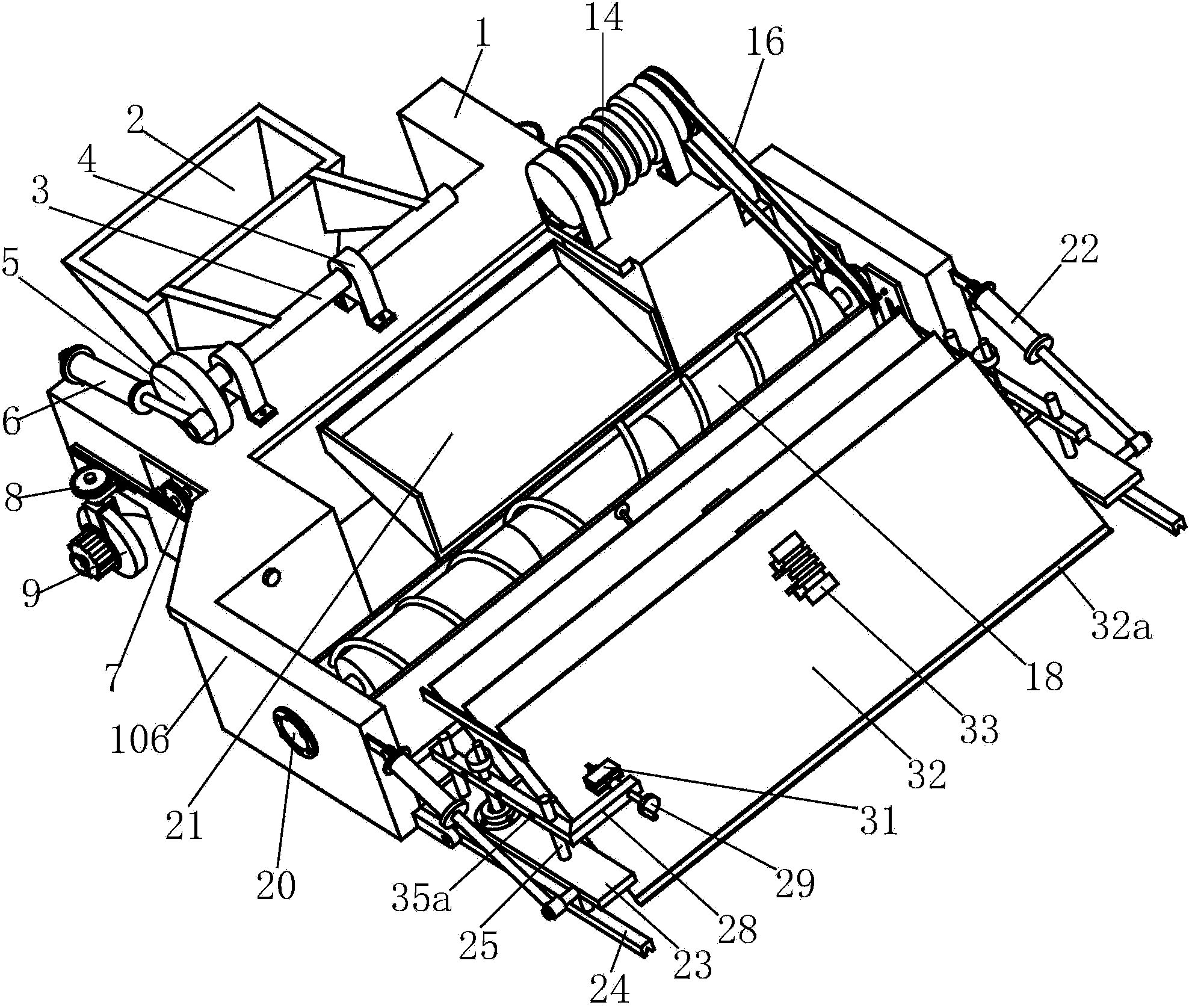

[0033] Such as Figure 1 to Figure 13 As shown, a high-efficiency paver for a hybrid plastic runway includes an I-shaped base 1, a walking device, a material turning device, a material distribution device and a multi-layer material spreading device. The walking device is symmetrically installed on the I-shaped On the left and right sides of the base 1, the material turning device is installed in the middle part of the rear side of the I-shaped base 1, the material distribution device is installed in the front middle part of the I-shaped base 1, and the multi-layer material spreading device It is located in front of the material distribution device, and the multi-layer material spreading device is fixedly installed on the front end of the I-shaped base 1. When in use, the operator pours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com