Assembling and packaging system and method of sensor

A packaging system and sensor technology, applied in the direction of instruments, microstructure devices, processing microstructure devices, etc., can solve the problems of unguaranteed alignment assembly quality, high requirements for operators, and low work efficiency, so as to reduce requirements and realize automation , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The manufacturing method of non-planar assembly of MEMS sensor is: first, the alignment assembly is manually completed with the support of the vision system, and then transferred to the packaging equipment for packaging. Because the production of MEMS sensors is different from general micro-assembly, it is the integration of micro-assembly and packaging processes, which has high requirements for operators and low work efficiency. Since the assembled MEMS sensor is not fixed during the transfer process, the quality of alignment assembly cannot be guaranteed, which reduces the yield.

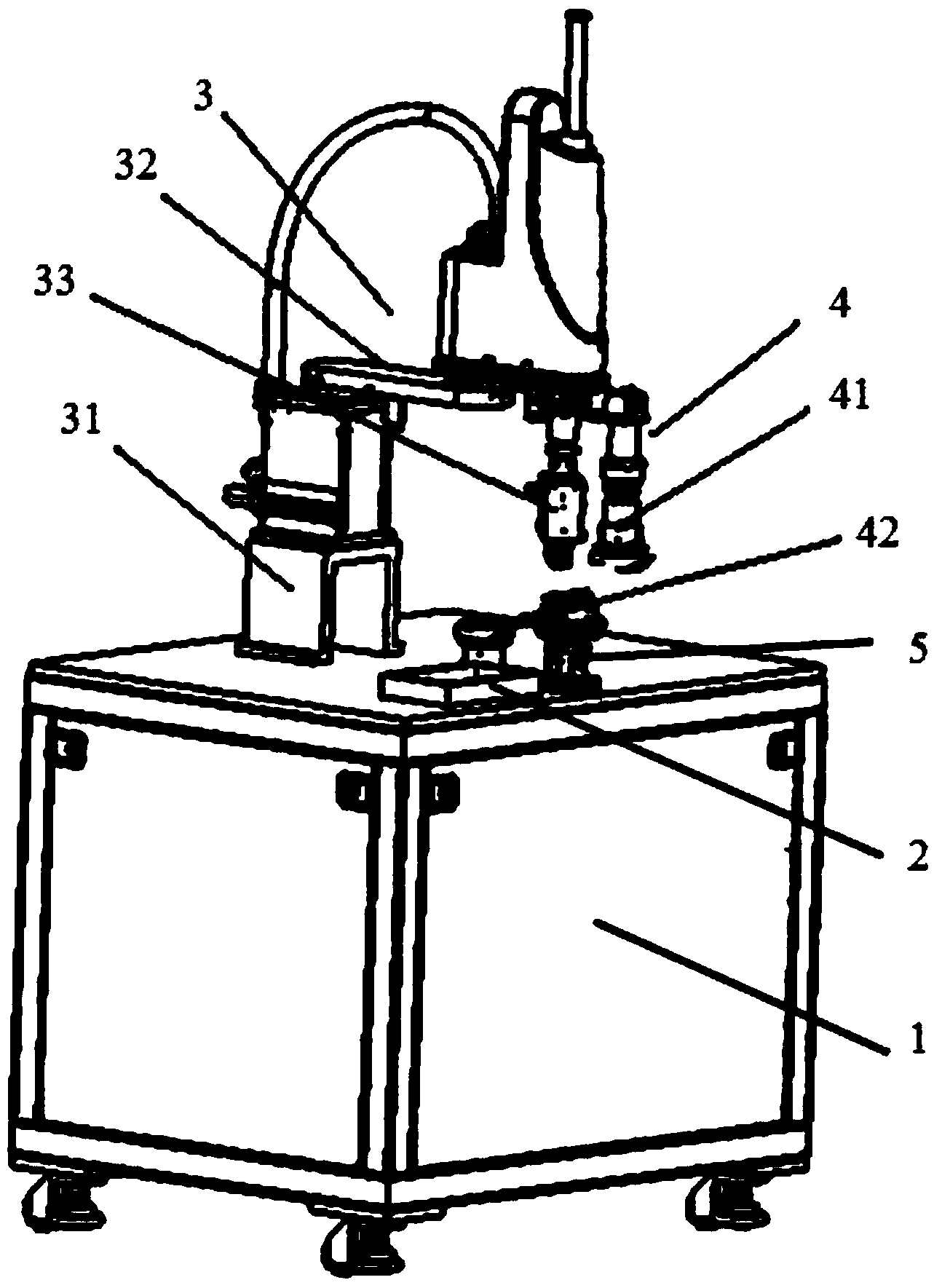

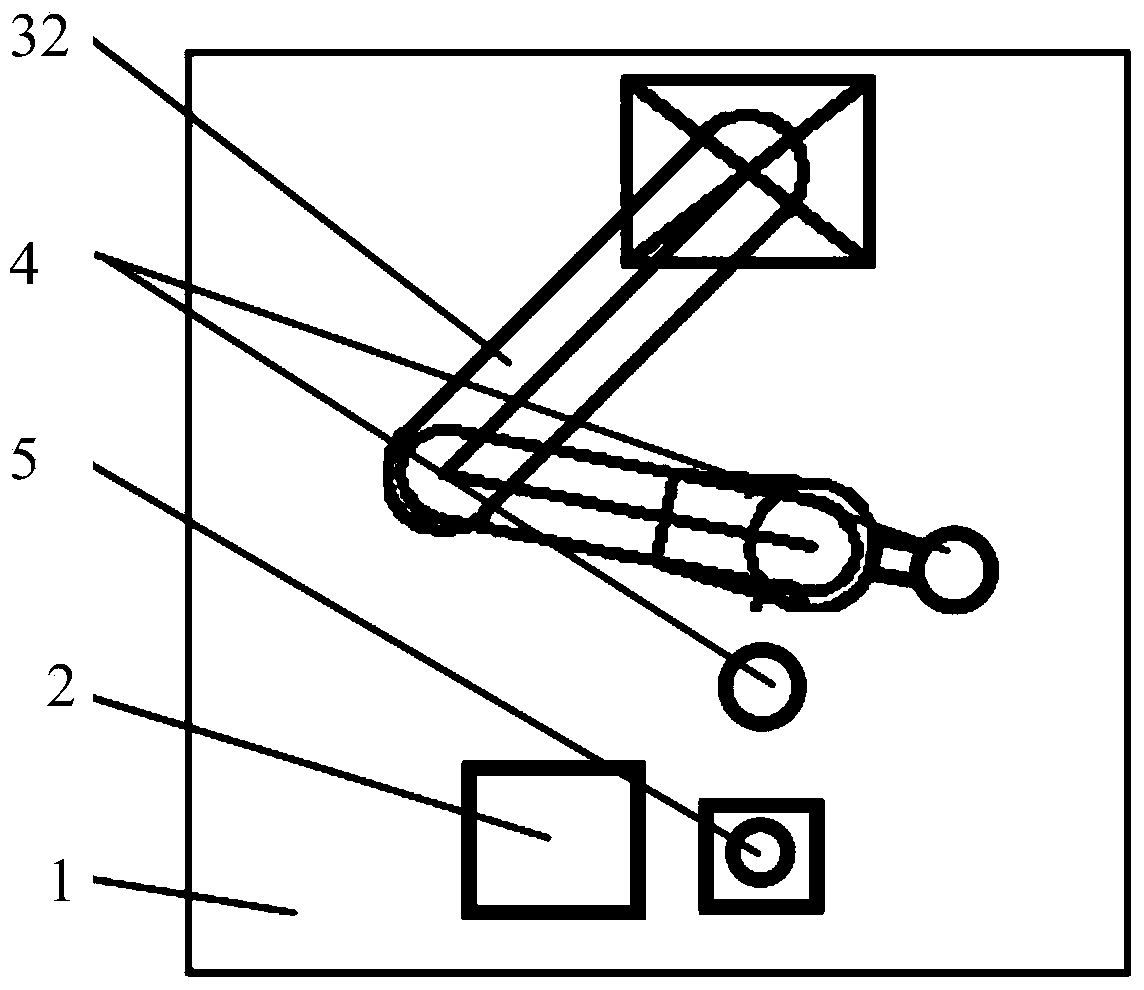

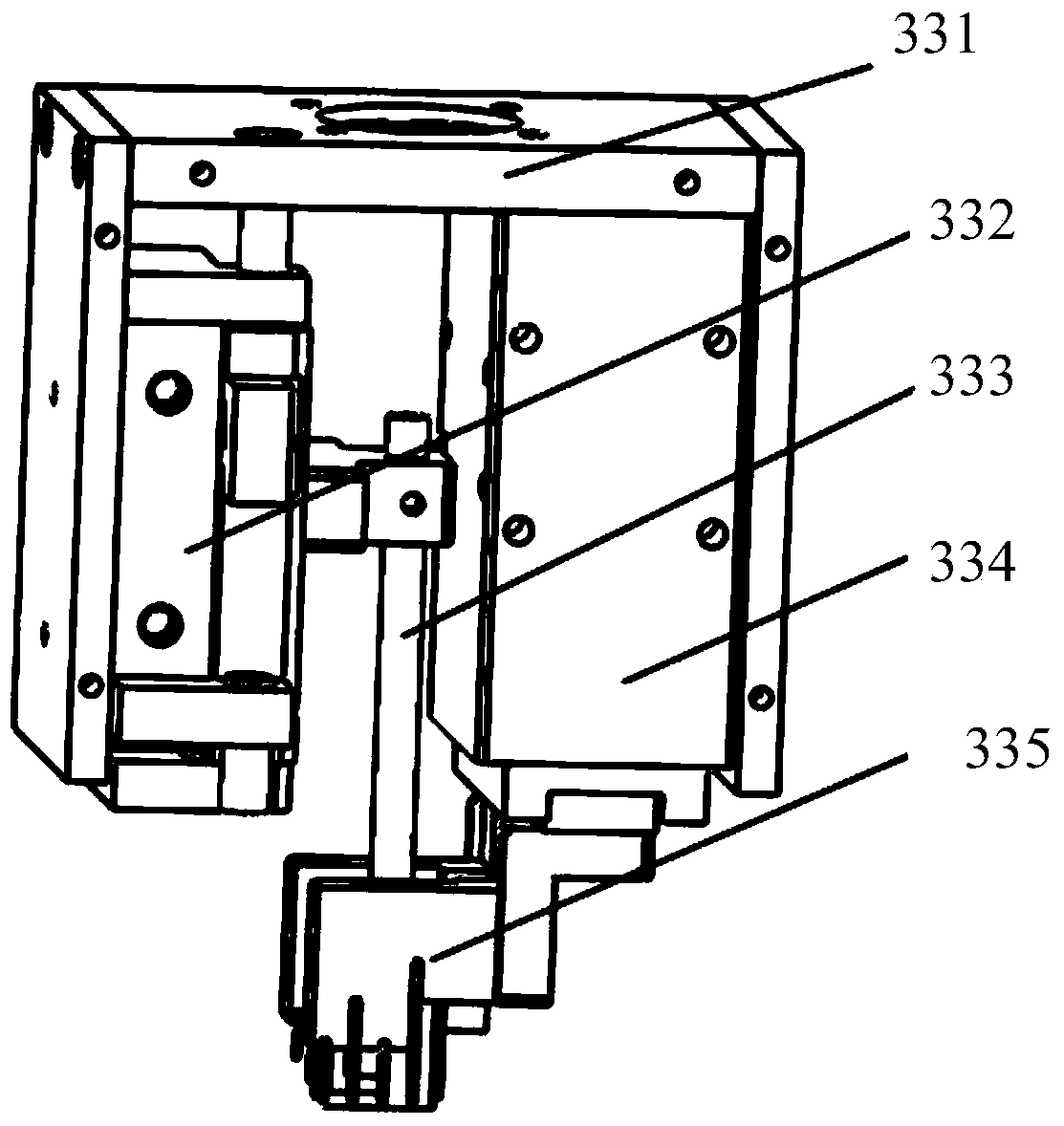

[0041] Aiming at the deficiencies in the prior art, the present invention provides a sensor assembly and packaging system and an assembly and packaging method. The system integrates equipment such as a microscope, a manipulator, and a bonding process platform. The application of this system can realize automatic processing of complex MEMS microstructures. The integrated operation of alignme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com