Card manufacturing machine and guide mechanism employing same

A technology of guiding mechanism and card making machine, which is applied in metal processing and other directions, can solve the problems of poor punching quality and uneven force, and achieve the effect of fast punching speed, good punching quality and light vibration disappearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

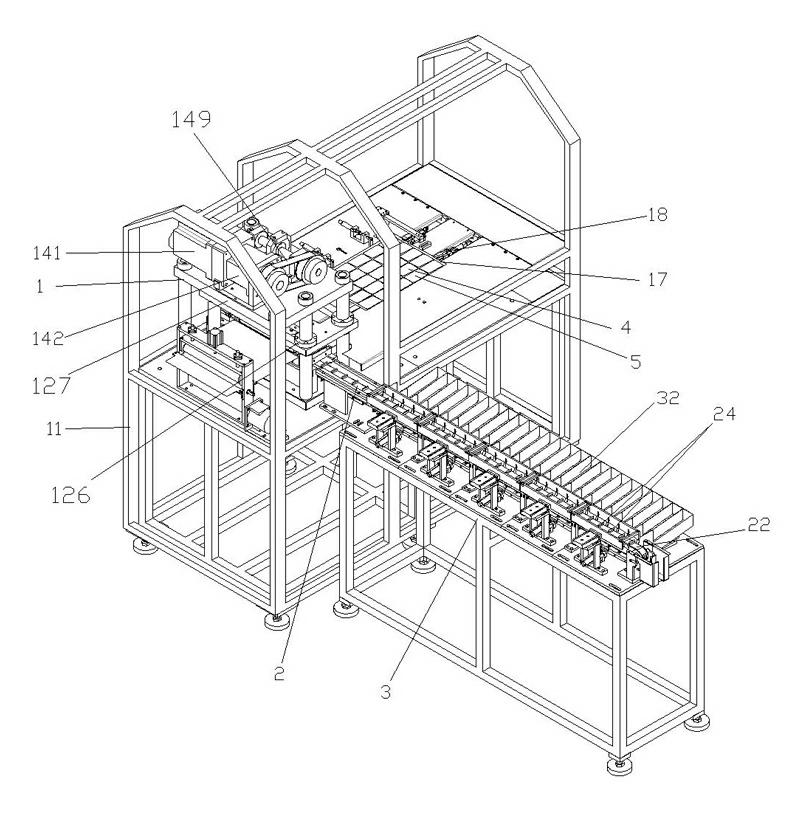

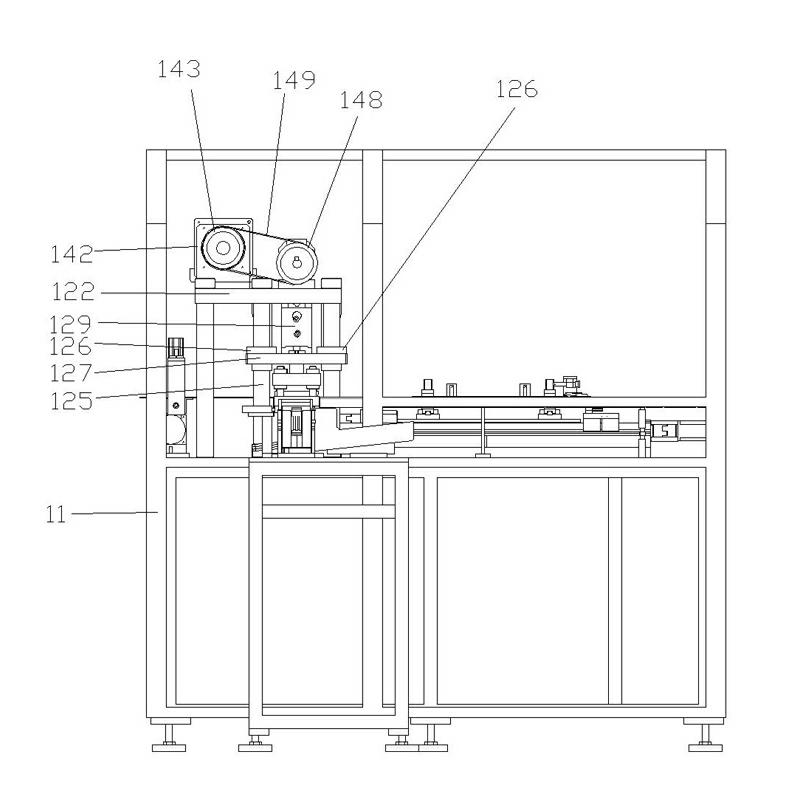

[0026] see Figure 1 to Figure 5 , The present invention proposes a card making machine, which includes a punching device 1 , a conveying device 2 , and a card receiving device 3 .

[0027] The punching device 1 includes a punching frame 11 , a guiding mechanism 12 , an eccentric shaft mechanism 14 , a punching die 16 , a worktable 17 , and a feeding mechanism 18 .

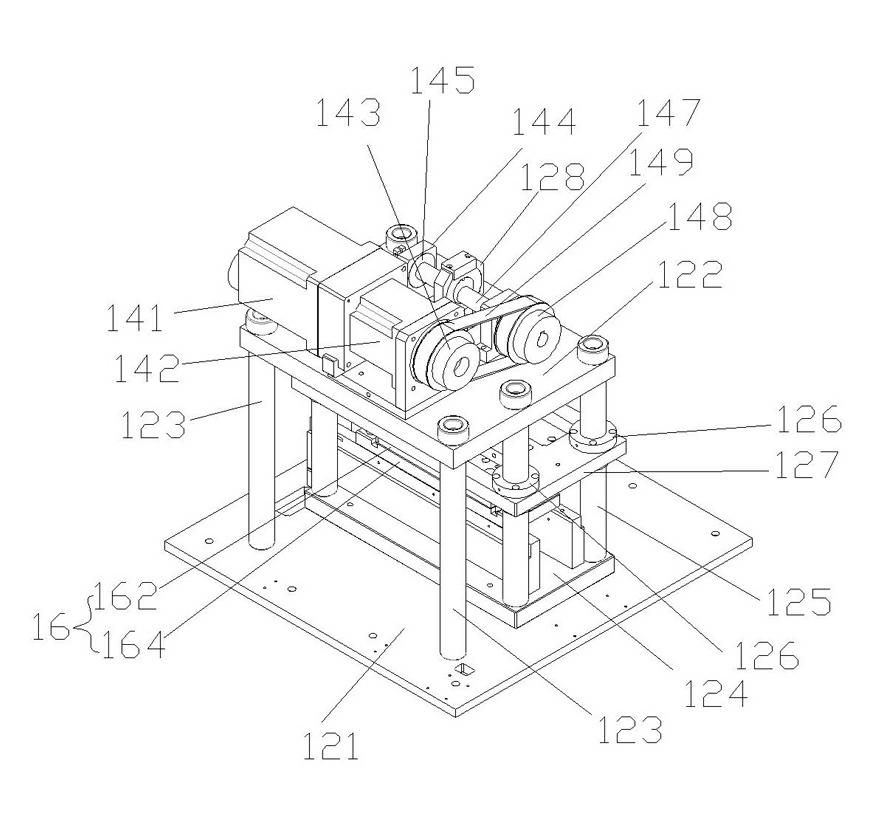

[0028] The guide mechanism 12 is installed at the rear end of the punching frame 11 , and the guide mechanism 12 includes a bottom plate 121 , a top plate 122 , two fixed columns 123 , a base 124 , four guide columns 125 , four guide sleeves 126 , A guide pressure plate 127, a swing arm 128, a guide block 129, a first connecting shaft 130, a rod end joint bearing 131, a second connecting shaft 132, a locking block 133, two guide seats 134, two guide Seat stiffener 135.

[0029] The bottom ends of the two fixed uprights 123 are mounted on the bottom plate 121 , and the top ends are mounted on the top plate 122 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com