Construction method of large-sized arc-shaped wall

A construction method and arc-shaped technology, applied in the direction of walls, formwork/formwork/work frame, building components, etc., can solve the problems of inability to measure and locate, difficult construction, complex curved surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

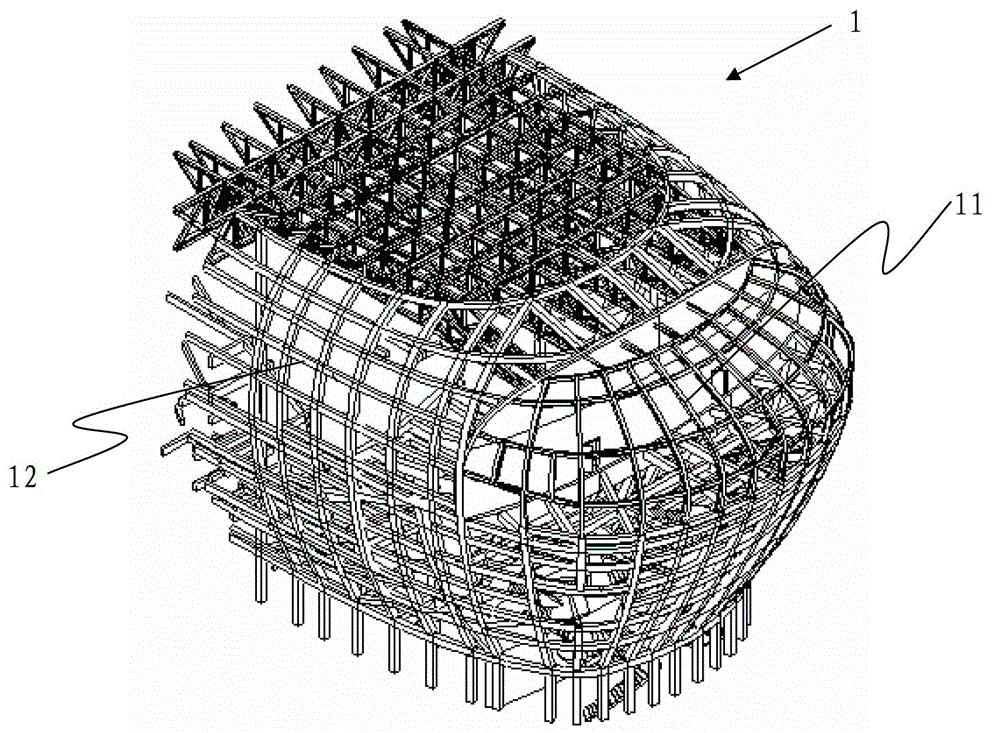

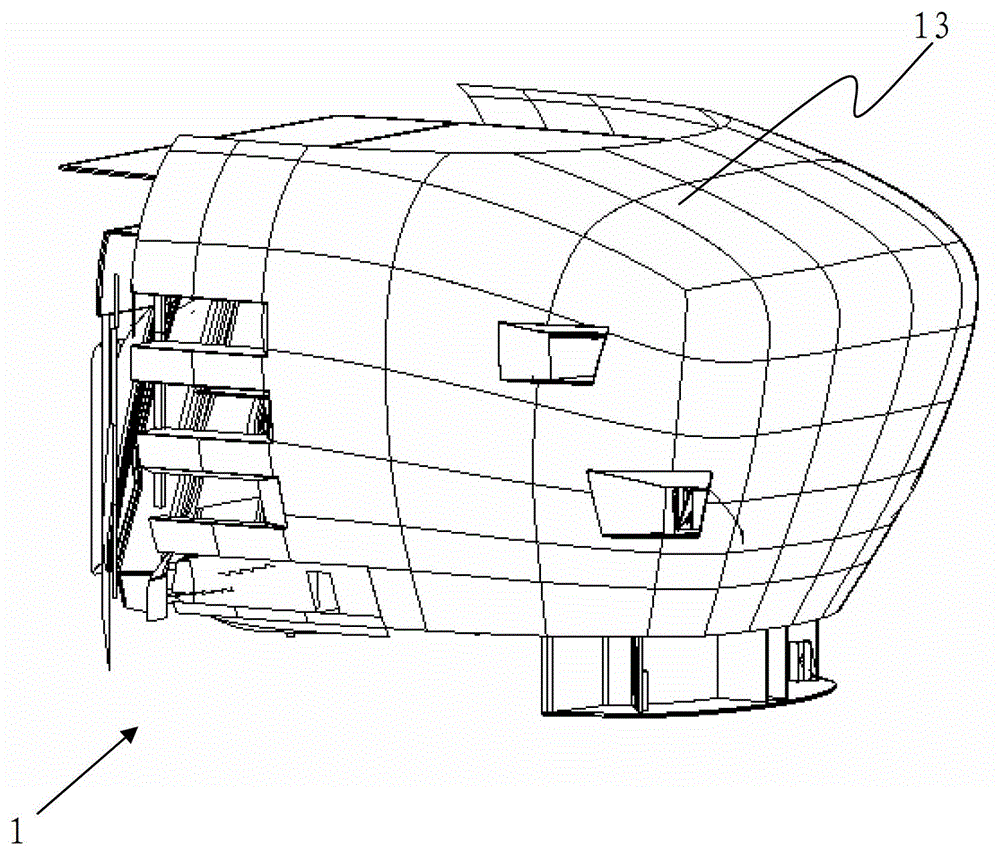

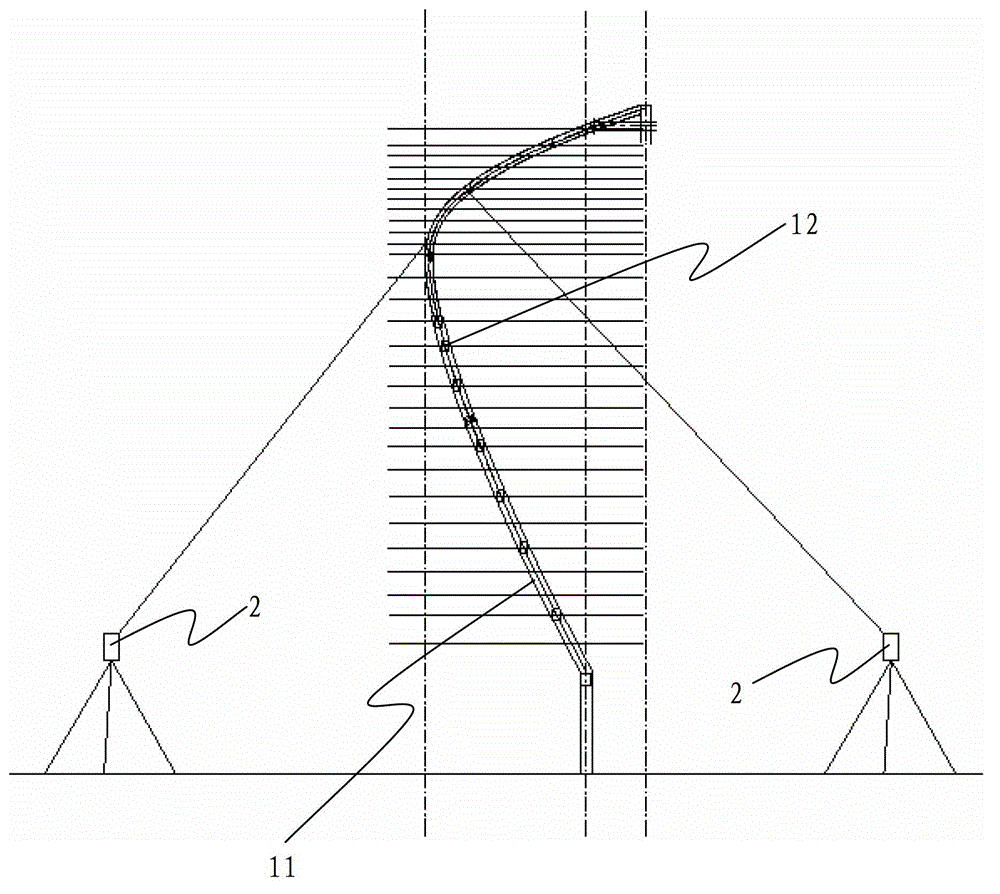

[0029] For the benefit of a further understanding of the structure of the present invention, the present invention uses figure 1 A preferred embodiment of the description.

[0030] refer to figure 1 and figure 2 As shown, the large-scale curved wall 1 of the present invention is a shell-shaped wall frame structure system composed of a 500×550 curved column 11, a 350×500 curved ring beam 12 intersecting it, and a 150 thick curved plate 13. H200×150×6×8 shaped steel is built into the curved column 11, the gluten bar and bottom reinforcement of the curved beam are both 5Φ25 steel bars, and the curved ring beam 12 at the elevation of 10.45m, 14.9m and 23.9m is built with H200×100×8×12 Sectional steel, horizontal arc ring beam 350×500 at the top 26.9m level, about 60m long, and the width of the inclined beam connected to it at the top 25.4m level is 500mm, and the height of the inclined beam is to be determined by design. The large curved wall 1 is constructed in vertical secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com