Preparation method and compacting stranding device of compacting soft structure conductor

A conductor and compression technology, which is applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems that conductors cannot be smooth and flat, unfavorable material saving and utilization, and increase in cable outer diameter, etc. Outer diameter and weight, effect of outer diameter reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

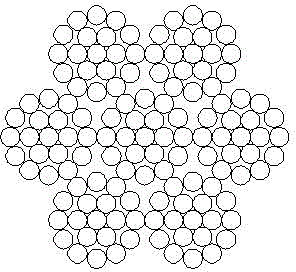

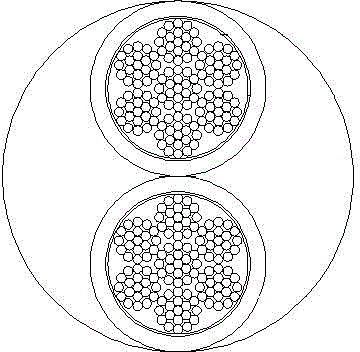

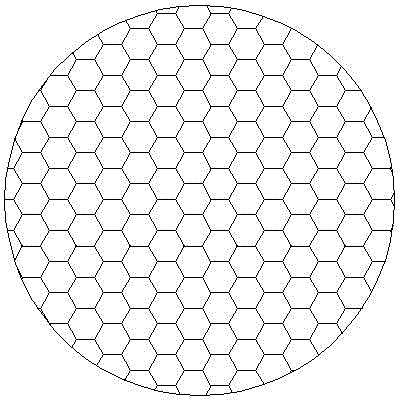

[0038]The compacted soft structure conductor involved in the present invention is formed by twisting at least one cable conductor and strands in the same direction, and the compacted soft structured conductor is wrapped with non-woven fabric, metal tape or semi-conductive tape, fire-resistant Tapes, water-blocking tapes and wrapping tapes, non-woven fabrics, metal tapes or semi-conductive tapes, fire-resistant tapes, and water-blocking tapes can play a role in tightening conductors and meeting product performance requirements. In addition, the cross-section of the compact soft structure conductor is a combination of one or more of circular, 180° fan-shaped, 120° fan-shaped, 90° fan-shaped, 90° tile-shaped, and 100° tile-shaped, and the combination method 2 cores, 3 cores, 4 cores, 3+1 cores, 5 cores, 4+1 cores or 3+2 cores, the cross-section of the compact soft structure conductor is 10-630 mm 2 , specifically as Figure 3 to Figure 14 shown.

[0039] For single-core cables,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com