Preparation method of deep sea cable filling strip

A deep-sea cable and filling tape technology, which is applied in the direction of submarine cables, insulated cables, cables, etc., can solve the problems that cannot meet the functional requirements of deep-water cables, the influence of cable materials is huge, and the electrical properties are easy to attenuate, etc., and achieve stable electrical performance and technical performance. Stable, self-adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Mixing process, 100 parts of butyl rubber, 3.0 parts of sulfur, 2 parts of vulcanization accelerator CZ, 1.5 parts of vulcanization accelerator TMTD, 1 part of anti-aging agent A, 10 parts of engine oil, 50 parts of N660 carbon black, 1.5 parts of oxidation The zirconium was kneaded, the kneading time was 10min, and the kneading temperature was 70°C.

[0022] (2) Send the above mixed rubber to the calender for calendering at a temperature of 40°C;

[0023] (3) Cutting the product obtained in step 2;

[0024] (4) Packaging the product obtained in step 3 is the finished product.

Embodiment 2

[0026] (1) Mixing process, 70 parts of butyl rubber, 1.5 parts of sulfur, 1 part of vulcanization accelerator CZ, 1.5 parts of vulcanization accelerator TMTD, 1 part of anti-aging agent RD, 10 parts of engine oil, 30 parts of N660 carbon black, 1 part of oxidation The zirconium was kneaded, the kneading time was 12min, and the kneading temperature was 50°C.

[0027] (2) Send the above mixed rubber to the calender for calendering at a temperature of 40°C;

[0028] (3) Cutting the product obtained in step 2;

[0029] (4) Packaging the product obtained in step 3 is the finished product.

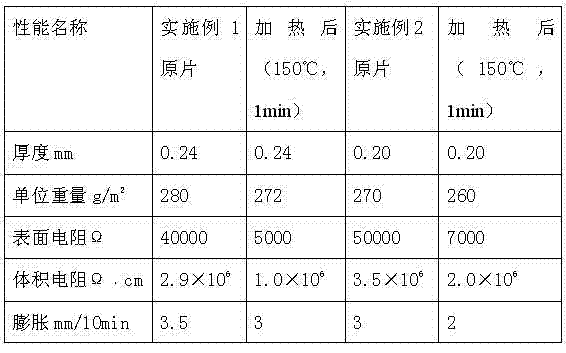

[0030] Product performance test results are as follows:

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com