Dry-type all-insulating tubular bus

A tubular busbar and fully insulated technology, applied in the direction of insulated cables, insulated conductors, conductors, etc., can solve problems such as deformation dislocation, large skin effect, busbar use and life impact, etc., to facilitate large-scale manufacturing and skin effect The effect of low coefficient and uniform electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

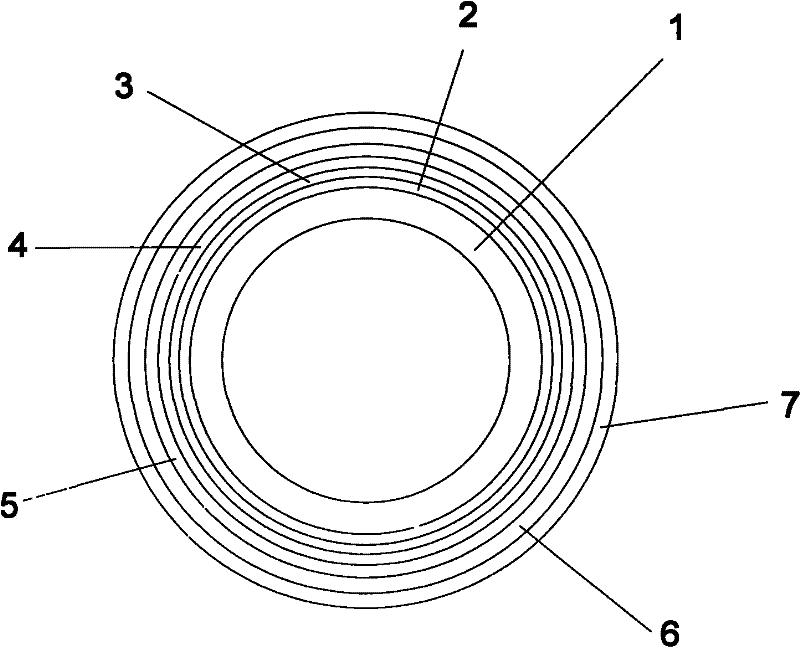

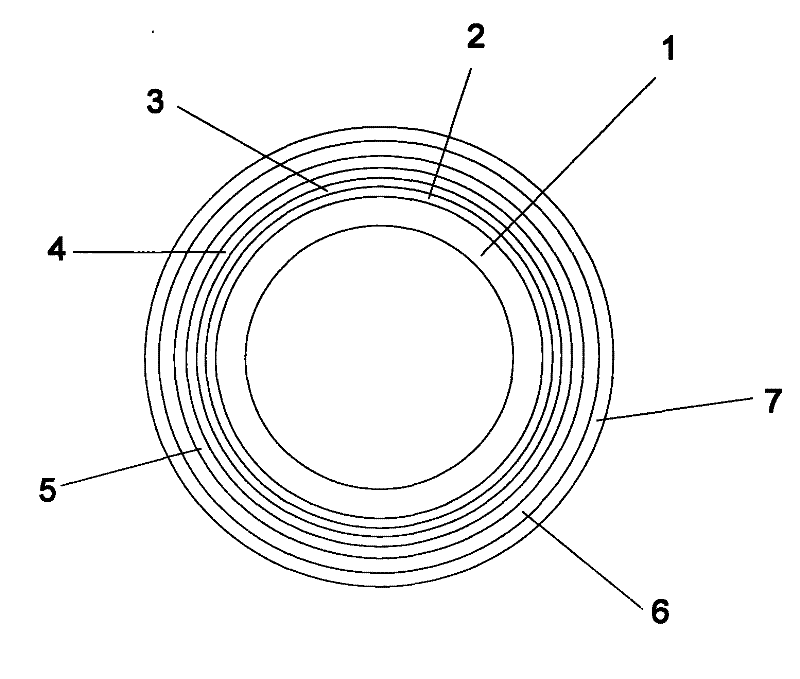

[0022] Such as figure 1 The dry-type fully insulated tubular busbar shown in the figure sequentially includes a hollow conductive tube 1, a first epoxy resin insulating layer 2, a first shielding layer 3, a second epoxy resin insulating layer 4, and a second shielding layer from the inside to the outside. 5. The third epoxy resin insulating layer 6, the third shielding layer 7, the third shielding layer is connected to the ground zero potential to form a shielding protection layer. The hollow conductive pipe, each epoxy resin insulating layer and shielding layer are coaxial circular pipe bodies.

[0023] The invention adopts a special molding process of epoxy resin, which releases the pressure evenly, balances the stress in all directions, the density of the village is consistent, the magnetic force lines are uniform and symmetrical without deformation, no bubbles, and the partial discharge is almost zero. Due to the excellent insulating properties and curing properties of ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com