Connection method of mechanically compressed rectangular busbars for generators in hydropower stations

A technology for hydropower generators and rectangular bus bars, applied in the direction of clamping/spring connection, etc., can solve the problems of reduced thermal stability of conductors at the connection, increased proximity effect coefficient, and poor electrical conductivity at the conductor connection. The skin effect coefficient is reduced, the proximity effect coefficient is reduced, and the thermal stability of the conductor is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

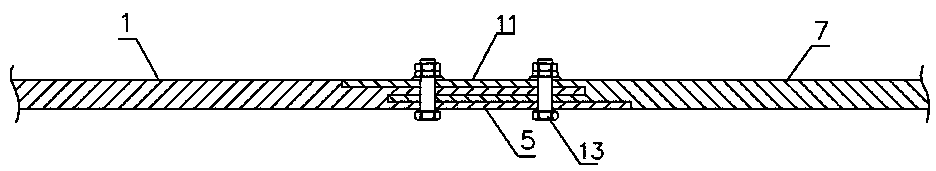

[0023] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

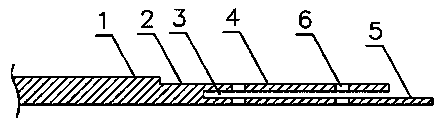

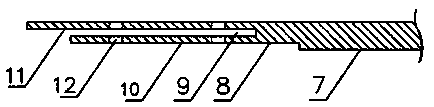

[0024] like Figure 1-6 As shown, the connection method of the hydropower generator machine-pressed rectangular bus bar of the present invention is carried out according to the following steps:

[0025] The first step is to form the shape of the teeth and grooves at the connecting ends of the rectangular copper bus bars that need to be connected by CNC machine tools; namely:

[0026] A first mesa 2 is processed on the connecting end of the first rectangular copper bus bar 1, and a first slot 3 is processed on the lower body of the first mesa 2, and the first slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com