Rectangular perforating current-carrying busbar design

A rectangular busbar, current-carrying technology, applied in the direction of a rod/rod/line/strip conductor, etc., can solve the problems of waste of resources, rising production costs, poor heat dissipation effect, etc., and achieve the effect of saving costs and increasing profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

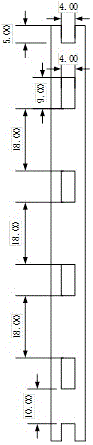

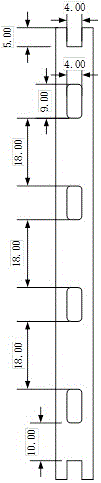

[0021] Such as Figure 1-Figure 4 As shown, on the basis of a 120*10mm rectangular busbar, four 4*9mm rectangular holes are opened in the cross section, and the four holes are evenly distributed with an interval of 18mm, and a 4*5mm slot is opened on each side of the rectangular section. The distance between the grooves on both sides and the rectangular hole in the middle is 10mm, and the distance between the short sides of the six holes and the left and right sides of the rectangular section is 3mm.

[0022] Wherein, the above-mentioned four rectangular holes in the center of the section can be modified into rounded rectangular holes.

[0023] Among them, on the basis of the 120*10mm rectangular busbar, 8 circular holes with a diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com