Preparation method of hydrogenation catlayst

A hydrogenation treatment and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of gas polluting the environment and affecting the stability of oil products, etc. , to achieve the effects of reducing interaction, complete vulcanization, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] In the preparation process of the catalyst of the present invention, the organic compound additive and the active metal component are loaded on the catalyst carrier, wherein at least one organic additive is a sulfur-containing organic additive. Improve the dispersion of active metal components, and further improve the performance of the catalyst.

[0015] A kind of concrete preparation process of catalyst of the present invention comprises the following steps:

[0016] (1) prepare porous catalyst carrier;

[0017] (2) Step (1) is used to obtain a porous catalyst carrier loaded active metal component and one or more non-sulfur-containing organic additives, which contain at least two hydroxyl groups and 2-20 carbon atoms of organic compounds;

[0018] (3) adding one or more sulfur-containing organic additives to the material obtained in the above step (2);

[0019] (4) Steps (2) and (3) of the above-mentioned catalyst preparation process may include one or more drying ...

Embodiment 1

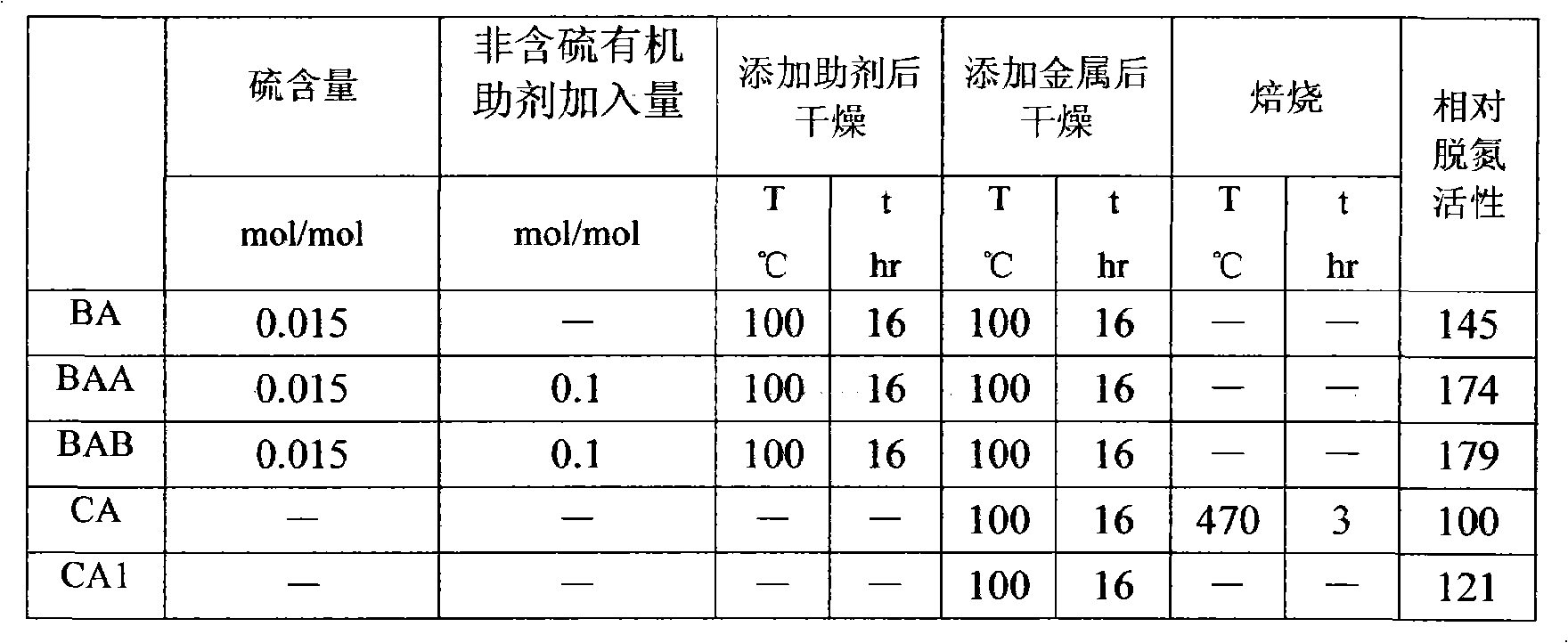

[0036] The catalyst was prepared using mercaptoformic acid.

[0037] Reference catalyst CA was prepared as follows. Catalysts were prepared using gamma-alumina carrier ZT (1.2mm, clover) with the following properties:

[0038] Pore volume: 0.75mL / g

[0039] Specific surface area: 320m 2 / g

[0040] Bulk density: 0.55g / mL

[0041] The gamma-alumina carrier was impregnated with an equal volume of aqueous impregnating solution containing an appropriate amount of molybdenum trioxide, nickel carbonate and phosphoric acid, and the impregnated carrier was dried at 100°C for 16 hours, and then the dried strip was calcined at 470°C for 3 hours in an air atmosphere. The prepared catalyst contains 12(w)% molybdenum (calculated as oxide), 3.2(w)% nickel (calculated as oxide) and 2(w)% phosphorus (calculated as P 2 o 5 count).

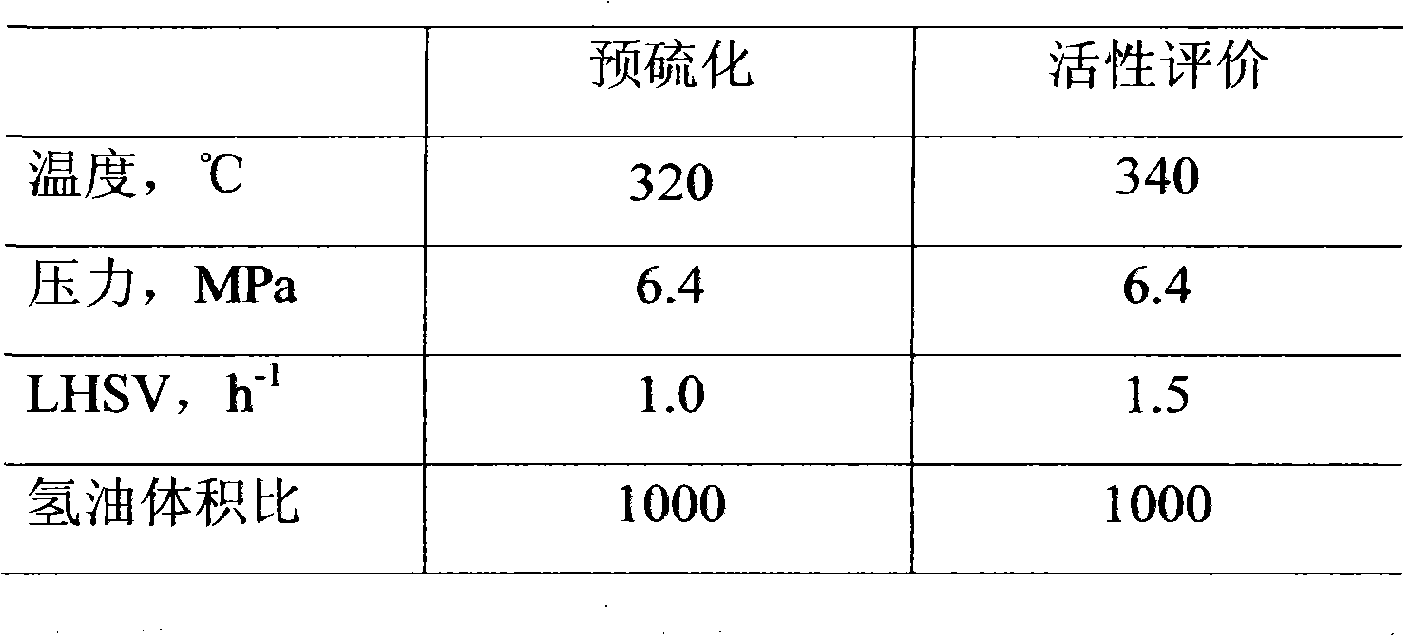

[0042] Catalyst BA of the present invention is to impregnate carrier ZT with the equal volume of the aqueous solution that contains appropriate amount of me...

Embodiment 2

[0056] The catalyst was prepared using methyl thioglycolate.

[0057] The reference catalyst CB impregnated the γ-alumina carrier with an equal volume of an aqueous impregnating solution containing an appropriate amount of molybdenum trioxide, nickel carbonate, phosphoric acid and diethylene glycol, and dried the impregnated carrier at 100°C for 16 hours. The prepared catalyst contains 12(wt)% molybdenum (calculated as oxide), 3.2(wt)% nickel (calculated as oxide) and 2(wt)% phosphorus (calculated as P 2 o 5 count). The amount of diethylene glycol is the molar ratio of diethylene glycol to the amount of active metal.

[0058] Catalyst BB of the present invention is to impregnate carrier ZT with equal volume of aqueous solution containing appropriate amount of methyl mercaptoacetate, dry under the condition of table 4, then with equal volume of water impregnating liquid containing appropriate amount of molybdenum trioxide, nickel carbonate, phosphoric acid and diethylene glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com