Hydrogenation catalyst and preparation method and application thereof

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low hydrogenation catalyst activity, complicated preparation process, poor controllability, etc., and achieve improved Effects of metal utilization, high catalytic performance, and hydrogenation performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a kind of preparation method of hydrogenation catalyst, and this preparation method comprises the following steps:

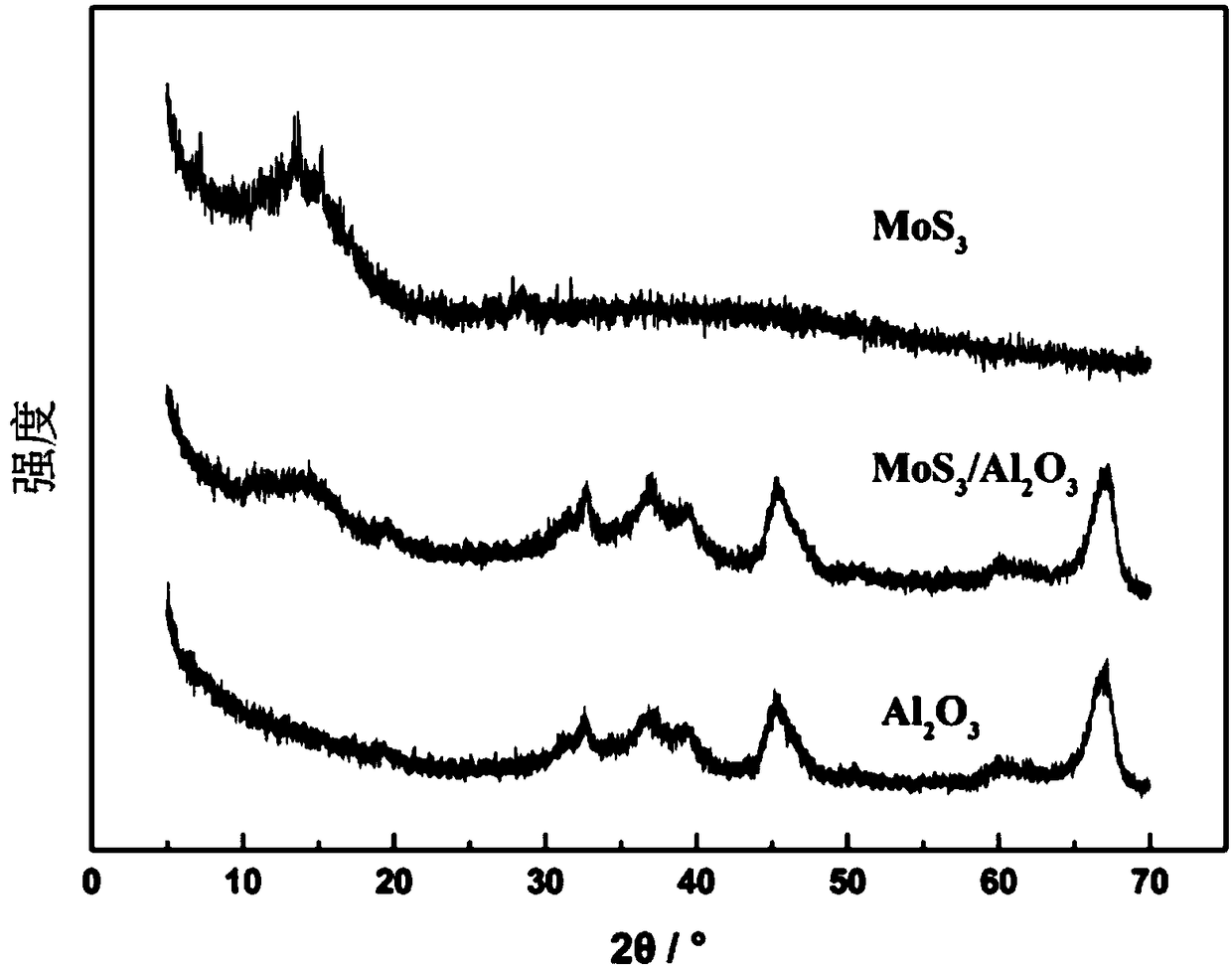

[0041] (1) The carrier is impregnated with a tetrathiomolybdate solution, and then heat-treated in an inert atmosphere or a reducing atmosphere to obtain a composite material A, and the heat treatment makes Mo in the composite material A exist in the form of trisulfide;

[0042] (2) impregnating the composite material A with a solution containing a Group VIII metal salt, and drying the impregnated solid material.

[0043] In the present invention, in order to further improve the hydrogenation performance of the prepared catalyst, simplify the operation steps, and reduce the catalyst production cost, the preferred tetrathiomolybdate solution is prepared by the following method:

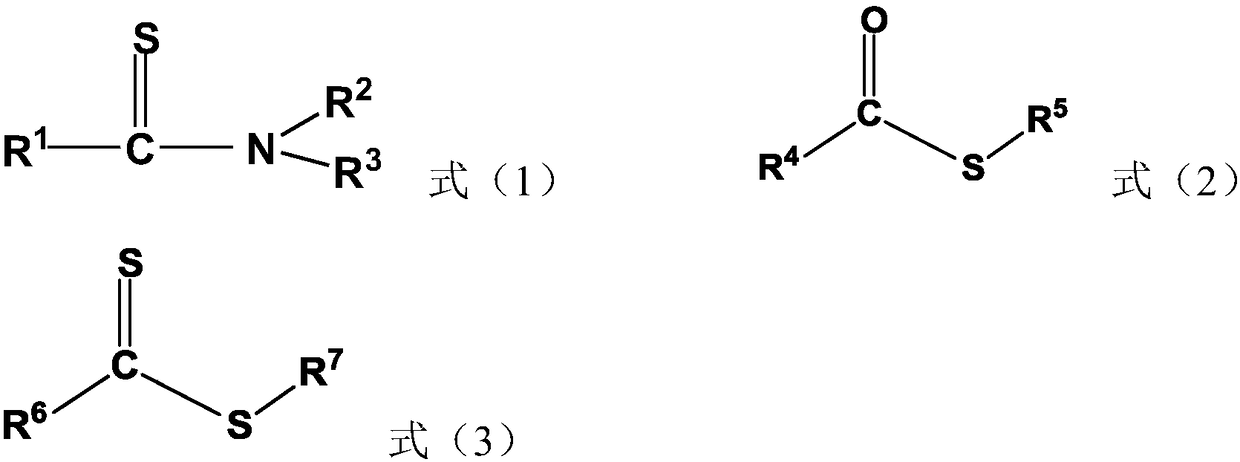

[0044] a) mixing molybdenum-containing compound, organic sulfur source and water;

[0045] b) reacting the mixture obtained in step a) at 50-1...

Embodiment approach

[0056] According to a preferred embodiment of the present invention, the reaction is carried out under airtight conditions. Operating under airtight conditions, the hydrogen sulfide obtained from the hydrolysis of organic sulfur sources will not be released into the air, which will neither cause air pollution, but also be more conducive to the hydrolysis of hydrogen sulfide into divalent sulfide ions, and more effective use of sulfur sources. Preparation of tetrathiomolybdate solution with better performance.

[0057] According to the present invention, it is preferred to adjust the pH by adding an acid and / or base to the mixture in step b), and the acid may be an organic acid or an inorganic acid, which is not particularly limited in the present invention.

[0058] According to the present invention, preferably, the acid is at least one selected from hydrochloric acid, nitric acid, sulfuric acid, phosphoric acid, formic acid and acetic acid, more preferably hydrochloric acid....

Embodiment 1

[0095] (1) Preparation of tetrathiomolybdate solution

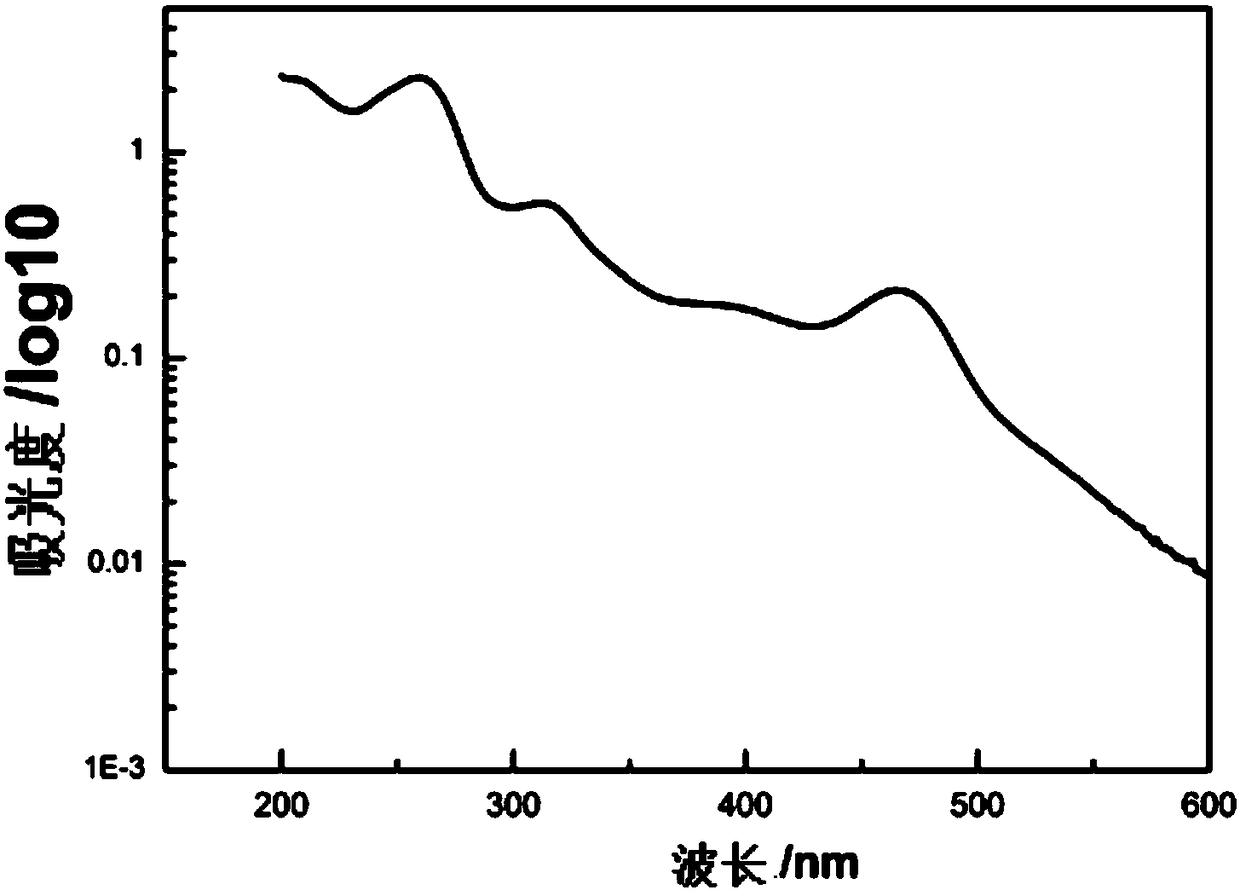

[0096] Mix sodium molybdate with water, stir for 40 minutes, add thioacetamide, and stir for 30 minutes to prepare 40 mL of a solution containing 0.35 mol / L sodium molybdate and 1.75 mol / L thioacetamide. It was heated to 95°C for 10 hours to obtain tetrathiomolybdate solution, which was then concentrated to 8 mL; UV-Vis test was carried out on the obtained tetrathiomolybdate solution, and the UV-Vis characterization results were as follows: figure 2 As shown, the peaks at wavelengths of 260nm, 317nm and 468nm in the figure indicate that MoS in solution 4 2- The presence.

[0097] (2) Preparation of hydrogenation catalyst

[0098] Saturated impregnation of the above-mentioned tetrathiomolybdate solution in 10 g of γ-Al with a diameter of 2-5 mm 2 o 3 Carrier (specific surface area 231m 2 / g, pore volume 0.709mL / g, the same below), the impregnation time was 4h, then dried at 80°C for 3h under nitrogen atmosphere, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com