Fireproof flame-retardant inorganic coating

An inorganic coating, fire retardant technology, applied in the field of coatings, can solve the problems of poor fire retardant performance, inability to achieve, large thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

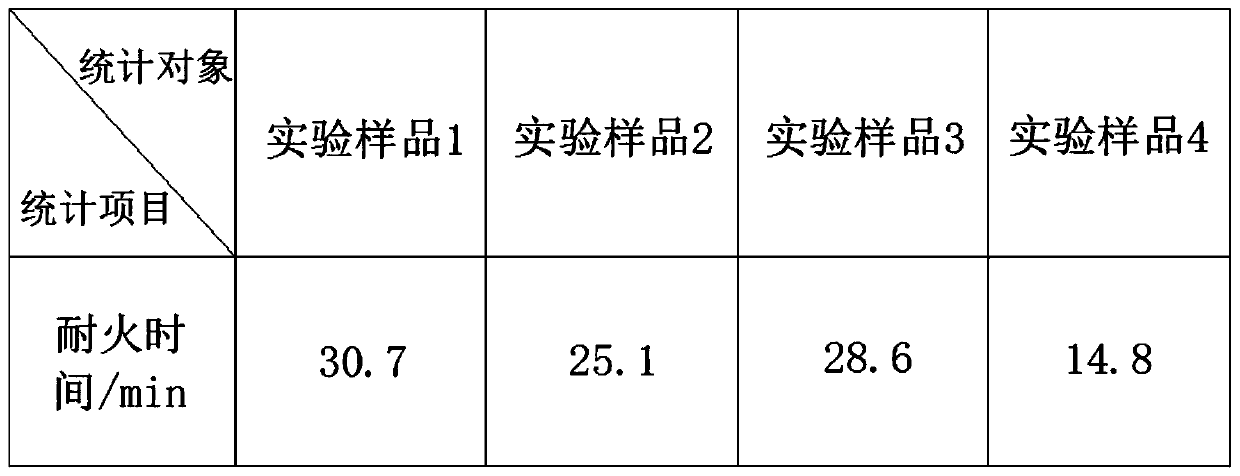

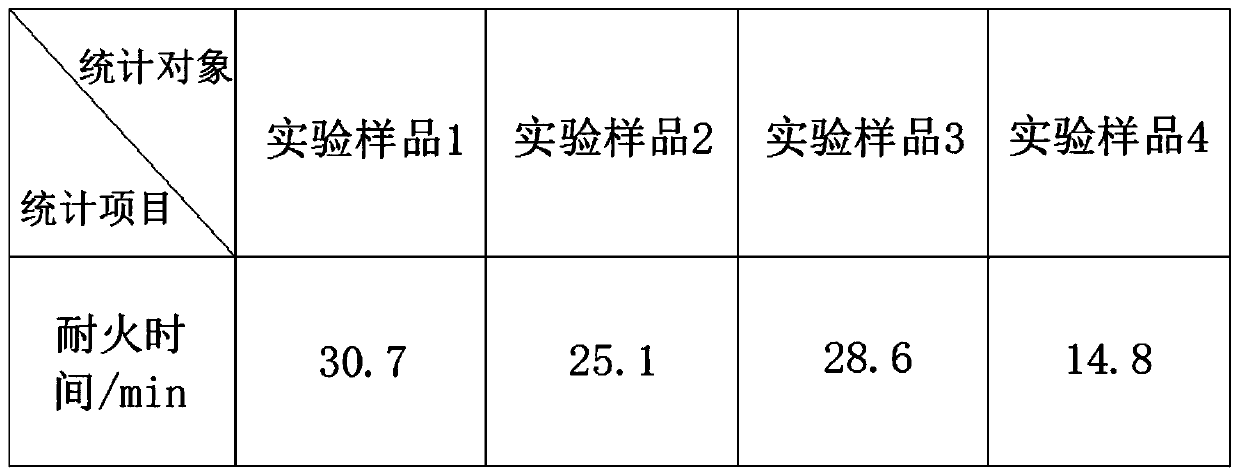

Examples

Embodiment 1

[0028] S1. First, pour 35 parts of silica sol and 35 parts of thermal insulation aggregate into the mixing mixer in turn, then add the corresponding proportion of clean water, and then stir at the speed of 450r / min and the temperature of 30°C. After 1.5 hours, the coating base material can be obtained, wherein the thermal insulation aggregate is a composition of expanded perlite, expanded vermiculite, diatomaceous earth, fly ash hollow microspheres and sepiolite powder;

[0029] S2, add 15 parts of chlorinated paraffins selected in the coating base material that S1 obtains, stir 35min with the rotating speed of 550r / min, then add 2.5 parts of foaming catalysts selected in the mixing tank, and then use the rotating speed as 550r / min Stir at a rotating speed for 45 minutes, so that the chlorinated paraffin can be fully catalyzed and foamed, thereby obtaining the initial mixed coating, wherein the foaming catalyst is a composition of ammonium polyphosphate and ammonium sulfate;

...

Embodiment 2

[0034] S1. First, pour 30 parts of silica sol and 30 parts of thermal insulation aggregate into the mixing mixer in turn, then add the corresponding proportion of clean water, and then stir at a speed of 400r / min and a temperature of 25°C. 1h, the coating base material can be obtained, and the thermal insulation aggregate is expanded perlite powder;

[0035] S2. Add 10 parts of chlorinated paraffins to the paint base material obtained in S1, stir for 30 minutes at a speed of 500r / min, then add 2 parts of foaming catalysts to the mixing tank, and then stir at a speed of 500r / min. Stir at a rotating speed for 40 minutes, so that the chlorinated paraffin can be fully catalyzed and foamed, so as to obtain the initial mixed coating, wherein the foaming catalyst is ammonium polyphosphate;

[0036] S3. Then add 1 part of the selected flame retardant to the initial mixed coating obtained in S2, and add corresponding proportions of clear water at the same time, and stir at a speed of 6...

Embodiment 3

[0040] S1. First, pour 40 parts of silica sol and 40 parts of thermal insulation aggregate into the mixing mixer in sequence, then add the corresponding proportion of clean water, and then stir at a speed of 500r / min and a temperature of 35°C. 2h, the coating base material can be obtained, wherein the thermal insulation aggregate is a composition of expanded perlite and sepiolite powder;

[0041] S2, add 20 parts of chlorinated paraffins selected in the coating base material that S1 obtains, stir 40min with the rotating speed of 600r / min, then add 3 parts of foaming catalysts selected in the mixing tank, and then with the rotating speed of 600r / min Stir at a rotating speed for 50 minutes, so that the chlorinated paraffin can be fully catalyzed and foamed, so as to obtain the initial mixed coating, wherein the foaming catalyst is ammonium sulfate;

[0042] S3, then add the selected 3 parts of flame retardant to the initial mixed coating obtained in S2, and add corresponding pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com