Chemical material polyurethane foaming machine

A foaming machine and polyurethane technology, which is applied in the field of polyurethane foaming machines, can solve the problems affecting the effect and quality of foaming materials, uneven air blowing, etc., and achieve the effect of convenient and quick disassembly and improvement of effect and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

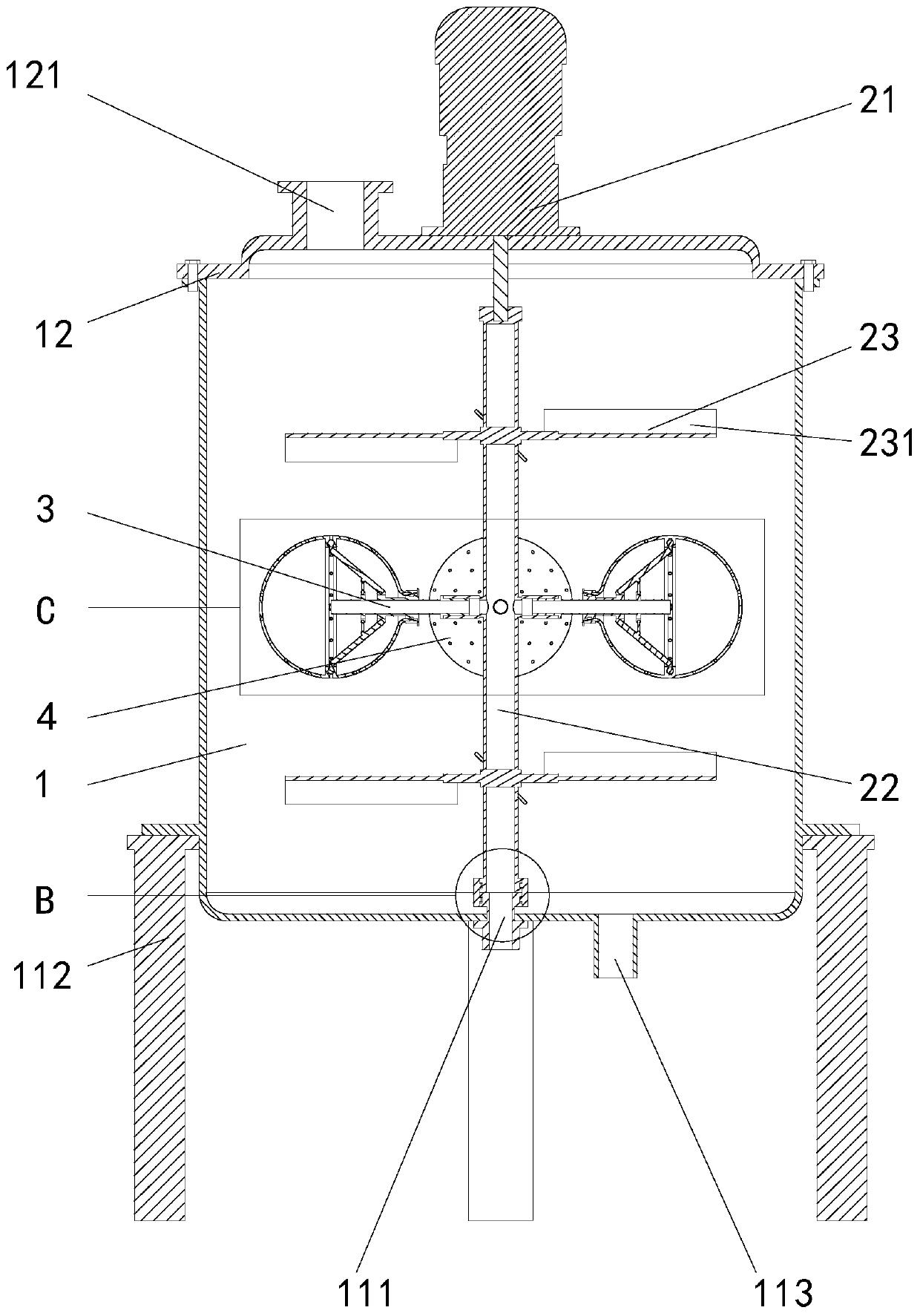

[0030] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention will be described in further detail, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and It is helpful for its implementation, but not as a limitation of the present invention.

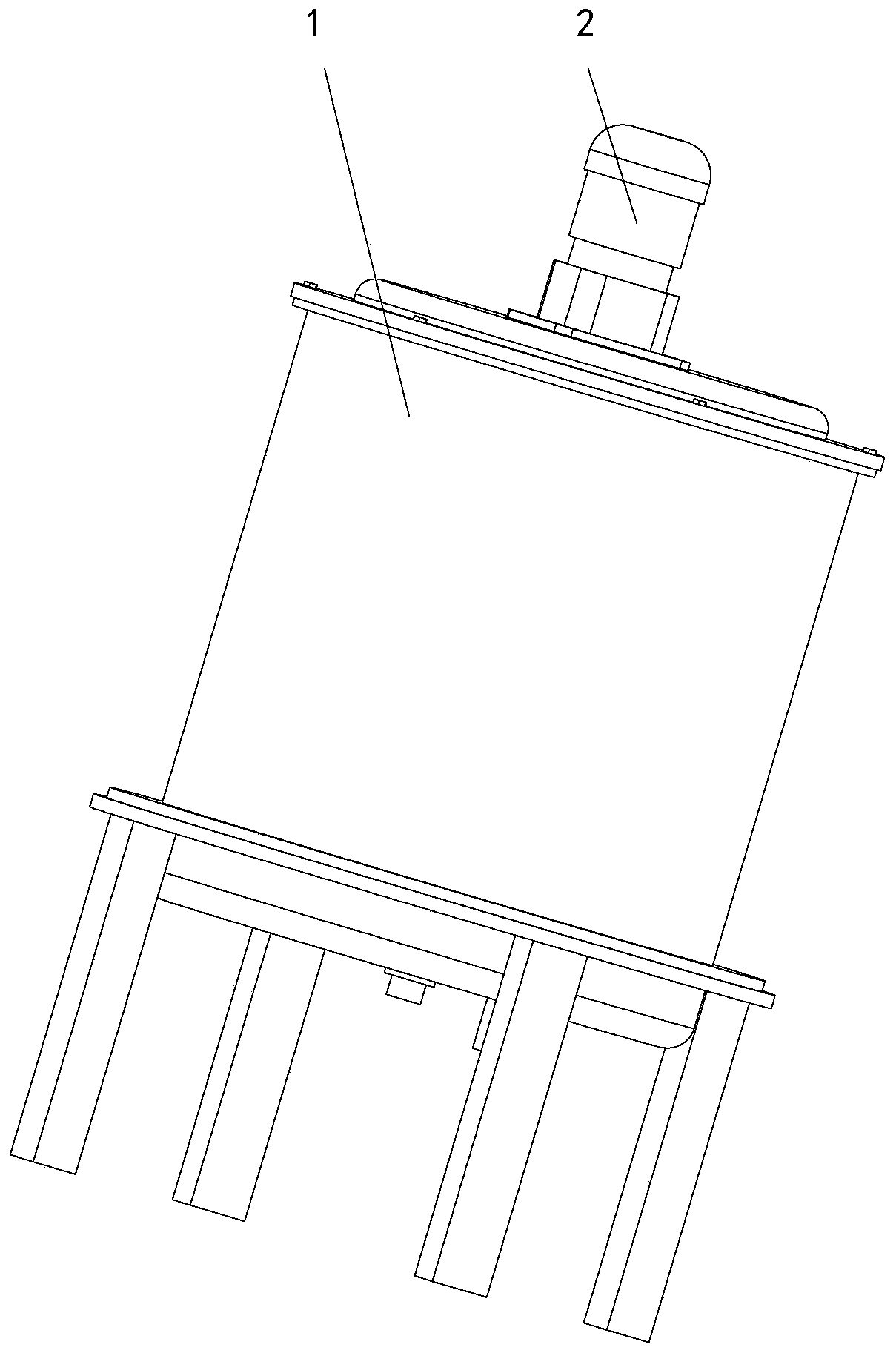

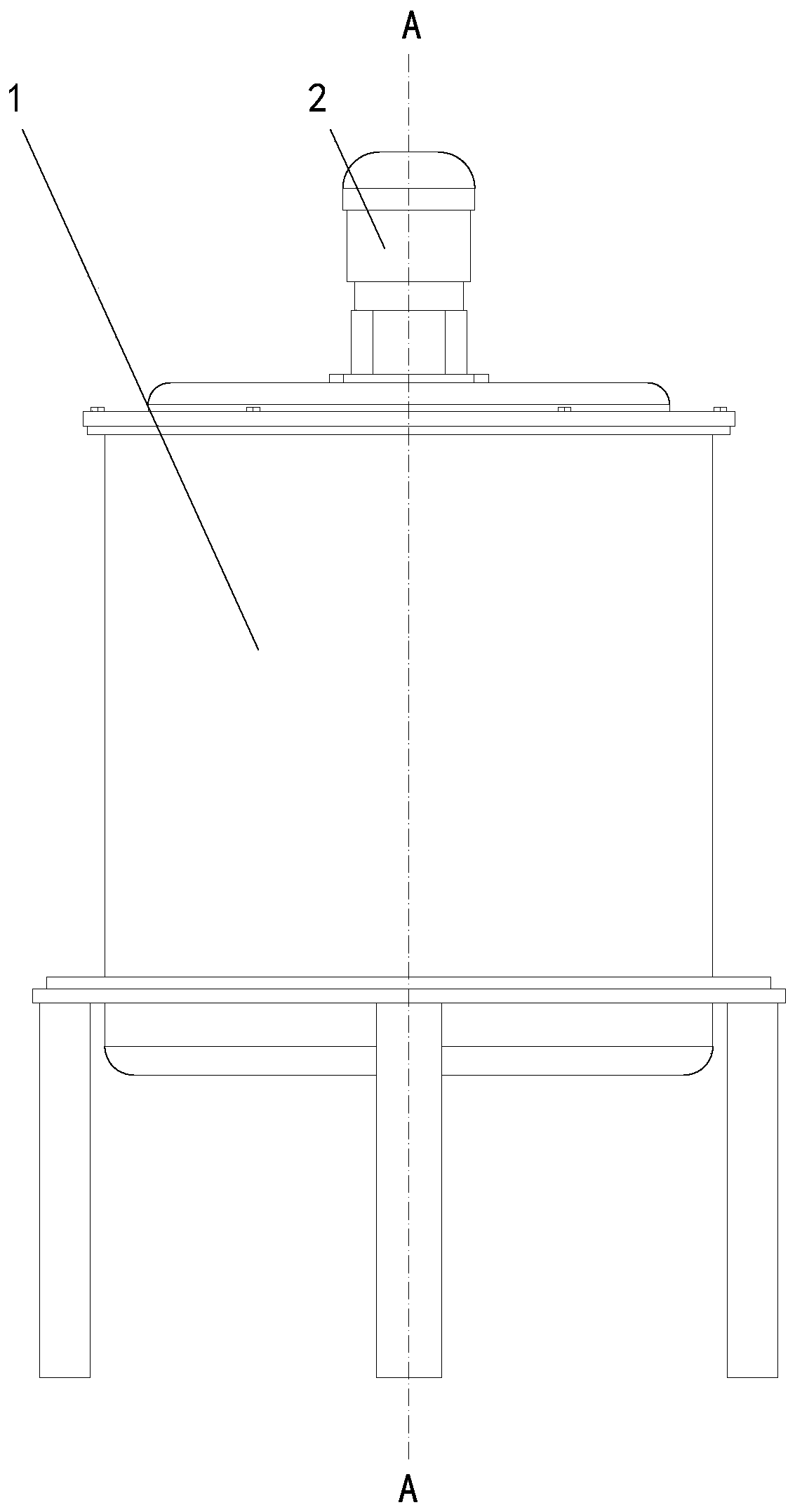

[0031] like Figure 1 to Figure 10 As shown in the figure, a chemical material polyurethane foaming machine provided by the present invention includes a foaming machine shell 1 and a stirring mechanism 2 fixedly installed on the foaming machine shell 1 for mixing the foaming agent. The foaming machine shell 1 includes a foaming barrel 11, the bottom of the foaming barrel 11 is provided with a joint pipe 111 that penetrates vertically into the foaming barrel 11, and the stirring mechanism 2 includes a hollow stirring shaft 22 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com