milk foaming machine

The technology of a foaming machine and milk is applied to the field of equipment for preparing foam from milk, and can solve the problems of insufficient and delicate milk foaming, air can no longer be incorporated, insufficient milk foaming, etc., and the operation process is simple and easy. The effect of simple operation, simple product structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

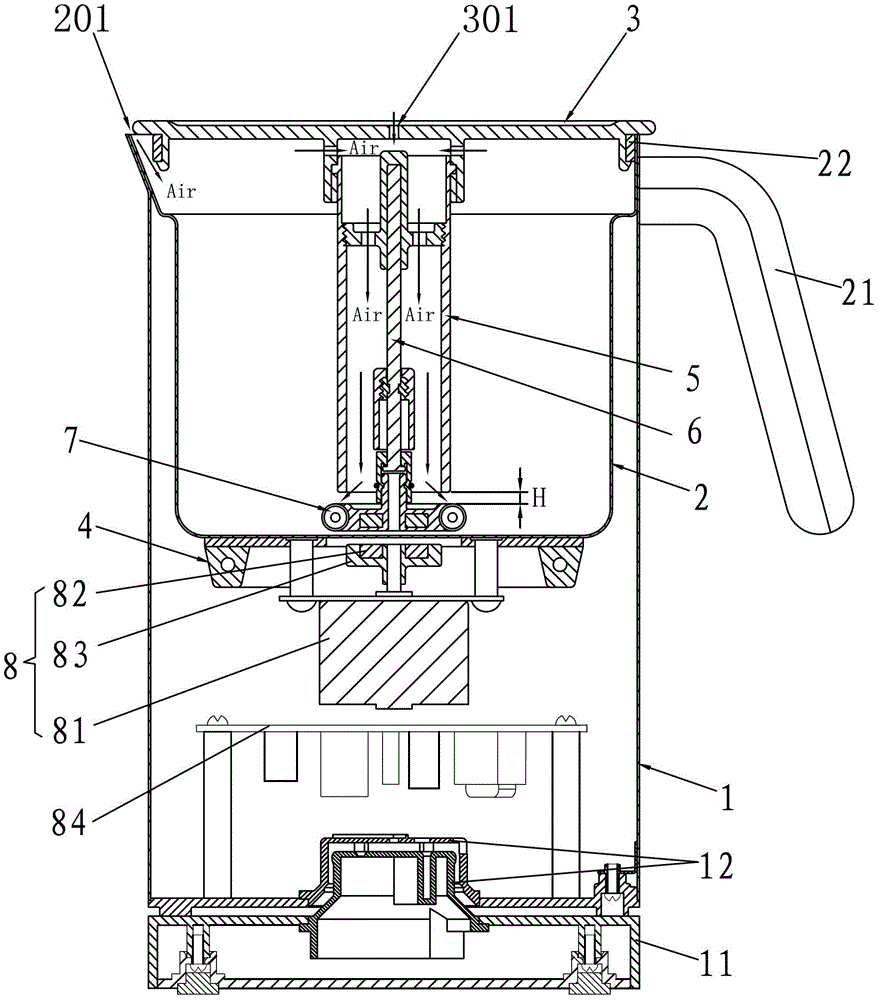

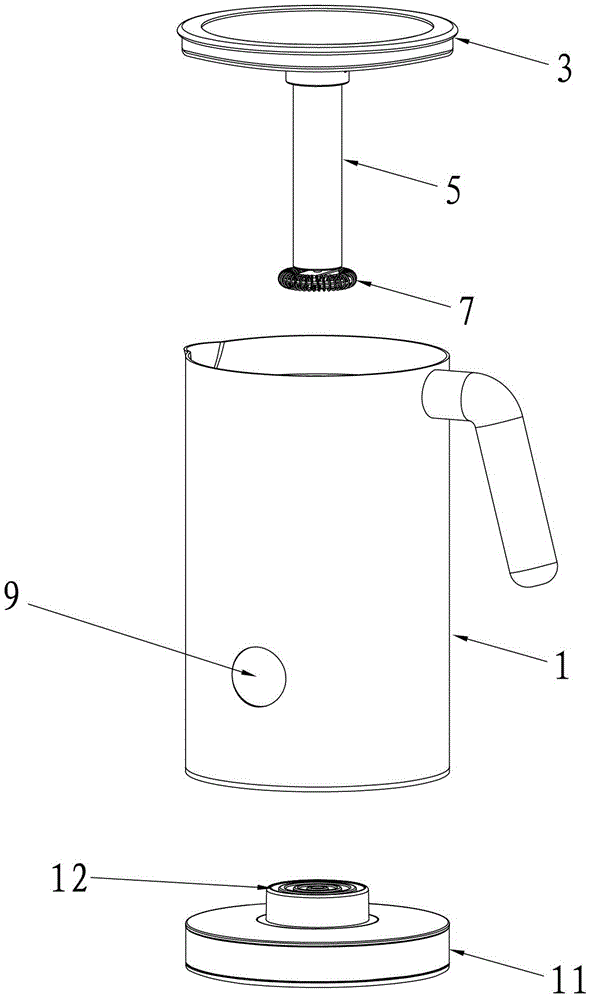

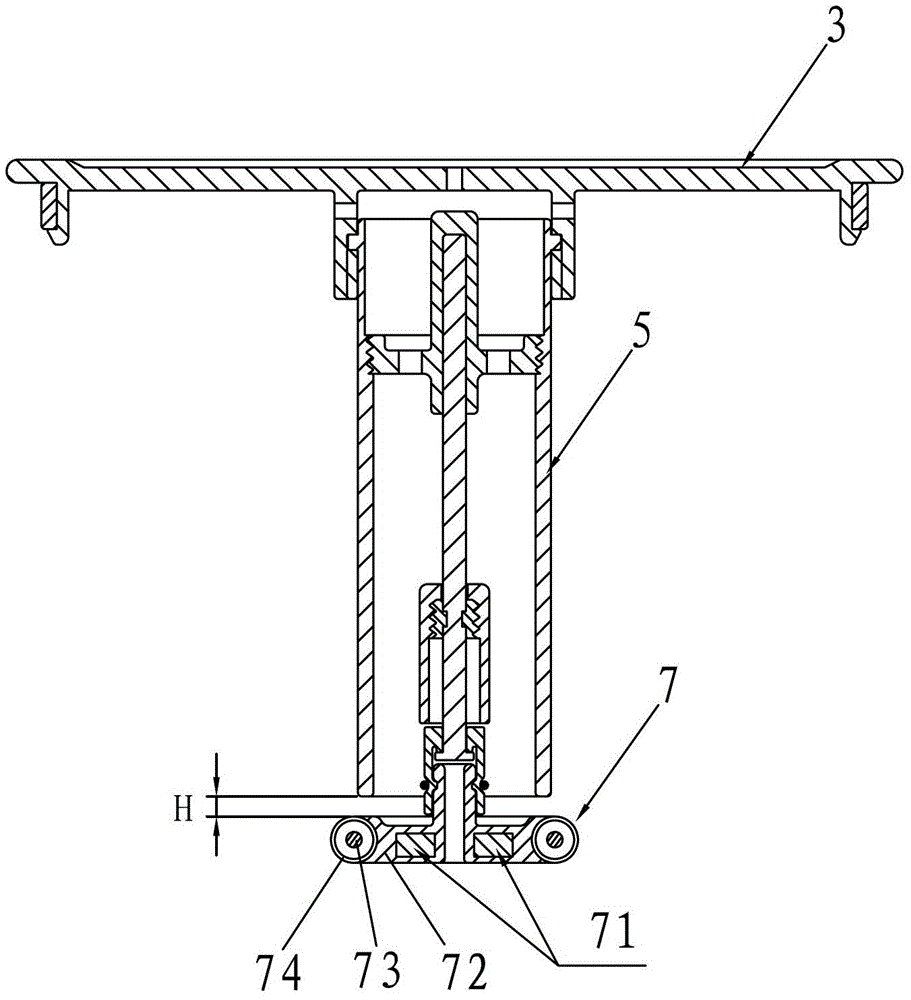

[0038] Such as figure 1As shown in Figure 6(b), the present invention provides a milk foaming machine, which includes a casing 1, a container cover 3 and a silicone anti-vibration ring 22 arranged on the side wall of the container cover 3, and a container 2 is arranged in the casing 1 And the heating device 4 and the magnetic driving device 8 for heating the container 2, the magnetic driving device 8 includes a motor 81, a driving magnet disk 83 and a magnet 82, and a magnet 82 is arranged in the driving magnet disk; The driving device is arranged below the container 2; the agitator 7 arranged in the container 2 has a built-in magnet 71; composition. The lower end of the housing 1 is provided with a power-taking connector 12 and a detachable power-taking base 11, a handle 21 is provided on the upper part of the housing, and a switch 9 is also provided on the housing; the upper end of the container 2 is set as an opening, and the container cover 3 is set at the upper end of t...

Embodiment 2

[0047] Such as Figure 7 and Figure 8 As shown, the principle of the second embodiment is the same as that of the first embodiment above, and the structure is similar, the difference is that the connection mode between the stirring shaft 6 and the air pipe 5 is different.

[0048] Such as figure 1 As shown in Figure 6(b), the present invention provides a milk foaming machine, which includes a casing 1, a container cover 3 and a silicone anti-vibration ring 22 arranged on the side wall of the container cover 3, and a container 2 is arranged in the casing 1 And the heating device 4 and the magnetic driving device 8 for heating the container 2, the magnetic driving device 8 includes a motor 81, a driving magnet disk 83 and a magnet 82, and a magnet 82 is arranged in the driving magnet disk; The driving device is arranged below the container 2; the agitator 7 arranged in the container 2 has a built-in magnet 71; composition. The lower end of the housing 1 is provided with a p...

Embodiment 3

[0066] The principle of this embodiment is the same as that of Embodiment 2, and the difference from the milk foaming machine in Embodiment 2 lies in the structure for realizing the quick release function of the agitator.

[0067] As another way to realize the quick release function, in this embodiment, such as Figure 14 As shown, the stirring shaft 6 is rotatably provided with a rotating connecting ring 66 , the rotating connecting ring 66 has a built-in magnet 63 , and the stirrer 7 has a built-in magnet 71 , and the rotating connecting ring 66 is magnetically connected to the stirrer 7 . The stirrer 7 is magnetically attracted to the magnet 63, and the user can easily remove the stirrer 7 for cleaning.

[0068] Specifically, the magnetic pole N on the upper magnet surface of the built-in magnet 71 of the agitator 7 forms a detachable magnetic connection with the magnetic pole S on the lower magnet surface of the built-in magnet 63 of the rotating connection ring 66, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com