Processing technique for polyurethane heat insulating plate

A technology of polyurethane insulation board and processing technology, which is applied in the field of polyurethane synthetic foaming, can solve problems such as incomplete filling, poor mechanical strength, and affecting the quality of foamed products, and achieve the effect of improving adequacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

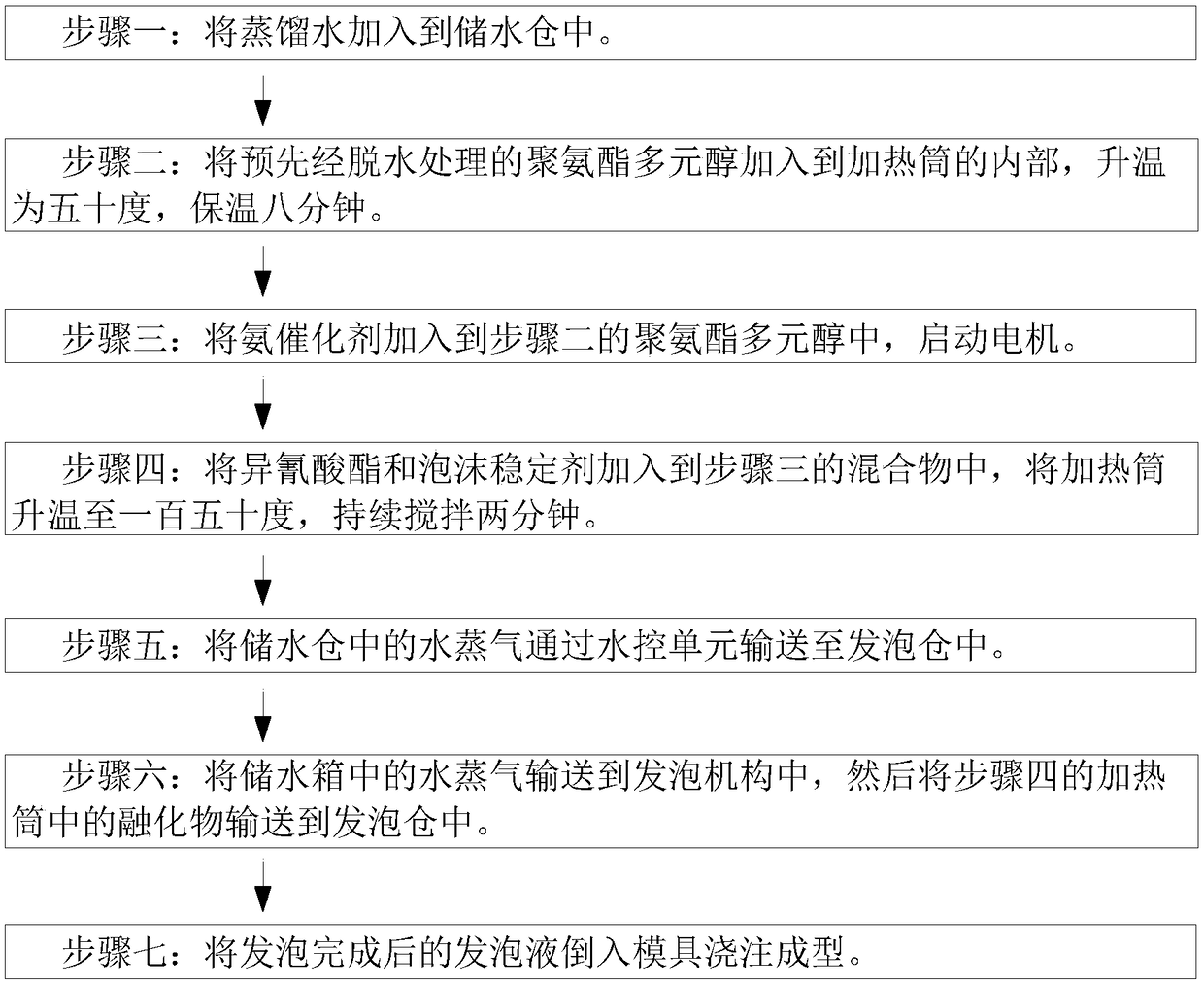

Method used

Image

Examples

Embodiment approach

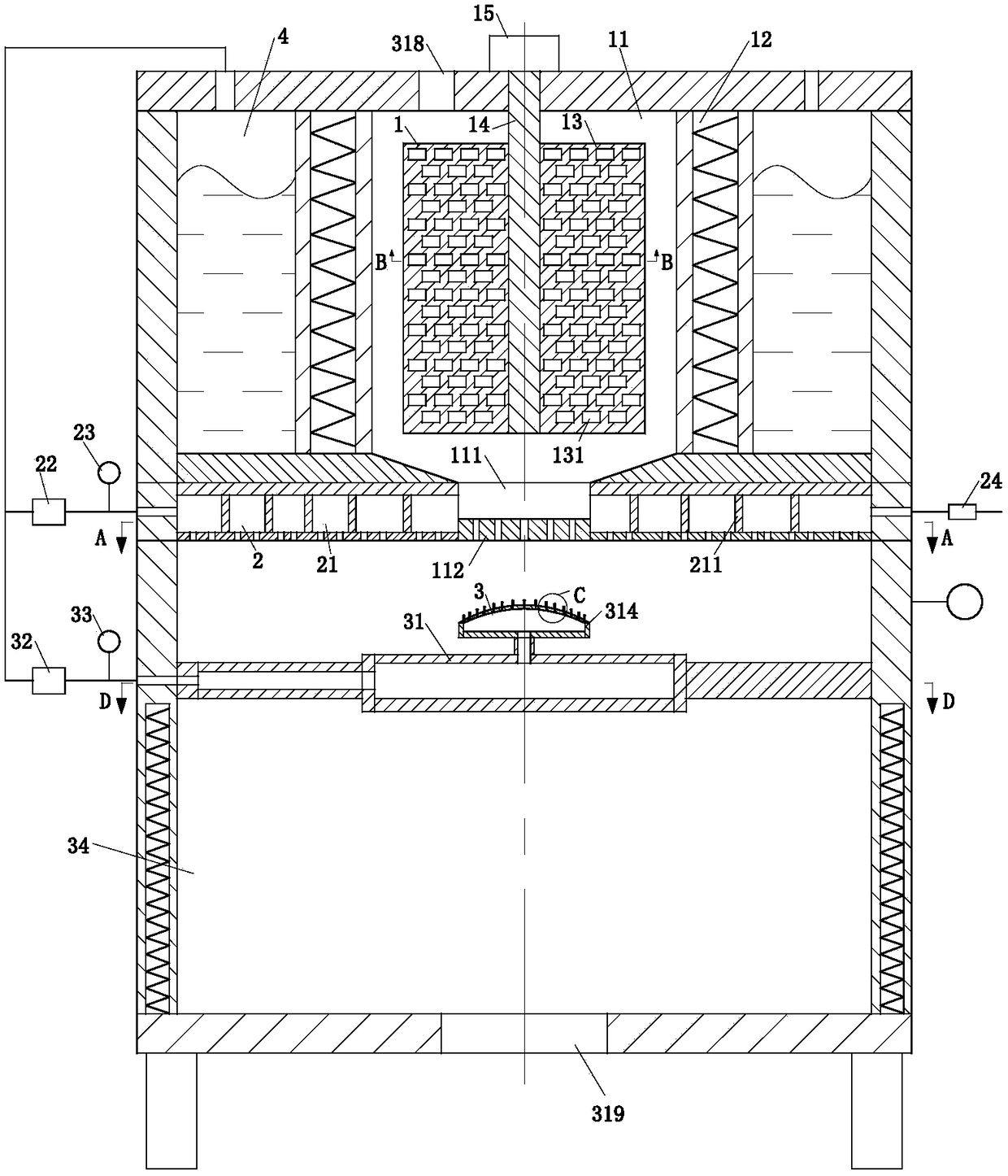

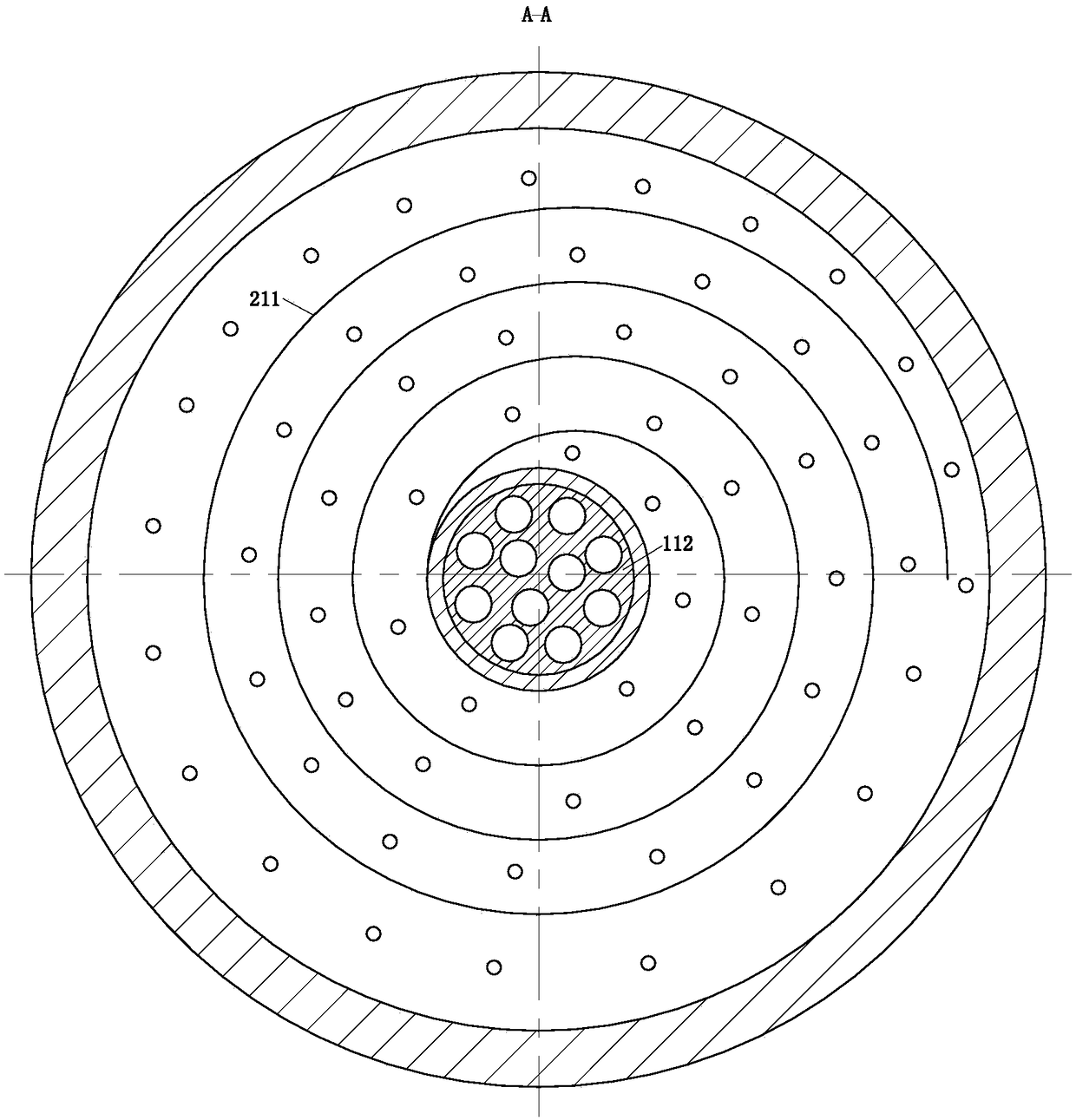

[0046] As an embodiment of the present invention, the center position of the lower surface of the air pressure balance plate 21 is provided with a No. 2 opening 111 that runs through the bottom plate of the stirring chamber 11; In the foaming chamber 34, the No. 2 opening 111 is provided with an automatic door, and the automatic door is used to control the closing of the No. 2 opening 111; the No. 2 opening 111 is circular, and the lower end of the No. 2 opening 111 is provided with a liquid guide plate 112 The upper surface of the liquid guide plate 112 is provided with a plurality of liquid outlets that penetrate the liquid guide plate 112; the liquid outlets are used to disperse the melt above the liquid guide plate 112 and flow into the foaming chamber 34 for Increase the contact area between the melt and water vapor, and improve the foaming efficiency of the melt.

[0047] As an embodiment of the present invention, the four stirring plates 13 are the same member, the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com