Patents

Literature

39results about How to "Intensity can be controlled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

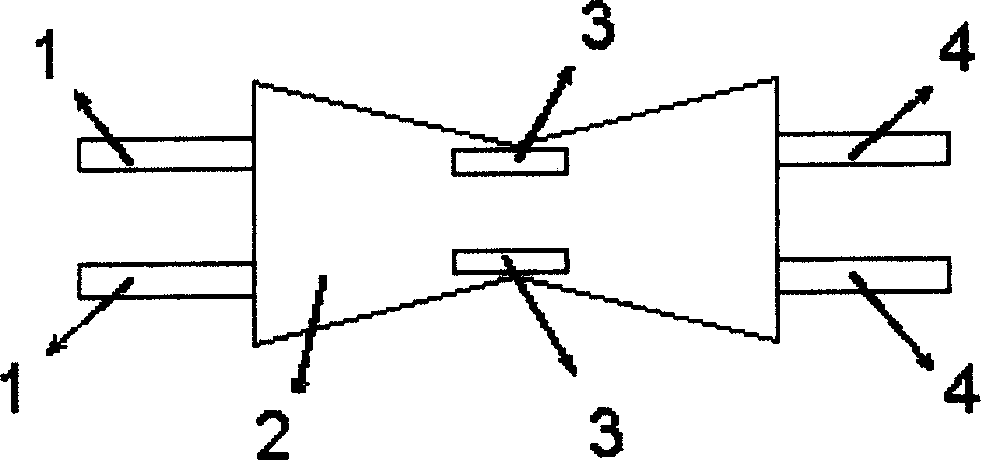

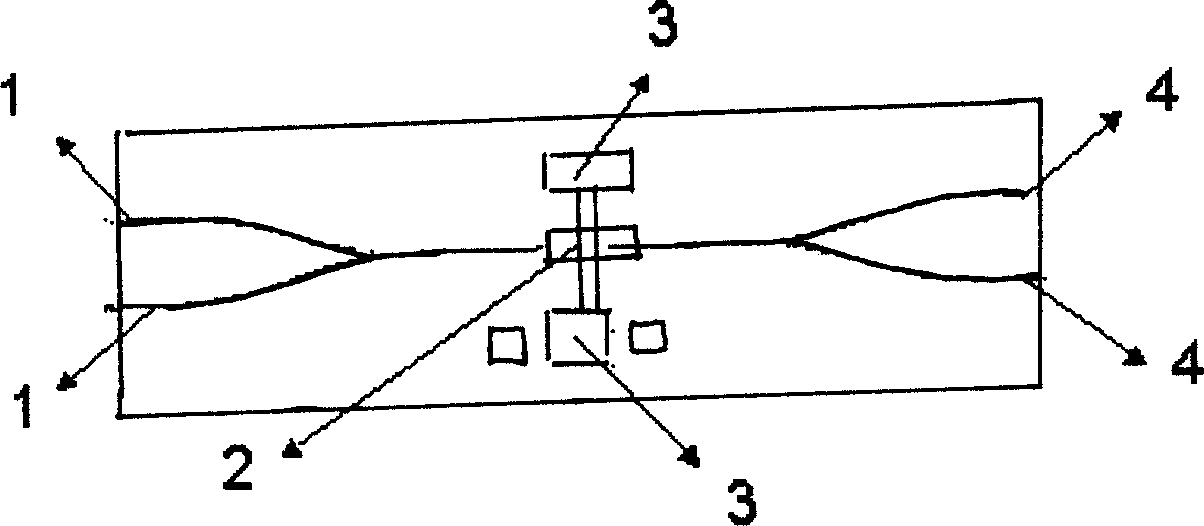

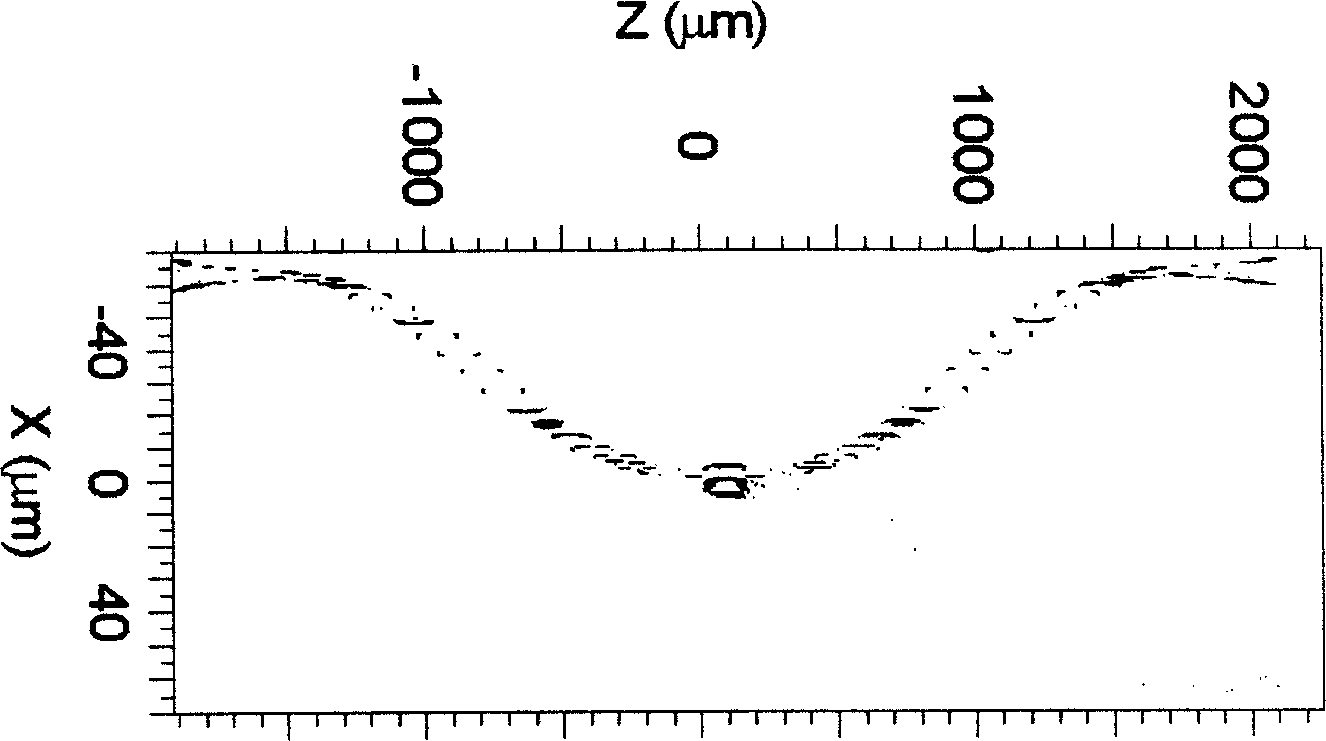

Compact regulatable type multi-mode interference coupler

InactiveCN1904656AReduce beat lengthShorten the lengthCoupling light guidesNon-linear opticsCommunications systemRefractive index

The invention discloses a compact adjustable multi-mode interfering coupler that includes input channel connecting to optical signal input end, multi-mode wave guide, modulating module, and output channel connecting to the output end of optical signal. The feature is that: the multi-mode wave guide is not rectangle, and input channel and output channel connecting to the two sides of the multi-mode wave guide along optical signal transferring direction, and the modulation module is set on the surface of multi-mode wave guide. The invention decreases the bat length of multi-mode wave guide and makes component compact. It could be used in the wave guide type coupler of optical communication system, optical computer system and photon / photoelectron integrated loop.

Owner:SOUTHEAST UNIV

Leaking stoppage reinforcing agent

The invention discloses a leaking stoppage reinforcing agent which comprises the following components in parts by weight: 2-8 parts of urea resin, 1-5 parts of phenolic resin, 8-15 parts of slag, 1-5 parts of calcium sulfate, 5-8 parts of aluminum oxide, 3-6 parts of calcium chloride, 10-20 parts of calcium carbonate, 10-20 parts of silicon oxide, 0.1-0.4 part of polyanionic cellulose PAC-LV and 0.1-0.4 part of sodium carboxymethylcellulose CMC-LV. The leaking stoppage reinforcing agent is prepared by the steps of sequentially adding the components in parts by weight into a reaction kettle according to a conventional preparation method at 30-50 DEG C under normal pressure, stirring and mixing for 6-8 hours, subsequently adding the components into a kneading machine, uniformly mixing and stirring, drying, and crushing into a powder product with the particle size of 0.01-0.5mm. The leaking stoppage reinforcing agent has a remarkable leaking stoppage and reinforcing effect, is temperature resisting, good in stability and coagulability, high in structural stoppage capability and good in compatibility, can be thickened without solidification, is controllable in reinforcing time, wide in application range, safe in construction and free of toxicity or pollution, can be widely applied to petroleum and geological drilling process, and is particularly applicable to leaking stoppage construction in large cracks, large karst caves, underground rivers, severe deficit earth layers and crushed earth layers.

Owner:DONGYING TAIER GASOLINE TECH

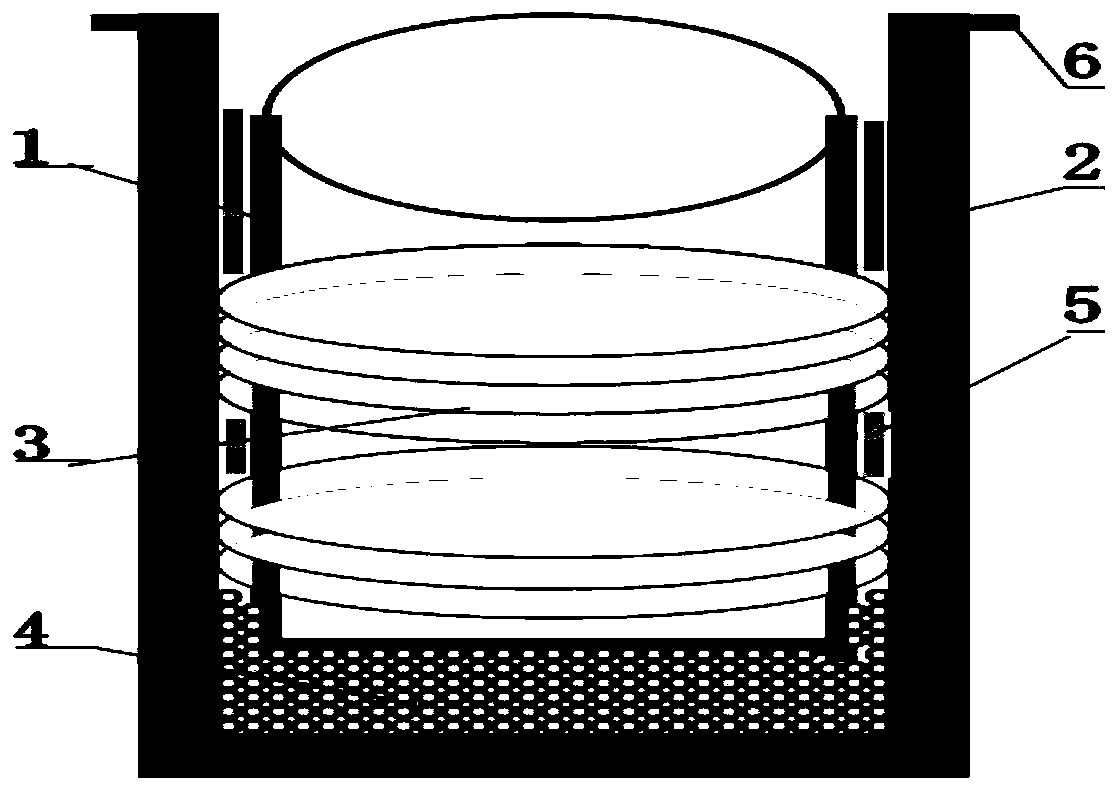

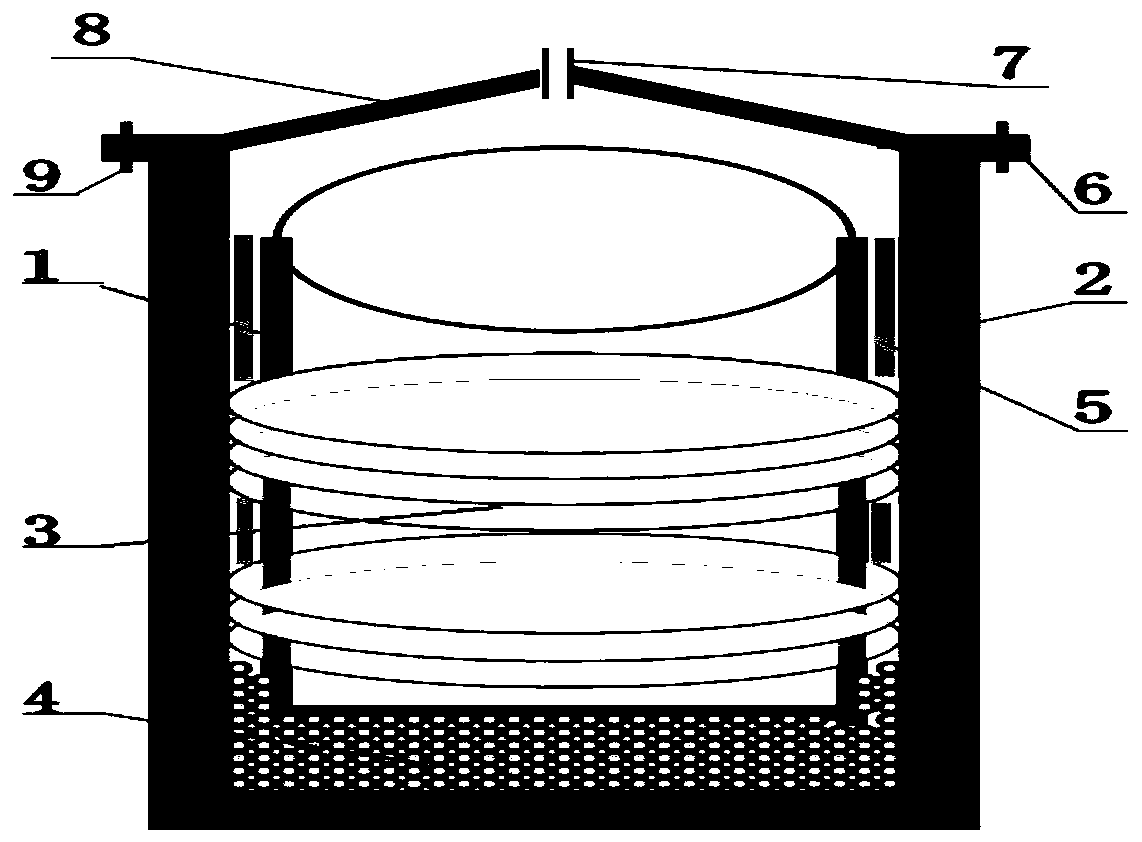

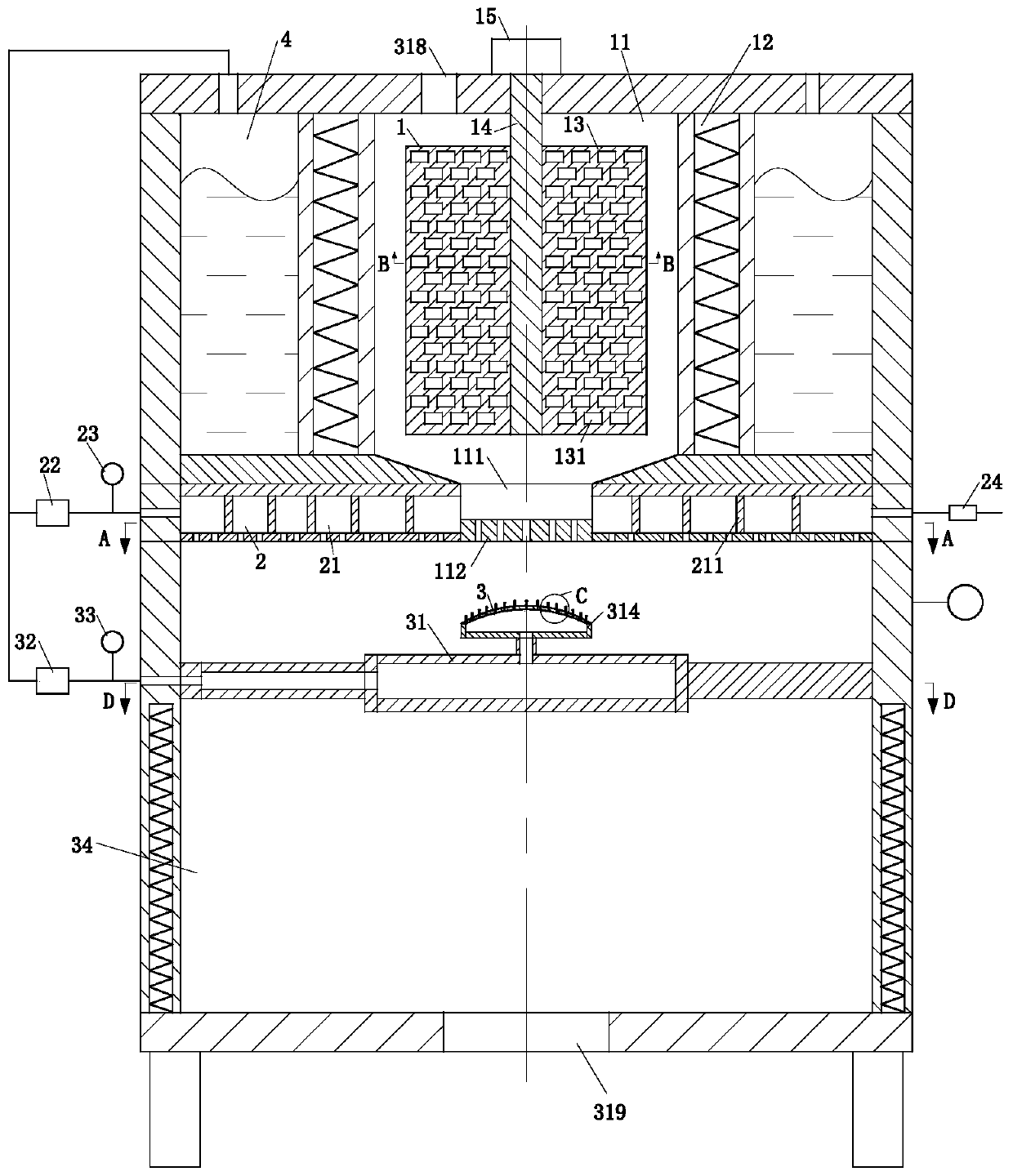

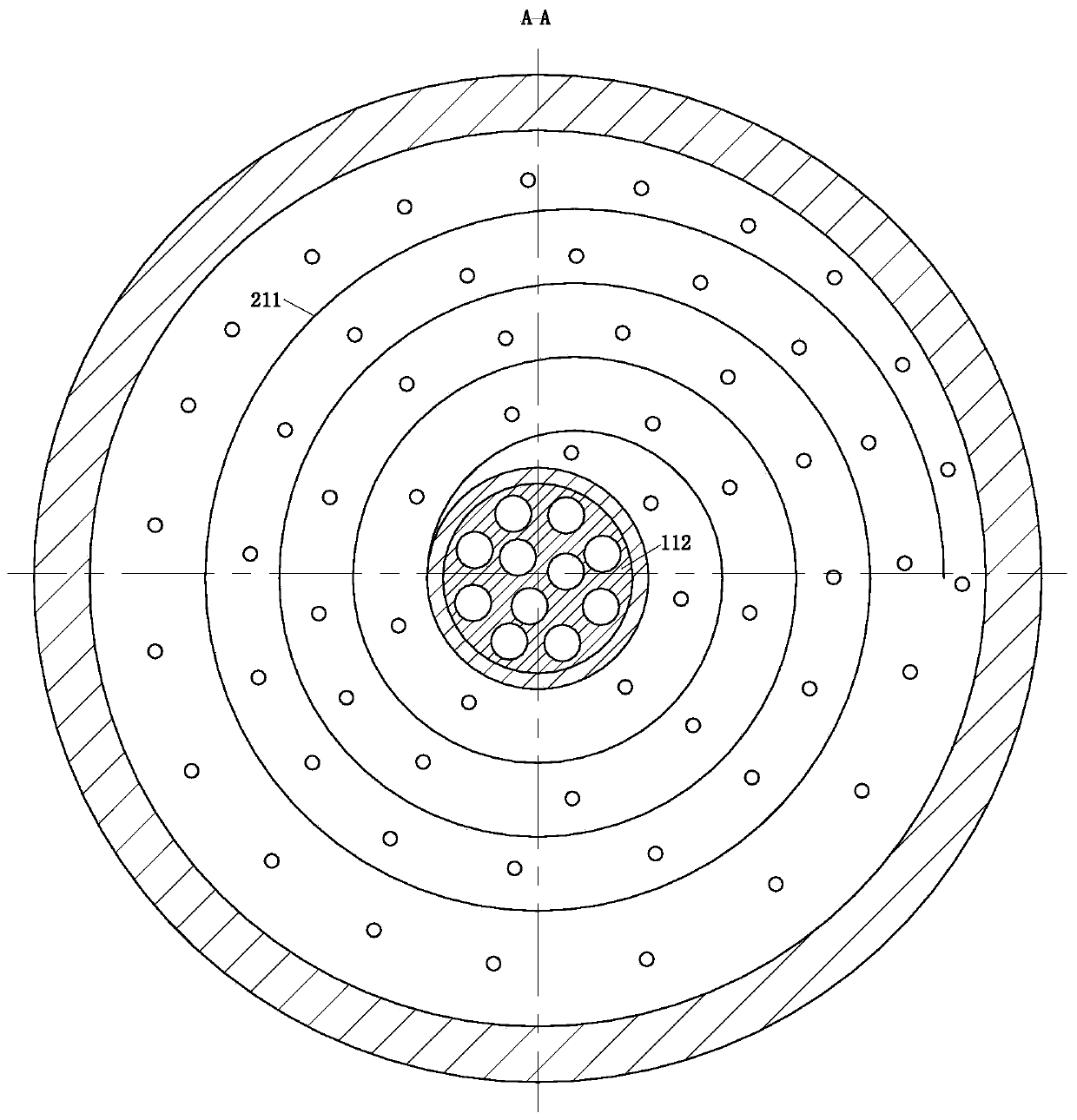

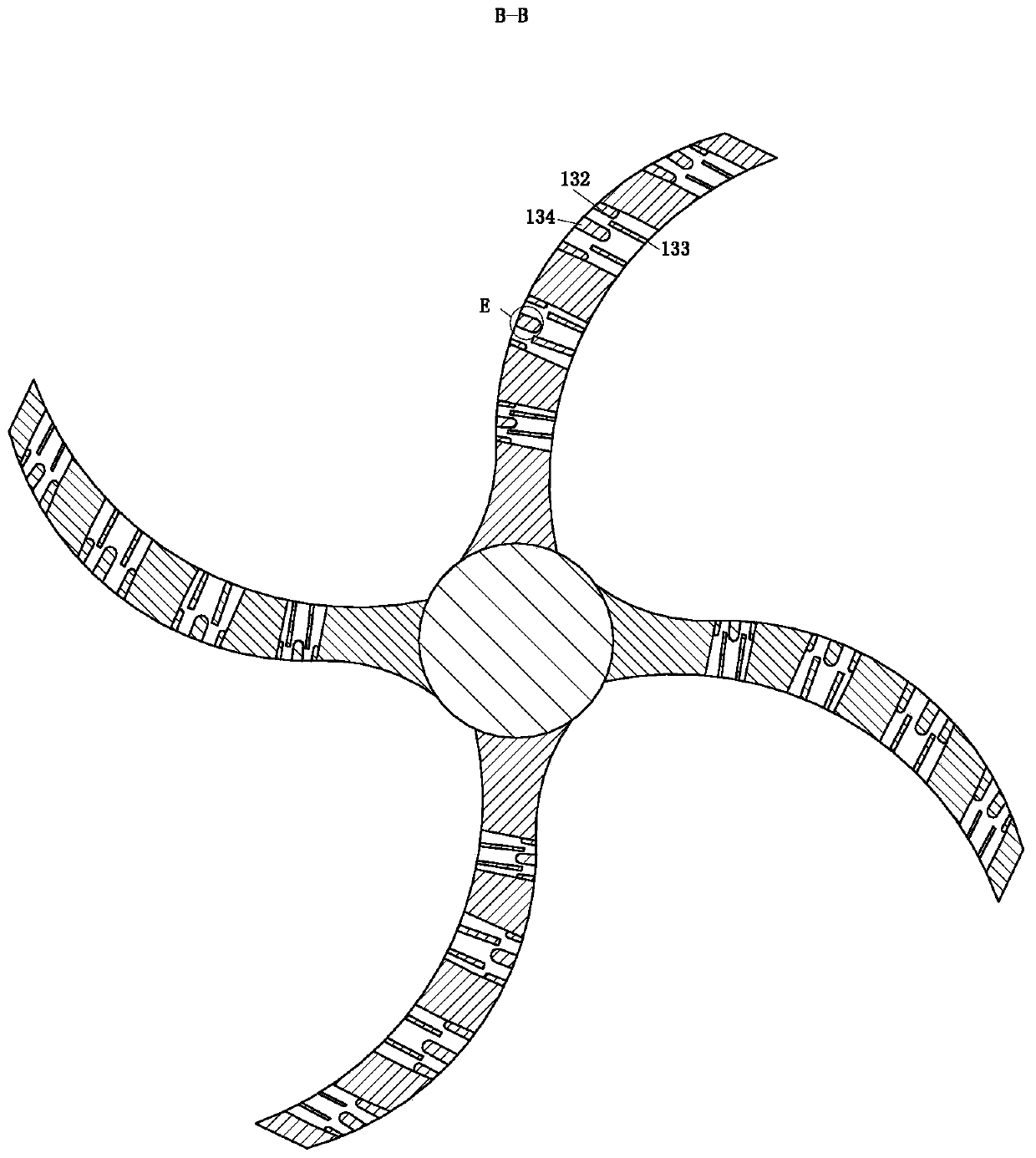

Preparation method for vanadium-aluminum alloy and reactor

The invention provides a preparation method for a vanadium-aluminum alloy and a reactor. The preparation method provided by the invention comprises the following steps: 1) mixing a vanadium source, analuminum source and a slag former to obtain a material mixture; 2) heating the material mixture to obtain a reaction product; and 3) under a vacuum-pumping condition or protective gas introducing condition, cooling the reaction product to obtain the vanadium-aluminum alloy. The reactor comprises a U-shaped container, a reaction container arranged in the U-shaped container, a heating device positioned on the outer wall of the reaction container, and a filler arranged between the U-shaped container and the reaction container. The preparation method provided by the invention solves the problemsthat a vanadium yield is low, the alloy separating effect is poor and an oxidization film appears in the prior art, overcomes splash due to fierce reaction, volatilization, due to a high temperature,of vanadium pentoxide, poor alloy separating effect, and vanadium loss due to the fact that the vanadium-aluminum alloy enters a slag phase.

Owner:HEBEI IRON AND STEEL

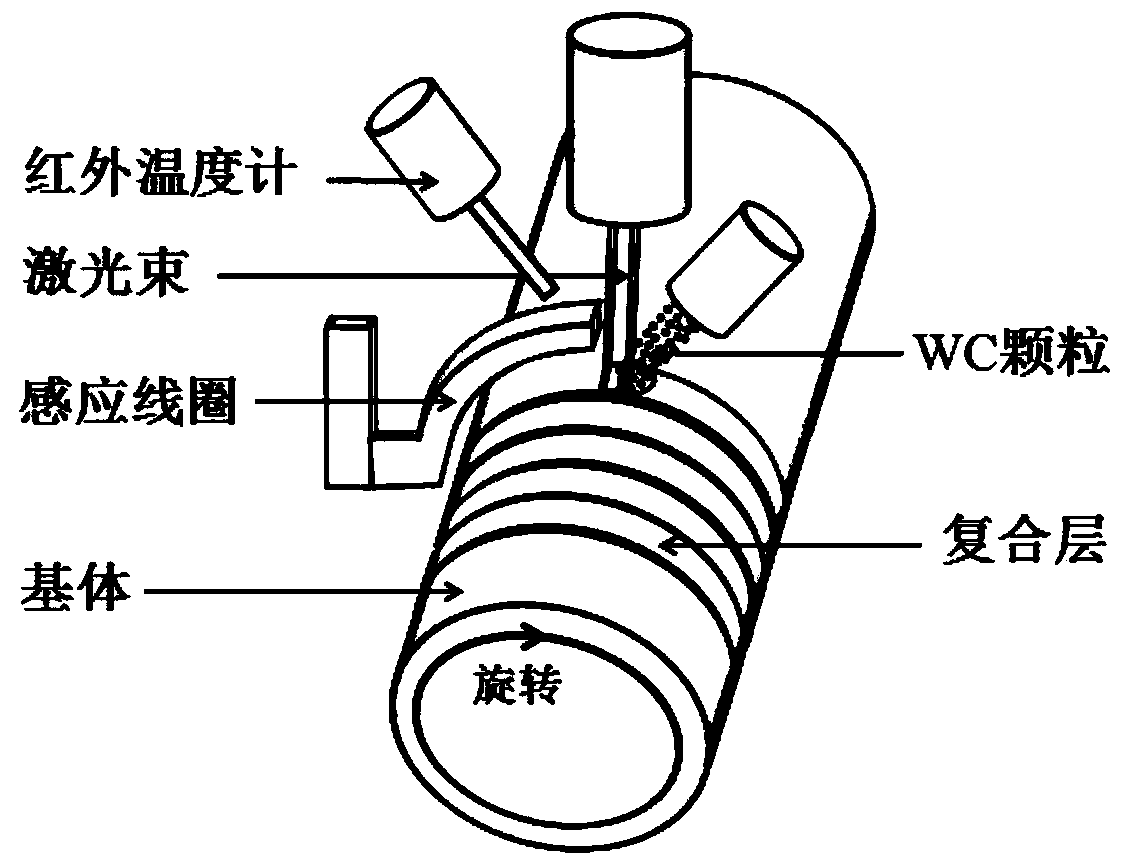

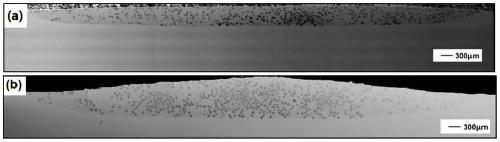

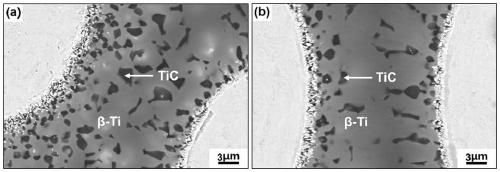

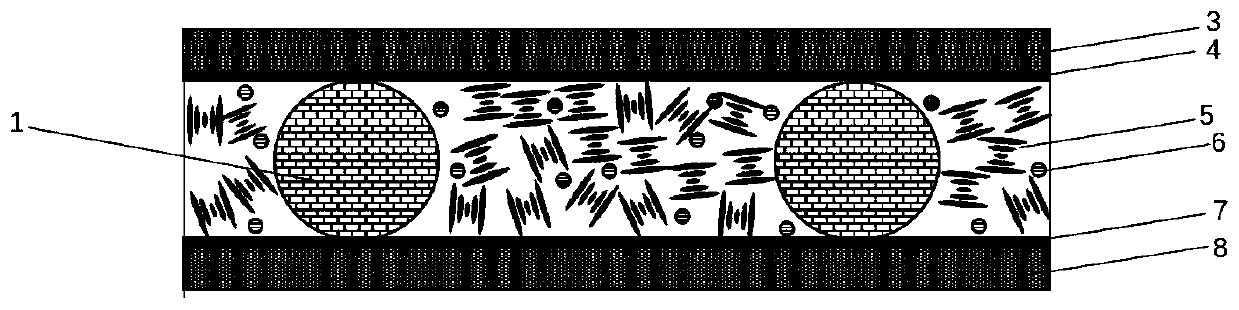

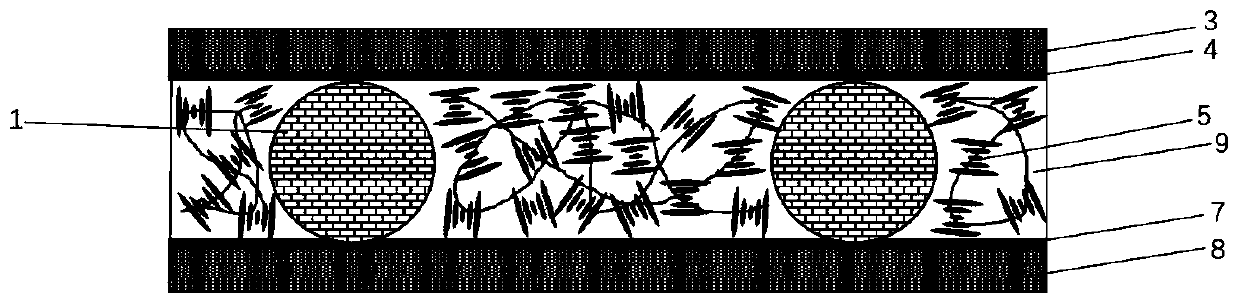

Method capable of giving consideration to laser melt injection efficiency, composite layer depth and metallurgical quality

ActiveCN110306184AReduce precipitationPrevent precipitationMetallic material coating processesInterfacial reactionNucleation

The invention belongs to the field of laser advanced manufacturing, and discloses a method capable of giving consideration to laser melt injection efficiency, composite layer depth and metallurgical quality. According to the method, a molten pool is formed on the surface of a metal base material through a laser beam, and meanwhile, a substrate is subjected to synchronous preheating through an induction coil; and then, ceramic reinforced particles are poured into the molten pool, the reinforced particles which are not completely molten are caught in the molten pool, and accordingly, and a particle-reinforced metal ceramic composite layer is formed on the surface of the metal base material. Induction preheating is synchronously introduced into the traditional laser melt injection technologytreatment process, the cooling rate of the molten pool can be properly decreased, nucleation of the brittle metal compound in the molten pool is inhibited, the problem that cracking occurs due to thefact that the precipitation amount of the brittle compound in the traditional metal ceramic composite layer laser melt injection process is too large is solved, and the intensity of interfacial reaction is effectively controlled while the laser melt injection efficiency and the composite layer depth are remarkably improved.

Owner:HUAZHONG UNIV OF SCI & TECH

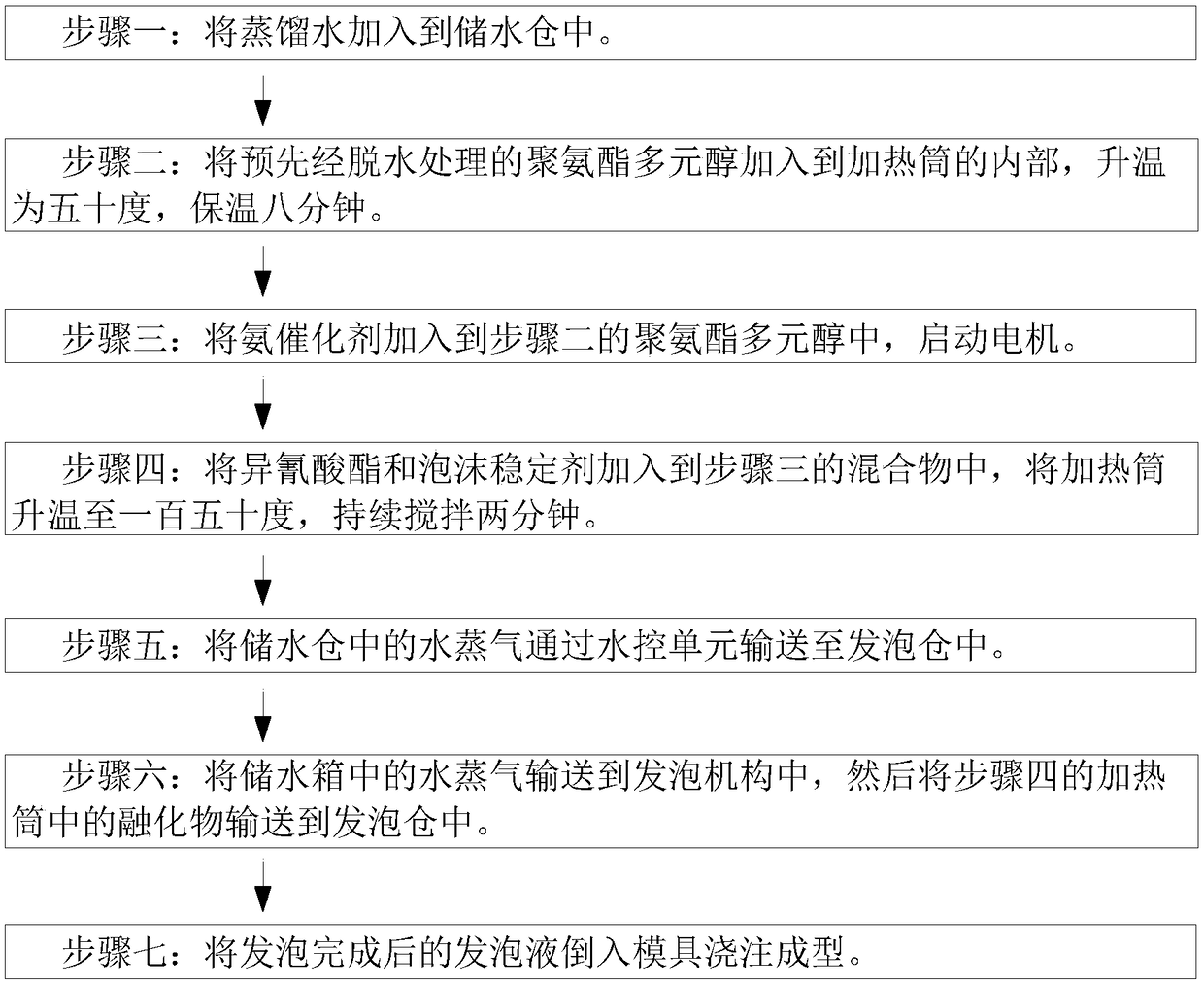

Processing technique for polyurethane heat insulating plate

The invention belongs to the technical field of synthesis and foaming of polyurethane and particularly provides a processing technique for a polyurethane heat insulating plate. The processing technique comprises step I to step VII; the step I to step IV are used for pretreating raw materials; the step V to step VII are used for carrying out foaming reaction of the raw materials; the technique adopts a foaming device; the foaming device comprises a mixing unit, a water control unit and a foaming unit; the mixing unit comprises a mixing bin, a heating cylinder, four mixing plates, a rotating rodand a motor; the mixing bin is cylindrical; the left side of the upper surface of the mixing bin is provided with a No.1 opening; the hating cylinder is fixedly installed inside the mixing bin; the four mixing plates are arranged inside the cylindrical heating cylinder; the mixing unit is used for mixing the raw materials; and the water control unit is matched with the foaming unit so as to foamthe raw materials. The processing technique provided by the invention is mainly used for implementing large-batch production of heat insulating materials, can improve the uniformity of the raw materials, can make the raw materials be foamed fully and improves the foaming efficiency of the raw materials.

Owner:长春华力汽车部件有限公司

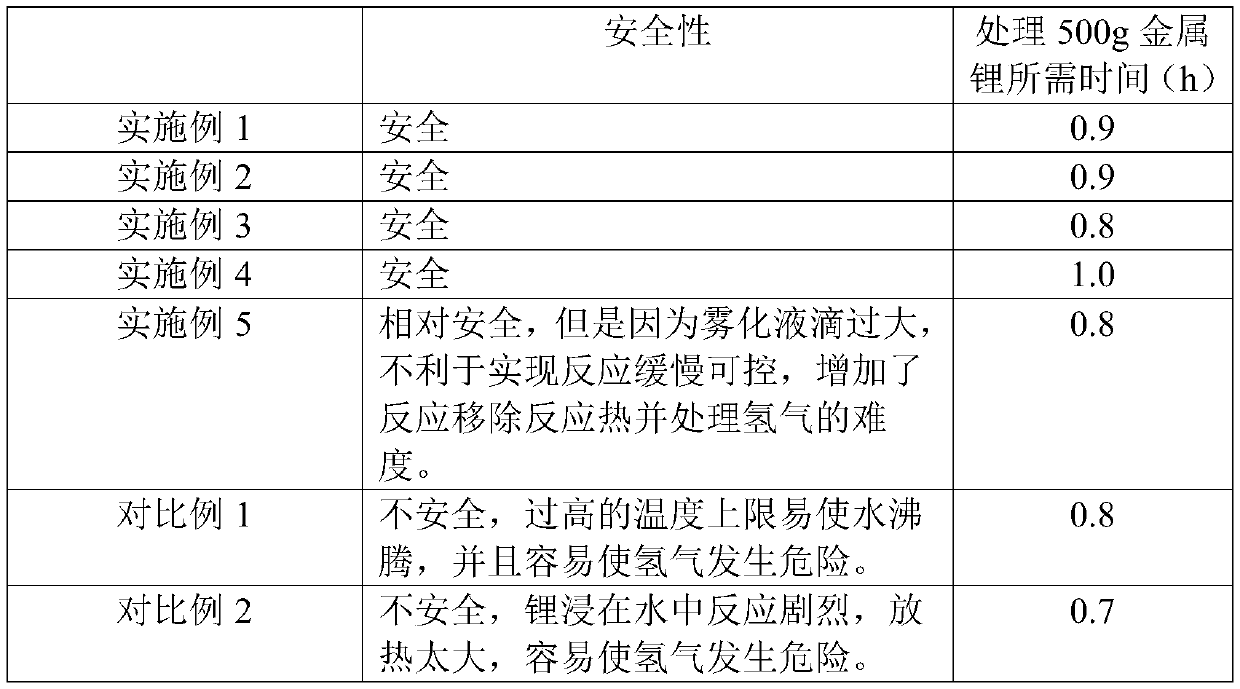

Harmless treatment method for metal lithium

PendingCN110436489AImprove securitySlow reaction rateLithium carbonates/bicarbonatesLithium carbonateMetal

The invention discloses a harmless treatment method for metal lithium. The method comprises: (1) reacting metal lithium and an atomized reactant to obtain a lithium-containing mixture; (2) immersing the lithium-containing mixture obtained in the step (1) into a reactant to carry out a reaction to obtain a lithium-containing solution. The reaction process is controlled by controlling the dosage ofthe atomized reactant, and a passivation layer generated by the atomized reactant and the metal lithium covers the metal lithium to retard the reaction process; after the lithium-containing mixture which is incompletely reacted is immersed into the reactant for neutralization, the passivation layer is dissolved into the reactant, and the metal lithium in the passivation layer solution reacts withthe reactant. The reaction process is controlled by substep control, the severity of the reaction is controlled, and safety of harmless treatment of the metal lithium is improved. Through feeding carbon dioxide, frequent treatment or adjustment of the component concentration of the passivation layer in the reactant is avoided, and lithium carbonate which can be easily and safely recovered is obtained.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

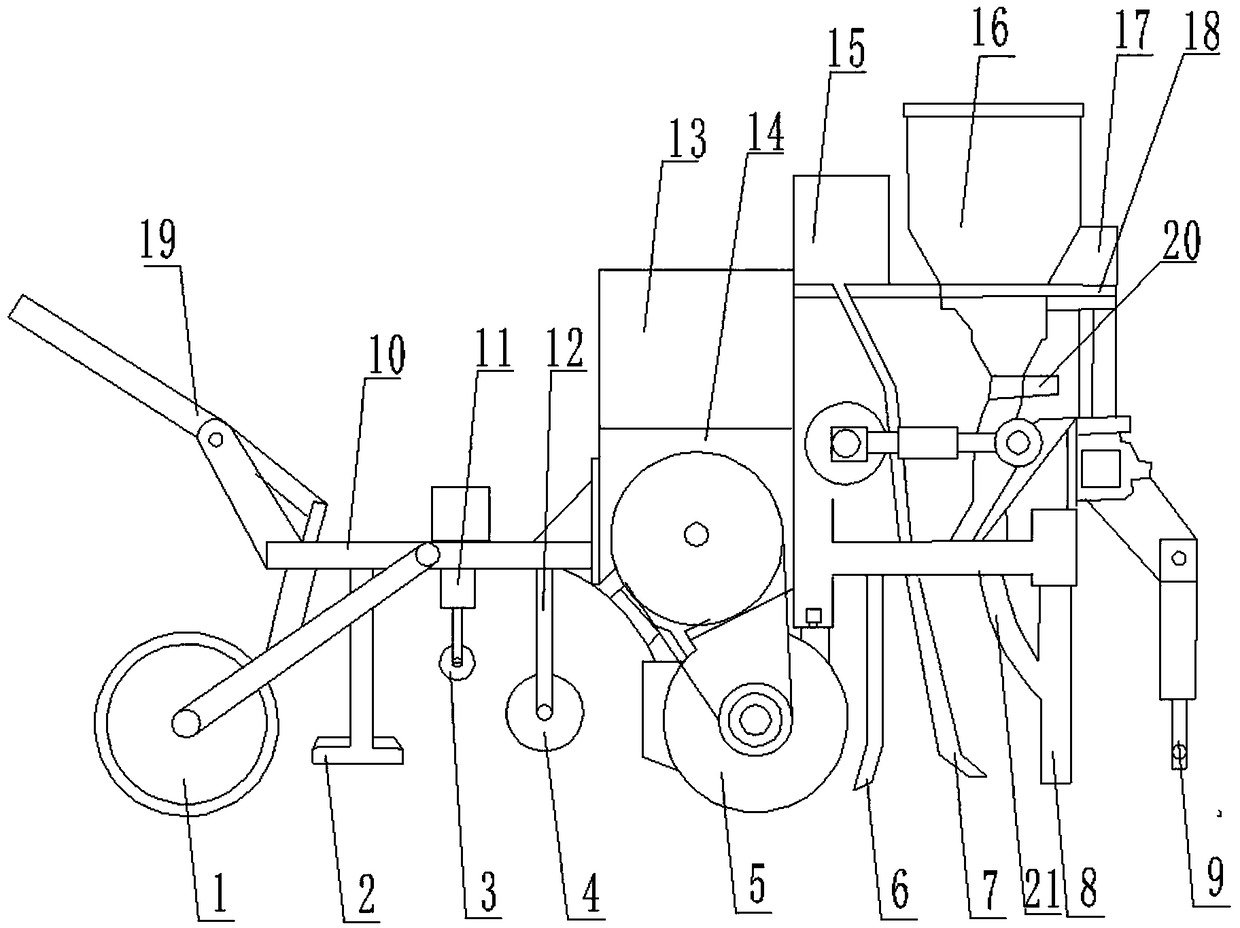

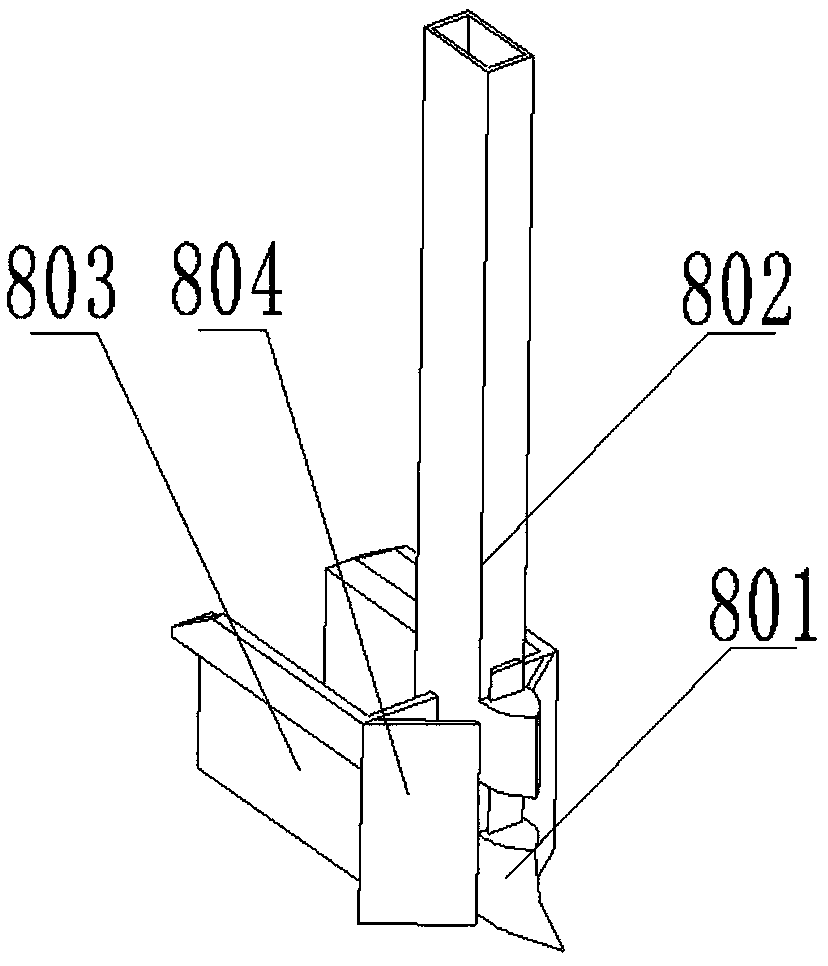

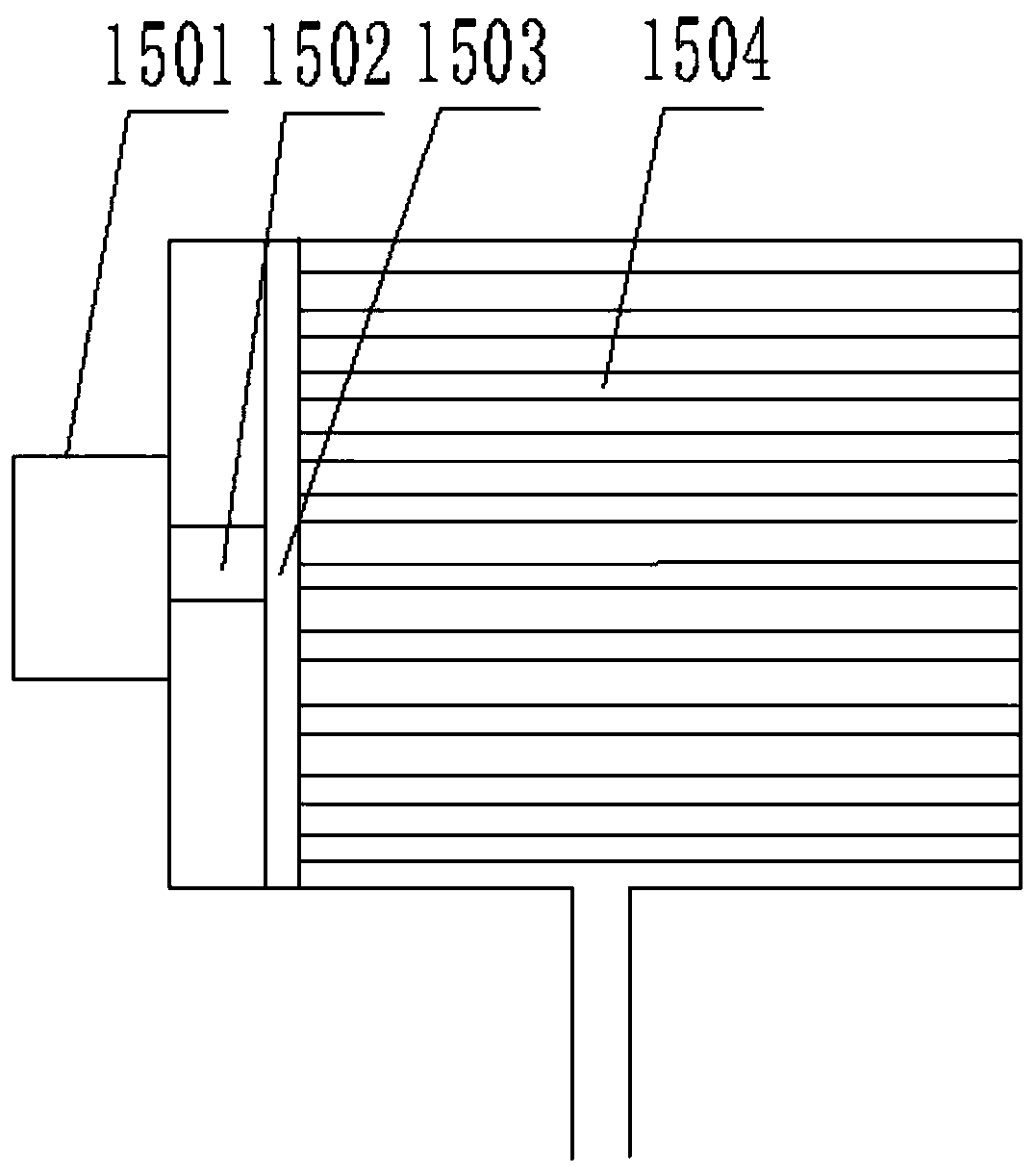

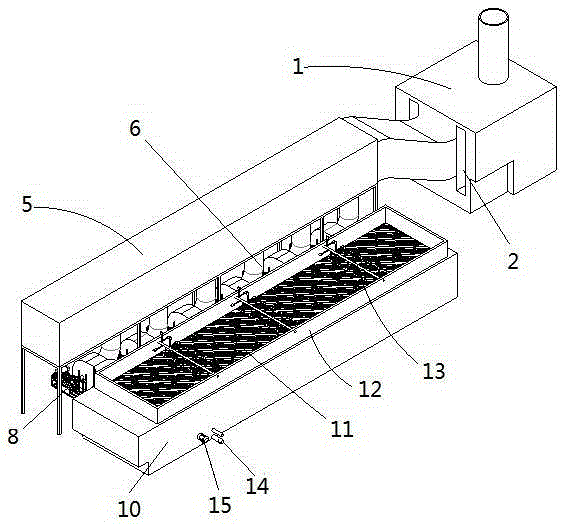

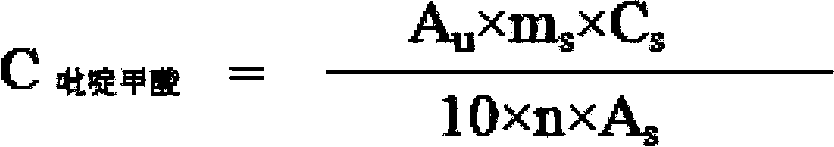

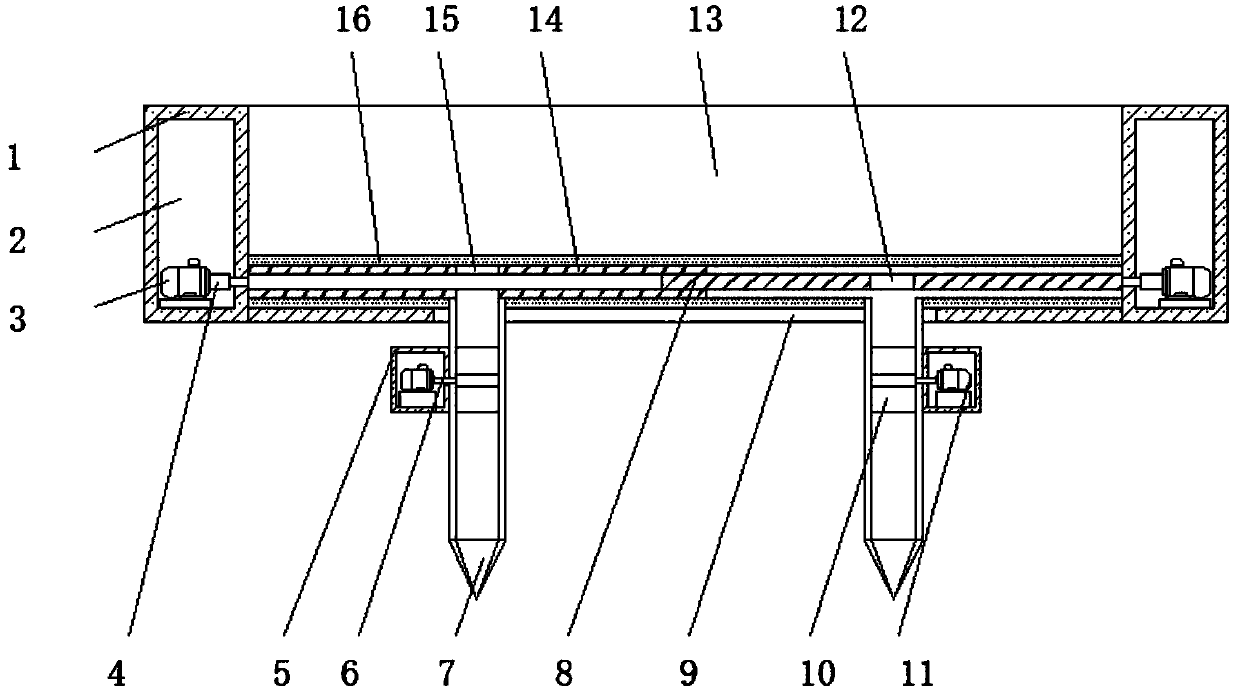

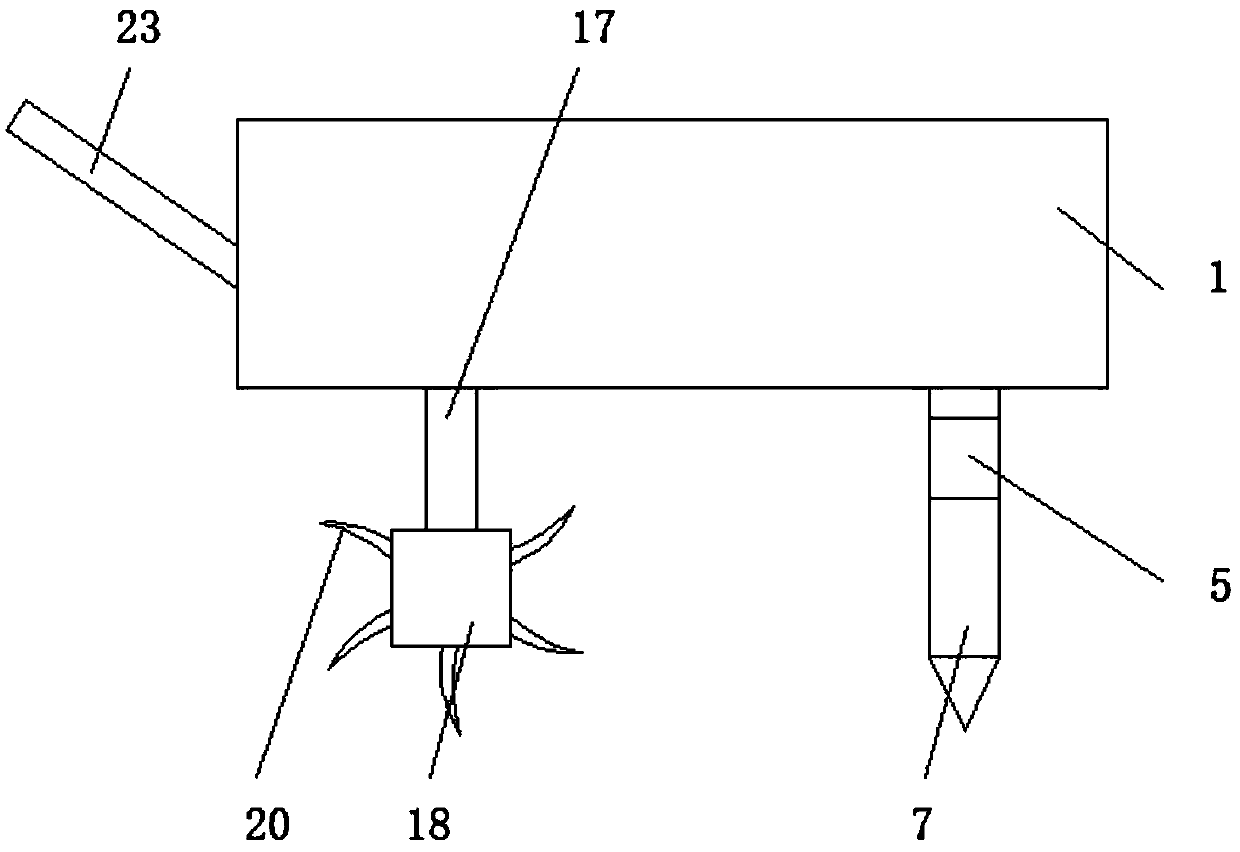

Fully-automatic maize irrigating, sowing and mulching integrated machine

InactiveCN108990480AImprove planting efficiencyControl the speed of playbackPlantingClimate change adaptationAgricultural engineeringFully automatic

The invention discloses a fully-automatic maize irrigating, sowing and mulching integrated machine comprising a film pressing roller, a furrow opener, a main frame and a mounting plate; the main frameis provided with a mulching film covering wheel; one side of the mulching film covering wheel is provided with a telescopic shaft; the tail end of the telescopic shaft is provided with the film pressing roller; one side of the telescopic shaft is provided with a stationary shaft; the bottom of the stationary shaft is provided with a mulching film roller; the main frame is further provided with apower box; a control box is arranged on the power box; one side of the control box is provided with the mounting plate; a seed storage box and a water tank are fixedly placed on the mounting plate; the seed storage box is connected to a seed metering device by a pipeline; the water tank is connected to the furrow opener by a water pipe; and one side of the water tank is provided with a water inletpump. The fully-automatic maize irrigating, sowing and mulching integrated machine has the beneficial effects that construction operations such as irrigation, furrow opening, sowing, mulching film covering and soil compaction in a maize planting process are finished at one time, so that the repetitive operation is reduced, and the maize planting efficiency is greatly increased.

Owner:FARMING & CULTIVATION RES INST OF HEILONGJIANG ACADEMY OF AGRI SCI

Additive capable of improving utilization rate of silicon power in synthesis of methyl chlorosilane

ActiveCN104151343ALow impurity contentIncrease contact areaGroup 4/14 element organic compoundsSilica fumeOxide

The invention discloses an additive capable of improving utilization rate of silicon power in synthesis of methyl chlorosilane. The additive is characterized by being prepared from the following components in parts by weight through mixing: 30-70 parts of an oxide, 25-50 parts of silicon powder, 4.5-15 parts of copper powder and 0.5-5 parts of zinc powder, wherein the average particle size of the additive is 70-100mm and the weight ratio of silicon oxide to aluminum oxide to calcium oxide in the oxides is (82-87) to (7-13) to (3-7). At the later stage of a reaction between silicon powder and chloromethane in a fluidized bed, by adopting the reaction additive disclosed by the invention, the intensity of the reaction in the fluidized bed is effectively controlled and thus the quality of the reaction product can be ensured, and meanwhile, since silicon powder is in full contact with chloromethane, the conversion rate of silicon powder is improved, the generation of waste silicon powder is reduced and therefore the production benefits are further increased.

Owner:LUXI CHEM GRP

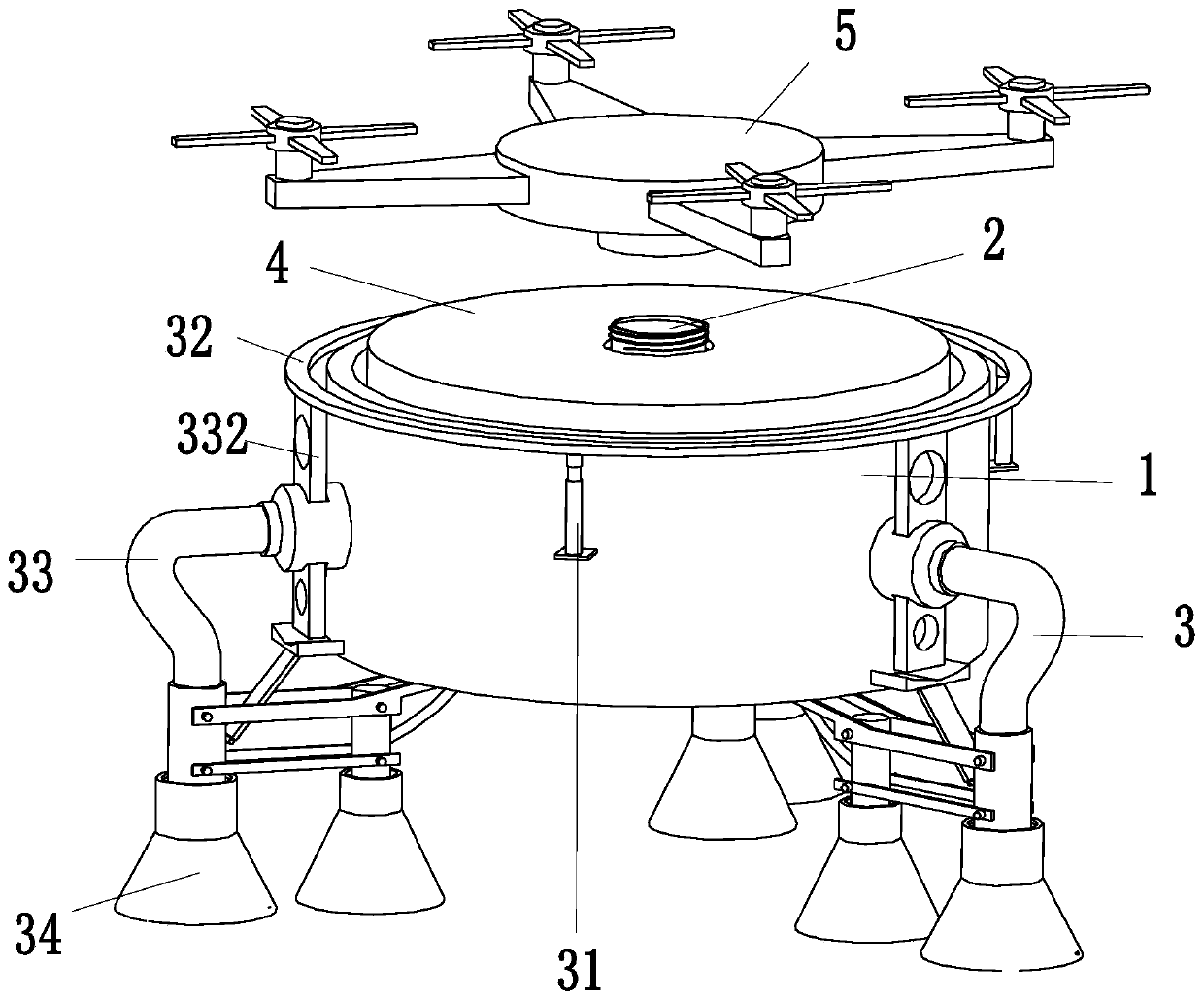

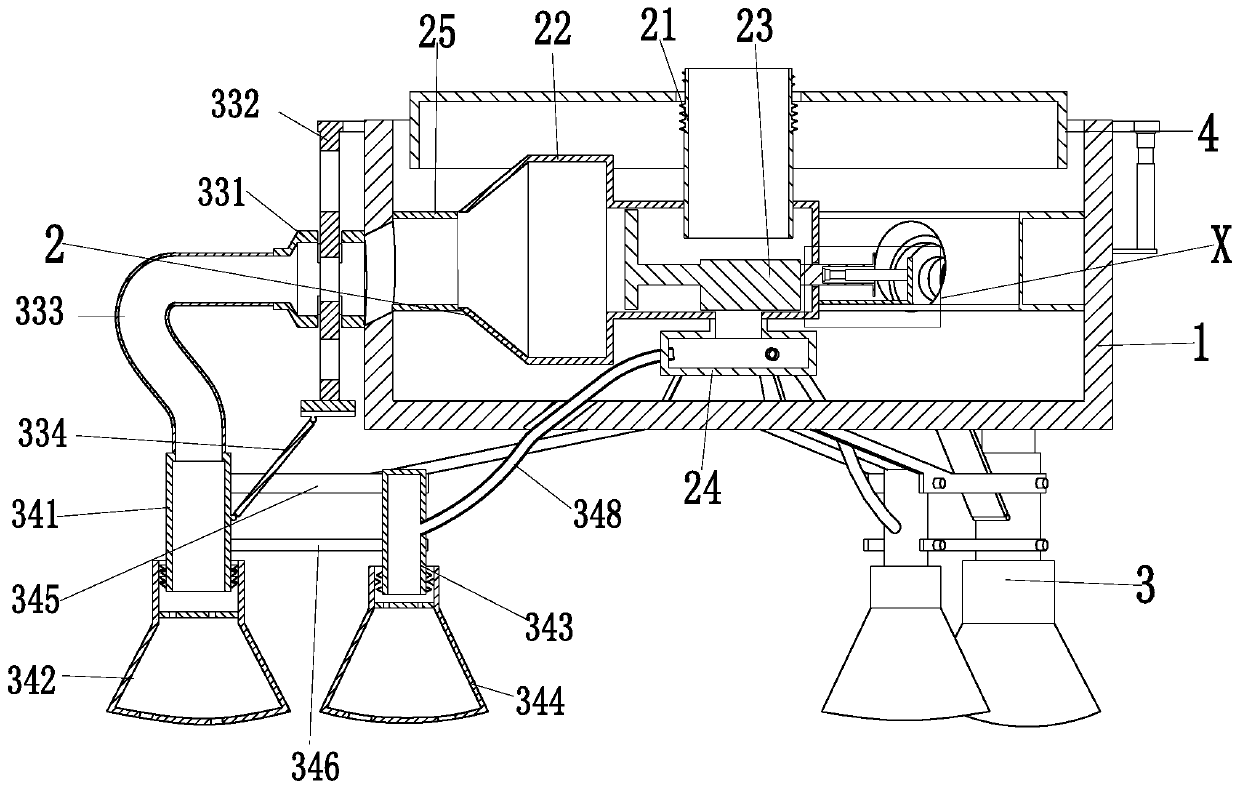

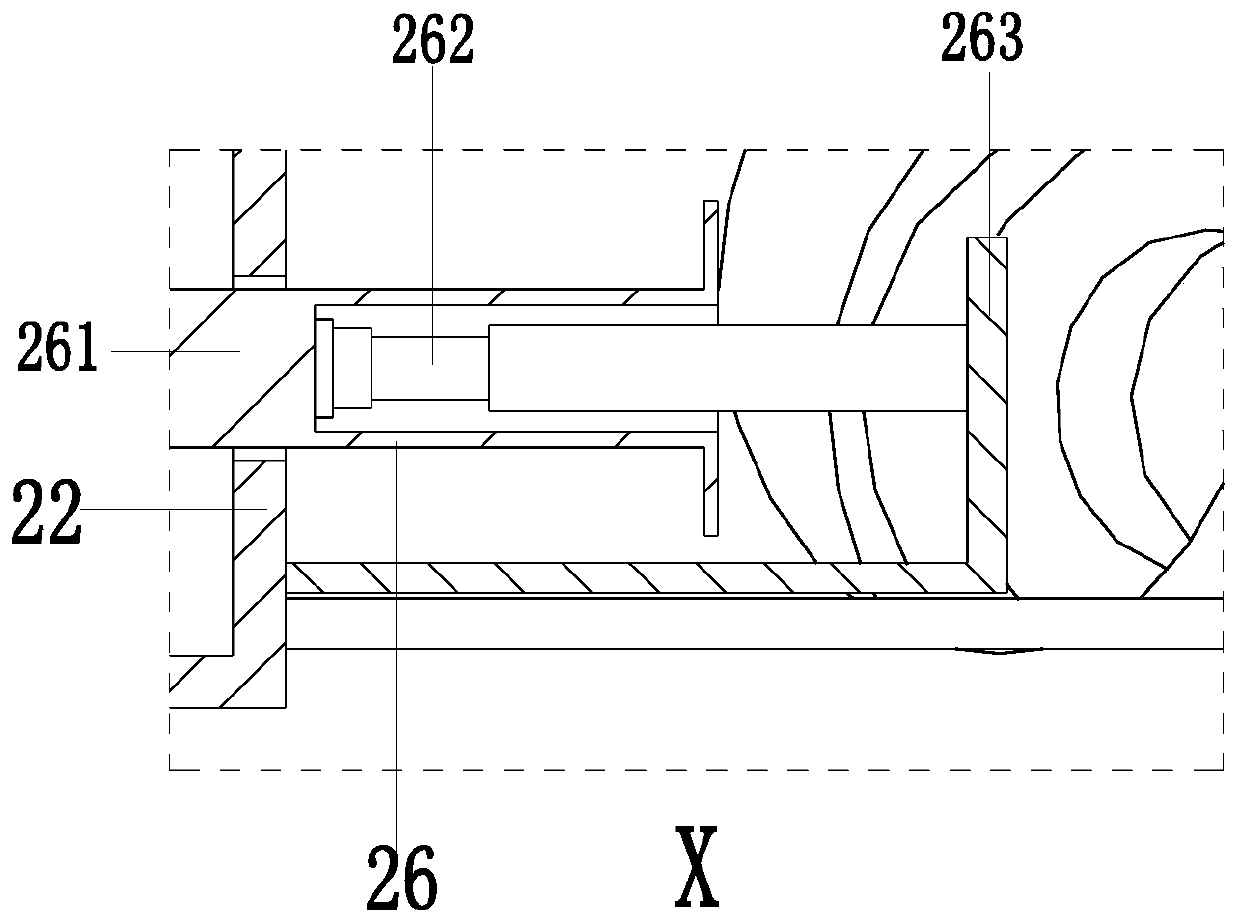

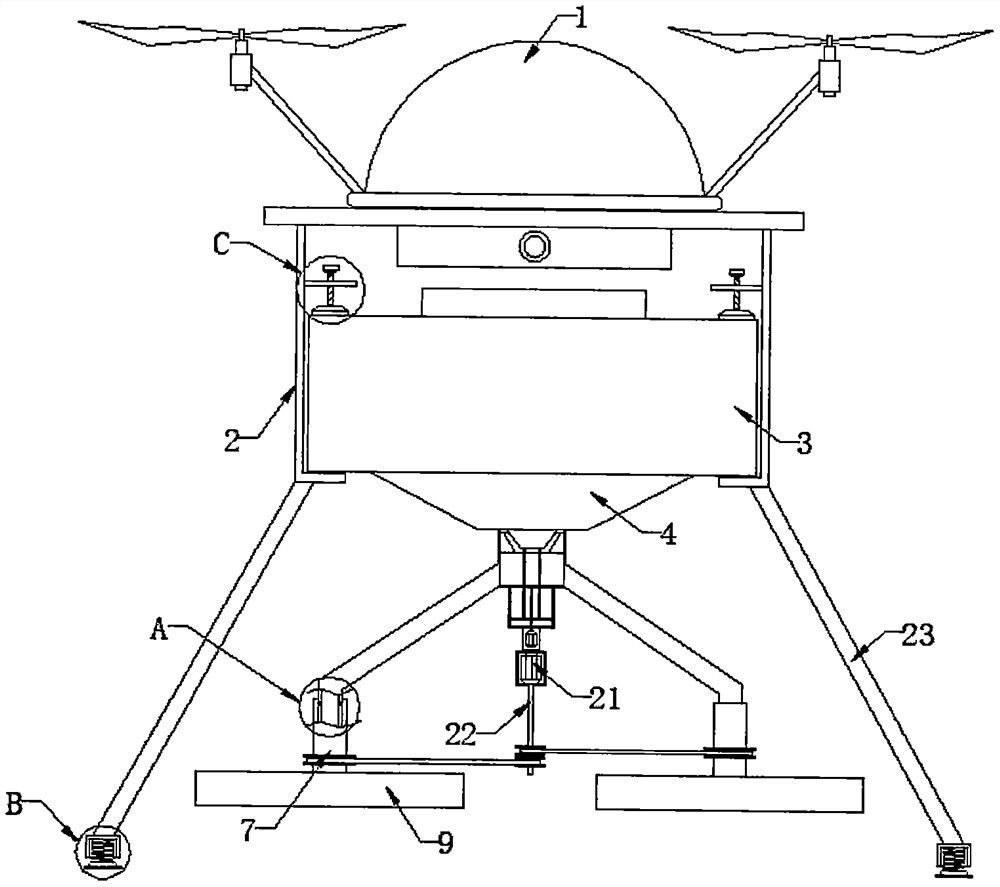

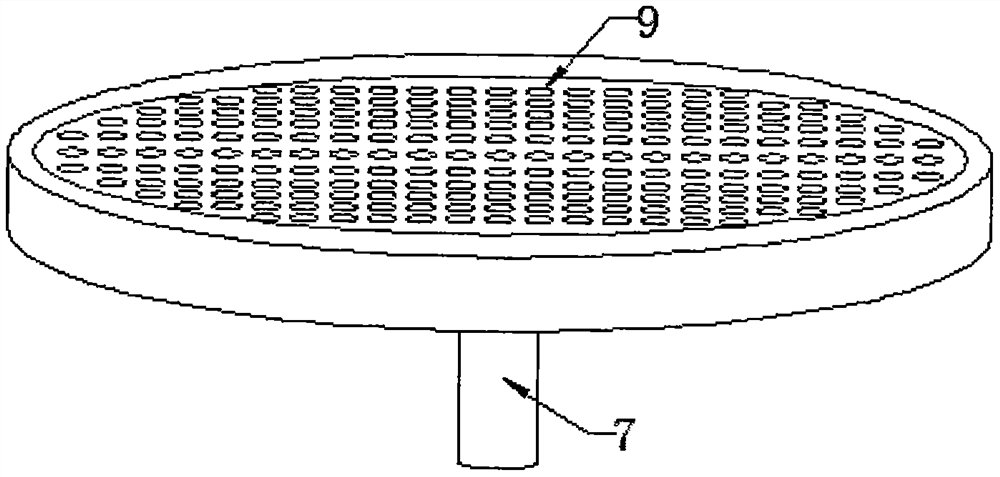

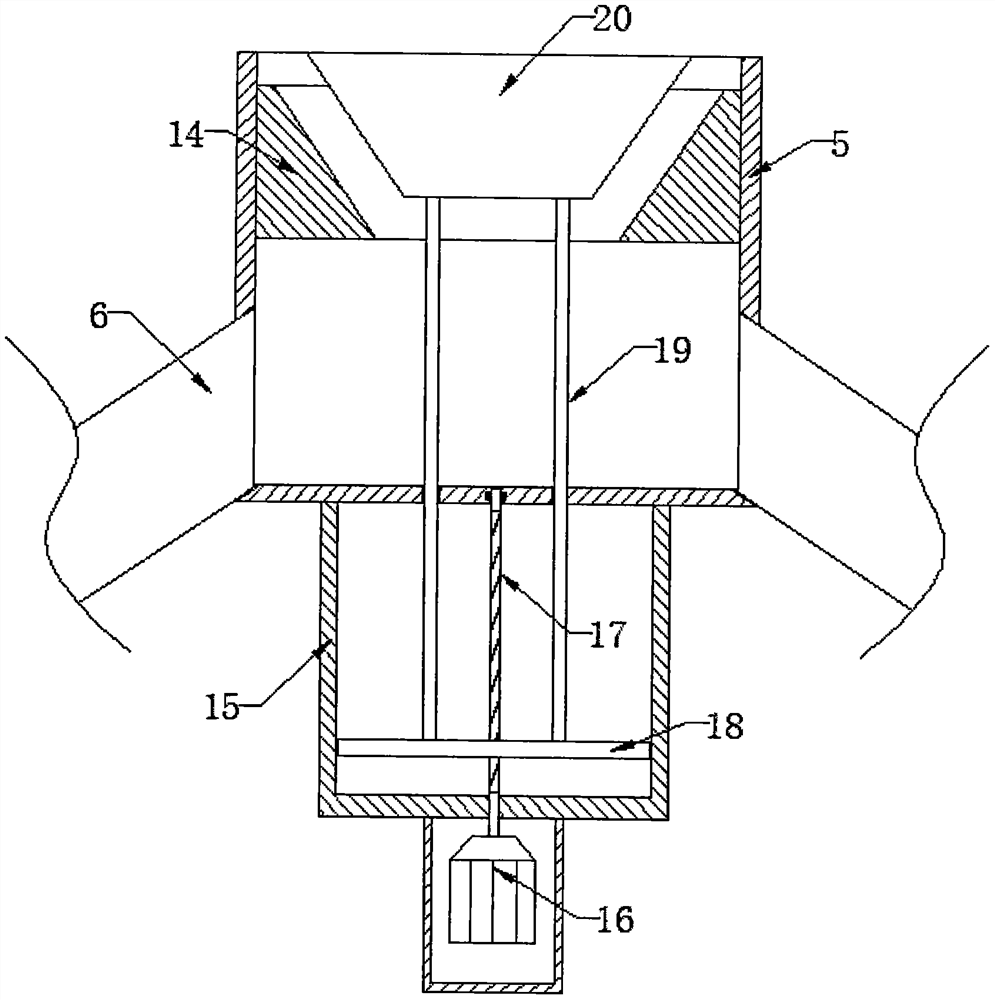

Pesticide spraying plant protection unmanned aerial vehicle

ActiveCN110001964AIntensity can be controlledExpand the spraying rangeAircraft componentsLaunching weaponsWater sourceEngineering

The invention relates to a pesticide spraying plant protection unmanned aerial vehicle. The pesticide spraying plant protection unmanned aerial vehicle comprises an outer frame, a water inlet controldevice, swinging devices and an opening and closing cover, the water inlet control device is installed inside the outer frame, the swinging devices are uniformly arranged on the outer wall of the outer frame, and the swinging devices are connected with the water inlet control device; the opening and closing cover is arranged at the upper end of the outer frame, and an unmanned aerial vehicle bodyis connected with the water inlet control device in a threaded mode. According to the pesticide spraying plant protection unmanned aerial vehicle, the difficult problems that during pesticide sprayingof existing unmanned aerial vehicles, nozzles are usually arranged fixedly, thus the spraying range is limited, part of agriculture and forestry plants may not be sprayed, and spraying cannot be controlled according to the actual situation can be solved, the water inlet control device adopts an injection-type piston principle to control water sources of first nozzles and second nozzles, thus theconcentration of pesticide spraying during operating is controlled, and the first nozzles and the second nozzles in the swinging devices swing synchronously through a four-bar mechanism principle, andconduct reciprocating swinging under driving of reciprocating air cylinders, so that the spraying range is expanded.

Owner:中业裕禄农业科技集团有限公司

Industrialized preparation method of 1,8-diaminonaphthalene

ActiveCN103664645AIntensity can be controlledEnsure safetyAmino compound purification/separationOrganic compound preparationOrganic solventFiltration

The invention discloses an industrialized preparation method of 1,8-diaminonaphthalene, which comprises the following steps: sequentially adding a catalyst, dinitronaphthalene and a solvent into a reaction kettle, stirring and heating materials in the reaction kettle to a temperature of 65-75 DEG C, slowly dripping hydrazine hydrate, then continuously heating materials in the reaction kettle to the temperature of 75-90 DEG C and keeping the temperature for 3-8 hours until the end of the reaction; cooling the materials after the reaction to the temperature of 40-45 DEG C for pressure filtration, washing and recovering the catalyst obtained through pressure filtration, and mixing the washing liquid and the filtering liquid to obtain a feed liquid; conducting decompression and desolvation on the feed liquid to recover the solvent; adding hot water with the temperature of 50-80 DEG C into the desolventized feed liquid for water washing stratification, wherein the upper layer is water phase and the lower layer is feed liquid phase; feeding the feed liquid phase obtained through stratification into a rectifying tower for rectification, and obtaining 1,8-diaminonaphthalene, wherein the purity of 1,8-diaminonaphthalene at the top of the rectifying tower is equal to or larger than 99.5%. The dinitronaphthalene raw materials comprise water and an organic solvent, wherein the organic solvent comprises an organic solvent used by a naphthaline-nitrified product in refining.

Owner:九江常宇化工有限公司

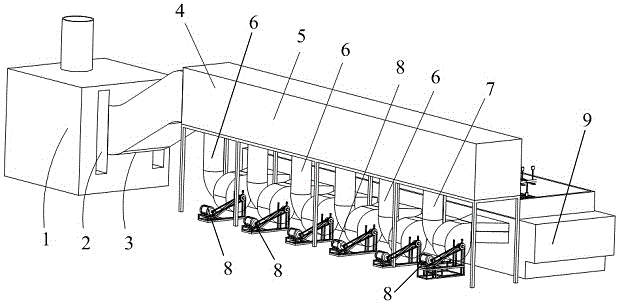

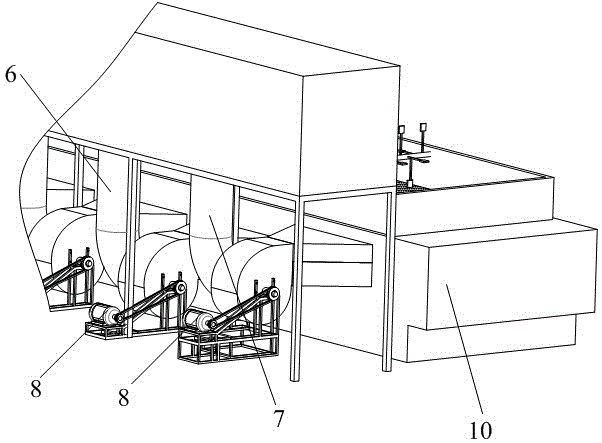

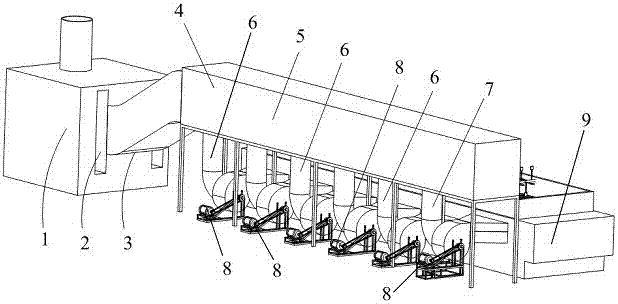

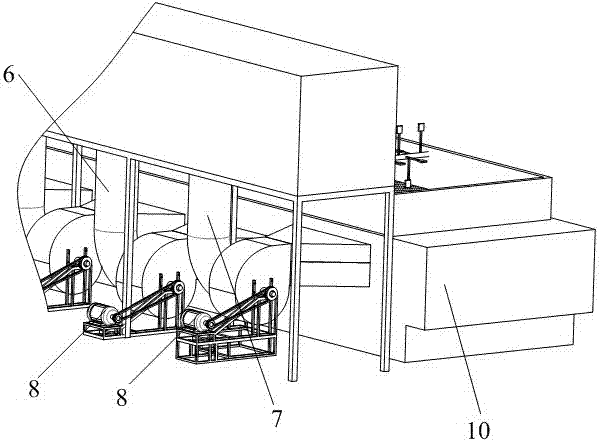

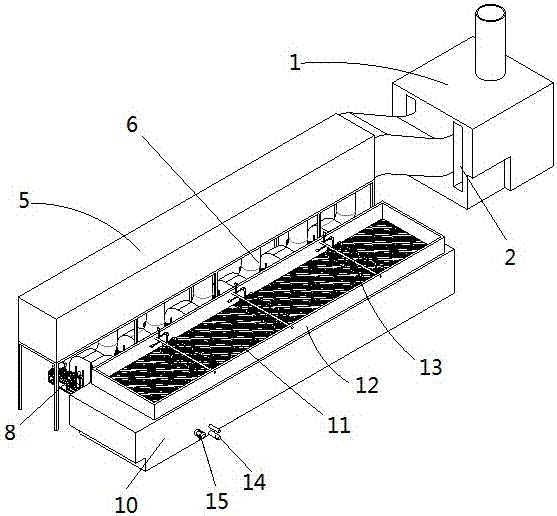

Combined hot-wind continuous drying equipment

InactiveCN105333719AEasy to control temperatureIntensity can be controlledDrying gas arrangementsEngineeringHot blast

The invention relates to the technical field of processing of dehydrated vegetables, in particular to combined hot-wind continuous drying equipment. The combined hot-wind continuous drying equipment comprises a hot blast stove, a wind distribution chamber and a continuous dryer. The hot blast stove is connected with the wind distribution chamber. The wind distribution chamber is connected with the continuous dryer. The hot blast stove comprises a natural wind inlet and a hot wind outlet. The hot wind outlet of the hot blast stove is connected with the wind distribution chamber. The wind distribution chamber comprises a main wind chamber body and at least three distribution air ducts connected with the main wind chamber body. Hot wind is distributed into the distribution air ducts through the wind distribution chamber and then enters at least three drying inner cavities. Along with the continuous lengthening and even turning of a hot wind drying chamber, the wind distribution chamber can be lengthened accordingly, the distribution air ducts are enlarged accordingly, and the drying inner cavities are enlarged accordingly so that the hot wind can still be distributed into each drying inner cavity, and accordingly the hot wind is blown out below a screen to be used for drying vegetable materials; the equipment is reasonable in structural design, and the temperature and the strength of the hot wind can be controlled.

Owner:NINGXIA FATUFA VEGETABLE IND GRP CO LTD

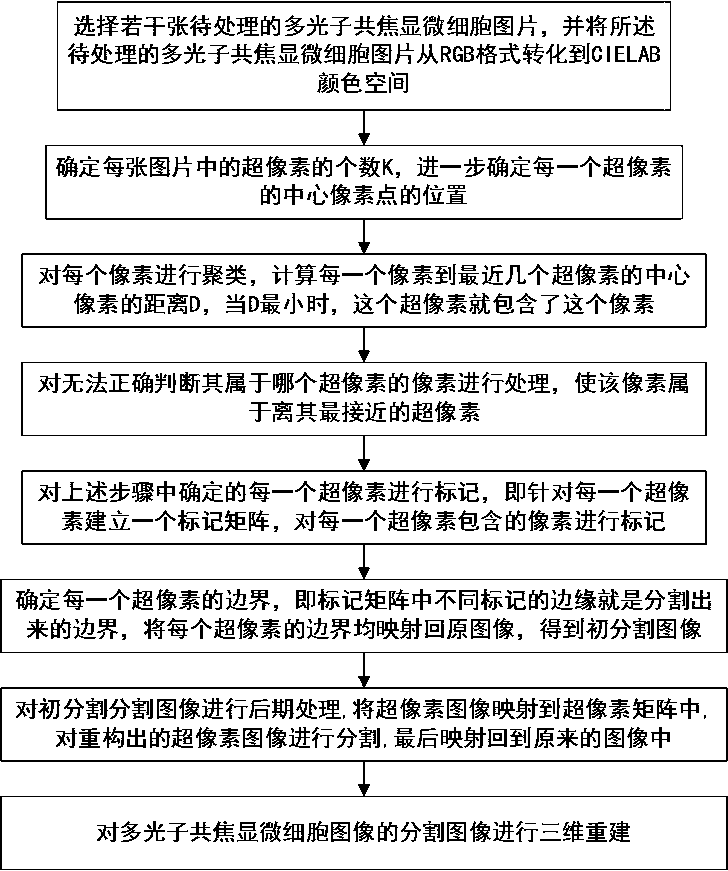

A Superpixel Reconstruction Segmentation and Reconstruction Method Based on Multiphoton Confocal Microscopic Cell Image

ActiveCN104933707BGood effectReduce running timeImage enhancementImage analysisReconstruction methodPhoton

The invention relates to a multi-photon confocal microscopic cell image based ultra-pixel refactoring segmentation and reconstruction method, which comprises the steps of firstly selecting a plurality of multi-photon confocal microscopic cell images to be processed, and converting the plurality of multi-photon confocal microscopic cell images into a CIELAB color space from an RGB format; determining the number of ultra-pixels in each image, and determining the position of a central pixel point gc of each ultra-pixel; carrying out clustering on each pixel, calculating the distance D between each pixel and central pixels of a plurality of nearest super-pixels, and determining which ultra-pixel each pixel belongs; marking each super-pixel, marking pixels contained by each super-pixel, determining the boundary of each super-pixel, mapping the boundary of each super-pixel to the original image, acquiring an initial segmentation image, carrying out post processing on the initial segmentation image, and acquiring a segmentation image of the multi-photon confocal microscopic cell image; and finally, carrying out three-dimensional reconstruction on the segmentation image. According to the invention, observation for growing conditions of a cell in different periods can be realized.

Owner:FUJIAN NORMAL UNIV

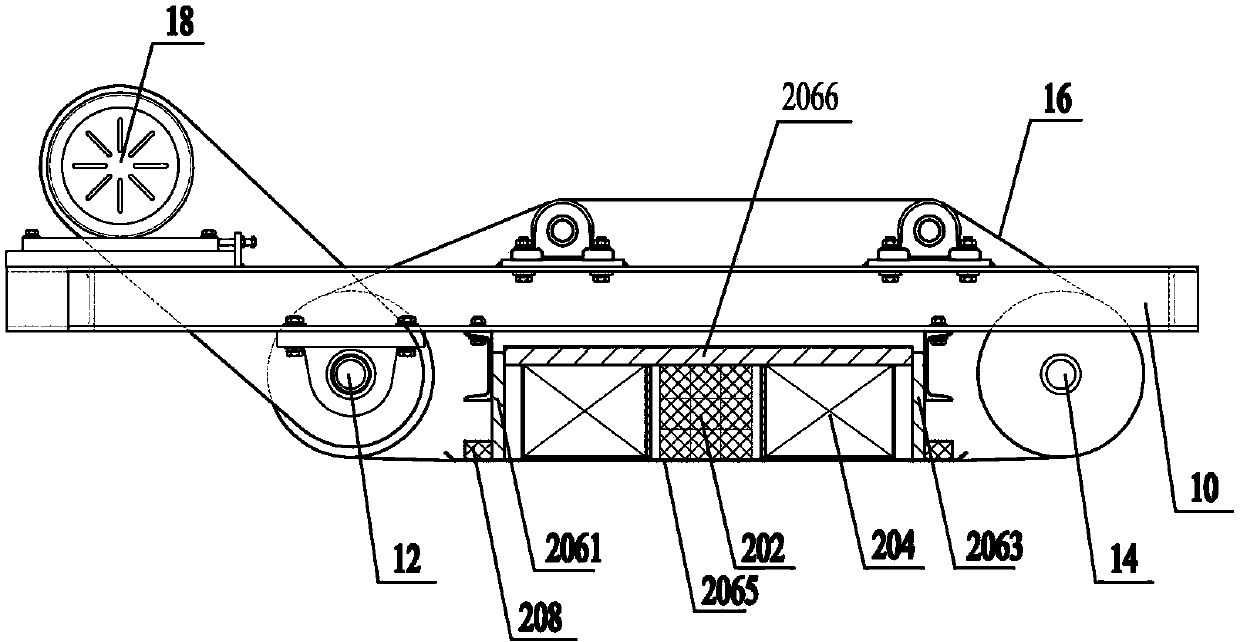

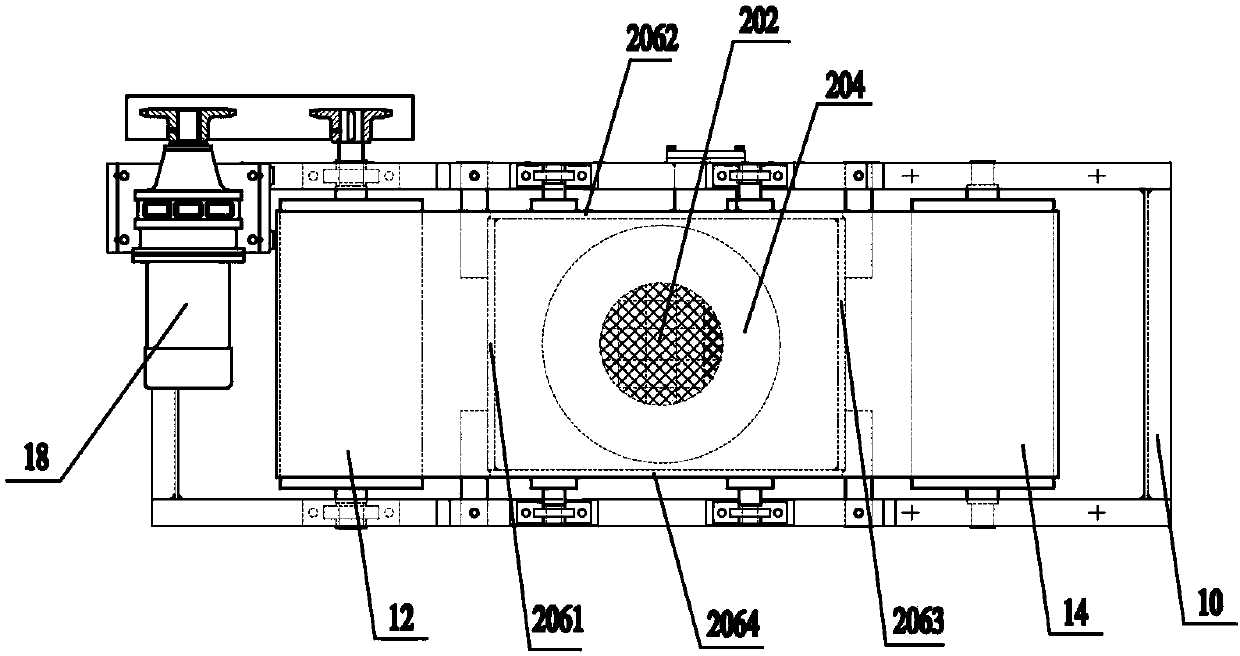

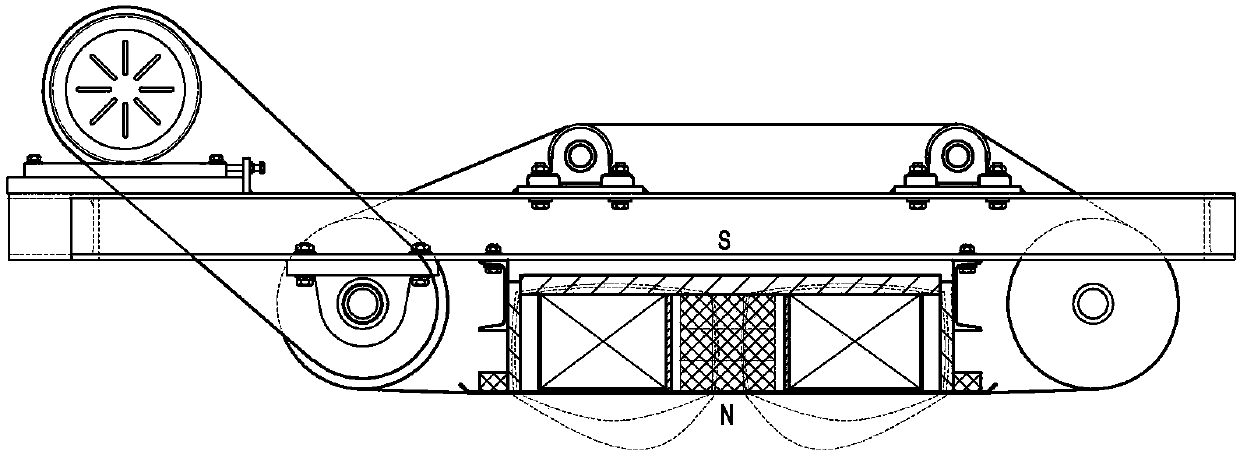

Electric permanent-magnet iron separator

InactiveCN104043524AIntensity can be controlledEasy to adjustMagnetic separationMagnetic tension forceElectricity

The invention provides an electric permanent-magnet iron separator. The electric permanent-magnet iron separator comprises a rack, a driving belt wheel, a driven belt wheel, an iron separation belt and a magnetic system body, wherein the driving belt wheel and the driven belt wheel are arranged at two ends of the rack; the iron separation belt is wound on the driving belt wheel and the driven belt wheel, and the head and tail ends of the iron separation belt are closed; the magnetic system body is arranged inside the bottom of the iron separation belt and comprises a permanent-magnet source, an electromagnetic coil which is wound on the periphery of the permanent-magnet source, and a magnetic conduction shell which is used for accommodating the permanent-magnet source and the electromagnetic coil; the direction of a magnetic field generated by the permanent-magnet source is parallel to the direction of the magnetic field generated by the electromagnetic coil. According to the electric permanent-magnet iron separator, a basic working magnetic field is generated by the permanent-magnet source, and the magnetic force can be automatically adjusted by virtue of energizing / de-energizing and change of the energizing direction, so that the functions of iron separation through normal excitation, strong excitation, short-time ultra-strong excitation, reversing excitation and the like are realized.

Owner:岳阳鸿升电磁科技有限公司

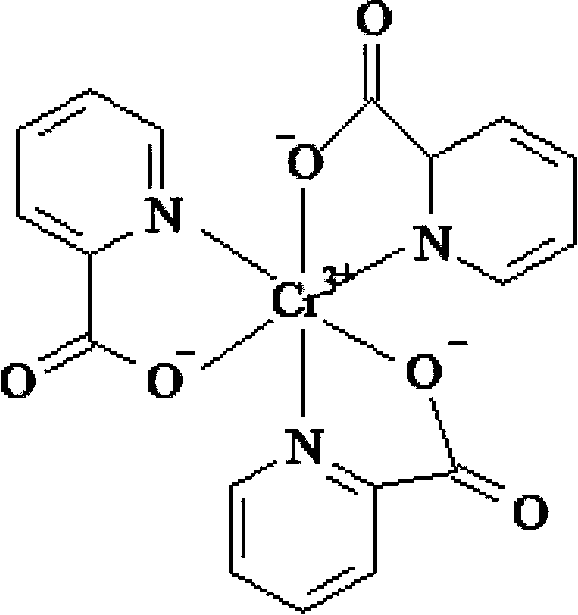

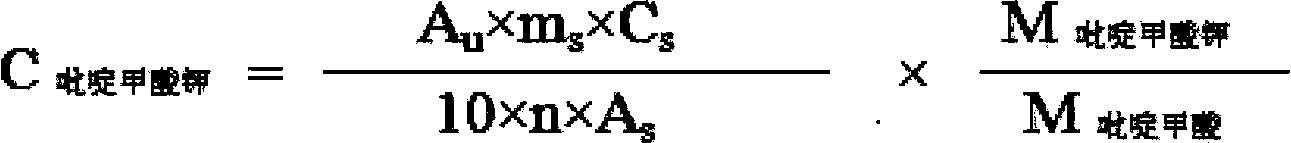

Synthesis method of chromium 2-pyridylformate

ActiveCN102875458BReduce pollutionTake advantage ofOrganic chemistryPhosphoniumQuaternary ammonium cation

The invention discloses a synthesis method of chromium 2-pyridylformate, which comprises the following steps: by using 2-methylpyridine, potassium permanganate and chromium chloride alcoholic solution as raw materials, adding a phase-transfer catalyst to synthesize the chromium 2-pyridylformate, wherein the phase-transfer catalyst is a quaternary ammonium salt or quaternary phosphonium salt in onium salt phase-transfer catalysts, preferably ammonium tetrabutylbromide, ammonium tetrabutylchloride or phosphonium methyltriphenylbromide. The method disclosed by the invention uses the phase-transfer catalyst to enable the sufficient reaction of 2-methylpyridine in an inorganic reaction environment, thereby enhancing the reaction yield (up to higher than 71%); the methanol or ethanol is used as the solvent to enhance the yield of the reaction step; and the solvent is recyclable, thereby saving the raw material cost, promoting the effective performance of the complex reaction, enabling the product to precipitate sufficiently, enhancing the maximum product yield by nearly 40%, and ensuring the yield and quality of the product.

Owner:HONGFENG CHEM GUAN COUNTY HEBEI PROV

High-purity diallyl ammonium chloride and preparation method thereof

ActiveCN108440304AControl reaction concentrationHigh purityAmino compound purification/separationOrganic compound preparationOrganic solventSolvent

The invention provides high-purity diallyl ammonium chloride and a preparation method thereof. According to the method, diallylamine is dissolved in a nonpolar organic solvent in a certain ratio, hydrogen chloride gas is slowly introduced into an organic liquor for a reaction under the cooling condition, a product obtained after the reaction is subjected to liquid-solid separation, a solvent on the surface of a solid is dried, and the high-purity diallyl ammonium chloride product is obtained. The diallylamine is dissolved in the nonpolar organic solvent, so that the reaction concentration of diallylamine is controllable, the nonpolar organic solvent can better transfer heat, and the system temperature is kept stable. Hydrogen chloride gas is introduced into a reactor, hydrogen chloride gasand diallylamine react on the bubble surface by use of the principle of surface reactology, the problem of violent reaction due to direct addition of hydrochloric acid or hydrogen chloride gas to diallylamine is solved, and the safety is improved.

Owner:山东聚发生物科技有限公司

Farming harrow device of peanut automatic planting machine

InactiveCN111149452AControl IntensityImprove survival rateSpadesPloughsAgricultural scienceAgricultural engineering

The invention discloses a farming harrow device of a peanut automatic planting machine. The device comprises a farming harrow body, a baffle, a stop groove and a first connecting frame, wherein a first seed-leaking groove is formed in the middle position of the bottom end of the farming harrow body, a connecting ring is installed at the middle position inside the first connecting frame, second motor boxes are installed at two sides of the connecting ring respectively, second rotary shafts which penetrate through the second motor boxes are horizontally installed at the output ends of third motors, motor bins are arranged at two ends inside the farming harrow body respectively, a first motor is horizontally installed at the bottom end inside each motor bin through a base, sliding rails are horizontally installed at the bottom ends of the side walls of two sides in a seed bin respectively, and the end, close to the stop groove, of the baffle penetrates through the stop groove. According to the farming harrow device of the peanut automatic planting machine, second motors are started to control the rotating rate, first rotary shafts and rotating rings are driven to rotate, so that peanut seeds in seed-leaking pipes uniformly leak off, and it is convenient to control the dense degree of peanut sowing.

Owner:阳新稳发水产养殖有限公司

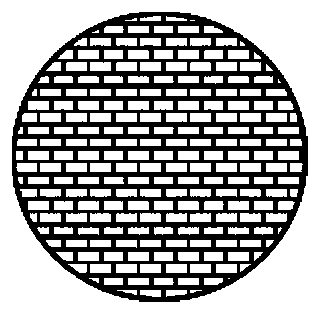

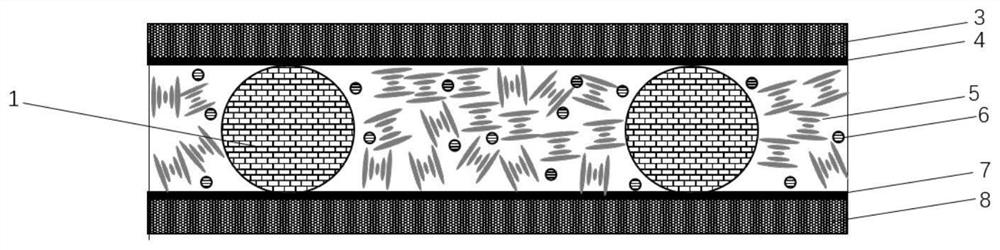

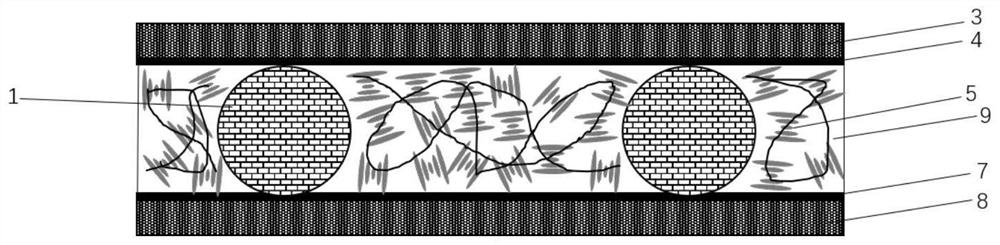

Modified spacer powder, preparation method thereof and liquid crystal handwriting board

ActiveCN111574739AGood compatibilityControl thicknessLiquid crystal compositionsNon-linear opticsMicrospherePolymethyl methacrylate

The invention provides modified spacer powder, a preparation method thereof and a liquid crystal handwriting board, and belongs to the technical field of liquid crystal materials. The modified spacerpowder provided by the invention is photoinitiator grafted spacer powder, a photoinitiator is benzoin methyl ether or Irgacure 651, and the spacer powder is polystyrene microspheres or polymethyl methacrylate microspheres; and the photoinitiator is connected with the spacer powder through a covalent bond. The modified spacer powder provided by the invention has good compatibility with liquid crystal in liquid crystal layer feed liquid, and the smoothness of handwriting of the liquid crystal handwriting board is improved. Moreover, the photoinitiator grafted on the modified spacer powder can initiate polymerization of polymeric monomers in the liquid crystal layer feed liquid, and finally, the spacer powder can be inserted into a polymer network, so that the polymer network close to the spacer powder microspheres is dense. The purpose of controlling the density of polymer networks in the liquid crystal handwriting board is achieved by controlling the amount of the photoinitiator graftedon the spacer powder microspheres, and then the handwriting thickness of the handwriting board is controlled.

Owner:SHENZHEN POLICRAL TECH CO LTD

Combined hot air continuous drying equipment

InactiveCN105333719BEasy to control temperatureIntensity can be controlledDrying gas arrangementsEngineeringHot blast

Owner:NINGXIA FATUFA VEGETABLE IND GRP CO LTD

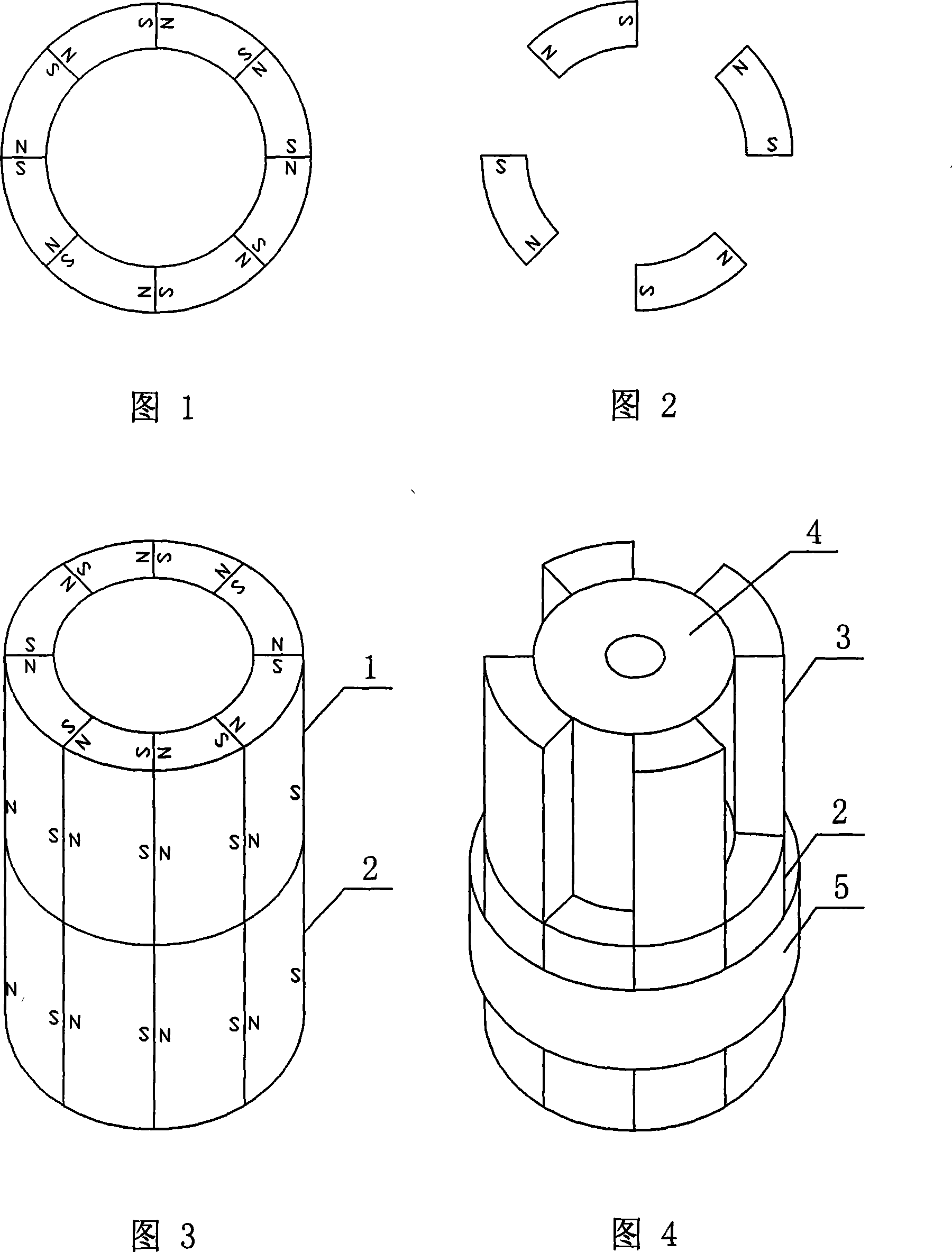

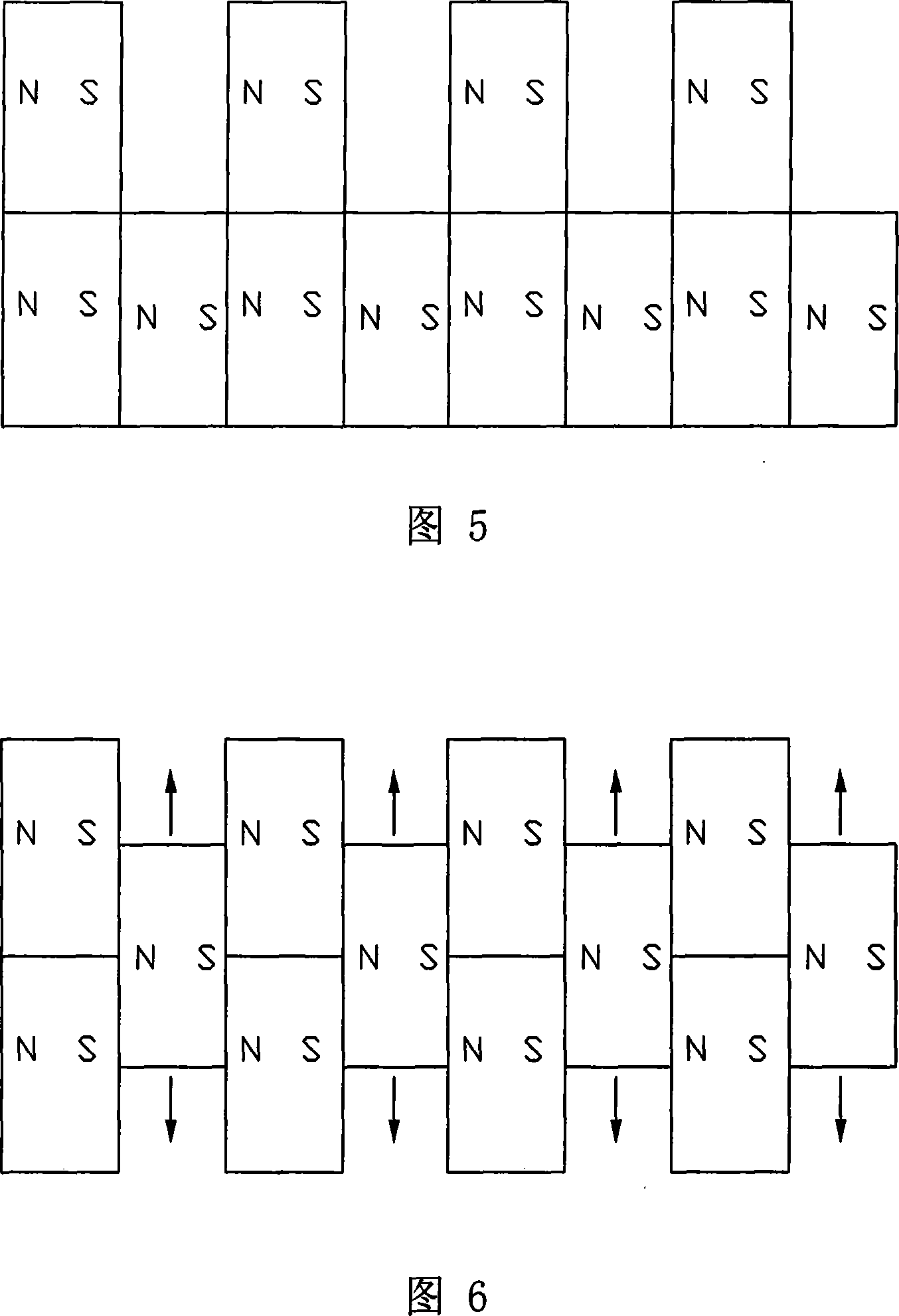

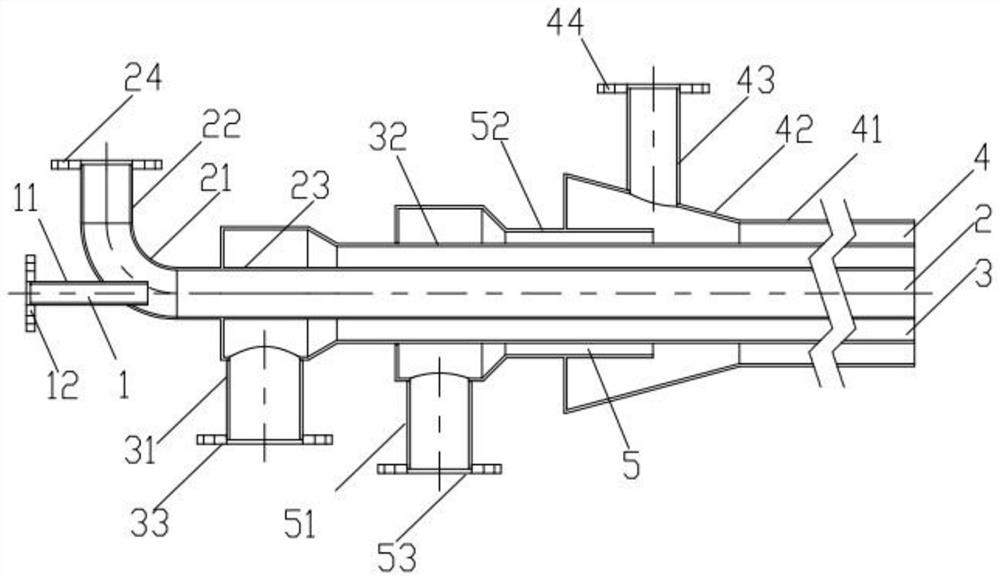

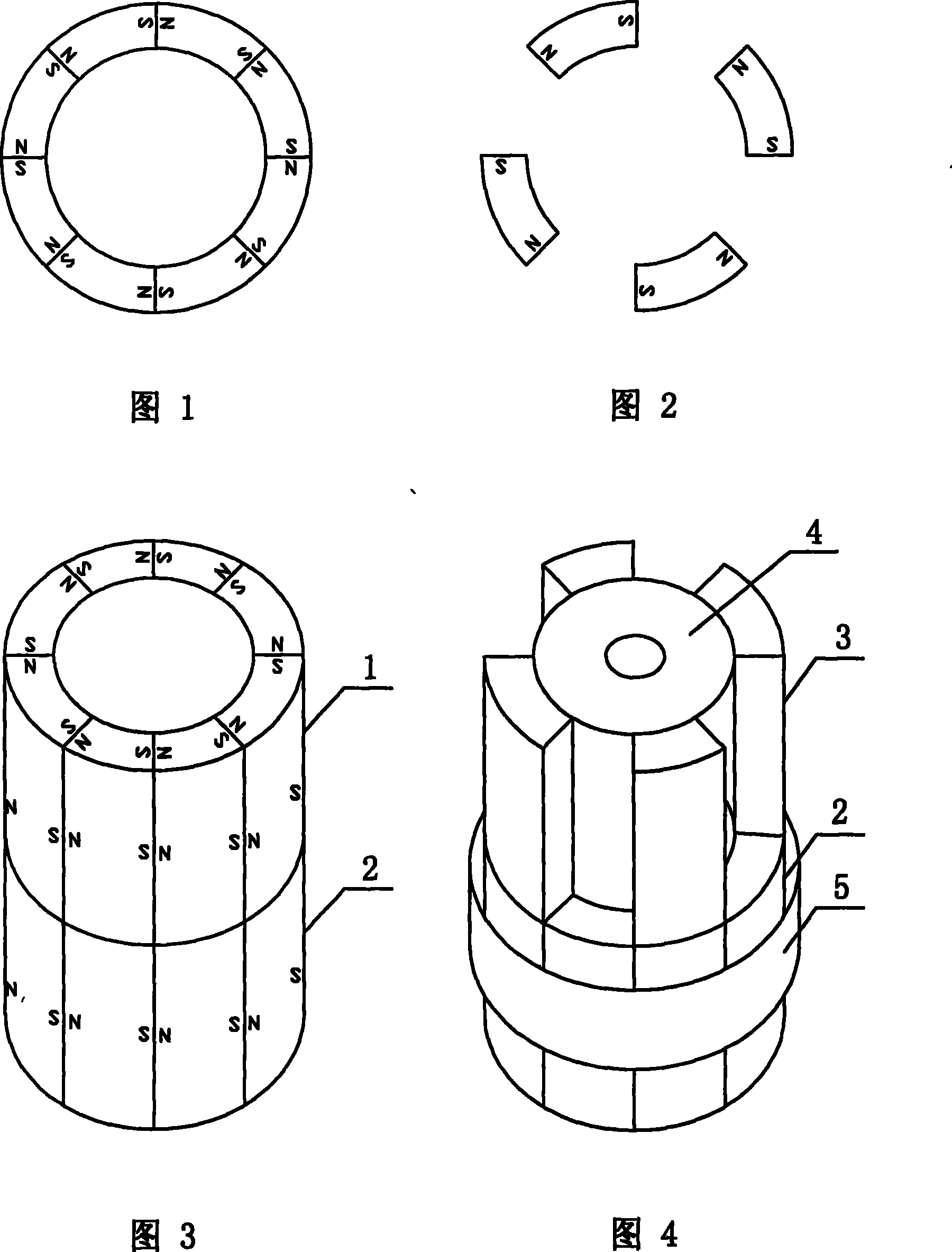

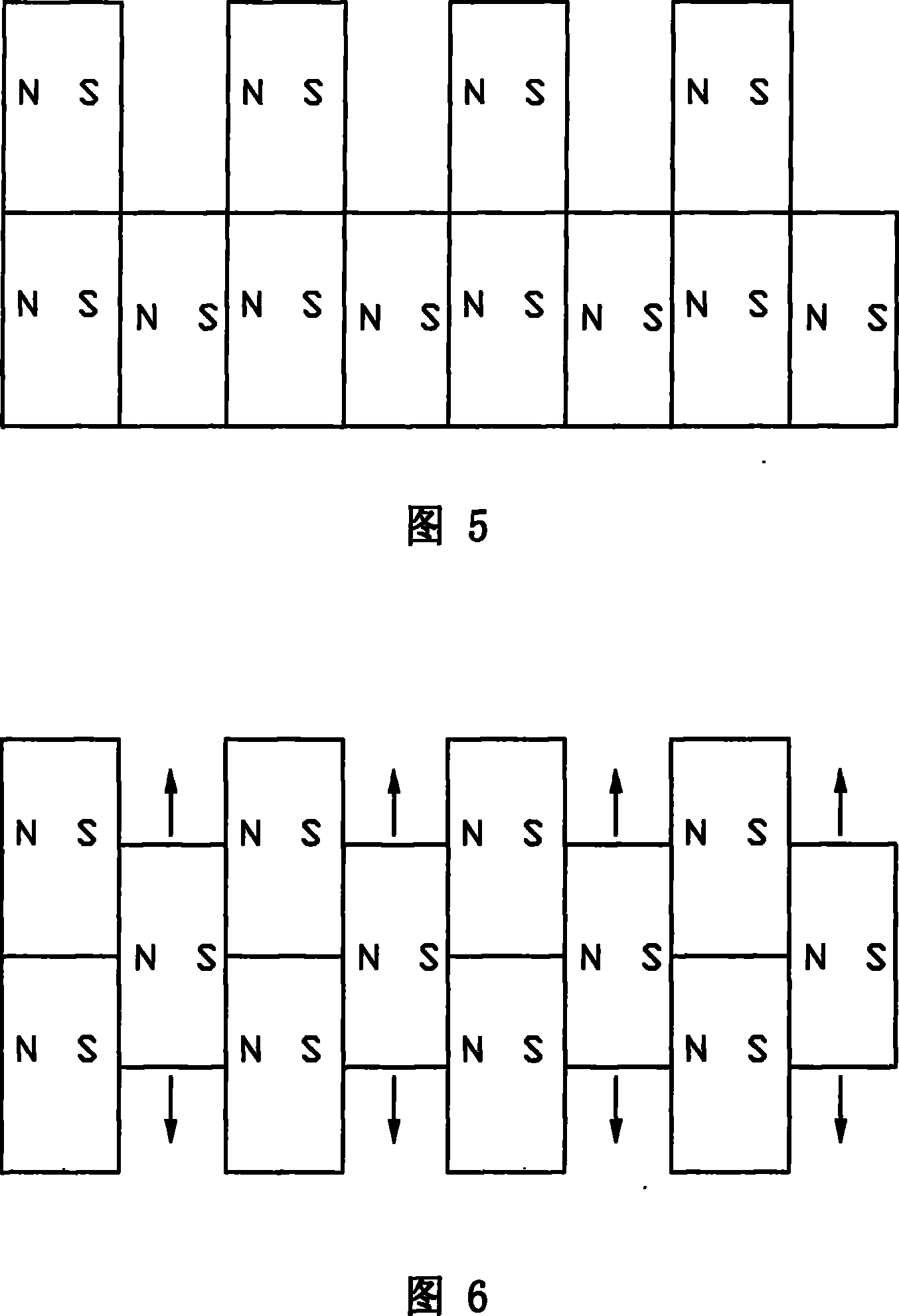

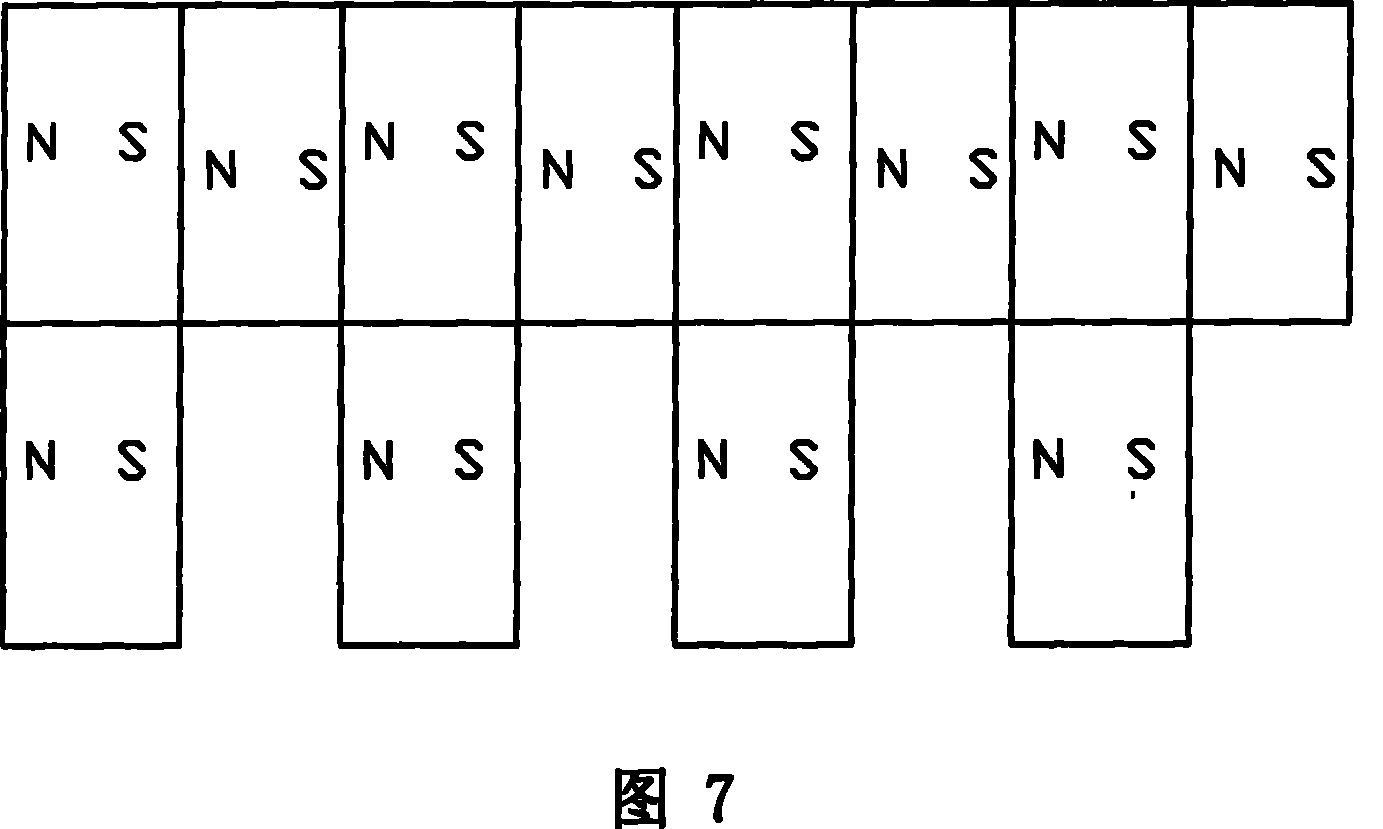

Method for controlling permanent magnet exterior magnetic field intensity using low energy consumption

InactiveCN101252036AIntensity can be controlledReduce magnetic field strengthPermanent magnetsEnergy consumptionMagnet

The invention relates to the magnetoelectric technical field, in particular to a method for utilizing low energy consumption to control the external magnetic field strength of a permanent magnet, wherein, firstly, a first closed magnetic field assembly is closely piled up together with a second closed magnetic field assembly; secondly, magnet blocks on the first closed magnetic field assembly are alternately taken off one by one to form a first isolated magnetic field assembly; thirdly, magnet blocks on the second closed magnetic field assembly are fixed together with magnetic blocks on the first isolated magnetic field assembly to form magnetic stators; fourthly, both poles of residual magnet blocks are cut to generate gaps between the poles and the magnetic stators, and the magnet blocks are integrated into a whole by fixation to form a reciprocating magnet; fifthly, the reciprocating magnet is pushed forward; when the reciprocating magnet enters into the first isolated magnetic field assembly, the prior second closed magnetic field assembly becomes the second isolated magnetic field assembly and the prior first isolated magnetic field assembly becomes the first closed magnetic field assembly, thereby realizing the control to the external magnetic field strength of the permanent magnet by variation of positions of the reciprocating magnet.

Owner:刘金玺

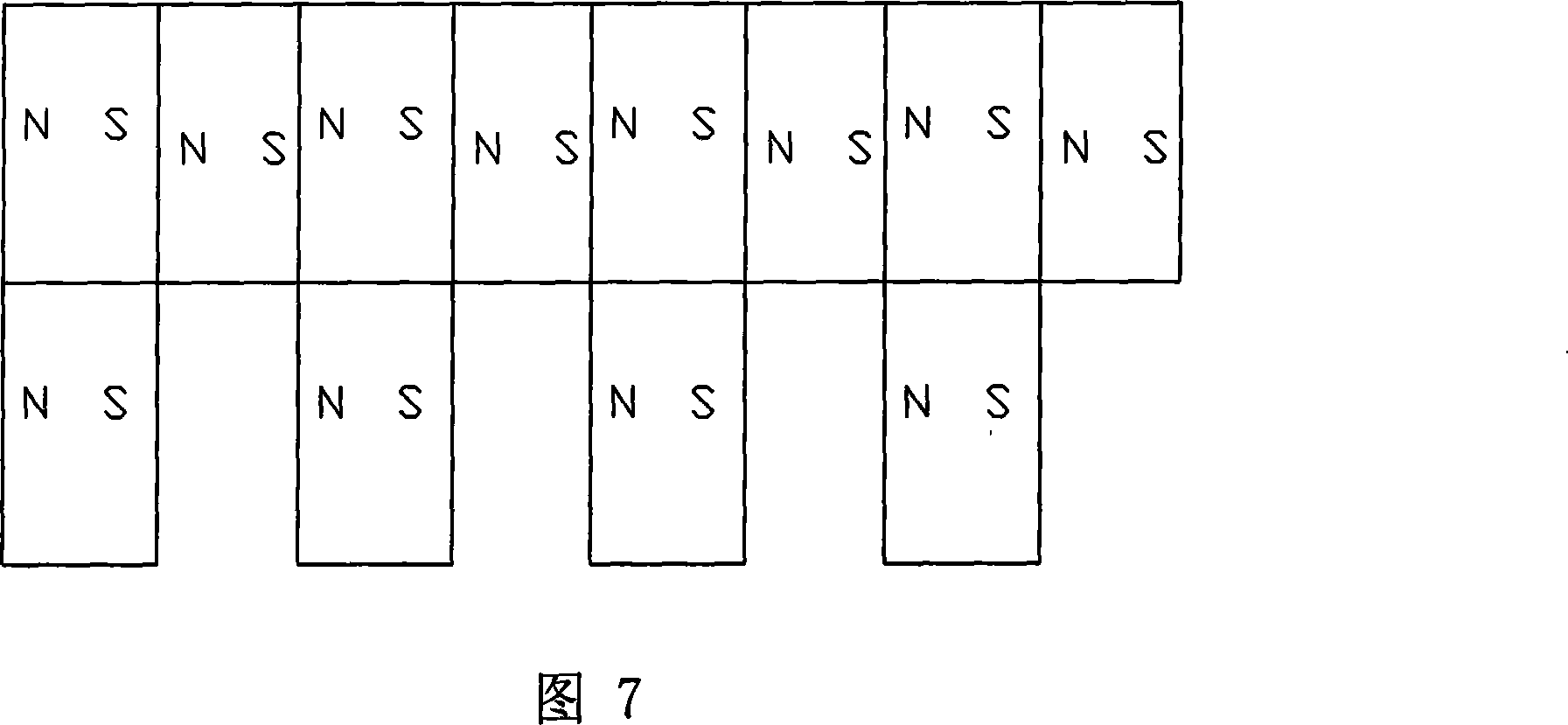

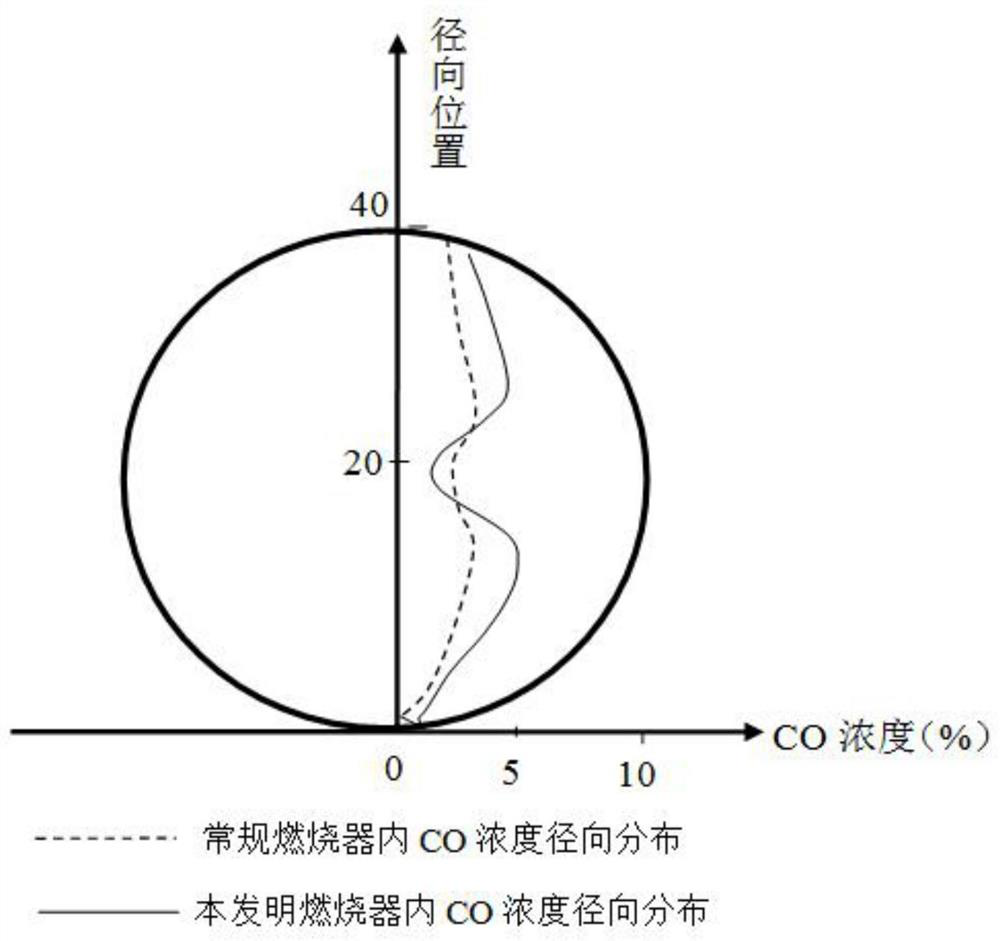

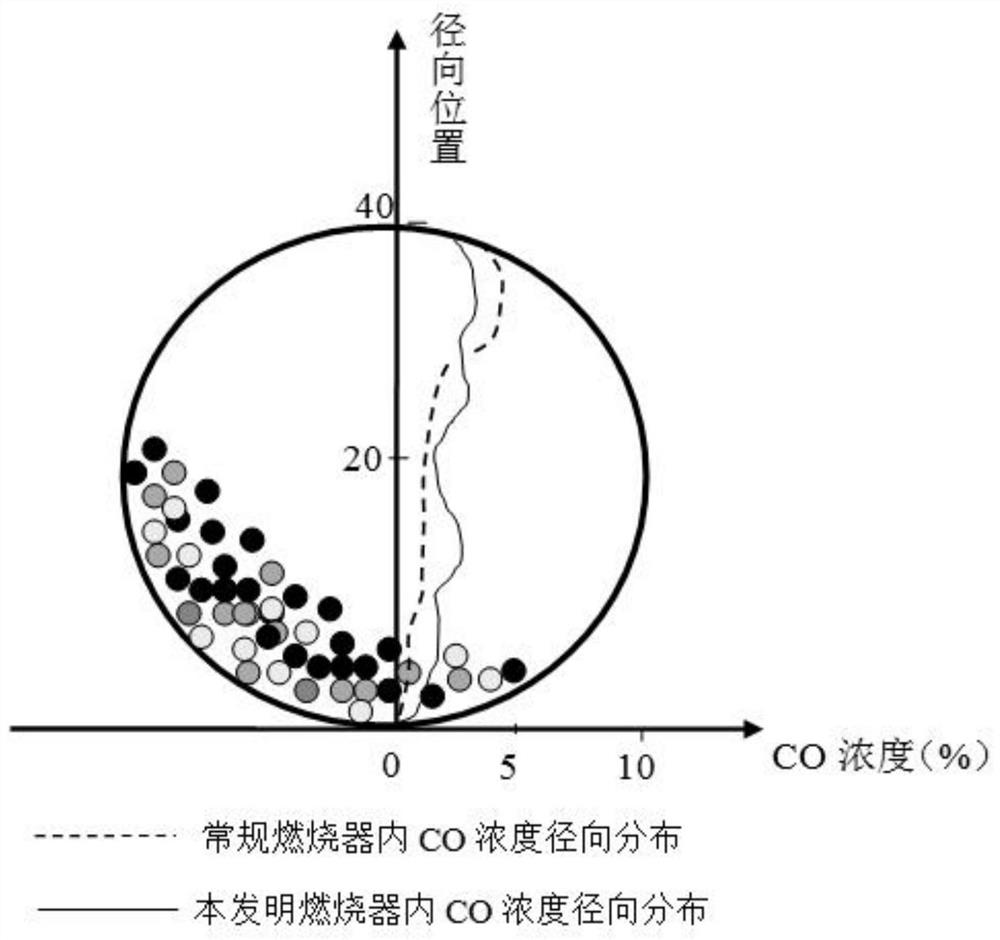

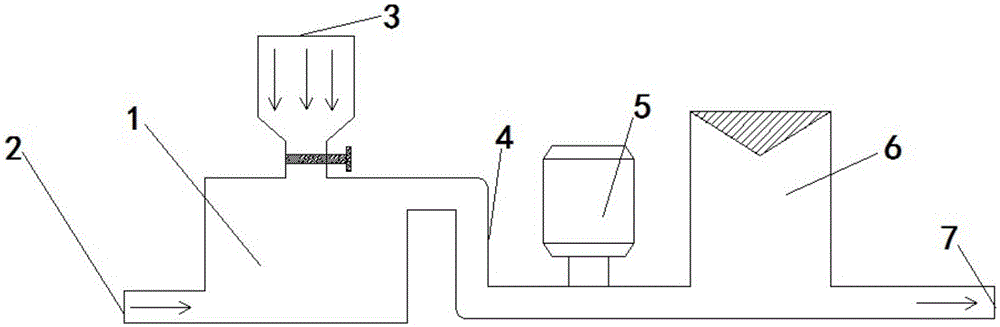

Combustor for magnetizing roasting rotary kiln

PendingCN113324403AFlexible and convenient controlReduce washoutRotary drum furnacesPulverulent fuel combustion burnersThermodynamicsCombustor

The invention discloses a combustor for a magnetizing roasting rotary kiln. The combustor comprises a coarse-grain pulverized coal feeding channel, a coarse-grain pulverized coal conveying air channel, a primary combustion-supporting air feeding channel, a fine-grain pulverized coal feeding channel and a fine-grain pulverized coal conveying air channel, and is characterized in that the primary combustion-supporting air feeding channel sleeves the coarse-grain pulverized coal feeding channel in a clearance manner, the fine-grain pulverized coal feeding channel sleeve the primary combustion-supporting air feeding channel in a clearance mode, the output end of the coarse-grain pulverized coal conveying air channel is arranged in the conveying direction of coarse-grain pulverized coal, and the output end of the fine-grain pulverized coal conveying air channel is arranged in the conveying direction of fine-grain pulverized coal. A reasonable temperature field can be formed, meanwhile, the temperature field is more flexible and convenient to regulate and control, the problems that the local temperature is too high, and more thermal NOx gas is produced can be further solved, and the combustion and reduction processes are more environmentally friendly.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

A kind of method of still residue treatment of 2-octyl-3 (2h)-isothiazolone

Owner:DALIAN JOIN KING FINE CHEM CO LTD

Preparation method of high-purity titanium diboride ceramic powder

The invention discloses a preparation method of high-purity titanium diboride ceramic powder, and belongs to the technical field of preparation of novel ceramic materials. The preparation method is characterized by comprising the following steps: 1) uniformly mixing titanium dioxide, a boron source and a reducing agent according to a mass ratio of 8: (6-9): (11-15) to obtain a mixed raw material; the reducing agent is a composition of one or two of calcium powder and magnesium powder in any proportion; (2) the mixed raw materials are loaded into a self-propagating reaction furnace, a self-propagating reaction is initiated under argon protection, a titanium diboride crude product is obtained, and the reaction temperature is controlled to range from 400 DEG C to 700 DEG C; and (3) the titanium diboride crude product is subjected to acid leaching, washing and drying, and titanium diboride powder is obtained. The method is short in technological process and low in production cost, and the prepared titanium diboride ceramic powder is high in purity, narrow in particle size distribution, high in activity and easy to sinter.

Owner:ZIBO SHENGTAI COMPOSITE MATERIAL TECH

A sewage treatment and power generation device based on nanometer metal powder

InactiveCN103613154BIncrease profitEnable recyclingWater/sewage treatment by heatingElectricityWater vapor

Owner:HARBIN ENG UNIV

Method for controlling permanent magnet exterior magnetic field intensity using low energy consumption

InactiveCN101252036BIntensity can be controlledReduce magnetic field strengthPermanent magnetsEnergy consumptionMagnet

The invention relates to the magnetoelectric technical field, in particular to a method for utilizing low energy consumption to control the external magnetic field strength of a permanent magnet, wherein, firstly, a first closed magnetic field assembly is closely piled up together with a second closed magnetic field assembly; secondly, magnet blocks on the first closed magnetic field assembly arealternately taken off one by one to form a first isolated magnetic field assembly; thirdly, magnet blocks on the second closed magnetic field assembly are fixed together with magnetic blocks on the first isolated magnetic field assembly to form magnetic stators; fourthly, both poles of residual magnet blocks are cut to generate gaps between the poles and the magnetic stators, and the magnet blocks are integrated into a whole by fixation to form a reciprocating magnet; fifthly, the reciprocating magnet is pushed forward; when the reciprocating magnet enters into the first isolated magnetic field assembly, the prior second closed magnetic field assembly becomes the second isolated magnetic field assembly and the prior first isolated magnetic field assembly becomes the first closed magnetic field assembly, thereby realizing the control to the external magnetic field strength of the permanent magnet by variation of positions of the reciprocating magnet.

Owner:刘金玺

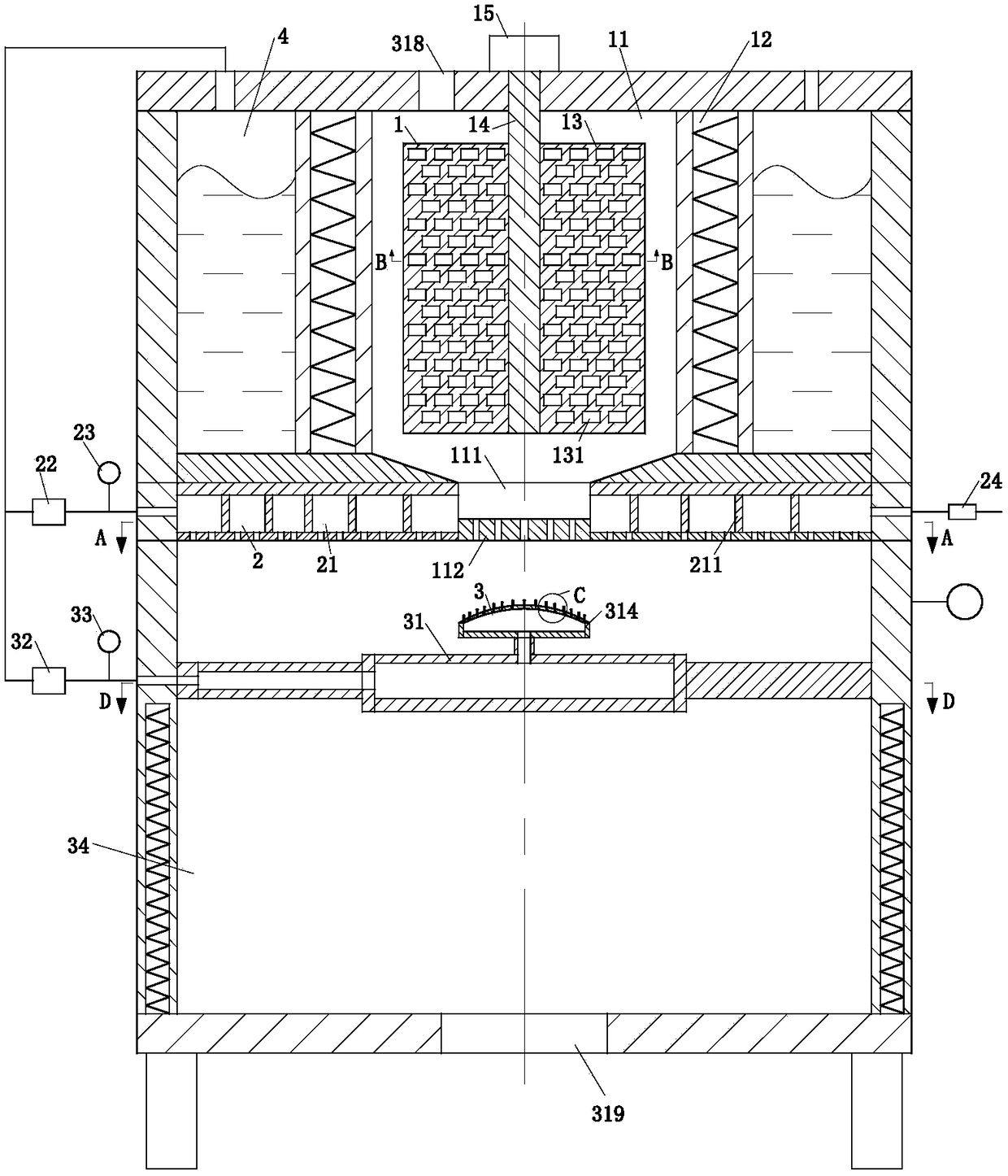

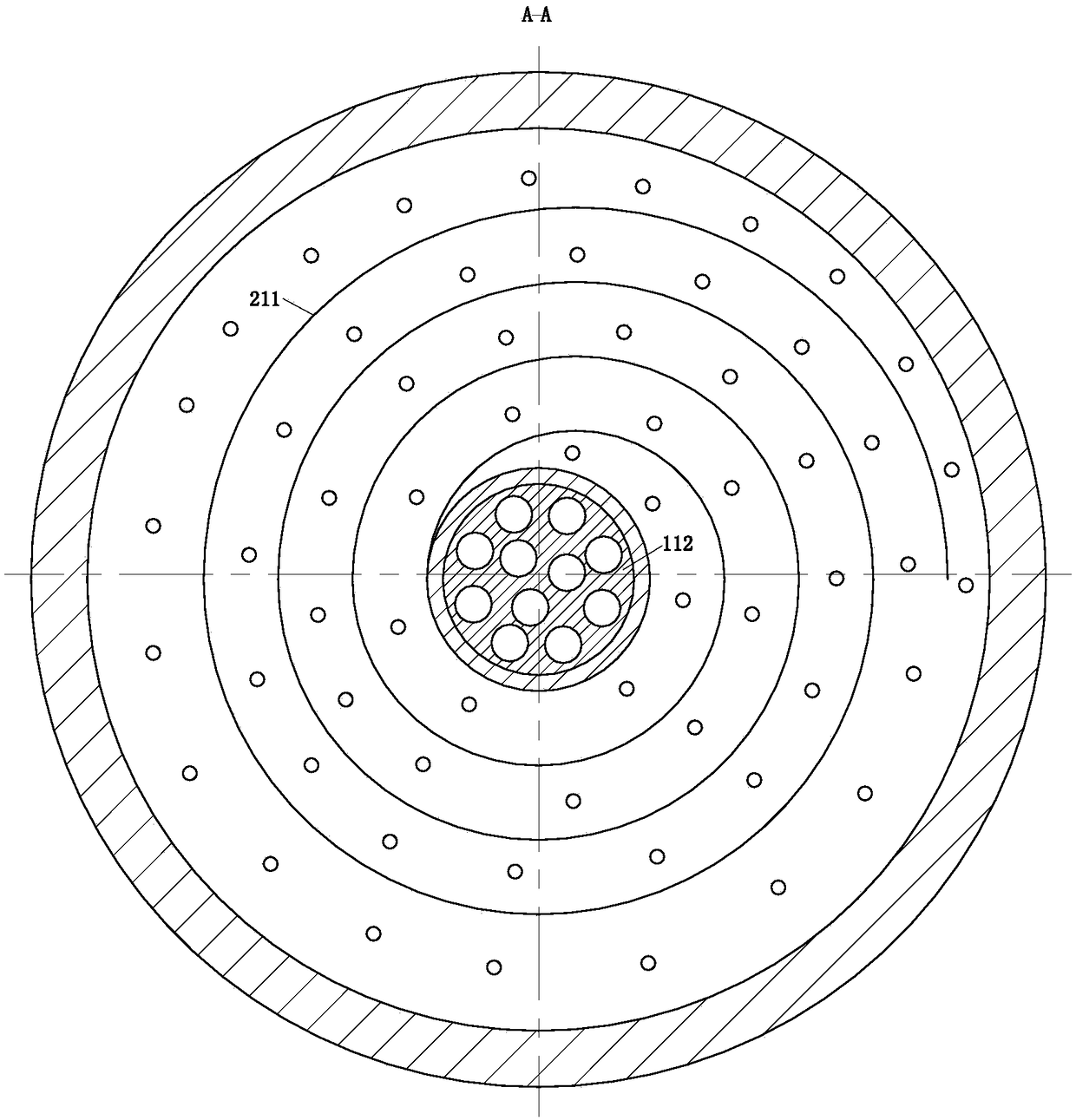

A polyurethane insulation board foaming system

The invention belongs to the technical field of polyurethane production equipment, and particularly relates to a polyurethane heat preservation board foaming system. The system comprises a stirring unit, a water control unit and a foaming unit; the stirring unit comprises a stirring bin, a heating cylinder, four stirring plates, a rotating rod and a motor; the stirring bin is cylindrical, a firstopening is formed in the left side of the upper surface of the stirring bin, and a heating cylinder is fixedly arranged in the stirring bin; the four stirring plates are arranged in the cylindrical heating cylinder; the stirring unit is used for stirring the raw materials, and the water control unit is used for allowing the raw materials to be foamed by being matched with the foaming unit; and airpressure balance plates in the water control unit are connected through a first electromagnetic valve, a first pressure gauge and a first opening, and the right sides of the air pressure balance plates are connected with the outside through a third electromagnetic valve. The polyurethane heat preservation board foaming system is mainly used for foaming the reactants in the production process of the polyurethane thermal insulation board, the uniformity of the raw materials can be improved, the raw materials can be sufficiently foamed, and the foaming efficiency of the raw materials is improved.

Owner:广东华珀科技有限公司

A kind of high-purity triallyl ammonium chloride and preparation method thereof

ActiveCN108440303BHigh purityControl reaction concentrationAmino compound purification/separationOrganic compound preparationSurface reactionOrganosolv

The invention provides high-purity triallyl ammonium chloride and a preparation method thereof. According to the method, triallylamine is dissolved in a non-polar organic solvent, hydrogen chloride gas is slowly introduced into an organic liquor for a reaction under the cooling condition, a product obtained after the reaction is subjected to liquid-solid separation, a solvent on the surface of a solid is dried, and the high-purity triallyl ammonium chloride product is obtained. The triallylamine is dissolved in the nonpolar organic solvent, so that the reaction concentration of triallylamine is controllable, the nonpolar organic solvent can better transfer heat, and the system temperature is kept stable. Hydrogen chloride gas is introduced into a reactor, hydrogen chloride gas and triallylamine are subjected to a reaction on the bubble surface by use of the principle of surface reactology, the problem of violent reaction due to direct addition of hydrochloric acid or hydrogen chloridegas to triallylamine is solved, and the safety is improved.

Owner:山东聚发生物科技有限公司

Method for preparing boron carbide powder by dilution self-propagating method

PendingCN114873596AHigh puritySmall particle sizeCarbon compoundsNuclear energy generationBoron oxideParticle-size distribution

The invention discloses a method for preparing boron carbide powder through a dilution self-propagating method, and belongs to the technical field of ceramic materials. The method is characterized by comprising the following process steps: 1) uniformly mixing glucose, boric oxide and calcium powder in a mass ratio of 1: (7-9): (14-17) to obtain a mixed raw material; 2) dispersing the mixed raw material, loading the dispersed mixed raw material into a self-propagating reaction furnace, initiating a self-propagating reaction by adopting a local ignition method under the protection of argon, and preparing a boron carbide crude product by adopting a dilution self-propagating method; and 3) carrying out acid leaching, washing and drying on the boron carbide crude product to obtain boron carbide powder. According to the method, the severity of the self-propagating reaction is controlled by adjusting the ratio of reactants, and the temperature of the whole reaction system and the purity and particle size of the product are controlled. The method is short in technological process and low in production cost. The boron carbide powder prepared by the method has the characteristics of high purity, narrow particle size distribution, small particle size and the like.

Owner:ZIBO SHENGTAI COMPOSITE MATERIAL TECH

Special aerial seeding device for oilseed rapes

PendingCN114532007AIntensity can be controlledPromote growthAircraft componentsAgriculture gas emission reductionAgricultural scienceEngineering

The invention belongs to the technical field of oil crop planting, and particularly relates to a special oilseed rape aerial seeding device which comprises a flying mechanism, L-shaped plates are longitudinally and fixedly arranged at the lower end of the flying mechanism, a rapeseed containing box is fixedly arranged between the two L-shaped plates through a fixing mechanism, and a discharging hopper is fixedly arranged on the lower side wall of the rapeseed containing box. A discharging pipe is fixedly arranged on the lower side wall of the discharging hopper, a discharging speed adjusting mechanism is arranged in the discharging pipe, symmetrical seeding pipes are fixedly arranged on the side wall of the discharging pipe, symmetrical rotating pipes are arranged at the lower ends of the two seeding pipes in a sleeving manner, annular grooves are formed in the pipe walls of the two seeding pipes, and the rotating pipes are arranged in the annular grooves. Symmetrical limiting blocks are fixedly arranged on the inner walls of the two rotating pipes, so that the discharging speed can be conveniently adjusted according to the soil condition and the sowing season, the sowing density of the rapeseeds is controlled, and the later growth of the rapeseeds is more convenient.

Owner:SHIJIAZHUANG ACADEMY OF AGRI & FORESTRY SCI

A kind of diallyl ammonium chloride and preparation method thereof

ActiveCN108440304BControl reaction concentrationIntensity can be controlledAmino compound purification/separationOrganic compound preparationSurface reactionOrganosolv

The invention provides high-purity diallyl ammonium chloride and a preparation method thereof. According to the method, diallylamine is dissolved in a nonpolar organic solvent in a certain ratio, hydrogen chloride gas is slowly introduced into an organic liquor for a reaction under the cooling condition, a product obtained after the reaction is subjected to liquid-solid separation, a solvent on the surface of a solid is dried, and the high-purity diallyl ammonium chloride product is obtained. The diallylamine is dissolved in the nonpolar organic solvent, so that the reaction concentration of diallylamine is controllable, the nonpolar organic solvent can better transfer heat, and the system temperature is kept stable. Hydrogen chloride gas is introduced into a reactor, hydrogen chloride gasand diallylamine react on the bubble surface by use of the principle of surface reactology, the problem of violent reaction due to direct addition of hydrochloric acid or hydrogen chloride gas to diallylamine is solved, and the safety is improved.

Owner:山东聚发生物科技有限公司

A kind of modified spacer powder and its preparation method and a kind of liquid crystal tablet

ActiveCN111574739BGood compatibilityControl thicknessLiquid crystal compositionsNon-linear opticsHandwritingPolymer science

The invention provides modified spacer powder, a preparation method thereof and a liquid crystal handwriting board, and belongs to the technical field of liquid crystal materials. The modified spacerpowder provided by the invention is photoinitiator grafted spacer powder, a photoinitiator is benzoin methyl ether or Irgacure 651, and the spacer powder is polystyrene microspheres or polymethyl methacrylate microspheres; and the photoinitiator is connected with the spacer powder through a covalent bond. The modified spacer powder provided by the invention has good compatibility with liquid crystal in liquid crystal layer feed liquid, and the smoothness of handwriting of the liquid crystal handwriting board is improved. Moreover, the photoinitiator grafted on the modified spacer powder can initiate polymerization of polymeric monomers in the liquid crystal layer feed liquid, and finally, the spacer powder can be inserted into a polymer network, so that the polymer network close to the spacer powder microspheres is dense. The purpose of controlling the density of polymer networks in the liquid crystal handwriting board is achieved by controlling the amount of the photoinitiator graftedon the spacer powder microspheres, and then the handwriting thickness of the handwriting board is controlled.

Owner:SHENZHEN POLICRAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com