A kind of modified spacer powder and its preparation method and a kind of liquid crystal tablet

A modified liquid crystal layer technology, applied in liquid crystal materials, chemical instruments and methods, nonlinear optics, etc., can solve problems such as handwriting burrs, uneven force on spacer powder, poor smoothness, etc., and achieve good compatibility , Improve the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of the modified spacer powder described in the above technical scheme, comprising the following steps:

[0029] The spacer powder is subjected to corona discharge treatment to obtain a surface-modified spacer powder;

[0030] The surface-modified spacer powder, anhydrous aluminum chloride, photoinitiator and tetrahydrofuran are mixed, grafting reaction is carried out under strict anhydrous and oxygen-free conditions, purification and drying are carried out to obtain the modified spacer powder.

[0031] In the invention, the spacer powder is subjected to corona discharge treatment to obtain the surface-modified spacer powder.

[0032] In the present invention, the voltage of the corona discharge treatment is preferably 2-200kV, more preferably 10-25kV; the frequency is preferably 2-10kHz, more preferably 3-5kHz.

[0033] The present invention uses corona discharge treatment to generate carbonyl, carboxyl and other...

Embodiment 1

[0054] Preparation method of modified spacer powder

[0055] PS microspheres (particle size 2-7μm, specific gravity 1.08g / cm 3 , with a refractive index of 1.59 and a thermal decomposition temperature of 340°C) was subjected to corona discharge treatment under conditions of 2kV and 3kHz to obtain surface-modified polystyrene microspheres;

[0056] Mix 15g of surface-modified polystyrene microspheres, 15g of anhydrous aluminum chloride and 10g of benzoin methyl ether in tetrahydrofuran, perform grafting reaction at room temperature for 135min under strict anhydrous and oxygen-free conditions, purify and dry to obtain modified spacer powder.

[0057] Preparation of liquid crystal tablet:

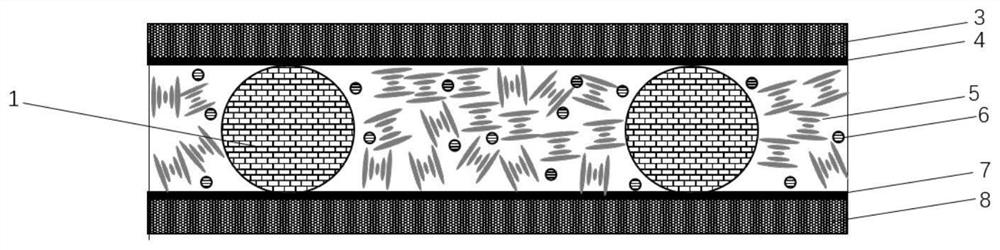

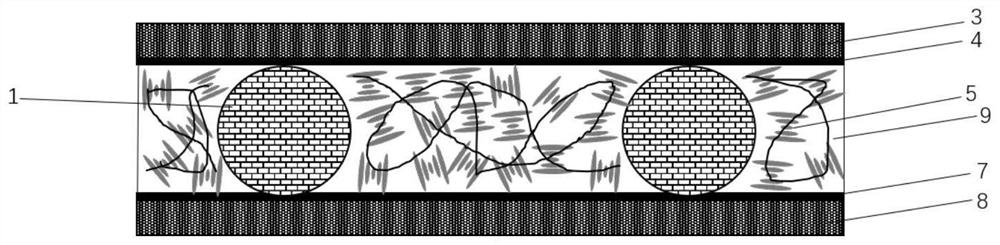

[0058] The first ITO conductive layer and the second ITO conductive layer with a thickness of 100nm are sequentially attached on the first substrate (made of PET) and the second substrate (made of PET) with a thickness of 50 μm;

[0059] Mix 2 parts by weight of modified spacer powder, 30 pa...

Embodiment 2

[0061] Preparation method of modified spacer powder

[0062] PMMA microspheres (particle size 5-7μm, refractive index 1.49, thermal decomposition temperature 280°C, specific gravity 2.03g / cm 3 ) Corona discharge treatment is carried out conditionally at 2kV, 3kHz to obtain surface-modified PMMA microspheres;

[0063] Mix 15g of surface-modified PMMA microspheres, 15g of anhydrous aluminum chloride and 10g of Irgacure 651 in tetrahydrofuran, perform a strict anhydrous and anaerobic grafting reaction at room temperature for 2.5 hours, obtain modified spacer powder after purification and drying.

[0064] Preparation of liquid crystal tablet:

[0065] The first ITO conductive layer and the second ITO conductive layer with a thickness of 100nm are sequentially attached on the first substrate (made of PET) and the second substrate (made of PET) with a thickness of 100 μm;

[0066] Mix 2 parts by weight of modified spacer powder, 30 parts by weight of polymerized liquid crystalline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com