Combustor for magnetizing roasting rotary kiln

A technology of magnetization roasting and rotary kiln, which is applied in the direction of burners, burners, and combustion methods for burning powder fuels, and can solve problems such as inability to react, side reactions, low temperature, and slow reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

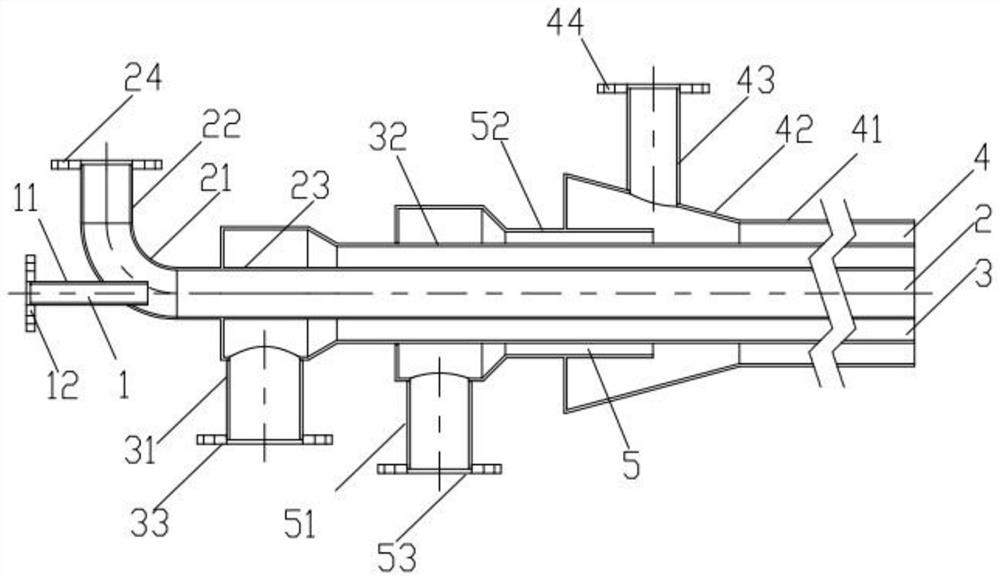

[0040] like Figure 1-3As shown, the present invention discloses a burner for a magnetized roasting rotary kiln, which includes a coarse-grained coal powder supply channel 2, a coarse-grained coal powder conveying air channel 1, a primary combustion-supporting air supply channel 3, a fine-grained coal powder The supply channel 4 and the fine-grained pulverized coal conveying air channel 5 are both formed by circular pipe fittings and arranged in sockets, and the socketed pipes are separated by high-temperature-resistant steel and arranged coaxially. The outlets of the coarse pulverized coal conveying air channel 1 , the primary combustion air supply channel 3 and the fine pulverized coal supply channel 4 are arranged in alignment. The primary combustion-supporting air supply channel 3 is socketed on the outside of the coarse-grained coal powder supply channel 2, and the gap of the fine-grained coal powder supply channel 4 is socketed on the outside of the primary combustion-su...

Embodiment 2

[0055] like Figure 4-5 As shown, the present invention discloses a burner for magnetization roasting rotary kiln, its main structure is similar to that of Embodiment 1, the difference is that it also includes a secondary combustion-supporting air supply channel 6, wherein the secondary combustion-supporting air supply The coaxial gap of the inlet channel 6 is sleeved on the outside of the fine-grained coal powder supply channel 4, and its output port is connected with the coarse-grained coal powder supply channel 2, the primary combustion-supporting air supply channel 3 and the fine-grained coal powder supply channel 4 The output ports are aligned. Thereby, the coarse-grained coal powder in the coarse-grained coal powder supply channel 2 is fed into the reaction furnace at a high speed through the ejection action of the coarse-grained coal powder conveying air channel 1, and the output end of the fine-grained coal powder transporting air channel 5 is inserted into the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com