Porous high-entropy hexaboride ceramic and preparation method thereof

A hexaboride, porous ceramic technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of increasing the thermal conductivity of porous materials, increasing the temperature and pressure of the substrate, and sintering porous materials, and achieving high porosity and high porosity. The effect of high porosity and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

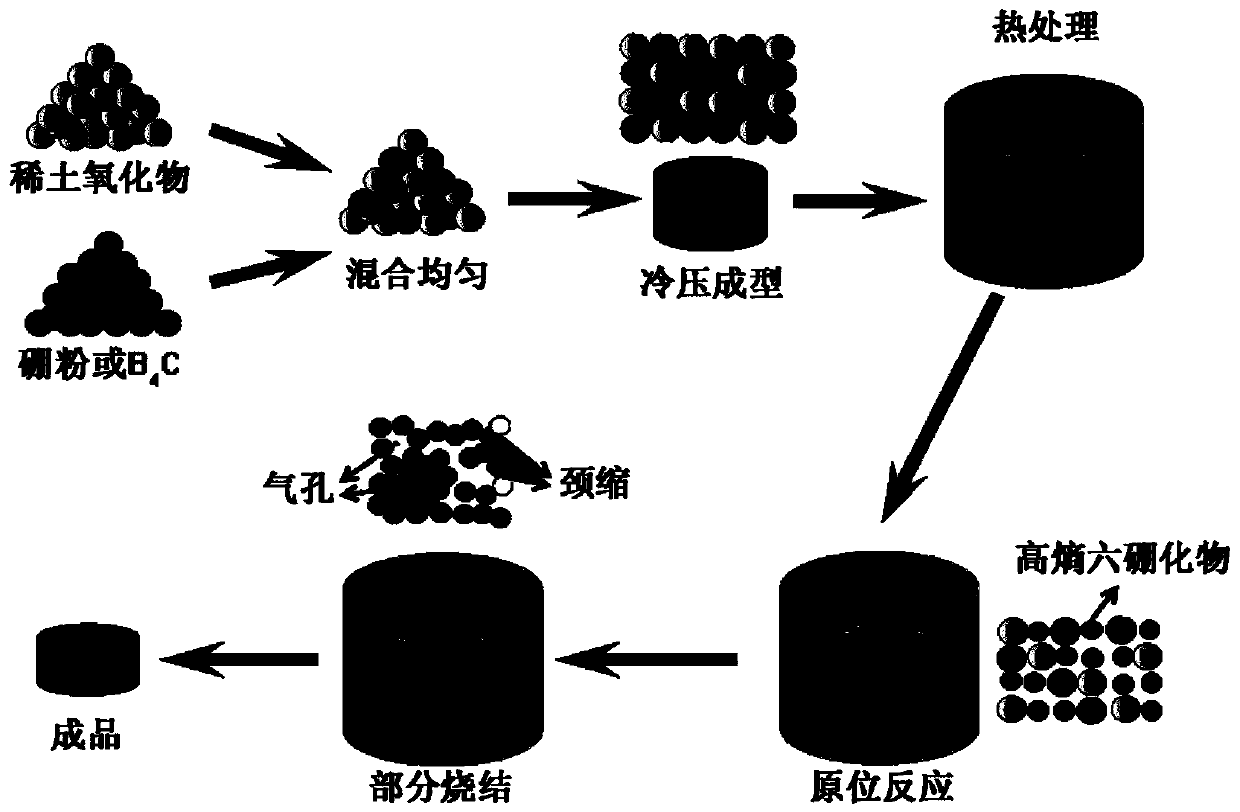

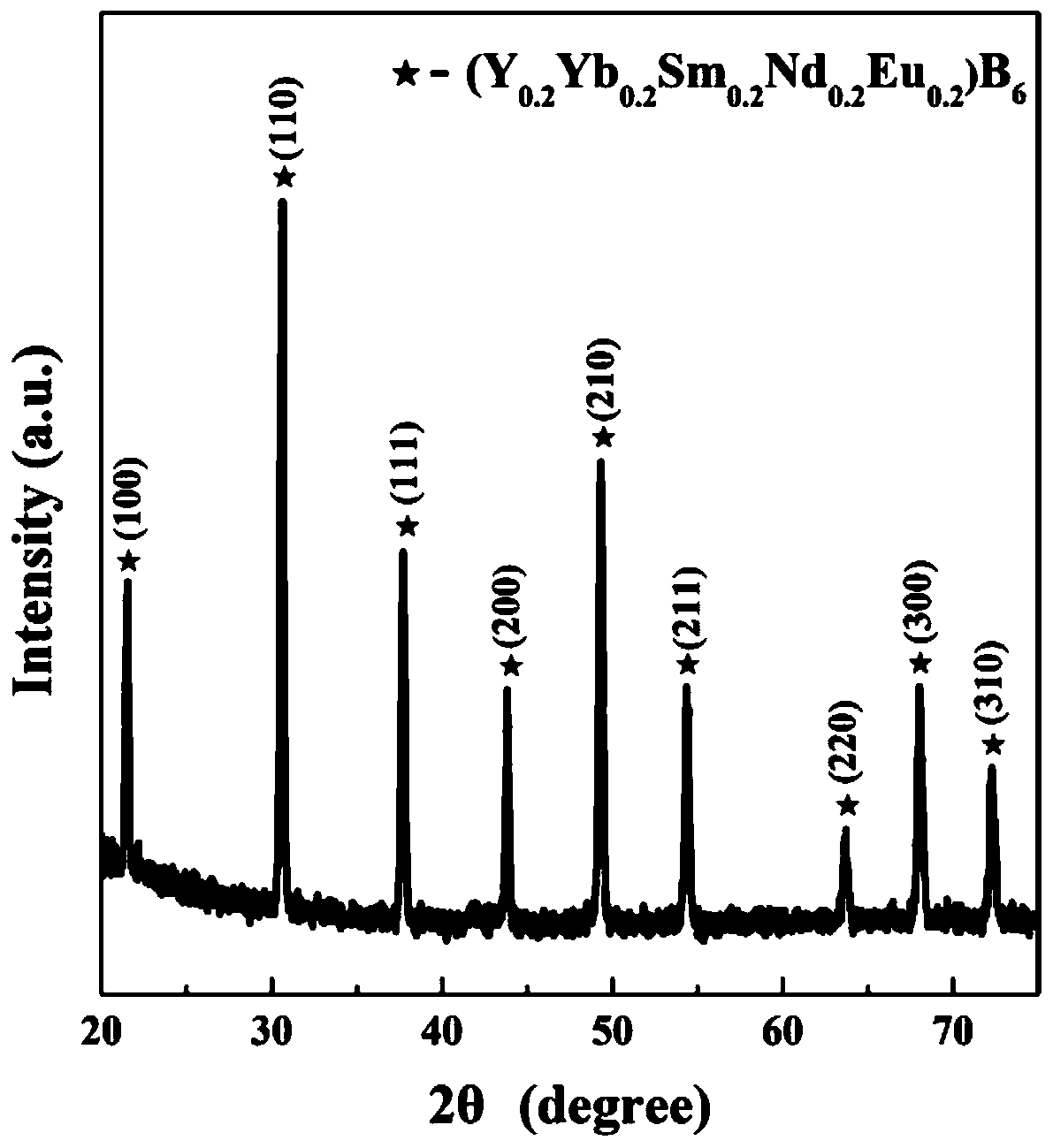

[0027] Y particles with a diameter of 2 µm 2 o 3 , Yb 2 o 3 、Sm 2 o 3 、Nd 2 o3 、Eu 2 o 3 and B 4 C Press Y 2 o 3 :Yb 2 o 3 :Sm 2 o 3 :Nd 2 o 3 :Eu 2 o 3 :B 4 C = 1:1:1:1:1:15.2 molar ratio weighing, adding absolute ethanol, mixing with a planetary ball mill for 12 hours, the mixed raw materials are vacuum dried to obtain a mixture powder, which is pressed into For a disc with a diameter of 15 mm and a thickness of 8 mm, the pressing pressure is 4 MPa. Put the dry-pressed sample into a high-temperature vacuum furnace, heat it to 1850°C at a heating rate of 5°C / min, and conduct a high-temperature gas-solid phase reaction for 2 hours with a vacuum degree of 14Pa. The obtained ultra-high temperature porous high-entropy hexaboride ceramics The porosity is 64%, and the compressive strength is 32MPa. The whole preparation process is as figure 1 As shown, the composition of the obtained ultra-high temperature ceramic porous framework is as follows figure 2 As s...

Embodiment 2

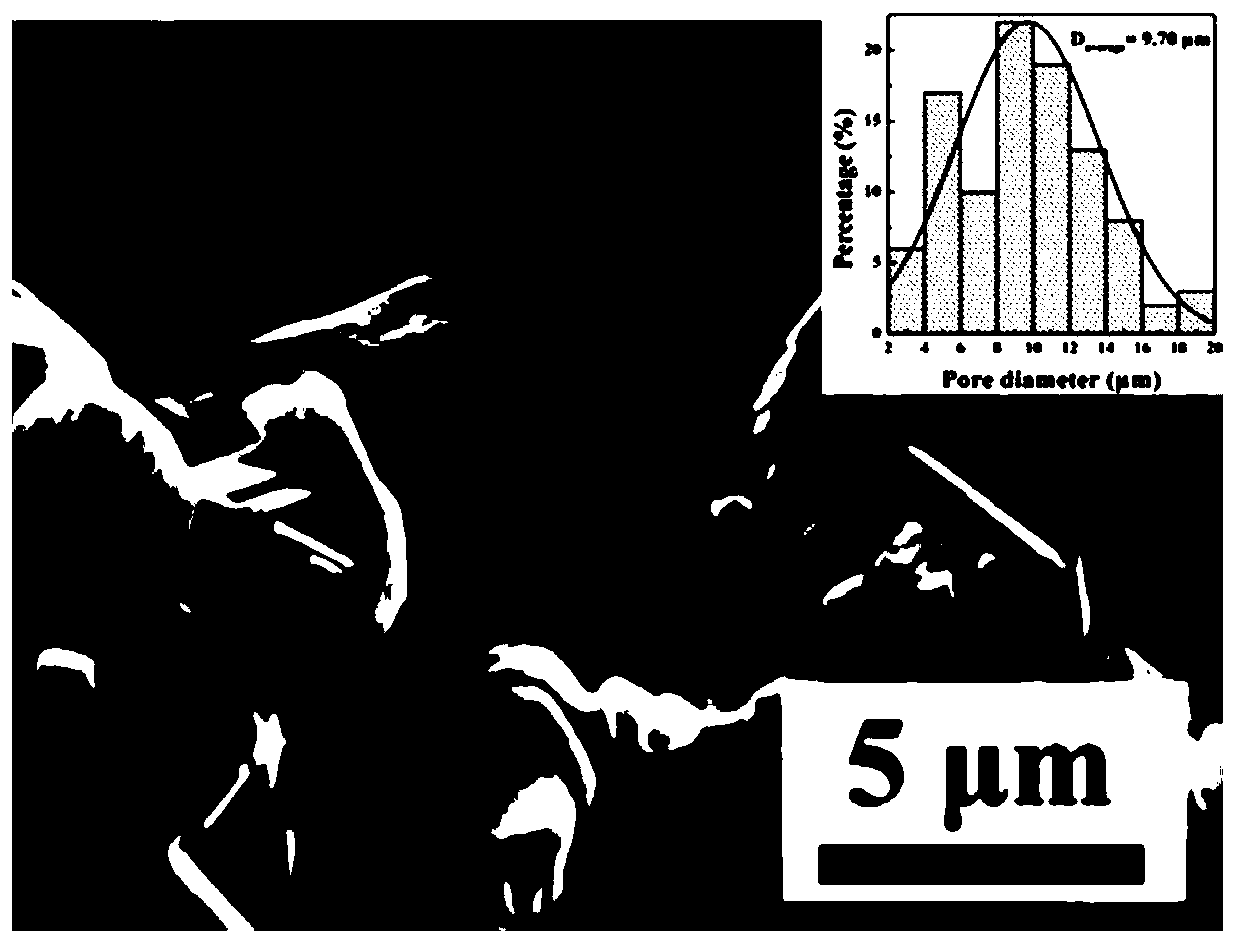

[0029] The particle diameter is 2 µm Y 2 o 3 , Yb 2 o 3 、Sm 2 o 3 、Nd 2 o 3 、Eu 2 o 3 and boron powder Y with a particle diameter of 10 microns 2 o 3 :Yb 2 o 3 :Sm 2 o 3 :Nd 2 o 3 :Eu 2 o 3 : boron powder=1:1:1:1:1:70.3 molar ratio weighing, adding absolute ethanol, mixing with a planetary ball mill for 6 hours, mixing uniform raw materials to obtain mixture powder through vacuum drying, pressing with dry pressing molding method Form into discs with a diameter of 12 mm and a thickness of 8 mm, and the pressing pressure is 2 MPa. Put the dry-pressed sample into a high-temperature vacuum furnace, heat it to 1850°C at a heating rate of 4°C / min, and conduct a high-temperature gas-solid phase reaction for 2.5 hours with a vacuum of 10 Pa. The obtained ultra-high temperature porous high-entropy hexaboride ceramics The porosity is 71%, and the compressive strength is 11MPa. Microstructure such as Figure 4 As shown, it can be observed that the pores are evenly di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com