Combined hot-wind continuous drying equipment

A drying equipment and combined technology, which is applied in the field of combined hot air continuous drying equipment, can solve the problems of reduced hot air intensity, constant change, and decreased drying effect, and achieve the effect of controllable strength and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

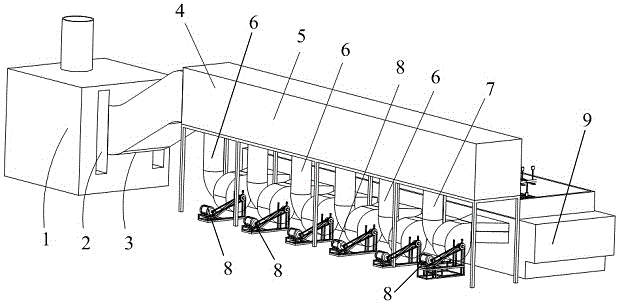

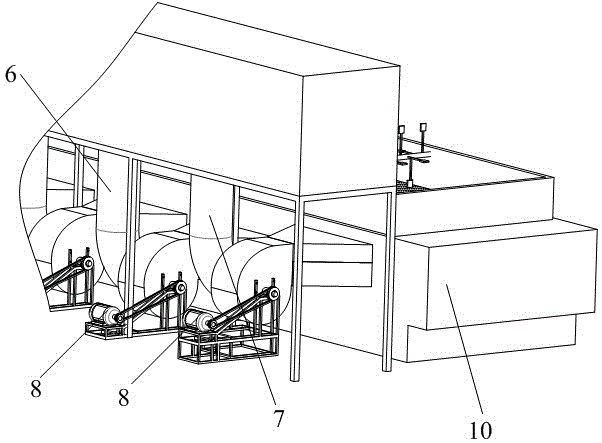

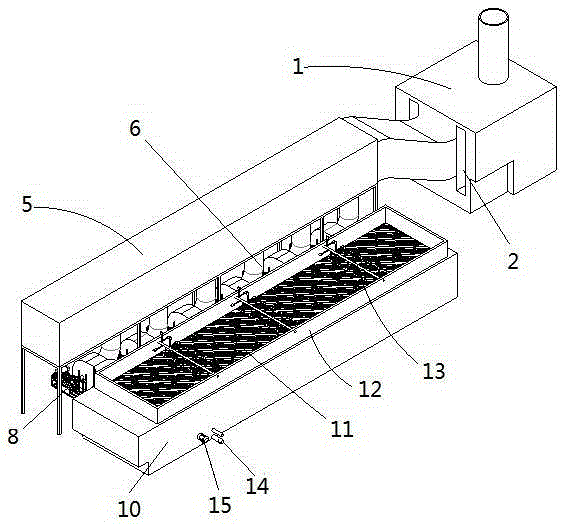

[0011] See Figure 1 to Figure 3 , Combined hot air continuous drying equipment includes hot air stove 1, air distribution chamber 4, continuous dryer 9, hot air furnace 1 is connected with air distribution chamber 4, and air distribution chamber 4 is connected with continuous dryer 9, hot air furnace 1 includes The natural air inlet 2 and the hot air outlet 3, and the hot air outlet 3 of the hot blast stove 1 are connected to the air distribution chamber 4. The air distribution chamber 4 includes an assembly air chamber 5 and at least three branch air ducts 6 connected to the assembly air chamber 5. The air generating chamber 5 is a sealed ventilation duct. One end of the ventilation duct is an air inlet. The air inlet is sealed and connected with the hot air outlet 3 of the hot blast stove 1. The other end of the ventilation duct is closed on the lower end surface of the ventilation duct of the assembly air chamber 5. At least three through holes are opened, one end of the at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com