Harmless treatment method for metal lithium

A harmless treatment, metal lithium technology, applied in the direction of lithium carbonate;/acid carbonate, can solve the problems of slow reaction speed, difficult control, high time cost, slow down the reaction process and high process efficiency , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

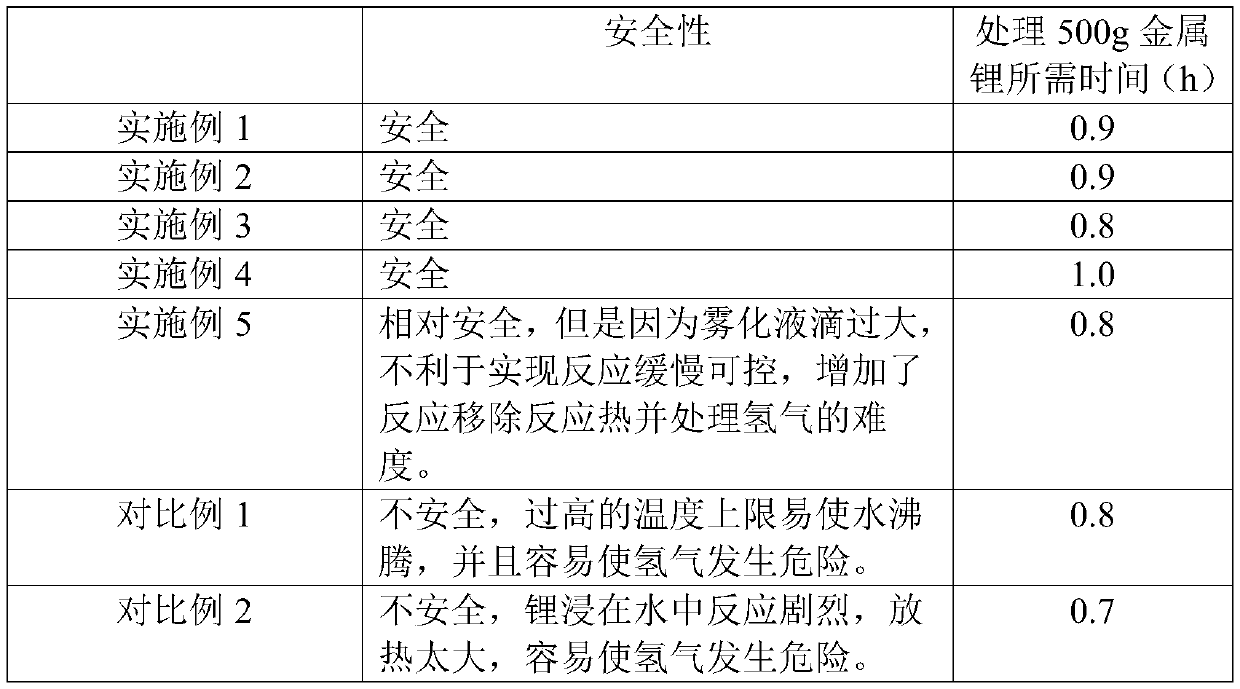

Examples

Embodiment 1

[0066] The present embodiment carries out the detoxification treatment of metal lithium according to the following method:

[0067] (1) In a closed processing box, under an argon atmosphere, react with atomized water and lithium metal, the initial flow rate of the atomized water is 50mL / s, and the controlled reaction temperature range is 40-85°C. When the temperature is higher than 85°C, reduce the flow rate of atomized water. When the reaction temperature is lower than 40°C, increase the flow rate of atomized water. The flow rate of atomized water ranges from 10-100mL / s, and the reaction humidity is 10-100% , during the reaction, continue to use the exhaust valve of the treatment box to remove the hydrogen generated by the reaction, after the reaction (that is, the reaction is basically stopped, and the temperature tends to be stable) to obtain a lithium-containing mixture;

[0068] Wherein, the droplet size of the atomized water is about 1.5mm. The exhaust valve of the trea...

Embodiment 2

[0075] The present embodiment carries out the detoxification treatment of metal lithium according to the following method:

[0076] (1) In a non-fully enclosed treatment box, under an air atmosphere, react with atomized water and lithium metal, the initial flow rate of the atomized water is 60mL / s, and the controlled reaction temperature range is 40-85°C, When the reaction temperature is higher than 85°C, reduce the flow rate of atomized water. When the reaction temperature is lower than 40°C, increase the flow rate of atomized water. The flow rate range of atomized water is 10-100mL / s, and the reaction humidity is 10- 100%, after the reaction (that is, when the reaction is substantially stopped and the temperature tends to be stable), the lithium-containing mixture is obtained, and the hydrogen generated in the reaction is burned in the treatment box;

[0077] Wherein, the droplet size of the atomized water is about 1 mm. The heat of reaction can be cooled by the cooling sys...

Embodiment 3

[0085] The present embodiment carries out the detoxification treatment of metal lithium according to the following method:

[0086] (1) In a closed processing box, under an argon atmosphere, react with atomized water and lithium metal, the initial flow rate of the atomized water is 40mL / s, and the controlled reaction temperature range is 50-75°C. When the temperature is higher than 75°C, reduce the flow rate of atomized water. When the reaction temperature is lower than 50°C, increase the flow rate of atomized water. The flow rate of atomized water is in the range of 30-80mL / s, and the reaction humidity is 20-90%. , during the reaction, continue to use the exhaust valve of the treatment box to remove the hydrogen generated by the reaction, after the reaction (that is, the reaction is basically stopped, and the temperature tends to be stable) to obtain a lithium-containing mixture;

[0087] Wherein, the droplet size of the atomized water is about 1.5mm. The exhaust valve of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com