Preparation method for vanadium-aluminum alloy and reactor

A vanadium-aluminum alloy and reactor technology, which is applied in the field of alloy materials, can solve the problems of oxide film, poor alloy separation effect, low vanadium yield, etc., and achieves the effect of reducing oxidation degree and vanadium loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

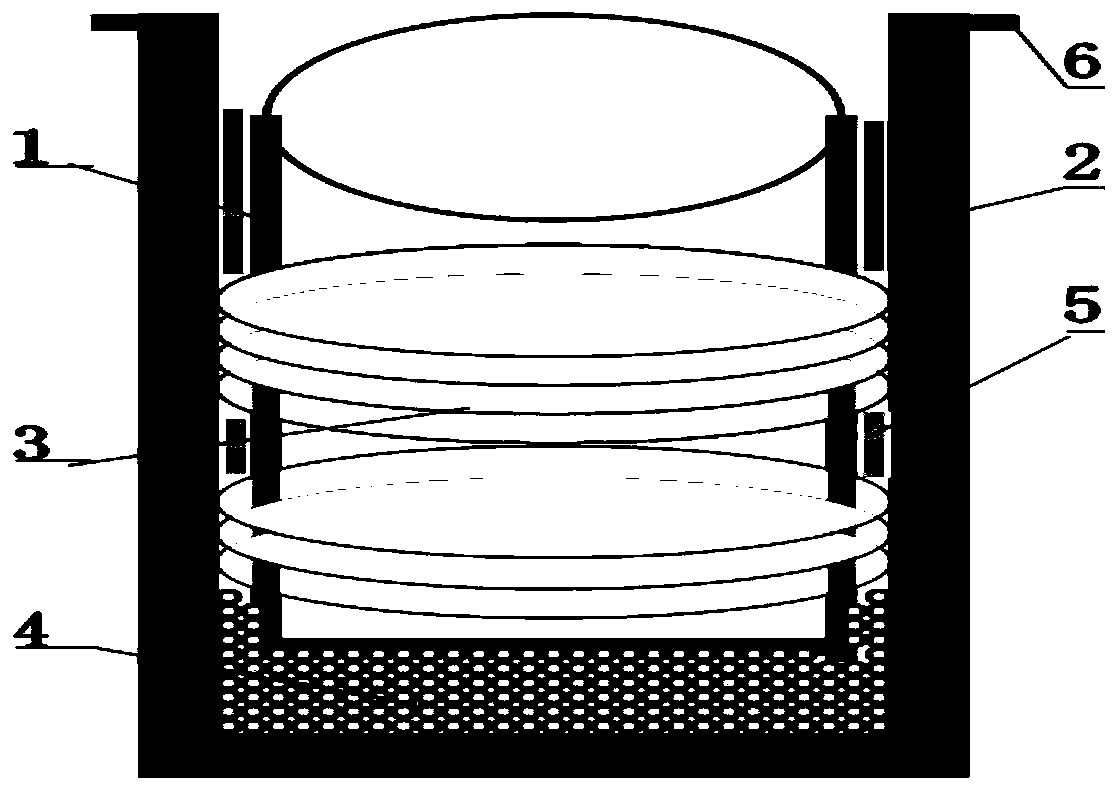

[0076] The structural representation of the reactor used in this embodiment when the furnace cover 8 is not covered is as follows: figure 1 shown. The reactor comprises: a U-shaped container 2 (iron outside, refractory brick inside), a reaction vessel 1 (made of graphite and cylindrical in shape) placed in the U-shaped container 2, located in the reaction vessel 1 the heating device 3 (electromagnetic induction coil) on the outer wall, and the filler placed between the U-shaped container 2 and the reaction vessel 1, the filler is composed of a first filler 4 (magnesia) and a second filler 5 (Asbestos) composition, the first filler 4 pads on the bottom of the U-shaped container 2, the reaction vessel 1 is placed in the first filler 4, and the second filler 5 is positioned at the side wall of the U-shaped container 2 and the reaction vessel 1 between the side walls.

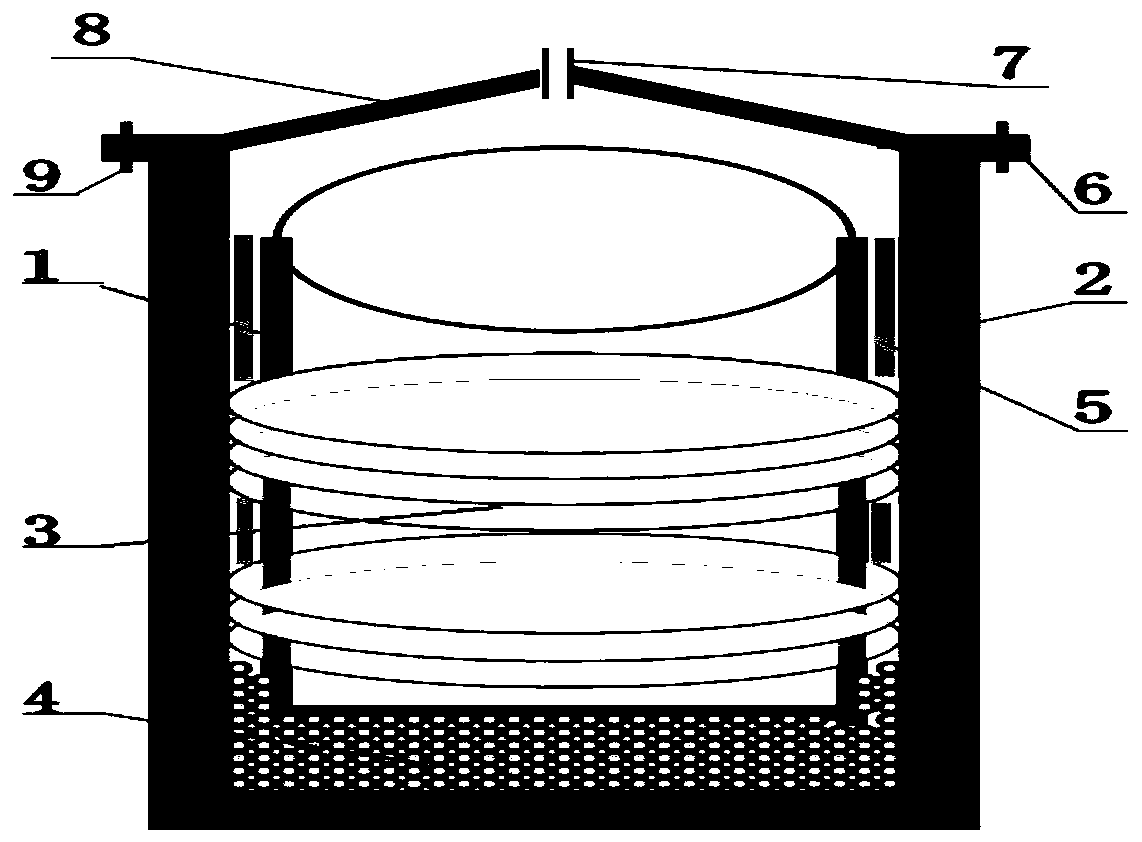

[0077] The structural representation of the reactor used in this embodiment after covering the furnace cover 8...

Embodiment 2

[0089] The reactor used in this embodiment is the same as the reactor in Example 1 except that two vent pipes 7 are provided on the furnace cover 8 to realize the circulation of the inert gas argon in the U-shaped container.

[0090] The preparation method that present embodiment provides uses the reactor of present embodiment, and the concrete steps of this method are:

[0091] (1) After mixing vanadium trioxide and metal aluminum for 2 hours, add calcium oxide and continue mixing for 2 hours to obtain a mixed material;

[0092] Among them, the purity of vanadium trioxide is 99.5%, and the particle size is 0.106-0.15mm; the purity of metal aluminum is 99.5%, and the particle size is 7-12mm; the purity of calcium oxide is 99.5%;

[0093] In parts by weight, the parts by weight of each component in the step (1) are:

[0094] Vanadium trioxide 1 part

[0095] Metal aluminum 0.96 parts

[0096] 0.18 parts of calcium oxide;

[0097](2) The mixed material described in step (1) ...

Embodiment 3

[0101] This embodiment uses the reactor identical with embodiment 1 to prepare vanadium aluminum alloy, and its specific method is:

[0102] (1) After mixing vanadium trioxide and metal aluminum for 1 hour, add calcium oxide and continue mixing for 1 hour to obtain a mixed material;

[0103] Among them, the purity of vanadium trioxide is 98.5%, and the particle size is 0.106-0.15mm; the purity of metal aluminum is 99.8%, and the particle size is 7-12mm; the purity of calcium oxide is 98.5%;

[0104] In parts by weight, the parts by weight of each component in the step (1) are:

[0105] Vanadium trioxide 1 part

[0106] Metal aluminum 0.92 parts

[0107] 0.15 parts of calcium oxide;

[0108] (2) The mixed material described in step (1) is placed in the graphite material reaction vessel 1 of the reactor for magnetic induction heating, the electromagnetic induction coil power of the magnetic induction heating is 200kW, and the heating rate of heating is 100° C. / min. Start the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com