Preparation process of high-resilience daily melamine foam

A technology of melamine and preparation process, applied in the field of material preparation, can solve problems such as lack of advantages, and achieve the effects of improving resilience, uniform foam dispersion, and improved foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation process of high-resilience daily-use melamine foamed plastics, the specific steps are as follows:

[0033] (1) Add melamine into the formaldehyde solution, use triethanolamine to adjust the pH value to 9, heat to 85°C and react for 50 minutes to generate melamine formaldehyde resin, add polyvinyl butyral, polyester polyol and polyether modification while stirring A non-toxic polysiloxane copolymer, fed with nitrogen, continued to react for 40 minutes, added concentrated hydrochloric acid to adjust the pH to neutral, and dehydrated to obtain a modified melamine resin;

[0034] (2) Mix and stir the modified melamine resin obtained in step (1) with a surfactant and a blowing agent to obtain the first material, which is set aside;

[0035] (3) Mix and stir isooctyl mercaptopropionate and liquid curing agent evenly to obtain the second material, which is set aside;

[0036] (4) Keep stirring the first material obtained in step (2) for 2 hours, preheat to 50°C,...

Embodiment 2

[0044] A preparation process of high-resilience daily-use melamine foamed plastics, the specific steps are as follows:

[0045] (1) Add melamine into the formaldehyde solution, use triethanolamine to adjust the pH value to 10, heat to 90°C for 60 minutes to generate melamine formaldehyde resin, add polyvinyl butyral, polyester polyol and polyether modification while stirring A non-toxic polysiloxane copolymer, fed with nitrogen, continued to react for 50 minutes, added concentrated hydrochloric acid to adjust the pH to neutral, and dehydrated to obtain a modified melamine resin;

[0046] (2) Mix and stir the modified melamine resin obtained in step (1) with a surfactant and a blowing agent to obtain the first material, which is set aside;

[0047] (3) Mix and stir isooctyl mercaptopropionate and liquid curing agent evenly to obtain the second material, which is set aside;

[0048] (4) Keep stirring the first material obtained in step (2) for 2 hours, preheat to 60°C, then add...

Embodiment 3

[0056] A preparation process of high-resilience daily-use melamine foamed plastics, the specific steps are as follows:

[0057] (1) Add melamine to the formaldehyde solution, use triethanolamine to adjust the pH value to 9, heat to 90°C for 50 minutes to generate melamine formaldehyde resin, and add polyvinyl butyral, polyester polyol and polyether modification while stirring A non-toxic polysiloxane copolymer, fed with nitrogen, continued to react for 50 minutes, added concentrated hydrochloric acid to adjust the pH to neutral, and dehydrated to obtain a modified melamine resin;

[0058] (2) Mix and stir the modified melamine resin obtained in step (1) with a surfactant and a blowing agent to obtain the first material, which is set aside;

[0059] (3) Mix and stir isooctyl mercaptopropionate and liquid curing agent evenly to obtain the second material, which is set aside;

[0060] (4) Keep stirring the first material obtained in step (2) for 2 hours, preheat to 50°C, then ad...

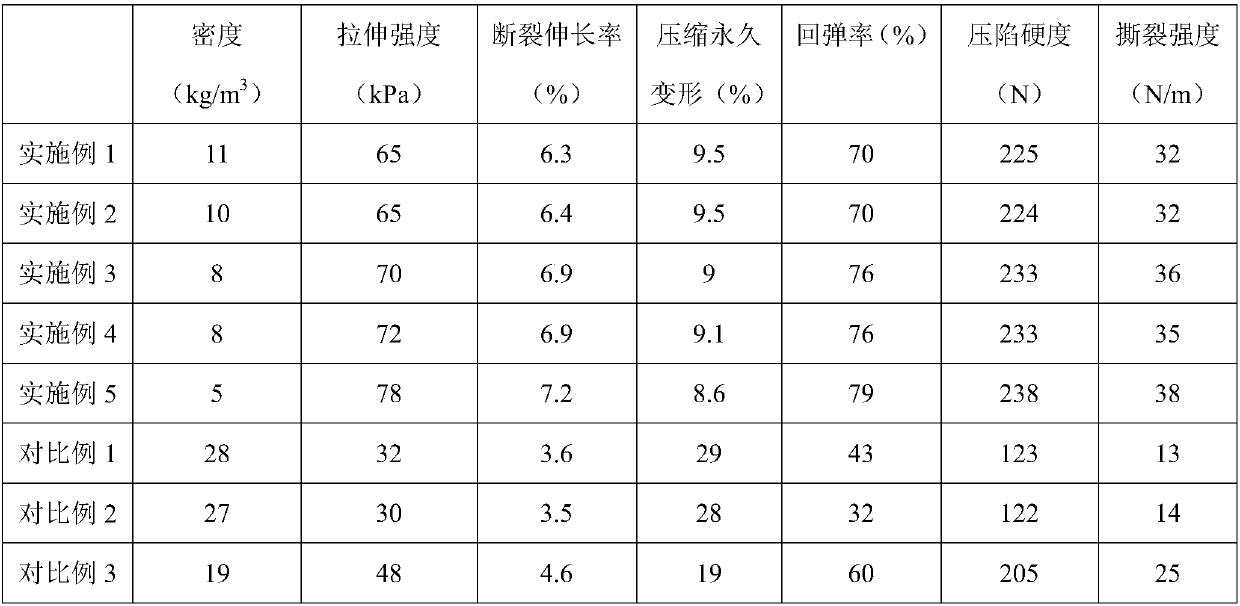

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com