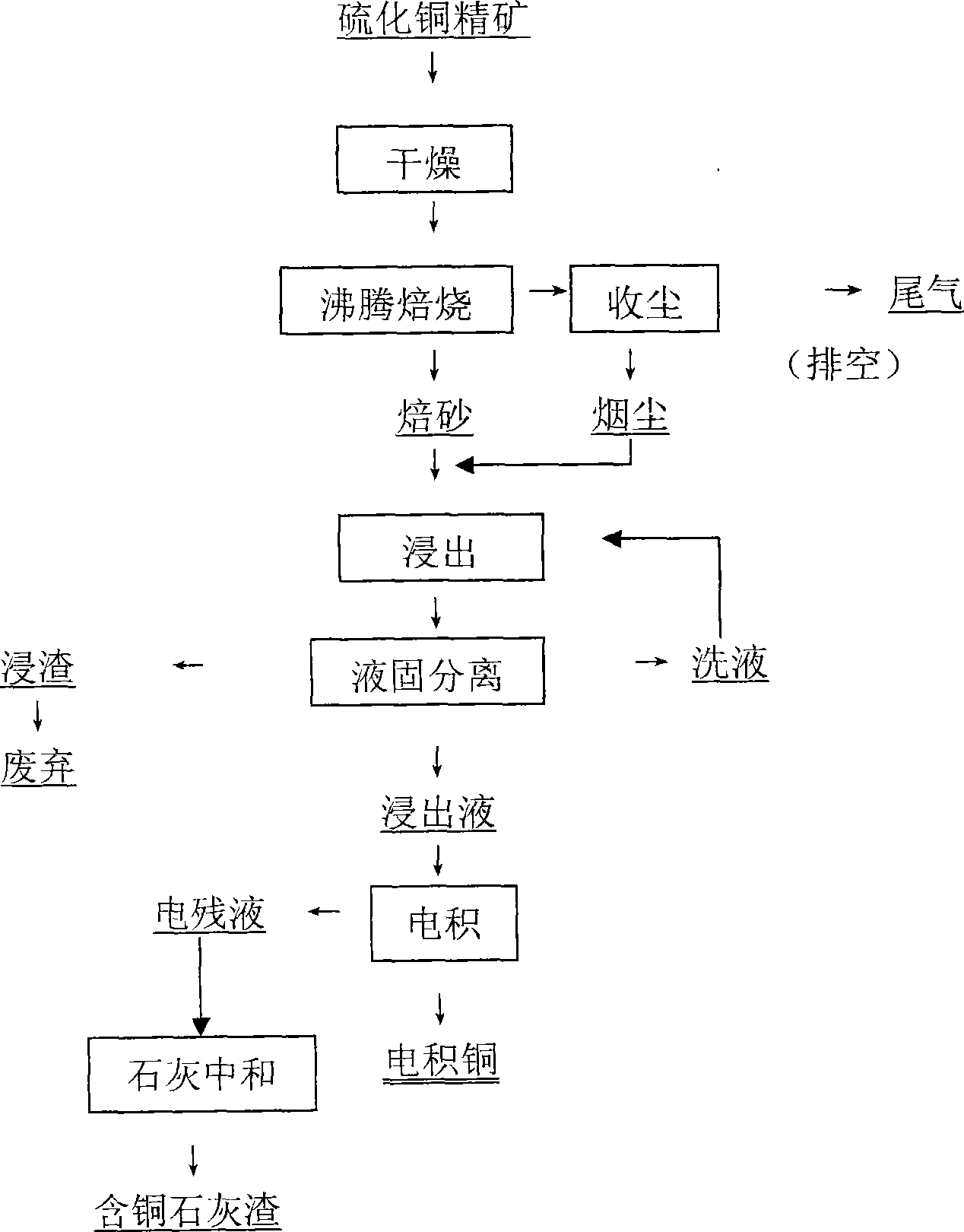

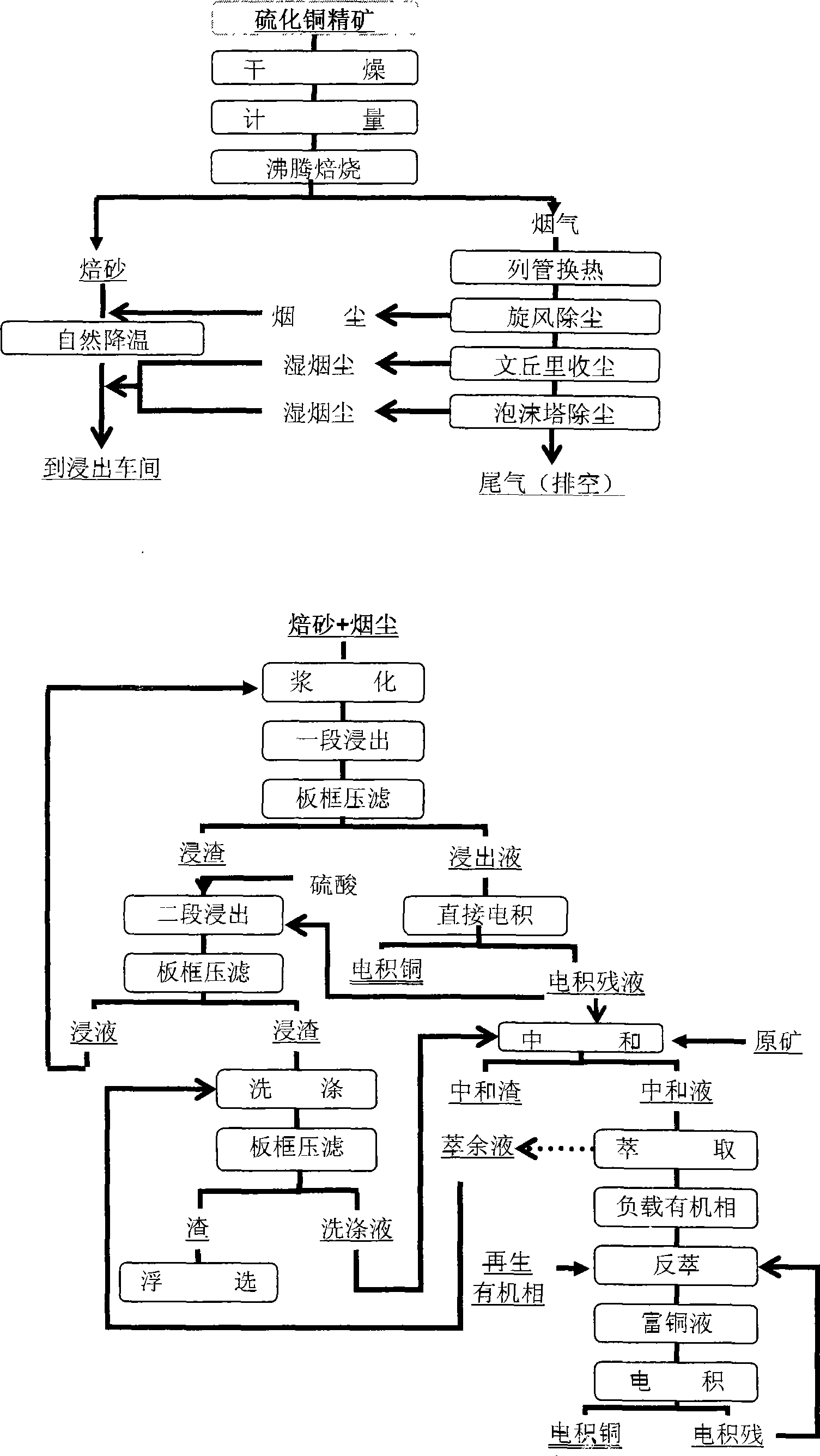

Technique for extracting copper from high-calcium high-magnesium cupric sulfide by wet method

A copper sulfide, high-calcium-magnesium technology, applied in the field of chemical metallurgy, can solve the problems of unreacted copper sulfide concentrate overall process, economic index is not as good as fire method, wet process stays in the test and small-scale production stage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Concentrate preparation: Yunnan Dongchuan Yinmin copper concentrate is dried naturally (3-7 days) on a cement-poured flat site, with a moisture content of 5-10%. After drying, it is crushed (<2mm) and stored in The roasting ore bunker is ready to go into the furnace.

[0035] (2) Roasting: The dry concentrate stored in the raw material ore bin is continuously and evenly fed into the fluidized furnace by the screw feeder, the roasting temperature is controlled at 600°C, the air is blown into the furnace and the concentrate is boiled and burned, and the residence time in the furnace is 10h. A large amount of calcium oxide and magnesium oxide minerals in the minerals are used to absorb the sulfur dioxide gas generated during the roasting process, and generate calcium sulfate and magnesium sulfate to reduce the emission of sulfur dioxide gas and achieve the effect of "self-cleaning" roasting. Part of the roasted ore overflows from the discharge port of the fluidized flu...

Embodiment 2

[0042] (1) Concentrate preparation: Tangdan copper sulfide concentrate in Dongchuan, Yunnan, is naturally dried to a water content of 5% to 10%, then crushed and screened to less than 2mm by a wheel mill, and dried naturally on a cemented level ground for 3 to 7 days, and then stored in the raw material mine;

[0043] (2) Roasting: The dry concentrate stored in the raw material ore bin is continuously and evenly fed into the fluidized furnace by the screw feeder, the roasting temperature is controlled at 650°C, the air is blown in and the concentrate is boiled and burned in the furnace, and the residence time in the furnace is 15h. Use a large amount of calcium oxide and magnesium oxide minerals in the minerals to absorb sulfur dioxide gas generated during the roasting process, generate calcium sulfate and magnesium sulfate, and reduce the emission of sulfur dioxide gas. The iron minerals in the feed are converted into ferric oxide, which stays in the solid phase, and the sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com