Industrial preparation method of water-soluble resin coating material and application thereof

A water-soluble resin, coating material technology, applied in the application, agriculture, fertilizer form and other directions, can solve the problems of easy agglomeration and destruction of coated fertilizers, easy re-sticking of emulsions, etc., achieves obvious film-forming flexibility, reduces manufacturing Cost, long-term effect of controlled-release fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 The batching of emulsion refers to the proportioning of following materials:

[0046] Water: 600-650 parts by weight;

[0047] Emulsifier: 15-30 parts by weight;

[0048] Mixed monomers: 500-550 parts by weight;

[0049] Initiator: 2.5-3.5 parts by weight.

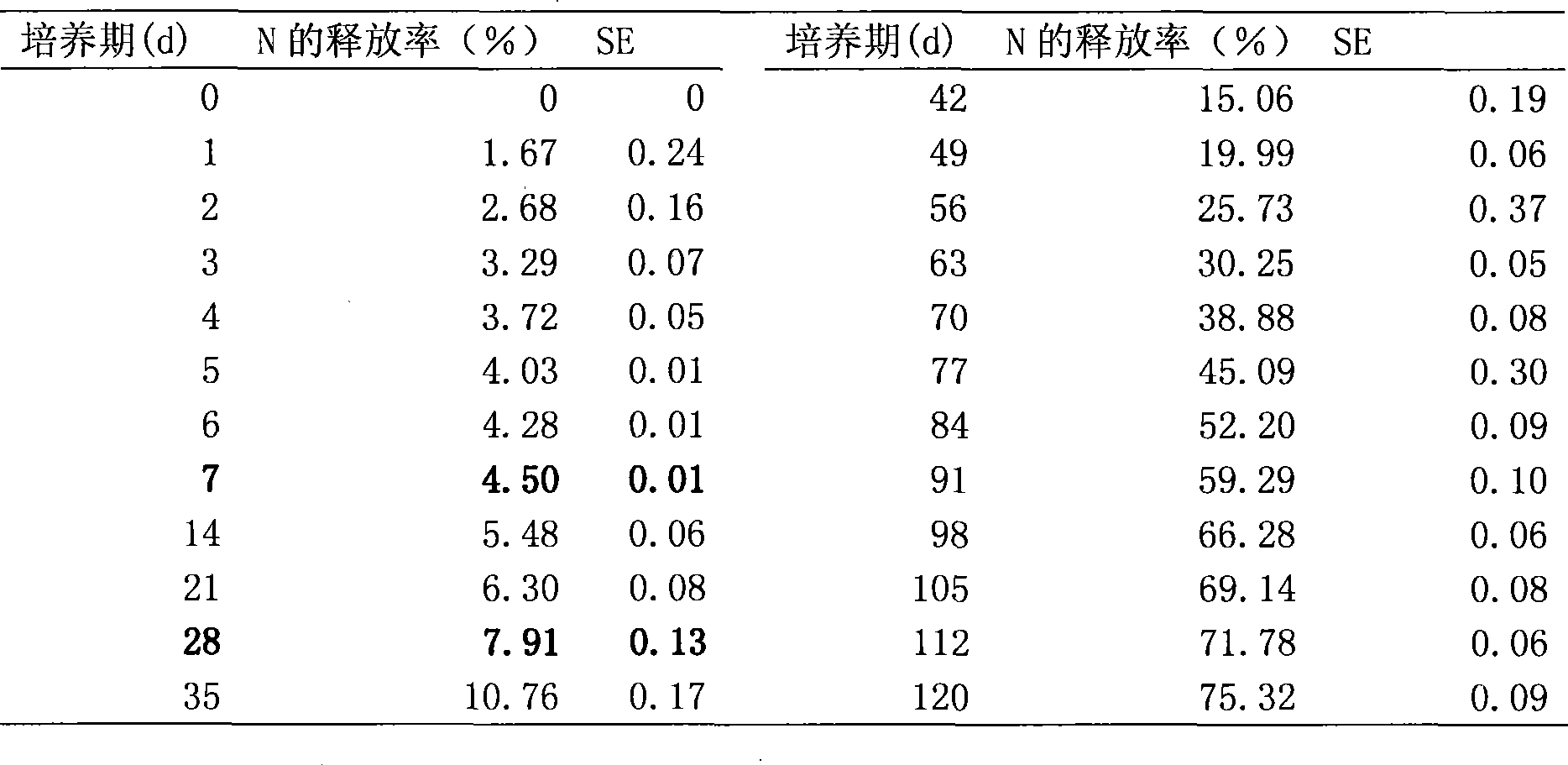

[0050] This embodiment provides Table 1 as a calculation example:

[0051] Table 1

[0052] A material calculation process for emulsion

[0053] Monomer (DT) kg kg

[0054] DT1 200 200

[0055] DT11 80 80

[0056] DT2 190 190

[0057] DT3-1 5 5

[0058] DT3-2 25 25

[0059] DT5 0 50

[0060] Individual subtotal 500.00 550.00

[0061] Emulsifier is 3~6% of DT Surfactant (BMHXJ1) 10.50 10.50

[0062] Non-grain 4.50 4.50

[0063] Surfactant (BMHXJ2) 0.00 0.00

[0064] OP-10 0.00 10.00

[0065] Total amount kg 15.00 25.00

[0066] Dissolved surfactant and mono 480.00 550.00

[0067] Initiator

[0068] 0.3~0.6% of total m...

Embodiment 2

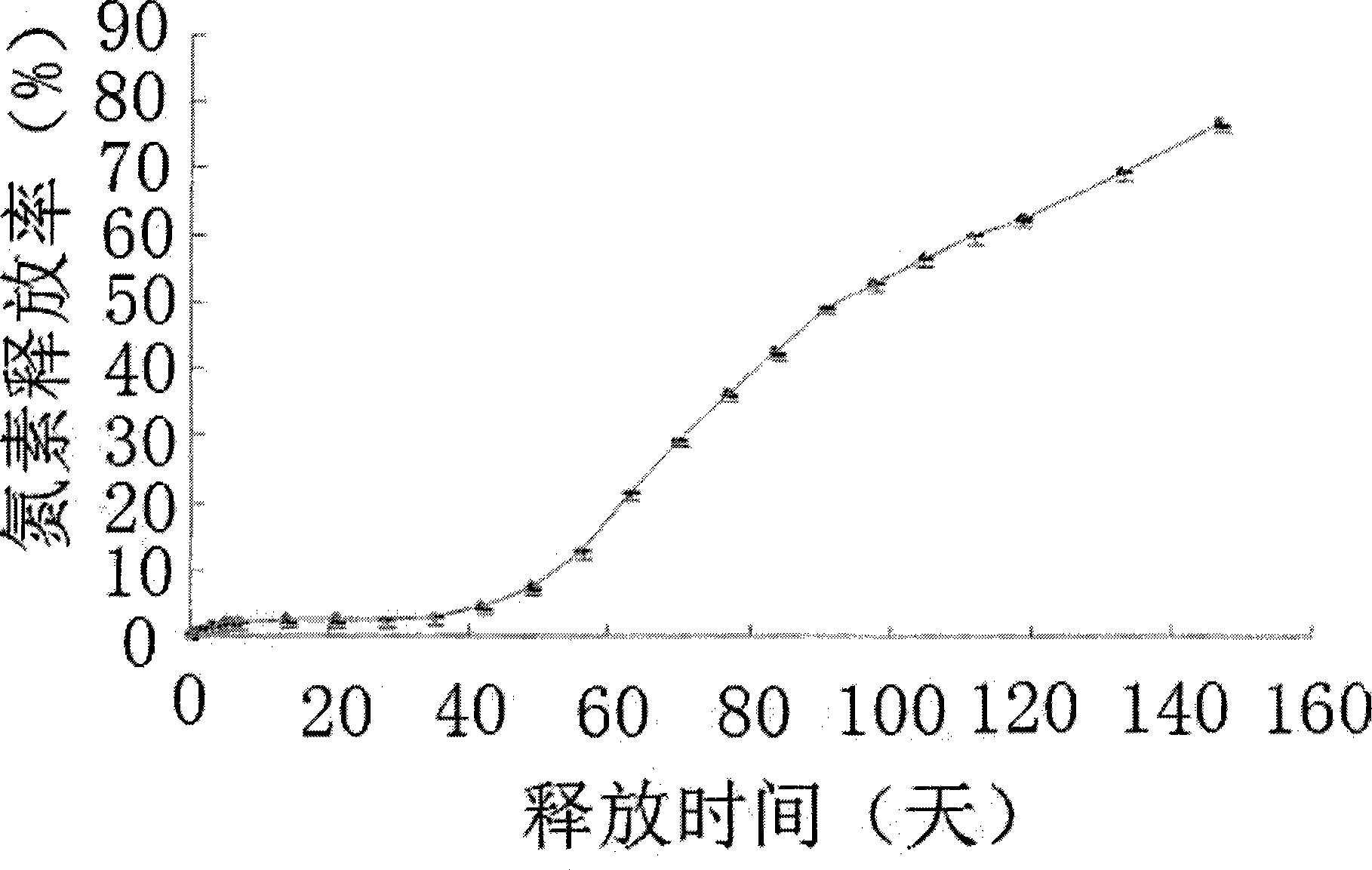

[0075] Example 2 Preparation of a kind of propylene emulsion and preparation of coated controlled-release fertilizer

[0076] (1) The industrial method synthesis process and steps of propylene water-based polymer (propylene water-soluble resin):

[0077] (1) Add 1015kg of pure water, 10kg of sodium dodecylsulfonate, 5kg of OP-10, 1.5kg of N-methylolacrylamide in the first 2-ton reactor, and stir to obtain an emulsifier solution;

[0078] (2) Take out 60kg emulsifier solution and place it in the second 2 ton reactor;

[0079] Add the mixture of 482kg methyl acrylate, 172kg butyl acrylate, 23kg methacrylic acid and 77kg isooctyl acrylate to the remaining emulsifier solution in the first reactor under stirring, and stir to obtain emulsified monomers;

[0080] The monomer of the emulsion polymer is acrylate and its emulsion, which is obtained by conventional batch emulsion polymerization process, semi-continuous emulsion polymerization process, continuous emulsion polymerization ...

Embodiment 3

[0097] Embodiment 3 industrial method prepares a kind of styrene-acrylic emulsion coating material and controlled-release fertilizer

[0098] (1) Industrial synthesis process and steps of styrene-acrylic water-based polymer (styrene-acrylic water-soluble resin):

[0099] (1) Add 1015kg pure water, 10kg sodium dodecylsulfonate, 5kg OP-10 and Tween 80 mixture, 1.5kg N-methylolacrylamide to the first 2-ton reactor, and stir to obtain emulsifier solution;

[0100] (2) Take out 60kg emulsifier solution and place it in the second 2 ton reactor;

[0101] Add the mixture of 338kg methyl acrylate, 145kg styrene, 172kg butyl acrylate, 23kg methacrylic acid and 77kg isooctyl acrylate to the remaining emulsifier solution in the first reactor under stirring, and stir to obtain emulsified single body;

[0102] The monomers of emulsion polymers are acrylate, styrene and their emulsions, which are polymerized by conventional semi-continuous method, pre-polymerization method, seed emulsion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com