System and method for local surface treatment

a local surface treatment and industrial technology, applied in the direction of electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of substantially equal speed, cost and energy consumption of the local surface treatment system, and achieve the effects of reducing the risk and effect of corrosion, facilitating the subsequent application of another treatment product, and improving chemical and mechanical resistance to environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

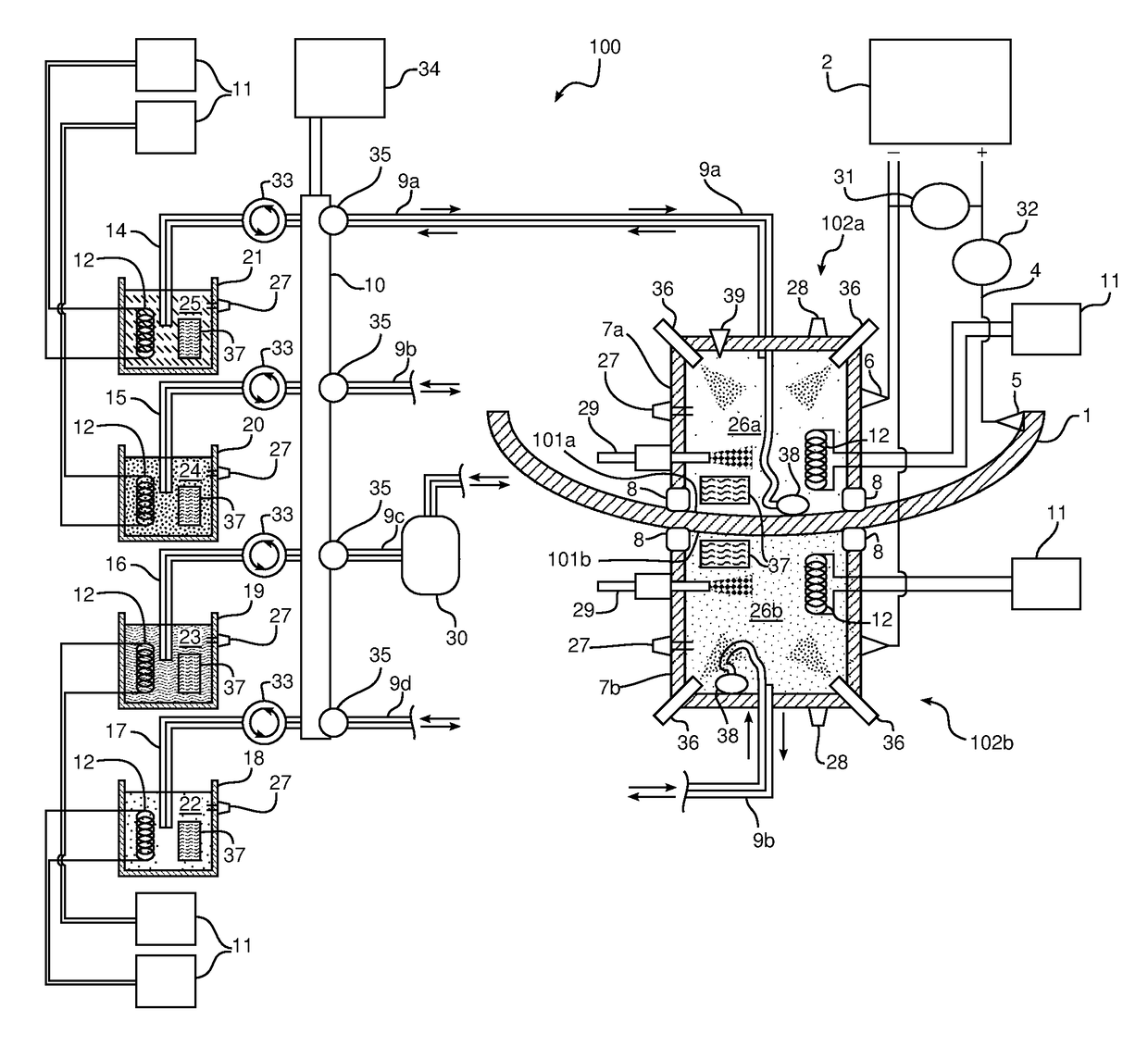

[0055]FIG. 1 depicts schematically in cross section a system 100 for the local surface treatment of a portion 101a, 101b of a part 1 to be treated according to the invention.

[0056]The system 100 makes it possible to treat a part 1 to be treated by means of treatment products 22, 23, 24, 25, each treatment product 22, 23, 24, 25 being respectively stored in a container 18, 19, 20, 21. The part 1 to be treated is, for example, a metal part forming part of an aircraft.

[0057]To carry out local treatment of the part 1 to be treated, for example on one or more portions 101a, 101b of the part to be treated, the local treatment system 100 comprises one or more bath enclosures, for example two bath enclosures 102a, 102b in this first embodiment, each being located on a face of the part 1 to be treated. Each bath enclosure 102a, 102b delimits a fluid-tight space 26a, 26b between walls 7a, 7b of each bath enclosure 102a, 102b and the portion 101a, 101b of the part to be treated. Each bath encl...

second embodiment

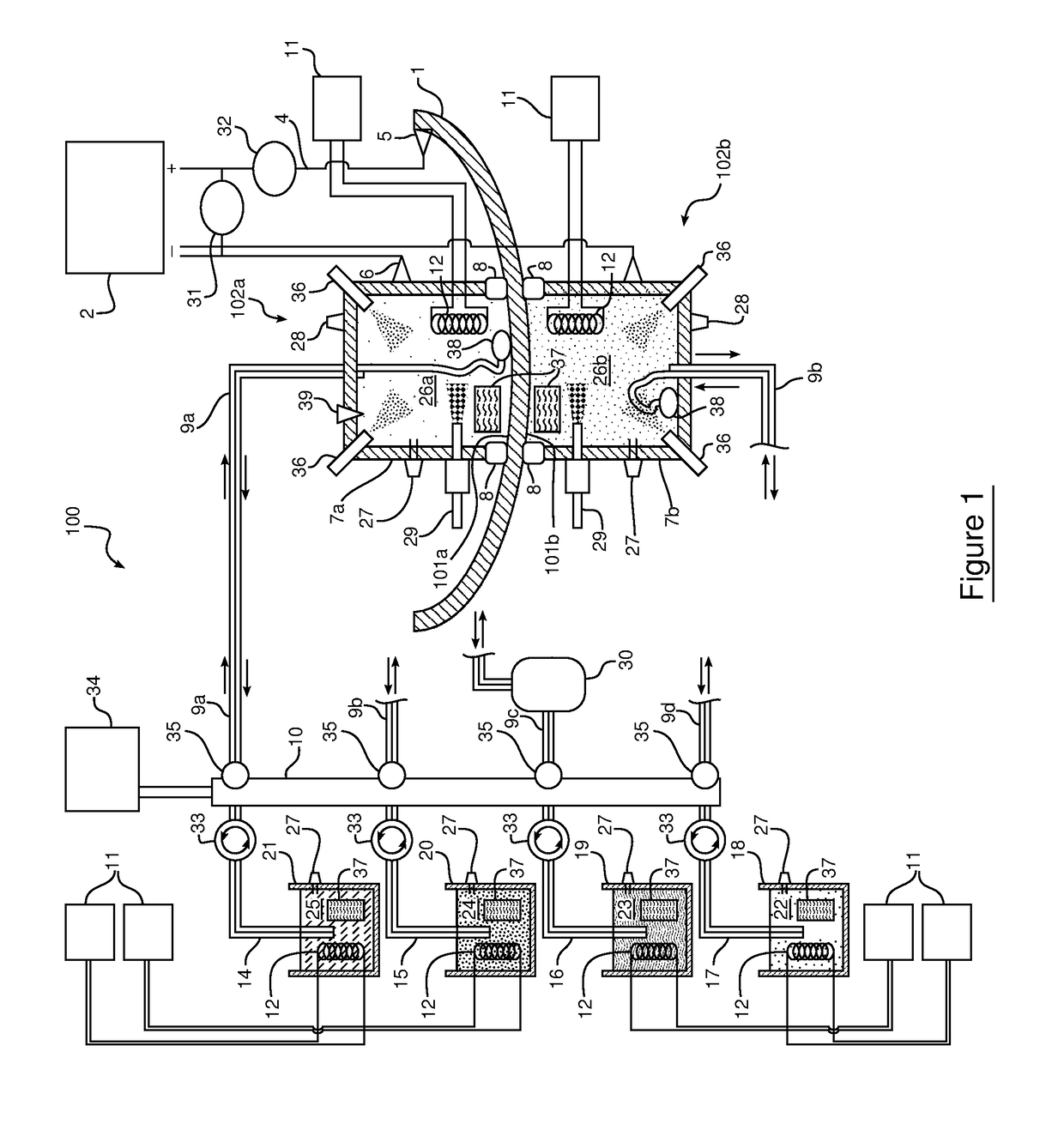

[0077]In this second embodiment, a single bath enclosure 105 is shown for treating a cylindrical part 106 to be treated, for example a pipe element. The part 106 to be treated is surrounded by the bath enclosure 105, and the bath enclosure 105 comprises a wall formed by portions 7c and 7d, joined by seals 8, for example electromagnetic suckers. The fixing of the two portions 7c, 7d of the wall is also reinforced by the addition of mounting flanges 40. The cylindrical part 106 to be treated is inserted in the bath enclosure through a circular opening having the same diameter as the cylindrical part 106 to be treated (not visible in the cross-sectional view). For reasons of legibility in the cross section shown in FIG. 2, the point 5 of connection to the part is shown inside the part, but the point 5 of connection to the part is advantageously located on a portion of the part that is not surrounded by the bath enclosure 105. The connection point 5 may also be located on a metal suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| corrosion | aaaaa | aaaaa |

| chemical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com