Process for the preparation of hollow cellulose vessels by culturing cellulose- producing microorganisms on the surface of a hollow carrier and providing a gas having an oxygen level of at least 35%

A technology of oxygen level and microbial cellulose, which is applied in the field of hollow cellulose tubes, can solve the problems of low blasting pressure, poor mechanical properties, and unsuitability, and achieve good mechanical properties and shorten the cultivation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

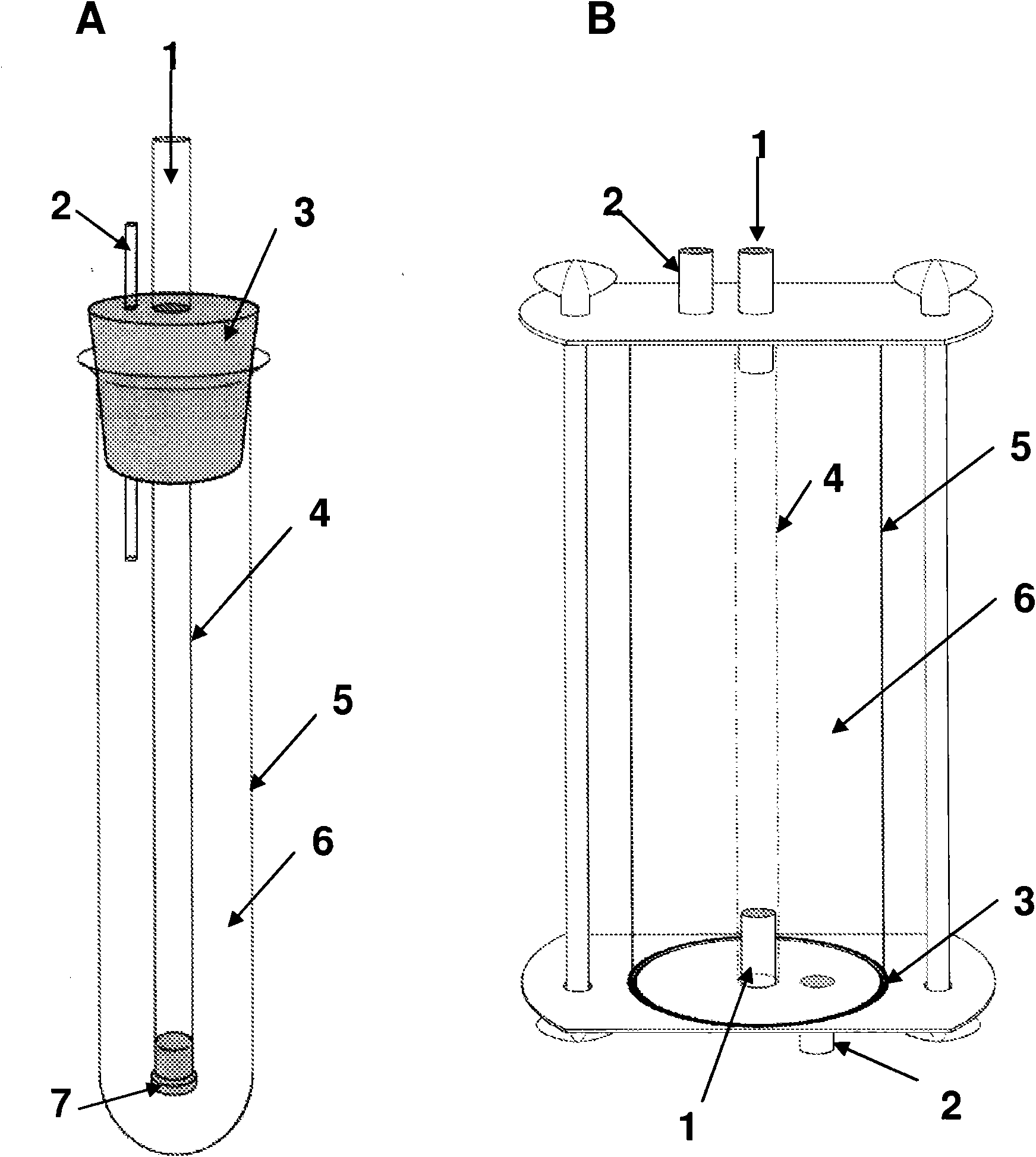

[0019] One embodiment of the present invention is an improved method of producing hollow microbial cellulose by culturing cellulose-producing microorganisms on the outer surface of a hollow carrier. An oxygen-containing gas is supplied to the inside of the hollow carrier.

[0020] The method is further characterized in that the oxygen-containing gas has an oxygen level higher than atmospheric oxygen. Preferably, at oxygen levels between 21%-100%, 35%-100%, 50%-100%, 60%-100%, 70%-100%, 80%-100% or 90%-100% cultivated in between. The remainder of the gas used may be any inert gas such as nitrogen, argon, helium. Oxygen percentages are expressed as v / v percentages.

[0021] Preferably, cultivation is performed at an oxygen level of 100%.

[0022] To further increase the partial pressure of oxygen, the gas may be provided at a pressure higher than atmospheric pressure, for example at a pressure of 0.2, 0.5, 1.0, 2.0 or 5.0 bar above atmospheric pressure.

[0023] Preferably,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com