Bottom unified aqueous anticorrosive paint and preparation method

A kind of anti-corrosion paint, water-based technology, applied in the direction of anti-corrosion paint, coating, etc., can solve the problems of heavy smell and high pollution of oil-based paint, and achieve the effect of solving heavy smell, good mixing, and simple preparation and construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

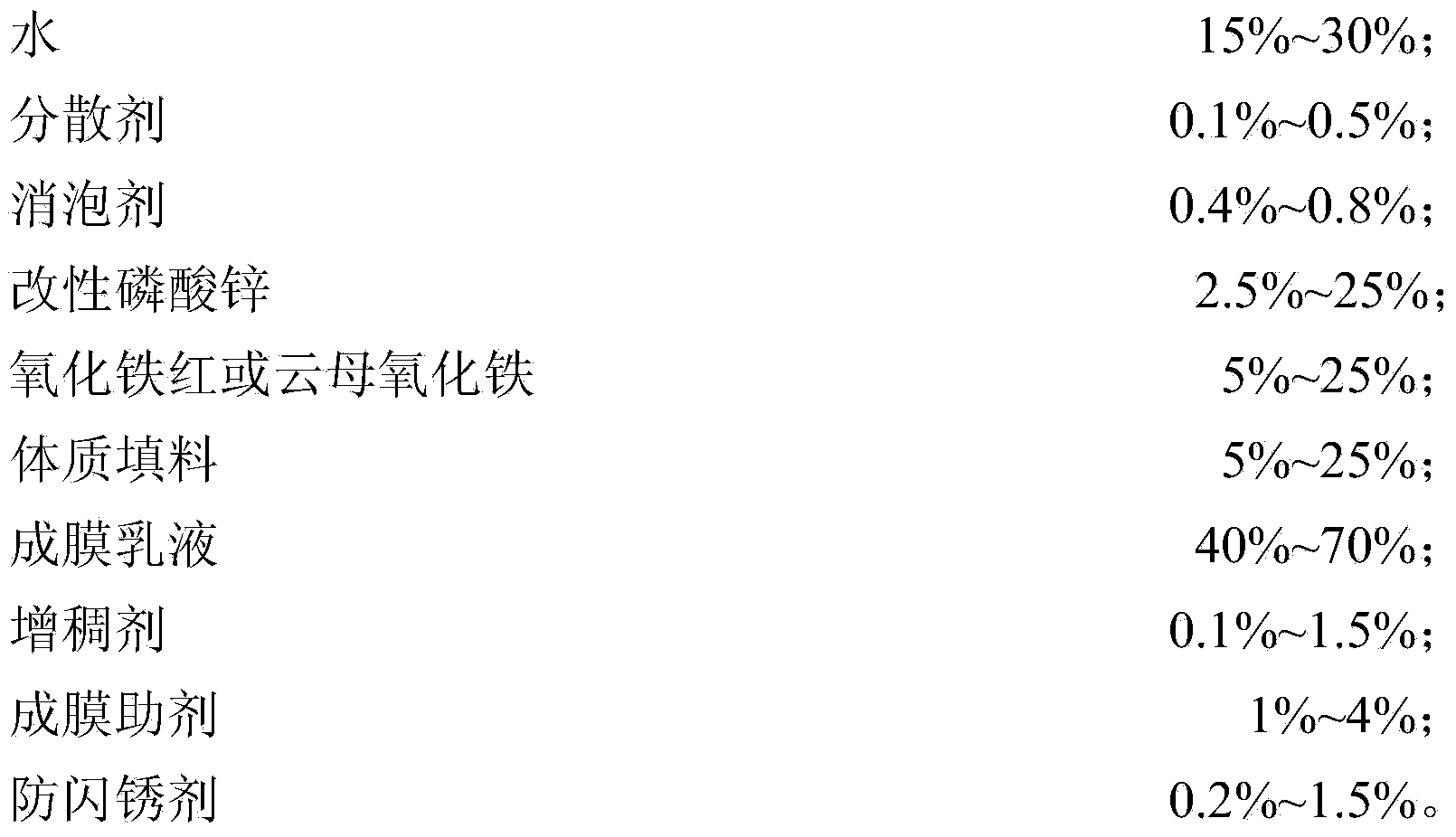

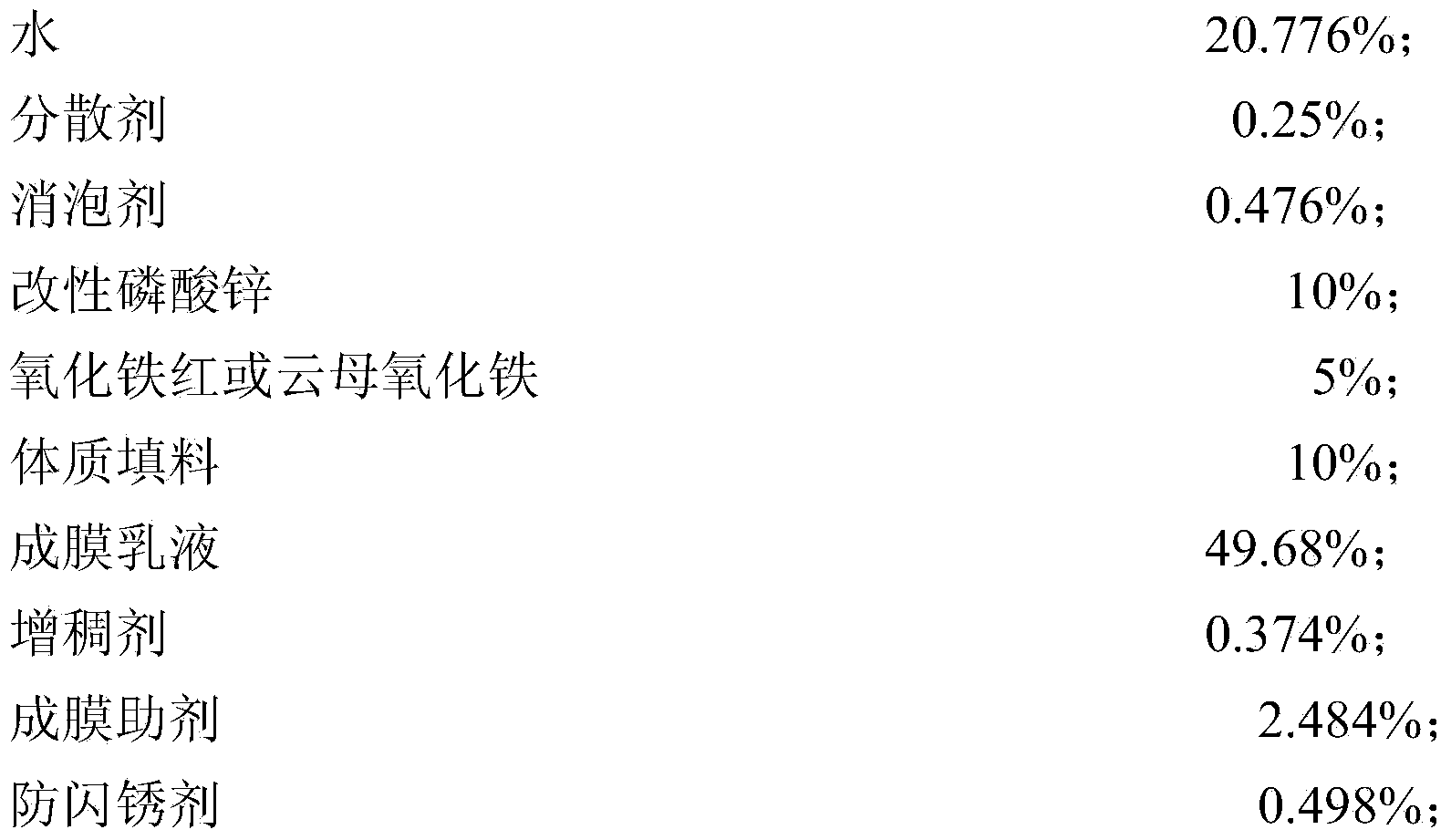

Method used

Image

Examples

Embodiment 1

[0040] Prepare 1000g of the bottom surface of the present invention in one water-based anti-corrosion coating, realize by following process: Add 2.0g dispersant, 1.76g defoamer, 4.62g pH regulator in 192.3g water successively and stir 20min with 500rmp low speed with disperser, make dispersant Distribute evenly in water. Add 100.00g of kaolin, 25.00g of modified zinc phosphate and 50.00g of red iron oxide into the solution, stir with a disperser at a high speed of 1000rmp for 30 minutes, reduce the dispersion rate after the dispersion is uniform, add 589.55g of styrene-acrylic emulsion, and add film-forming 27.98g of additives, 4.98g of anti-flash rust agent and 3.74g of thickener were stirred at 500rmp at a low speed for 10 minutes to make the viscosity reach 100-105KU, and finally 3g of defoamer was added to obtain the bottom-surface-integrated water-based anti-corrosion coating.

Embodiment 2

[0042] Prepare 1000g of the bottom surface of the present invention in one water-based anti-corrosion coating, realize by following process: Add 2.0g dispersant, 1.76g defoamer, 4.62g pH regulator in 192.3g water successively and stir 20min with 500rmp low speed with disperser, make dispersant Distribute evenly in water. Add 100.00g of kaolin, 50.00g of modified zinc phosphate and 50.00g of red iron oxide into the solution, stir with a disperser at a high speed of 1000rmp for 30 minutes, reduce the dispersion rate after the dispersion is uniform, add 559.62g of styrene-acrylic emulsion, and add film forming after the dispersion is uniform 27.98g of additives, 4.98g of anti-flash rust agent and 3.74g of thickener were stirred at 500rmp at a low speed for 10 minutes to make the viscosity reach 100-105KU, and finally 3g of defoamer was added to obtain the bottom-surface-integrated water-based anti-corrosion coating.

Embodiment 3

[0044] Prepare 1000g of the bottom surface of the present invention in one water-based anti-corrosion coating, realize by the following process: add 2.25g dispersant, 1.76g defoamer, 4.62g pH regulator in 199.94g water successively and stir 20min with disperser at 500rmp low speed, make dispersant Distribute evenly in water. Add 100.00g of kaolin, 75.00g of modified zinc phosphate and 50.00g of red iron oxide into the solution, stir with a disperser at a high speed of 1000rmp for 30 minutes, reduce the dispersion rate after the dispersion is uniform, add 528.3g of styrene-acrylic emulsion, and add film forming after the dispersion is uniform 26.41g of additives, 4.98g of anti-flash rust agent and 3.74g of thickener were stirred at 500rmp at a low speed for 10 minutes to make the viscosity reach 100-105KU, and finally 3g of defoamer was added to obtain the bottom-surface-integrated water-based anti-corrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com