Aqueous anticorrosive heat-insulation paint and preparation method

A heat-insulating paint, water-based technology, applied in anti-corrosion paints, reflective/signal paints, coatings, etc., can solve the problems of poor inter-layer matching of multi-coating systems, traditional oil-based paints with heavy odor and long construction period, etc. Construction and color matching, good cost performance, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are to further illustrate the present invention, but not to limit the scope of the present invention.

[0032] 1. Preparation of water-based anti-corrosion and heat-insulating coating:

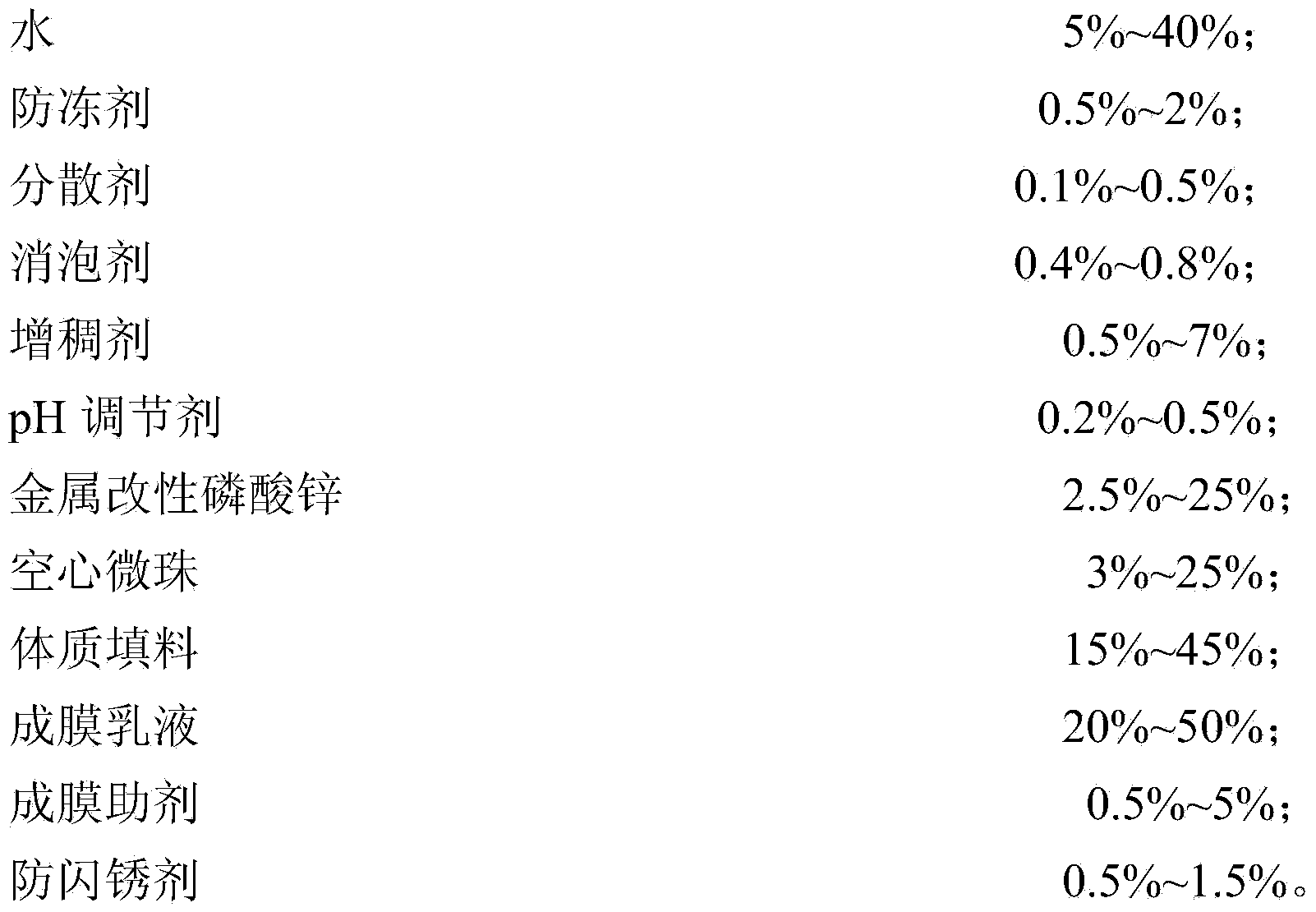

[0033] Add antifreeze, dispersant, and pH regulator to the water first, and use a disperser to stir at a low speed of 500rmp for 20 minutes to obtain a dispersion. Add metal-modified zinc phosphate and fillers to the dispersion to obtain the first material liquid. Stir at a high speed of 1000rmp for 30 minutes, and add hollow microspheres and 1 / 2 amount of defoamer to obtain the second feed liquid, and finally add film-forming emulsion, film-forming aids, anti-flash rust agent and enhancer to the second feed liquid. Thickener, stir at 500rmp at a low speed for 10 minutes, and finally add the remaining 1 / 2 amount of defoamer to obtain a water-based anti-corrosion and heat-insulating coating.

[0034]Table 1 Composition of water-based anticorrosion and heat insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com