Array type continuously-flowing microfluidic chip device and manufacture method and application thereof

A microfluidic chip, microchip technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve complex and expensive external equipment reaction reagents, unable to deliver fresh reaction solution in time, etc. problem, to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1. Fabrication of array type continuous flow microfluidic chip device

[0048] (1) Fabrication of six-channel synthesis reaction microchip

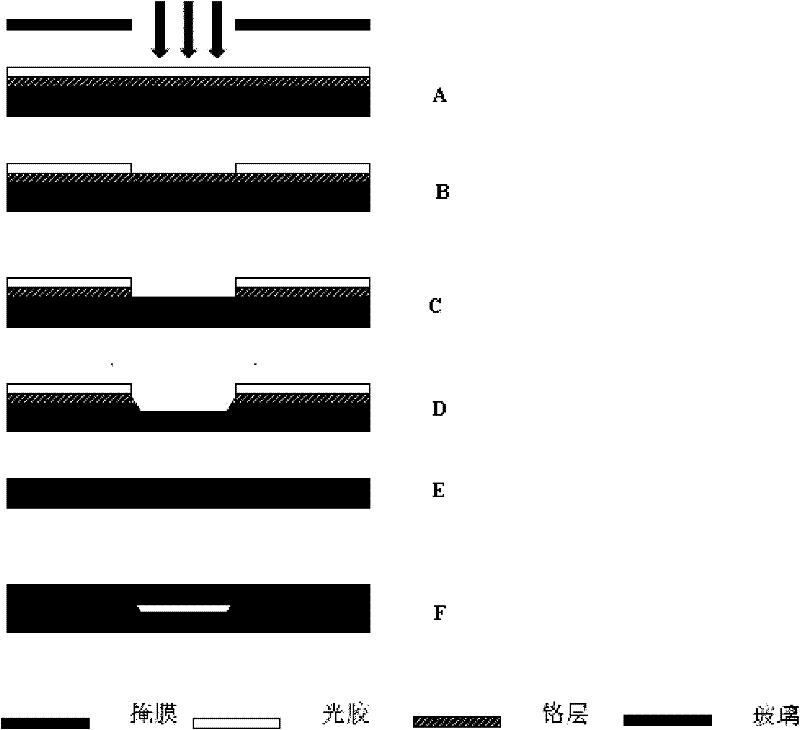

[0049] The manufacturing process of the six-channel synthesis reaction microchip is as follows image 3 As shown, step A represents an exposure step, step B represents a development step, step C represents a chromium removal step, step D represents an etching step, step E represents a photoresist and chromium removal step, and step F represents a bonding step.

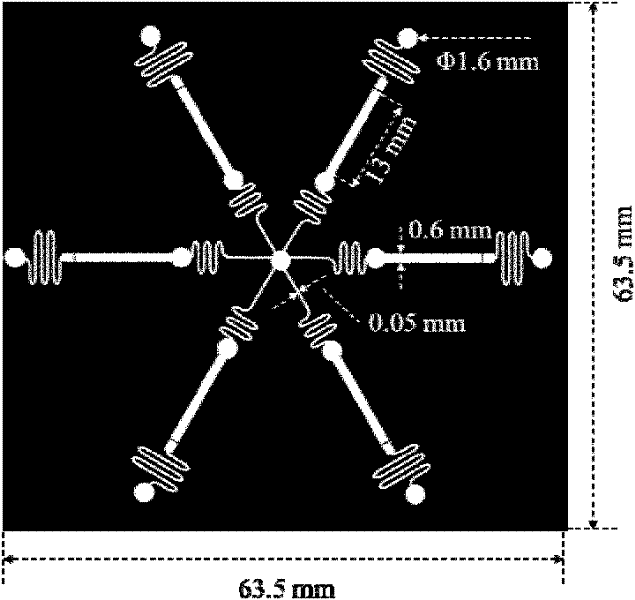

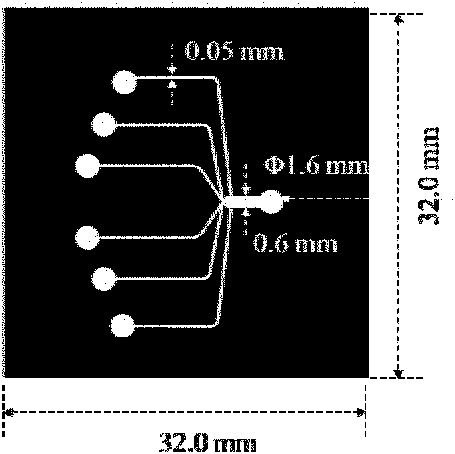

[0050] The microchannel size design of the synthetic reaction microchip is as follows figure 1 As shown, the designed synthetic reaction microchip pattern is made into a film mask by laser phototypesetting; the film mask is covered on a 63.5mm×63.5mm×1.5mm homogenous chrome plate (chrome type: LRC; chrome thickness: 145nm; glue thickness: 570nm), exposed to UV light (365nm) for 8 seconds; the exposed chromium plate is developed in a 0.7% NaOH aqueous solution by mass, and ...

Embodiment 2

[0061] Example 2. Using the continuous flow microfluidic chip device made in Example 1 to perform the peptide synthesis reaction of each reaction unit

[0062] (1) Preparation of solid phase carrier

[0063] The carrier resin used in solid-phase peptide synthesis in conventional containers has a relatively low degree of cross-linking and swells in an organic solvent atmosphere. If the swollen resin is filled into the reaction chamber of the microfluidic chip, it will deform and block the microchannel. Therefore, the highly cross-linked rigid carrier microspheres suitable for the microfluidic chip device of the present invention are prepared by the seed one-step swelling polymerization method, and the specific preparation method is as follows:

[0064] a. Preparation of polyethylene (PS) seeds: According to literature (Macromolecules, 1990, 23, 3104-3109.), PS seeds with a particle size of about 10 μm were prepared.

[0065] b. The oil phase of the reaction system includes 2.5 mL of 4...

Embodiment 3

[0085] Example 3. The Fmoc-Leu, Fomc-Ser and Fmoc-Phe modified solid-phase peptide synthesis carriers prepared in Example 2 were used as solid-phase carriers, and the continuous flow microfluidic chip device made in Example 1 was used for integrated solidification. Phase peptide synthesis reaction

[0086] (1) According to the method reported in the literature (Combinatorial Chemistry, Oxford University Press, 1998, ch. 3, pp. 42-43.), six kinds of anti-β-endorphin 3E7 mAb affinity peptide library with higher affinity activity were synthesized Polypeptides YGAFLS (AR1), YGAFS (AR2), YGAFL (AR3), YGGFLS (AR4), YGAF (AR5) and YGALS (AR6).

[0087] The specific synthesis steps are as follows:

[0088] a. Use a precision syringe pump to push a 1mL syringe through the sub-injection port 3 to inject the hydroxymethyl phenol methyl polystyrene resin microspheres prepared in Example 2 dispersed in DMF into the reaction chamber 4 respectively. The cavity 4 is filled with six resins prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com