All-glass vacuum heat collection pipe with regular prism-shaped inner pipe and production method thereof

A technology for vacuum heat collecting tubes and manufacturing methods, which is applied to glass manufacturing equipment, glass forming, glass reshaping, etc., and can solve the problem of uneven wall thickness at the sealing line, uneven wall thickness of the semicircular spherical surface, and heat collection effect. Unsatisfactory and other problems, to achieve the effect of improving technical performance indicators, reducing the water capacity of the inner pipe, and smooth transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

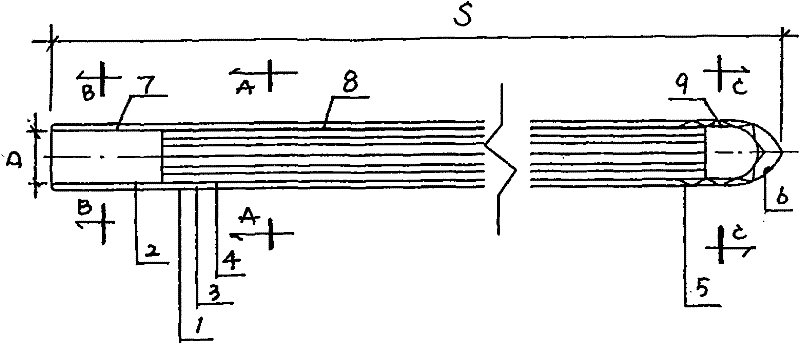

[0020] Further explain in detail in conjunction with accompanying drawings;

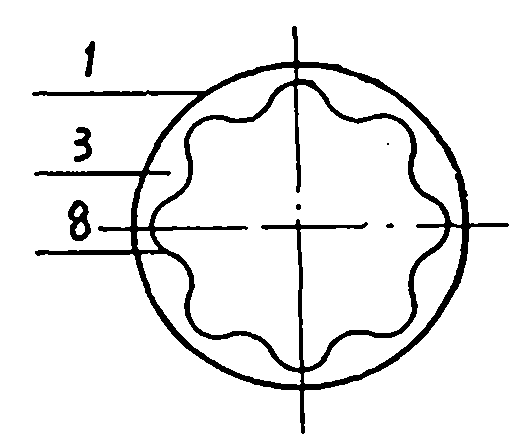

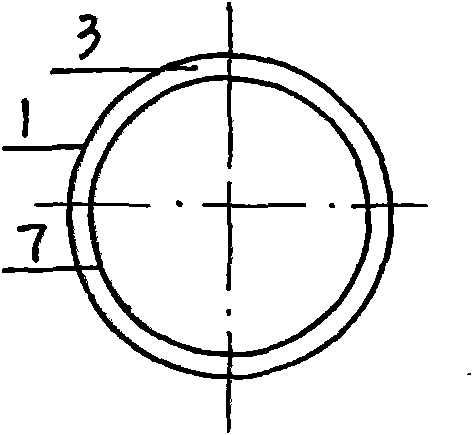

[0021] Such as Figure 1~4 As shown, the all-glass vacuum heat-collecting tube with a positive prism-type inner tube has the basic structural composition of a conventional all-glass vacuum heat-collecting tube, including an outer tube 1, an inner tube 2, a vacuum chamber 3 composed of an inner and outer tube, and a coating on the outer wall of the inner tube. The coated selective absorption coating 4, the steel card 5 and the getter mirror 6 installed in the vacuum chamber; the inner tube 2 is composed of a left section 7, a middle section 8, and a right section 9 that are coaxial and continuous with each other, and the middle section 8 is a regular prism Type structure, its radial cross-section is a regular polygonal cross-section, the regular polygonal cross-section has the largest geometric outer diameter D; the right section 9 that is continuous with the middle section 8 coaxially transitioning t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com