A gas-controlled solid-phase polypeptide synthesis microfluidic chip device and its application

A solid-phase peptide synthesis and microfluidic chip technology, which is applied in peptides, peptide preparation methods, chemical/physical/physicochemical processes, etc., can solve problems such as difficult direct application, achieve low cost, and realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

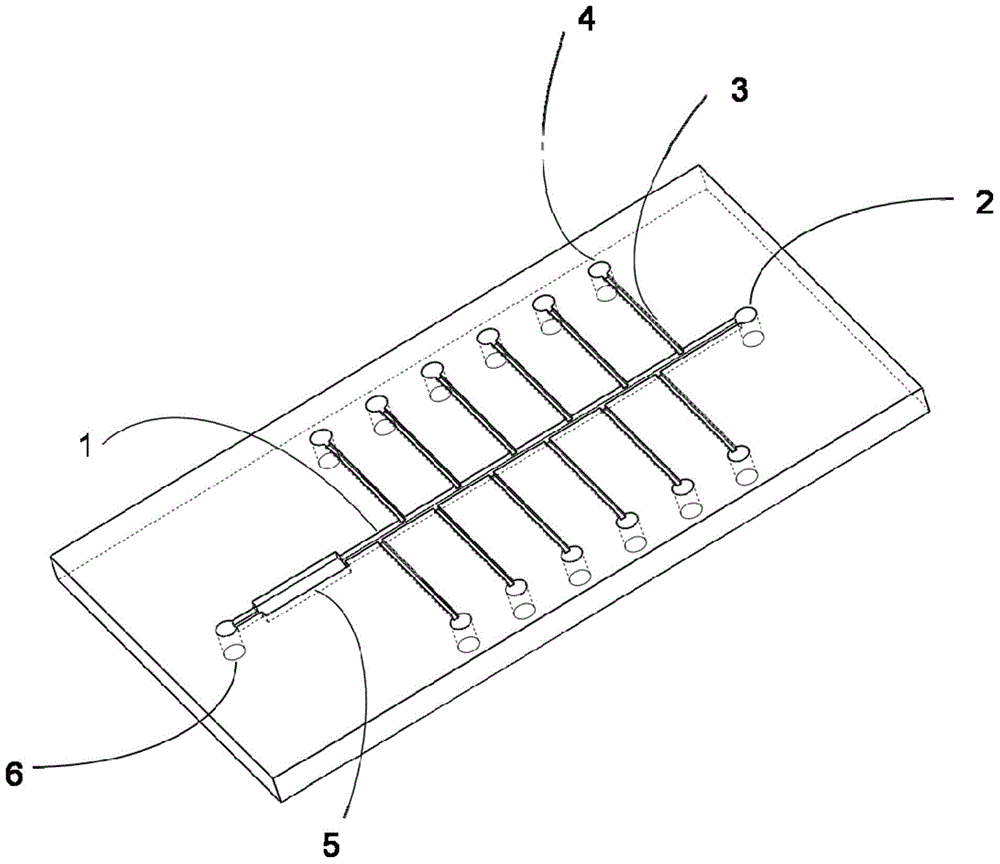

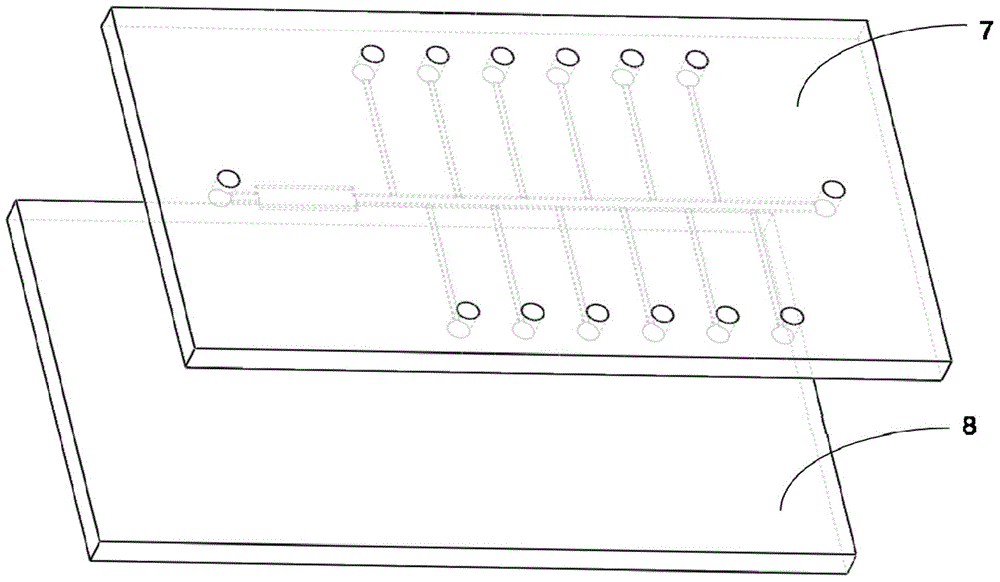

[0060] Example 1, Fabrication of gas-controlled solid-phase polypeptide synthesis microfluidic chip device

[0061] (1) Fabrication of synthetic reaction microfluidic chip

[0062] The production process of the synthetic reaction microfluidic chip includes: exposure, development, chromium removal, glass wet etching, delustering glue, chrome removal and bonding steps, as follows:

[0063]The pattern of the designed synthetic reaction microfluidic chip cover sheet is made into a film mask by a high-resolution printer; the film mask and the homogeneous chrome plate (chrome type: LRC; chrome thickness: 145nm; glue thickness: 570nm ) in a UV lithography machine with an exposure time of 5 seconds; the exposed chromium plate was developed in an aqueous solution of 0.7% by mass of NaOH, and the pattern on the mask was copied to the photoresist layer; Put the developed homogeneous chromium plate into the chromium removal solution (the mass-volume concentration of ammonium cerium nitra...

Embodiment 2

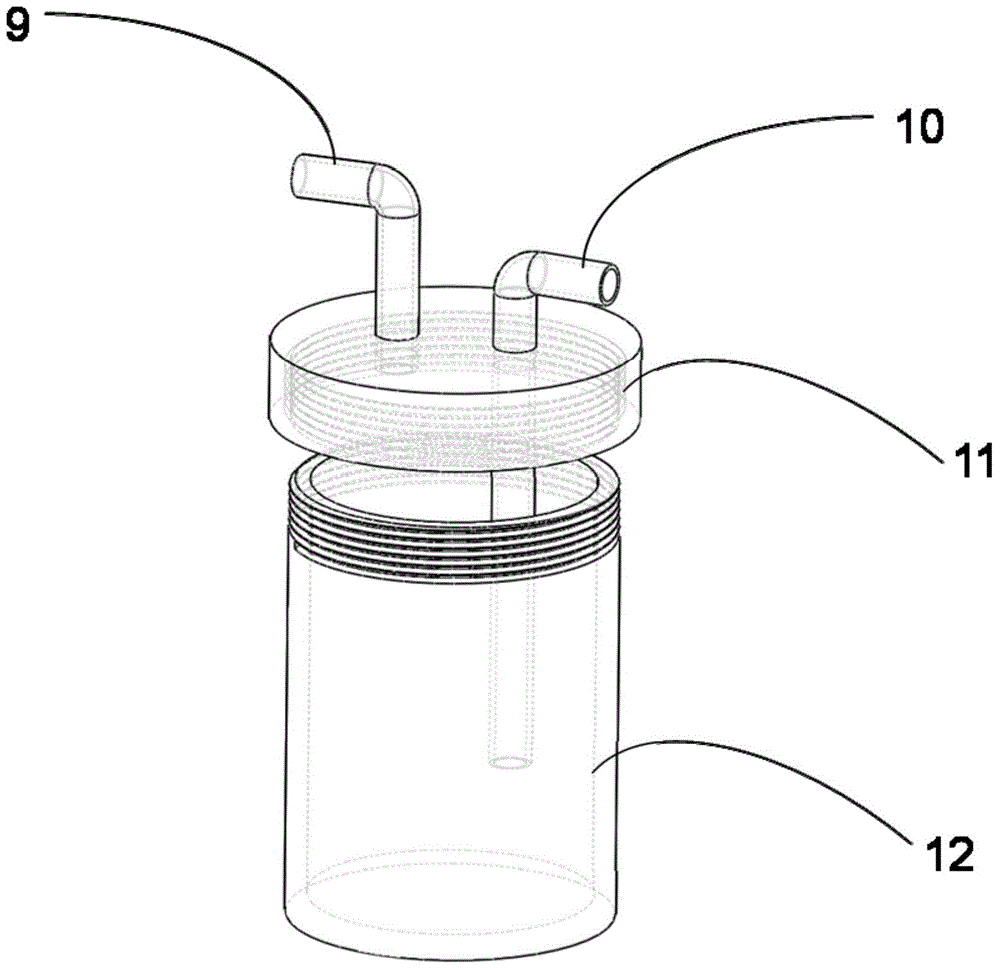

[0072] Example 2, using the device made in Example 1 to carry out solid-phase peptide synthesis

[0073] As the solid phase carrier, commercial Wang resin is selected, and the amino acid at the C-terminal of the polypeptide is connected to the resin in advance according to the sequence of the polypeptide to be synthesized. The polypeptide sequence to be synthesized in this example is Tyr-Gly-Gly-Phe-Leu. In this example, a commercially available Fmoc-Leu modified solid-phase peptide synthesis carrier was used as the solid-phase carrier, and the peptide was synthesized using the air-controlled solid-phase peptide synthesis microfluidic chip device prepared in Example 1.

[0074] Concrete synthetic steps are as follows:

[0075] a. This step is a manual operation step, and the synthetic carrier is loaded. Use a syringe to pour Fmoc-Leu-modified solid-phase peptide synthesis carrier (resin) dispersed in N'N-dimethylformamide (DMF) into the reaction cavity from the main injectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com