Method for removing surface coating of reflective PET (Polyethylene Terephthalate) aluminium plating film

A technology of surface coating and reflective film, applied in the field of removing the surface coating of PET aluminized reflective film, can solve the problems of PET's "yellowing, power consumption, increased white pollutant emissions, etc., to achieve recycling and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

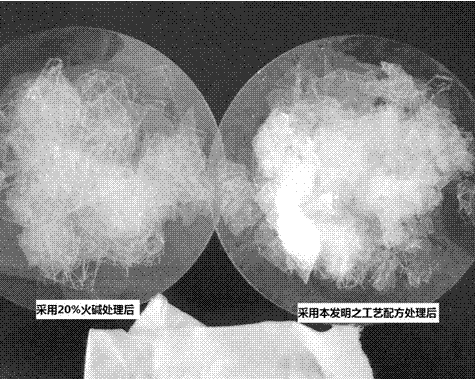

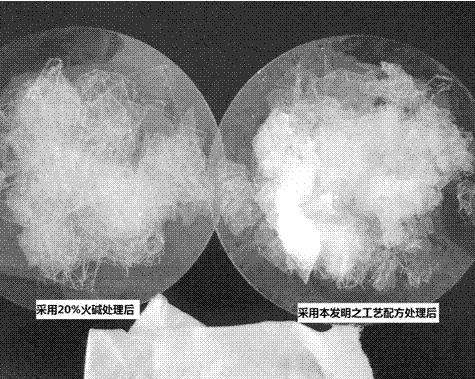

Image

Examples

Embodiment 1

[0042] ① Prepare cleaning solution. First mix chlorobenzene with water, then add sodium hydroxide, sodium dodecylbenzene sulfonate and sodium carbonate and mix them uniformly to prepare a cleaning solution. Wherein the mass concentration of sodium hydroxide is 10 grams / L; The volume percentage of chlorobenzene is 40%, and the mass concentration of sodium dodecylbenzenesulfonate is 5 grams / L; The mass concentration of sodium carbonate is 5 grams / L;

[0043]② Cut the PET aluminized reflective film into pieces, put it into a reactor with a heating device, add the cleaning solution prepared in step ① into the reactor, and completely immerse the diaphragm. The quality of the PET aluminized reflective film is the same as that of the cleaning solution used. The ratio of volume (plasmid ratio g / mL) is 2:1;

[0044] ③ Turn on the heating device, heat with a medium with a temperature of 80°C, and heat at 80°C for 4 hours;

[0045] ④ After the material in the reactor is lowered to ...

Embodiment 2

[0048] ① Prepare cleaning solution. First mix ethanol and water, then add potassium hydroxide, sodium lauryl sulfate and potassium carbonate and mix them uniformly to prepare a cleaning solution. Wherein the mass concentration of potassium hydroxide is 80 grams / L; The volume percentage of ethanol is 20%, and the mass concentration of sodium lauryl sulfate is 10 grams / L; The mass concentration of potassium carbonate is 10 grams / L;

[0049] ② Cut the PET aluminized reflective film into pieces, put it into a reactor with a heating device, add the cleaning solution prepared in step ① into the reactor, and completely immerse the diaphragm. The quality of the PET aluminized reflective film is the same as that of the cleaning solution used. The ratio of volume (plasmid ratio g / mL) is 1:1;

[0050] ③ Turn on the heating device, heat with a medium with a temperature of 60°C, and heat at 60°C for 8 hours;

[0051] ④ After the material in the reactor is lowered to room temperature, tak...

Embodiment 3

[0054] ① Prepare cleaning solution. Firstly mix ethylene glycol with water, then add lithium hydroxide, methyl silicone oil and sodium silicate and mix evenly to prepare the cleaning solution. Wherein the mass concentration of lithium hydroxide is 40 grams / L; The volume percentage of ethylene glycol is 10%, and the mass concentration of methyl silicone oil is 1 gram / L; The mass concentration of sodium silicate is 1 gram / L;

[0055] ② Cut the PET aluminized reflective film into pieces, put it into a reactor with a heating device, add the cleaning solution prepared in step ① into the reactor, and completely immerse the diaphragm. The quality of the PET aluminized reflective film is the same as that of the cleaning solution used. The ratio of volume (plasmid ratio g / mL) is 3:2;

[0056] ③ Turn on the heating device, heat with a medium with a temperature of 40°C, and heat at 40°C for 10 hours;

[0057] ④ After the material in the reactor is lowered to room temperature, take out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com