Method for preparing tea seed oil in low-temperature cold pressing manner

A technology of tea seed oil and cold-pressed oil, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problems of large differences in oil composition and active components, ordinary oil presses cannot operate normally, and shelling and difficulty in separating shell and kernel to achieve the effect of reducing energy consumption, large mechanical wear and low oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

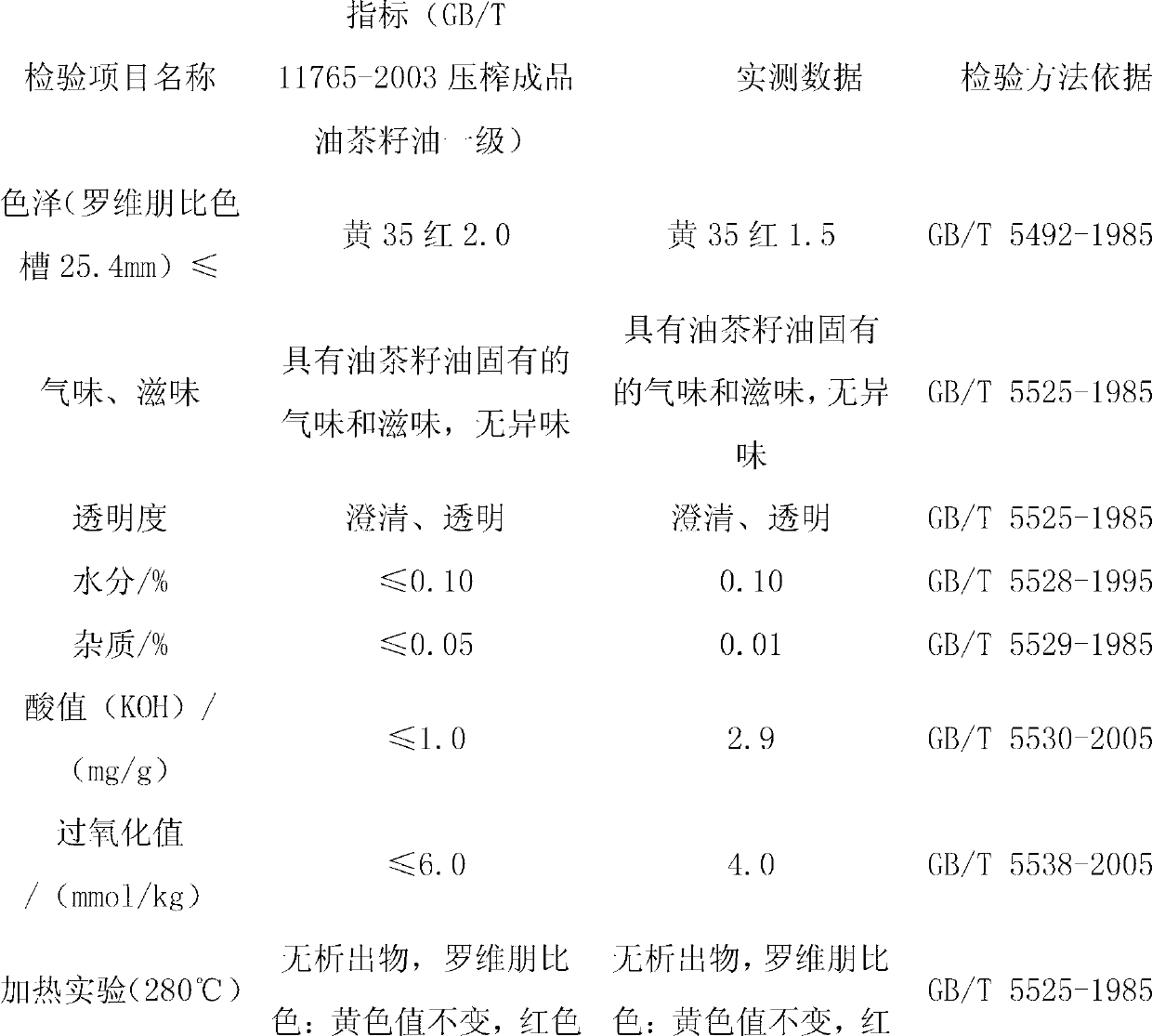

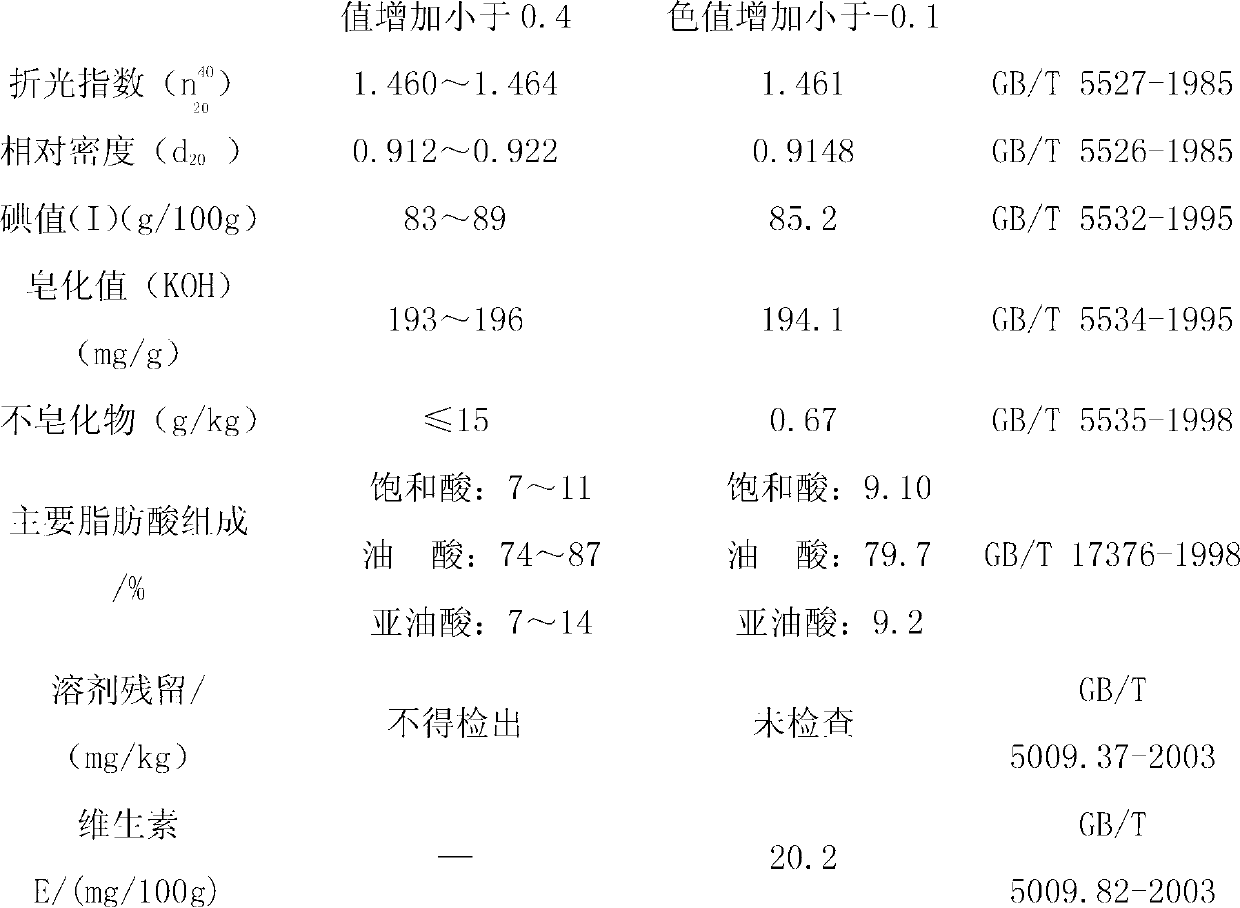

[0025] Take the production of 100kg tea seed oil as an example.

[0026] (1) Dry the collected Camellia oleifera cones naturally, break the shell, take out the camellia oleifera seeds and dry them in the sun, store them in a low temperature environment of 0-5°C for a period of time, let them ripen naturally, and then clean the moldy tea seeds, moisture Content 7%-10%;

[0027] (2) take by weighing 600kg the tea seed after screening, carry out dehulling and separation by the tea seed peeling and separating machine, require husk content 10% in the seed kernel;

[0028] (3) Put the separated tea seed kernels into a twin-screw oil press, press the oil at a low temperature between -10°C and 40°C, and control the temperature of the cake outlet at 40°C to 60°C to achieve normal temperature oil pressing , to obtain cold-pressed crude oil, screw speed 35-40r / min, feed rate 80-100kg / h;

[0029] Crude oil filtration: The crude oil is filtered twice with a closed filter and a bag filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com