Long life and energy saving single stage centrifugal pump

A centrifugal pump, single-stage technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of large force on the fulcrum rolling bearing, wear of the impeller and sealing ring, and short service life of the bearing, so as to reduce the sealing pressure and shaft. The effect of force and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to illustrate the embodiments of the present invention or the technical solutions in the prior art more clearly, the embodiments and the accompanying drawings will be briefly introduced below. Obviously, the accompanying drawings in the following description are only some embodiments, which are common to those skilled in the art. As far as technical personnel are concerned, other drawings can also be obtained under the premise of not paying creative labor.

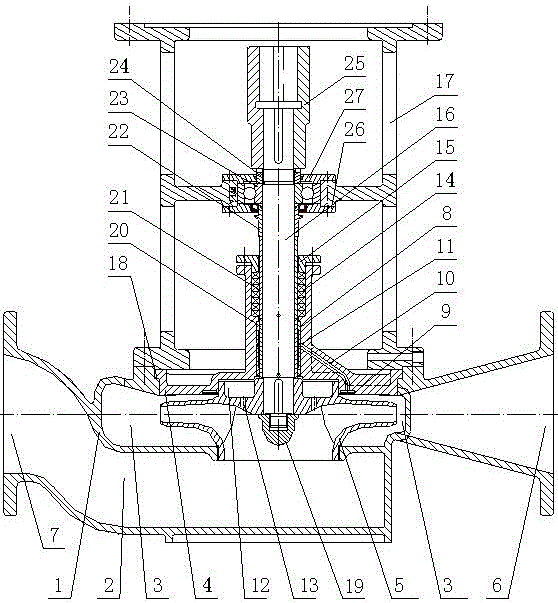

[0032] Such as figure 1 As shown, a long-life energy-saving single-stage centrifugal pump includes a pump body 1, a pump suction chamber 2, a pump discharge chamber 3, and a pump cover 4. The lower part of the pump body 1 is the pump suction chamber 2, and the upper part is the pump. The pressure chamber 3, the pump cover 4, and the impeller 5, the pump cover 4 covers the upper part of the pressure chamber 3 of the pump, and the impeller 5 rotates at a high speed in the pressure chamber 3 of the pump, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com