Preparation method of 6-bromine-2-pyridine methyl formate

A technology of methyl picolinate and picolinic acid, which is applied in the field of preparation of methyl 6-bromo-2-picolinate, can solve the problems of not being suitable for large-scale industrial production, insufficient product purity, troublesome post-processing, etc. The effect of preparation yield, less process pollution and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

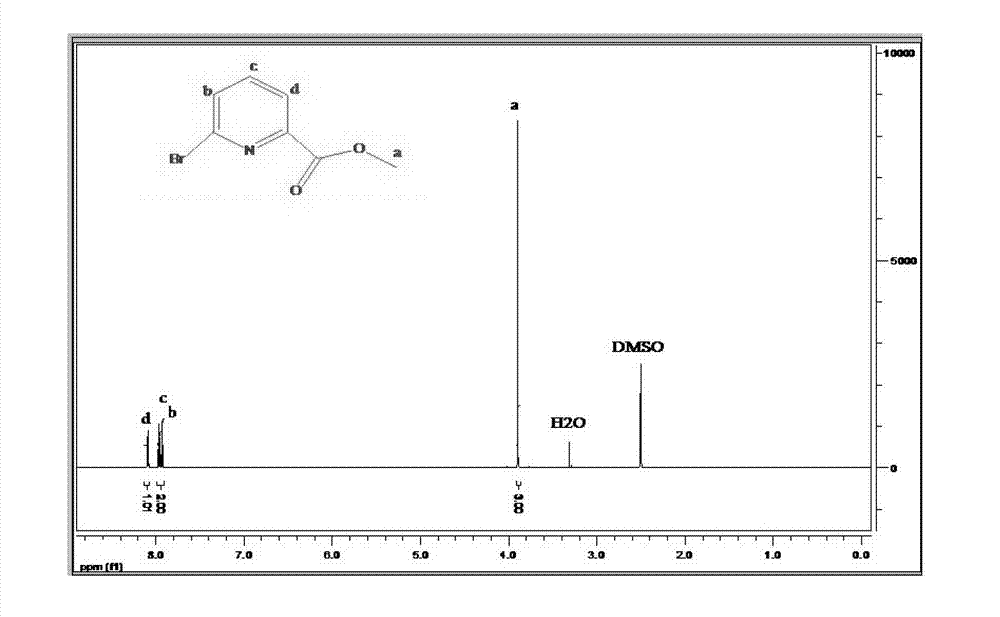

[0025] The preparation method of 6-bromo-2-picolinic acid methyl ester provided by the invention comprises:

[0026] Add anhydrous methanol, 6-bromo-2-pyridinecarboxylic acid and p-toluenesulfonic acid into the reaction vessel, wherein the molar ratio of 6-bromo-2-pyridinecarboxylic acid to anhydrous methanol is 1:40-60, 6-bromo-2-pyridinecarboxylic acid - The molar ratio of 2-pyridinecarboxylic acid to p-toluenesulfonic acid is 1:0.06-0.2, preferably 1:0.1-0.16, heated to reflux under stirring for 2-8 hours, preferably refluxed for 4-6 hours, stop heating after the reaction is completed, continue Stir to cool to room temperature.

[0027] After the reaction system is spin-dried, the solid is dissolved in organic solvents such as ethyl acetate, dichloromethane or ether, washed with saturated sodium bicarbonate or sodium carbonate solution, and then washed with water for 2-3 times, and dried with a desiccant such as anhydrous Magnesium sulfate, sodium sulfate, calcium sulfate,...

Embodiment 1

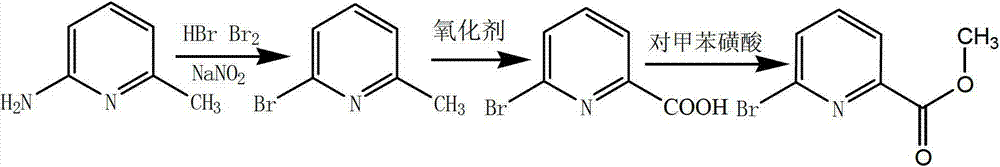

[0041] (1) Preparation of 6-bromo-2-methylpyridine

[0042] Add 46mL of hydrobromic acid with a concentration of 48% and 10.8g of analytically pure 2-amino-6-picoline into the reaction flask, slowly add 6.2mL of liquid bromine dropwise at -10°C, complete the dropwise addition for 0.5h, and react for 1.5h; At -10°C-0°C, 22.8 mL of aqueous sodium nitrite solution with a concentration of 25% by mass was added dropwise. After the dropwise addition was completed, the reaction was carried out at 15°C for 0.5 h; Reacted for 1 h, left to stand and separated, the aqueous phase was extracted 3 times with 200 mL of dichloromethane, the organic phases were combined, washed with water, the organic phase was concentrated, and distilled under reduced pressure to obtain 15.8 g of light yellow liquid with a calculated yield of 92%. The purity of 6-bromo-2-picoline product obtained by phase chromatography is 99.3%.

[0043] (2) Preparation of 6-bromo-2-pyridinecarboxylic acid

[0044] Add 15....

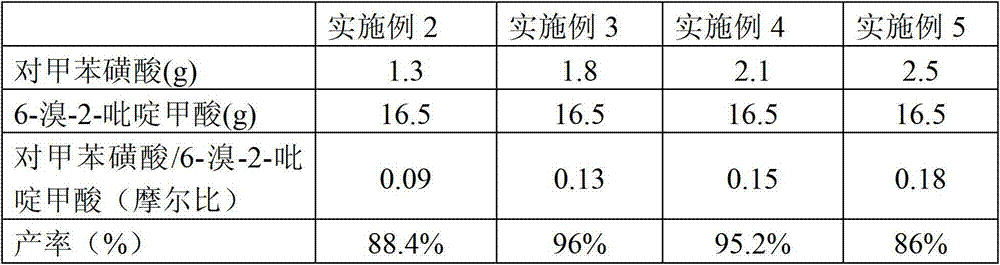

Embodiment 2-5

[0048] Embodiment 2-5 differs from Example 1 in that the molar ratio of p-toluenesulfonic acid and 6-bromo-2-pyridinecarboxylic acid is shown in Table 1 below, and other steps and conditions are the same as in Example 1, and the yield obtained They are listed in Table 1 respectively.

[0049] Table 1

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com