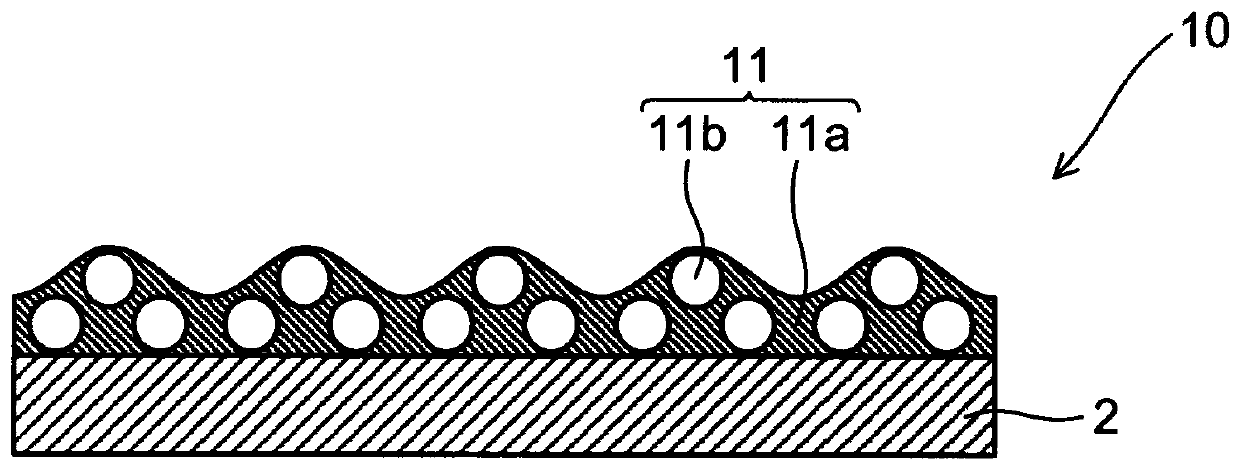

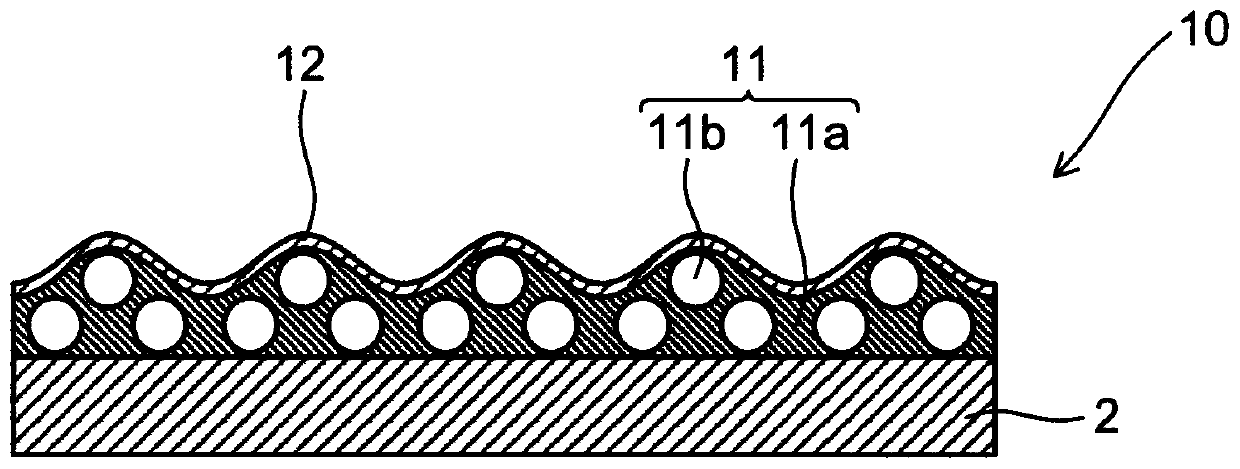

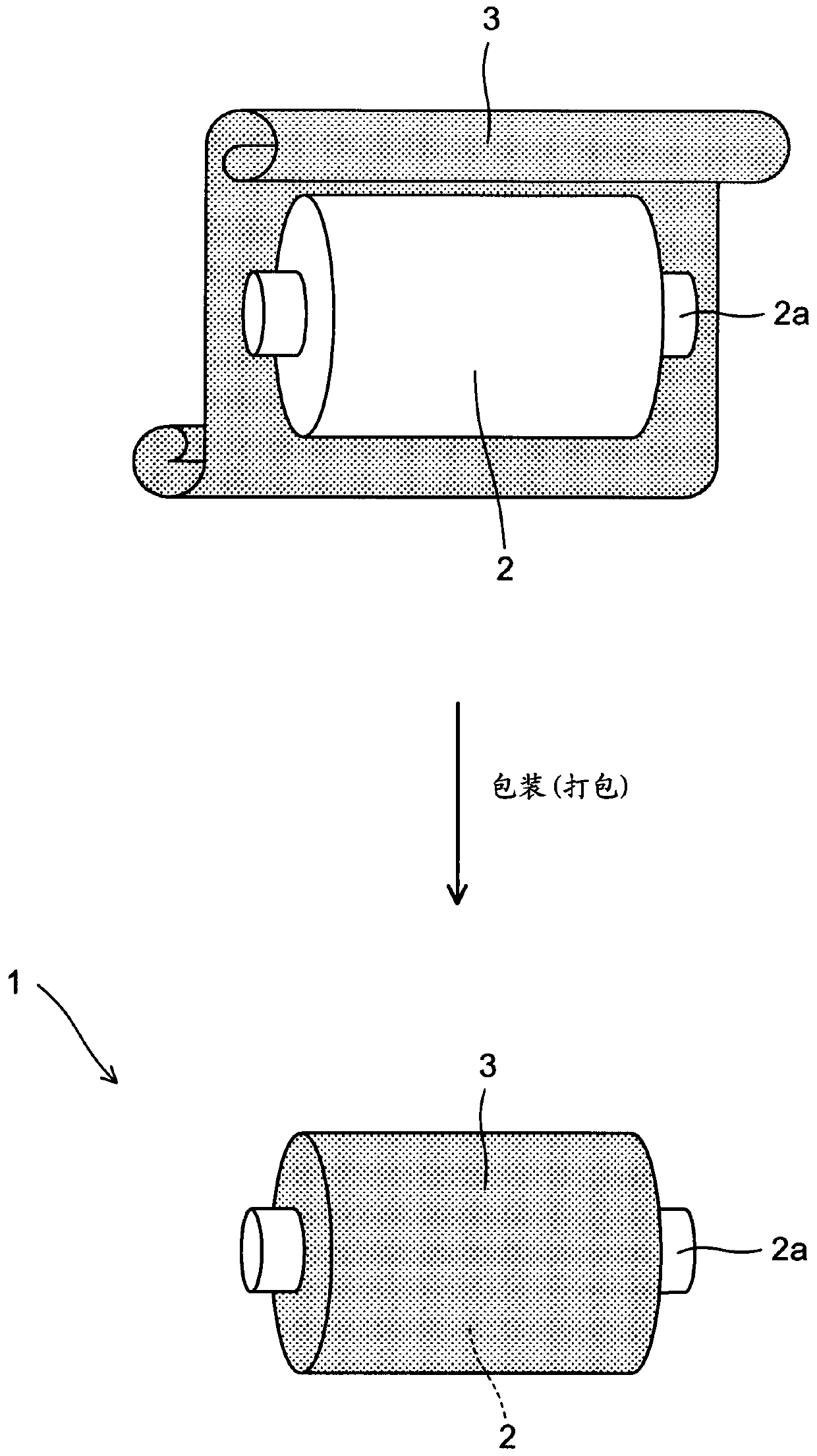

Film roll and method for manufacturing same

A technology of film roll and roll state, which is applied in packaging, coating, diffusion elements, etc., and can solve the problems of dimensional changes and pattern dimensional accuracy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0254] Hereinafter, the present invention will be specifically described with reference to examples, but the present invention is not limited to these examples. It should be noted that when the marks of "part" or "%" are used in the examples, they mean "parts by mass" or "% by mass" unless otherwise specified.

[0255] [Additives used in base film]

[0256]

[0257] 251g of 1,2-propanediol, 244g of phthalic anhydride, 103g of adipic acid, 610g of benzoic acid, and tetratitanate as an esterification catalyst were fed into a 2L four-necked flask equipped with a thermometer, a stirrer, and a spherical condenser. 0.191 g of isopropyl ester was slowly heated up to 230°C while stirring in a nitrogen stream. The dehydration condensation reaction was performed while observing the degree of polymerization. After completion of the reaction, unreacted 1,2-propanediol was distilled off under reduced pressure at 200° C. to obtain polycondensation ester compound M. At this time, the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com