Patents

Literature

37results about How to "Solve the problem of low quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

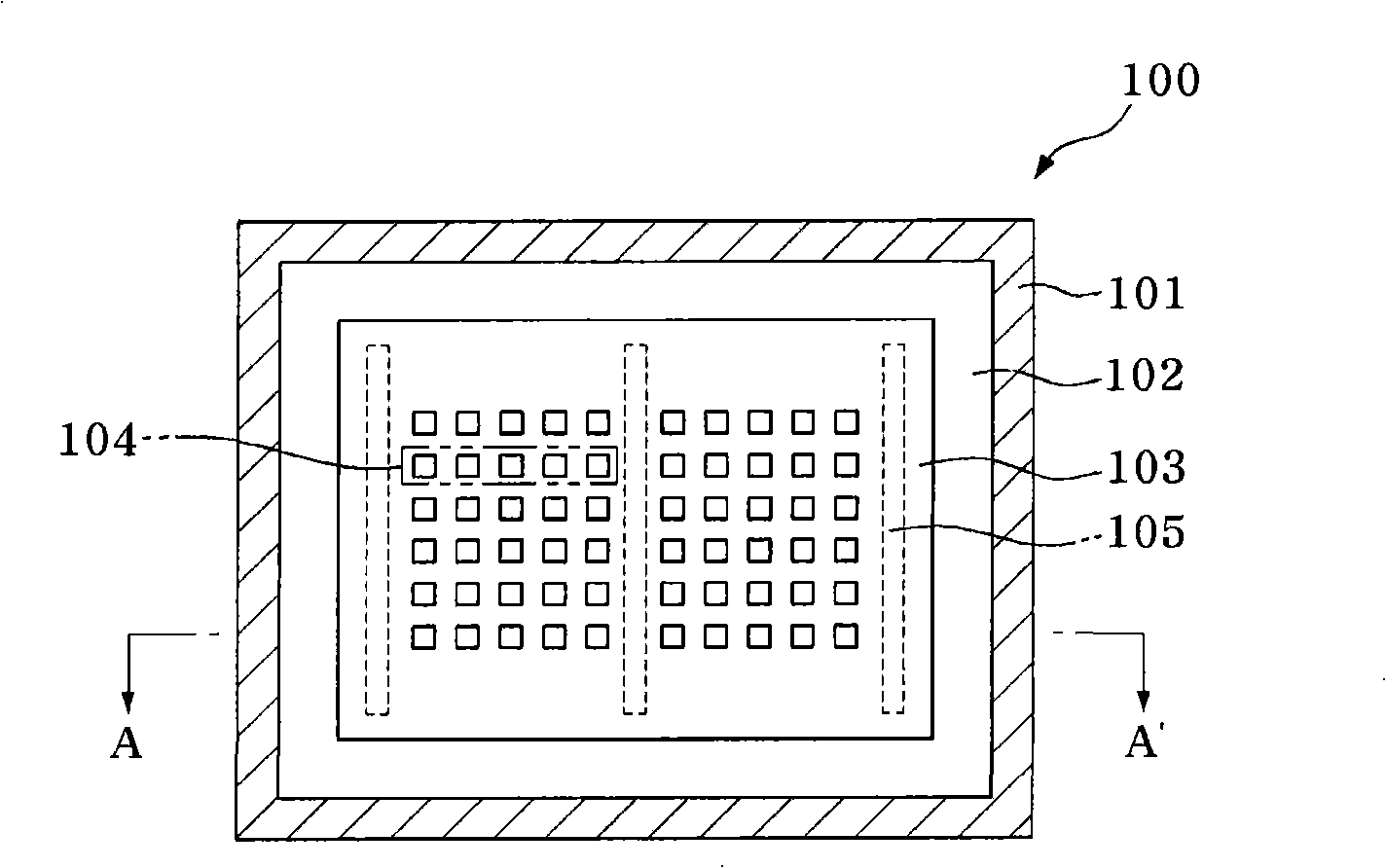

Mask for screen printing and screen printing method using the same

InactiveCN101352954ASolve the problem of low qualityPrinted circuit assemblingScreen printersScreen printingElectrical and Electronics engineering

This invention relates to a mask for screen printing, which includes a mask body composed of a plurality of pattern areas having holes for screen printing and a peripheral area surrounding the outside of the pattern areas; and a protrusion portion formed in the peripheral area of a back surface of the mask body, and to a screen printing method using the same.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

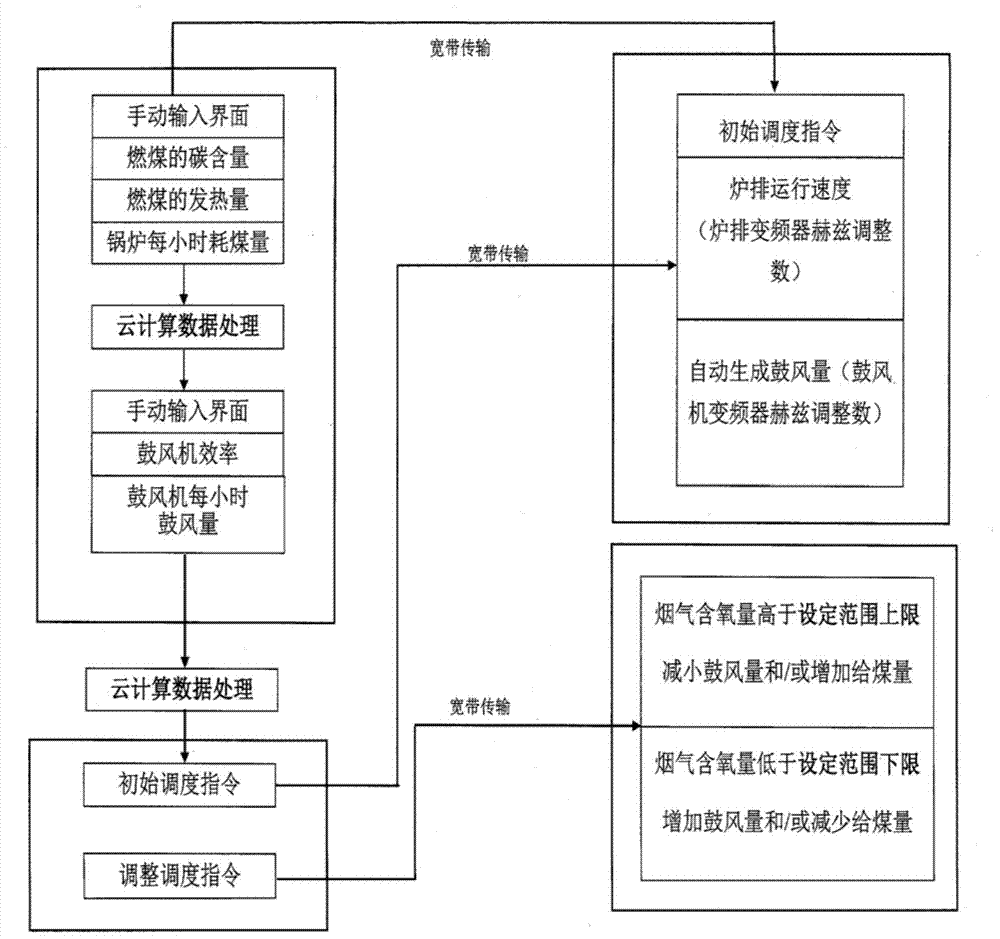

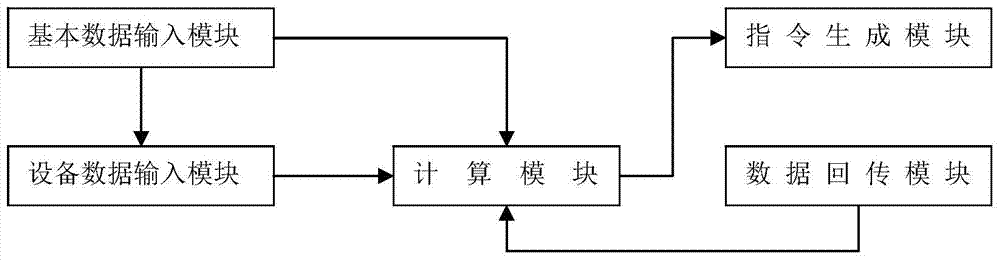

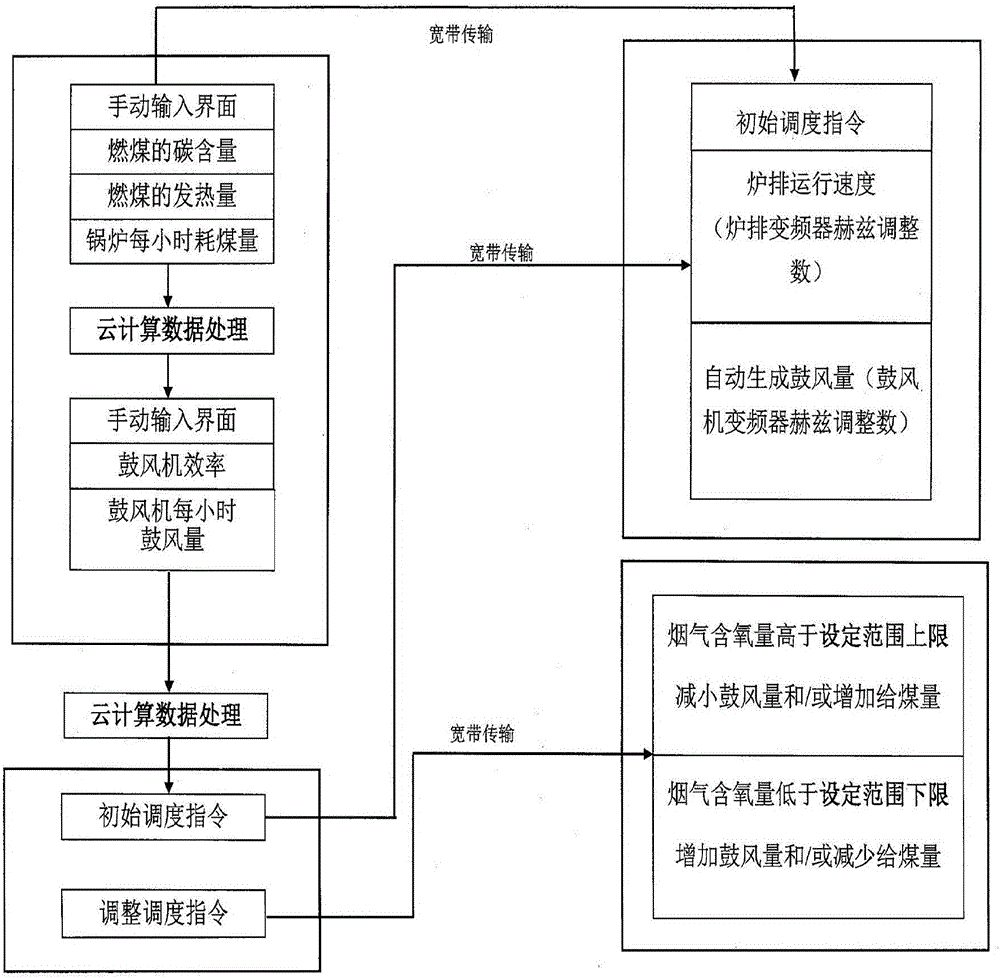

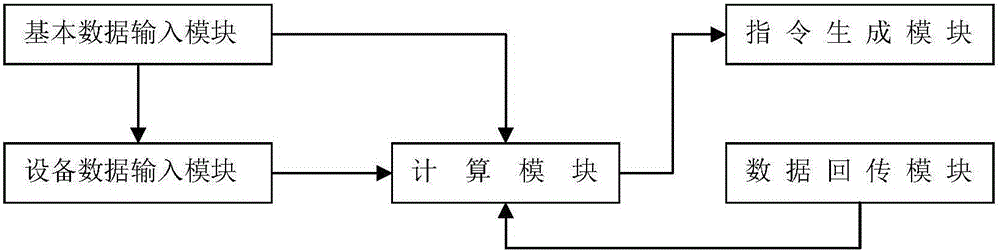

Energy saving control method and energy saving system for boiler automatic combustion

InactiveCN103486608ASolve the blast volumeSolve the technical problem that the oxygen content cannot be precisely controlledFuel supply regulationAir supply regulationAir volumeFlue gas

The invention discloses an energy saving control method and energy saving system for boiler automatic combustion. The energy saving control method and energy saving system for the boiler automatic combustion are used for a heating supply system. The control method comprises the first step that the flue gas oxygen content of the boiler of the heating supply system is detected, the second step that whether the detected flue gas oxygen content is within a setting range or not is judged, and the third step that if the detected flue gas oxygen content is not within the setting range, the blast volume of an air blower or the coal supply amount of a coal feeder of the heating supply system is controlled until the detecting value of the fuel gas oxygen content is within the setting range. According to the energy saving control method and energy saving system, the blast volume meets the requirement for the sufficient burning of fuel, the reduction of the temperature of a hearth cannot be caused by too many blast volumes, and therefore the boiler has the highest heat efficiency.

Owner:张久明

Synthesis technology for 2, 4, 6-trimethylbenzene acetyl chloride

ActiveCN102633626ASolve the problem of low qualitySimple methodOrganic compound preparationCarboxylic compound preparationDistilled oilOil phase

The invention relates to a synthesis technology for 2, 4, 6-trimethylbenzene acetyl chloride, comprising the following steps of: putting thionyl chloride, a catalyst and 2, 4, 6-trimethylbenzene acetic acid into a reaction kettle in batches, and controlling temperature to carry out reaction; and after the reaction, distilling (high vacuum) in a heating way in the reaction kettle, and acquiring a final product. The preparation method of the 2, 4, 6-trimethylbenzene acetic acid can comprise the following steps of: carrying out chloromethylation reaction by taking trimethylbenzene, formaldehyde and concentrated hydrochloric acid as raw materials, adding toluene to extract after reacting, and washing to obtain a toluene solution of 2, 4, 6-trimethyl benzyl chloride; taking the toluene solution of 2, 4, 6-trimethyl benzyl chloride and the sodium cyanide as raw materials, adding a phase transfer catalyst, reflowing in a heating way to carry out cyanation reaction, washing by adding water after reacting, distilling oil phase to recover toluene and mesitylene, and rectifying to obtain 2, 4, 6-trimethylbenzene acetonitrile; and hydrolyzing the 2, 4, 6-trimethylbenzene acetonitrile, centrifuging to obtain a 2, 4, 6-trimethylbenzeneacetic acid crude product, and optionally selecting and carrying out the aftertreatment to obtain the 2, 4, 6-trimethylbenzeneacetic acid. The content of the 2, 4, 6-trimethylbenzene acetyl chloride synthesized by the method disclosed by the invention is more than or equal to 98.0%, and the content of the 2, 4, 6-trimethylbenzene acetonitrile is less than or equal to 0.5%.

Owner:SUQIAN COSMOS CHEM +1

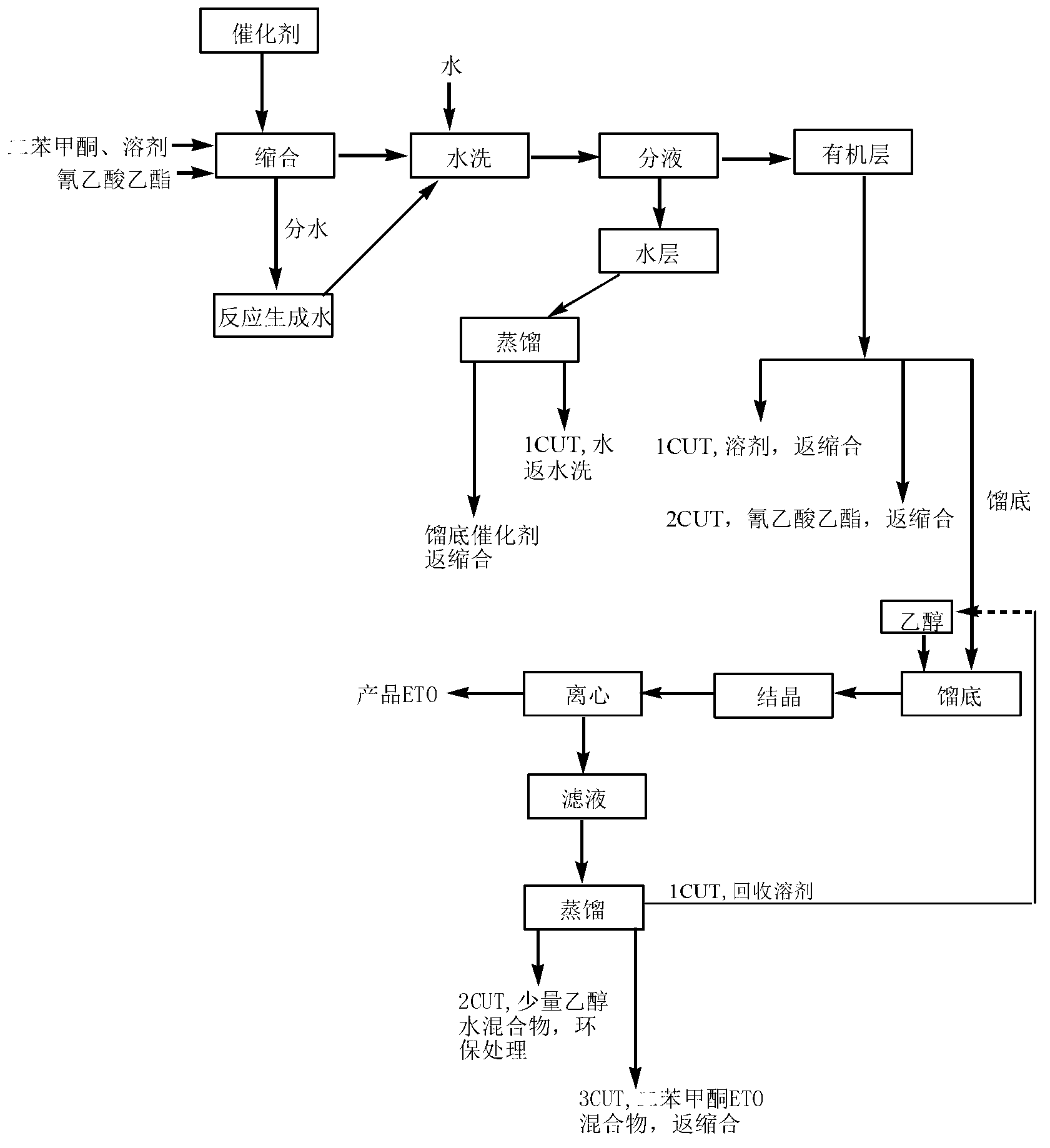

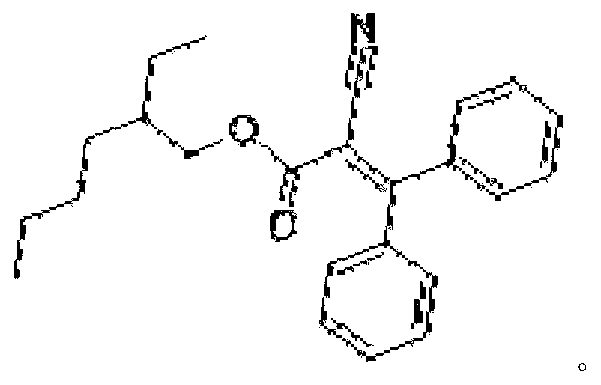

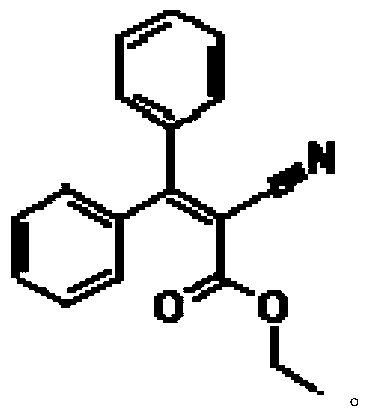

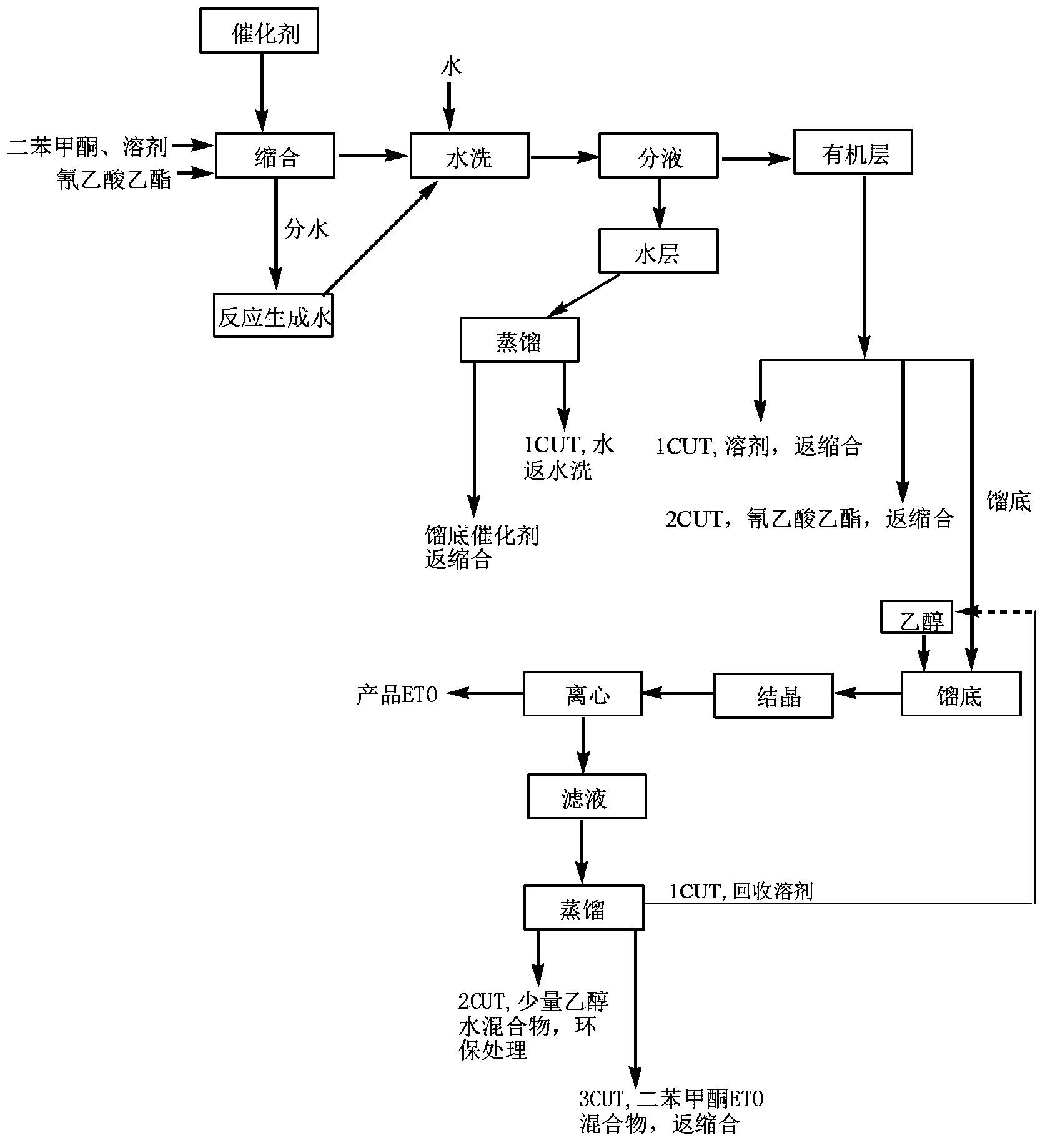

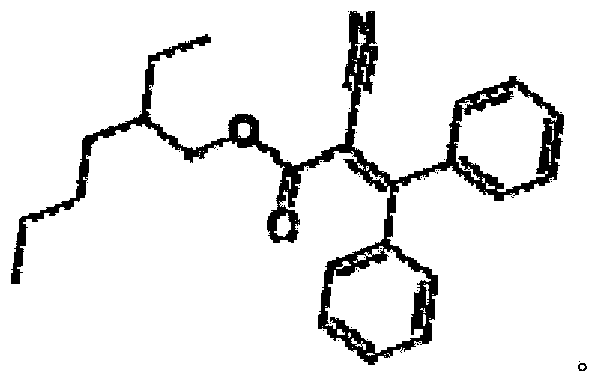

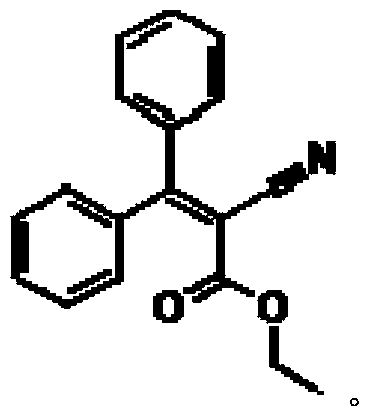

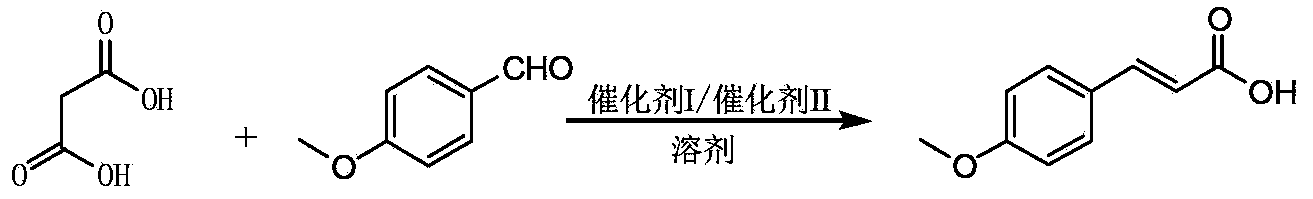

Preparation method of ultraviolet absorbent intermediate etocrilene (ETO)

ActiveCN103242197AHarm reductionReduce manufacturing costCarboxylic acid nitrile preparationOrganic compound preparationDistillationEthyl cyanoacetate

The invention relates to a preparation method of an ultraviolet absorbent intermediate etocrilene (ETO). The preparation method comprises the following steps of: 1, adding benzophenone, ethyl cyanoacetate, a catalyst and a water-insoluble solvent into a condensation reaction kettle, carrying out backflow water distribution reaction for 12-15h, and then, cooling to 50-55 DEG C, wherein the excessive equivalent of the ethyl cyanoacetate relative to the benzophenone is 0.2-5; 2, washing the reaction liquid by using water, and separating the liquid to respectively obtain a water layer and an organic layer; distilling the recycled water at the water layer at normal pressure, dissolving distillation tailings by using a solvent same as the solvent used in the step 1, and then, replenishing a proper quantity of catalyst to obtain a product, wherein the distilled recycled water is used in the step 2, and the product is used in the step 1; and distilling the recycled solvent at the organic layer at normal pressure, and carrying out reduced pressure distillation to recycle the excessive ethyl cyanoacetate, wherein the recycled solvent and ethyl cyanoacetate are used in the step 1; 3, carrying out reduced pressure distillation on the distillation tailings, adding 75-100% of ethanol for crystallizing, and filtering to obtain the etocrilene; and 4, filtering a mother solution obtained in the step 3, recycling the ethanol at normal pressure, and carrying out reduced pressure recycle on the benzophenone and the etocrilene, wherein the recycled ethanol is used in the step 3, and the recycled benzophenone and etocrilene are used in the step 1. The preparation method has the advantages of simplicity in operation, short production period, little environment pollution, low energy consumption, realization of material recycling, and the like.

Owner:ANHUI SHENGNUOBEI CHEM TECH

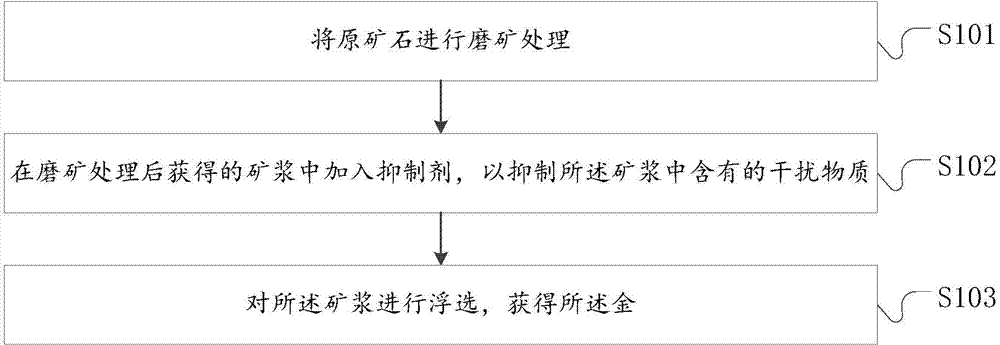

Recovery method of gold

InactiveCN104492591AHigh recovery rateSuppress interferenceFlotationWet separationRecovery methodCarboxymethyl cellulose

The invention discloses a recovery method of gold, and is applicable to carlin-type gold deposits. An inhibitor which at least comprises carboxymethyl cellulose (CMC) is added into ore pulp, fine slime obtained by interference flotation and non-purposive substance minerals (for example, carbonate, aluminosilicate and the like) are inhibited, and then gold carrying minerals are activated and then floated. The technological process is simple and the operation is convenient. Since the interference of interference substances to the ore pulp can be effectively inhibited by the inhibitor, previous slime removal operation can also be saved, and the gold recovery rate is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Process for synthesizing p-tert-butylbenzoic acid

ActiveCN102617335AReduce usageReduce recycling stepsOrganic compound preparationCarboxylic compound separation/purificationOxygenMoisture

The invention relates to a process for synthesizing p-tert-butylbenzoic acid. The process comprises the following steps of: adding p-tert-butyltoluene and cobalt acetate into a reaction kettle, introducing oxygen-containing gas, triggering at the temperature of between 150 and 155 DEG C, performing oxidation reaction for 0.5 to 1 hour, and continuously reacting at the temperature of between 135 and 145 DEG C for more than 5 hours to obtain a p-tert-butylbenzoic acid crude product; cooling the p-tert-butylbenzoic acid crude product to crystallize, performing centrifuge dripping, and striking and washing by using p-tert-butyltoluene to obtain a centrifugation crude product; and adding the centrifugation crude product into a dissolution kettle, adding methylbenzene, raising temperature and dissolving, filtering when a mixture is hot to remove impurities, adding water to wash, transferring materials to a recrystallization kettle, cooling to crystallize, centrifuging, striking and washing by using methylbenzene, and drying to obtain a p-tert-butylbenzoic acid finished product. The prepared p-tert-butylbenzoic acid is white crystals and does not contain mechanical impurities; and the melting point is 164.0 to 167.0 DEG C, the acid value is 312 to 316mgKOH / g, high performance liquid chromatography (HPLC) purity is more than or equal to 99.2 percent, moisture is less than or equal to 0.08 percent, and methylbenzene is less than or equal to 0.05 percent.

Owner:SUQIAN COSMOS CHEM +1

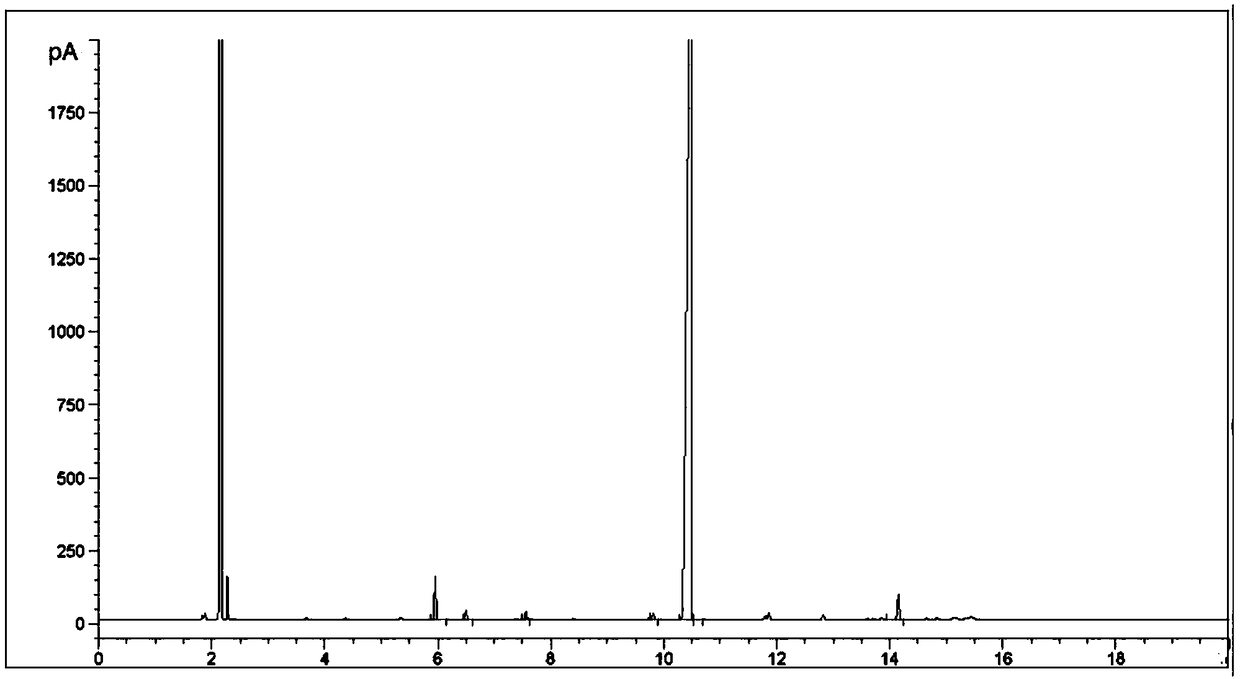

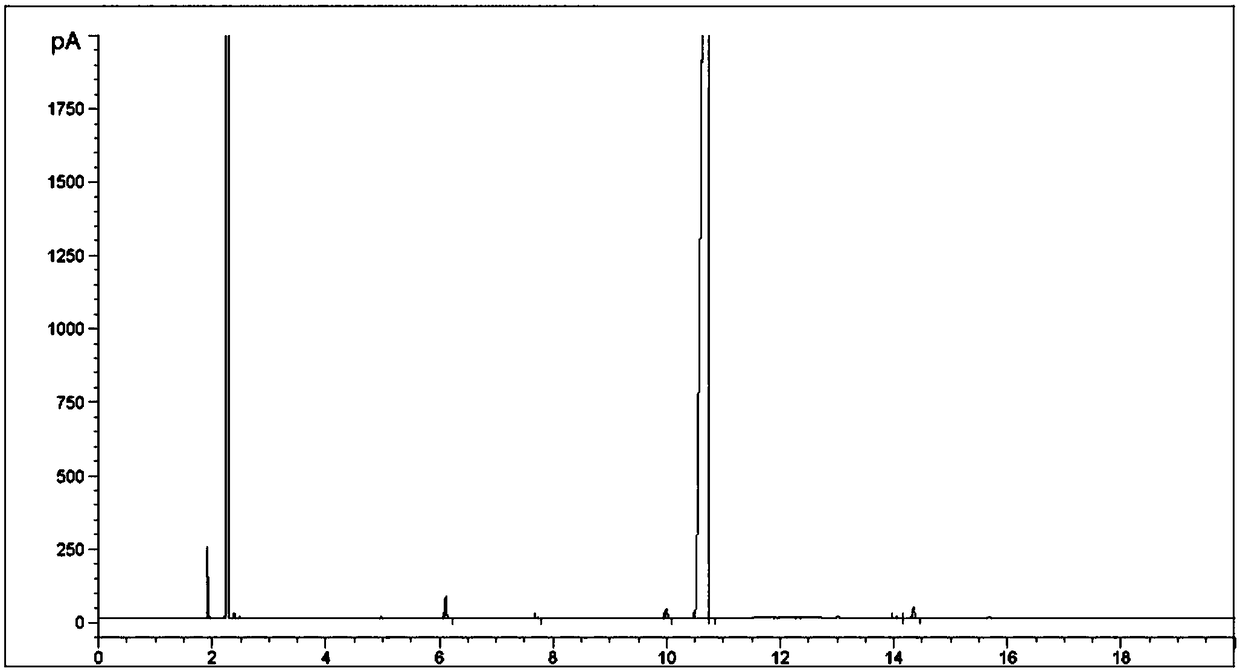

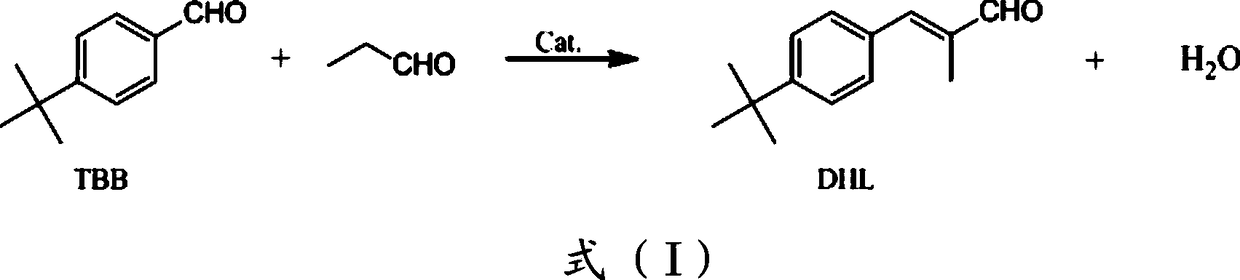

Preparation method of lilial

ActiveCN102627538ASolve the problem of low qualitySimple methodOrganic compound preparationCarbonyl compound preparationBenzaldehydeDistillation

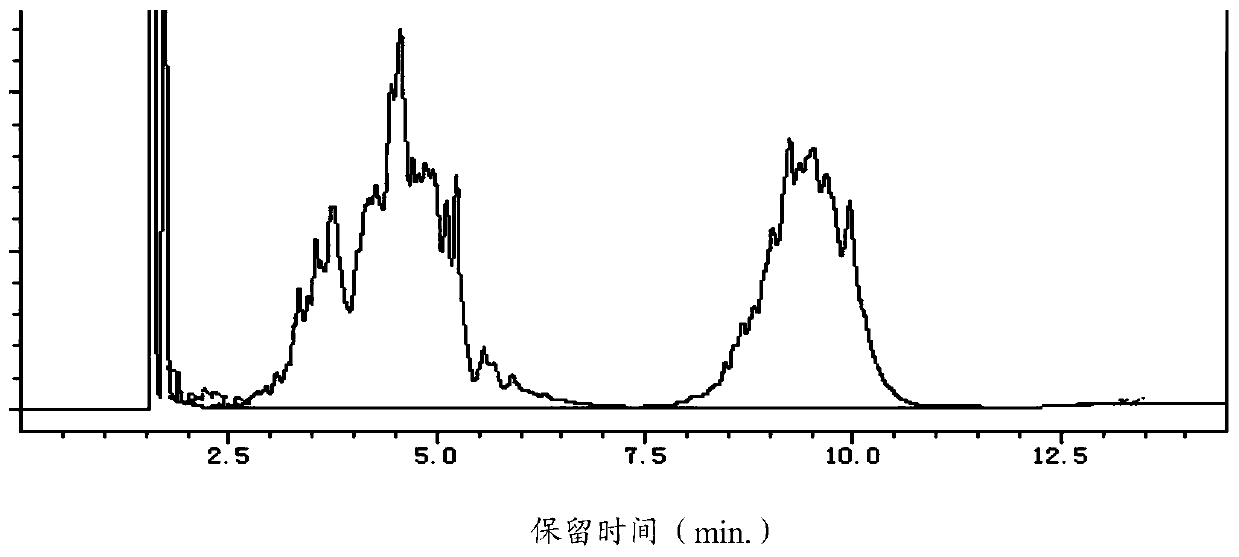

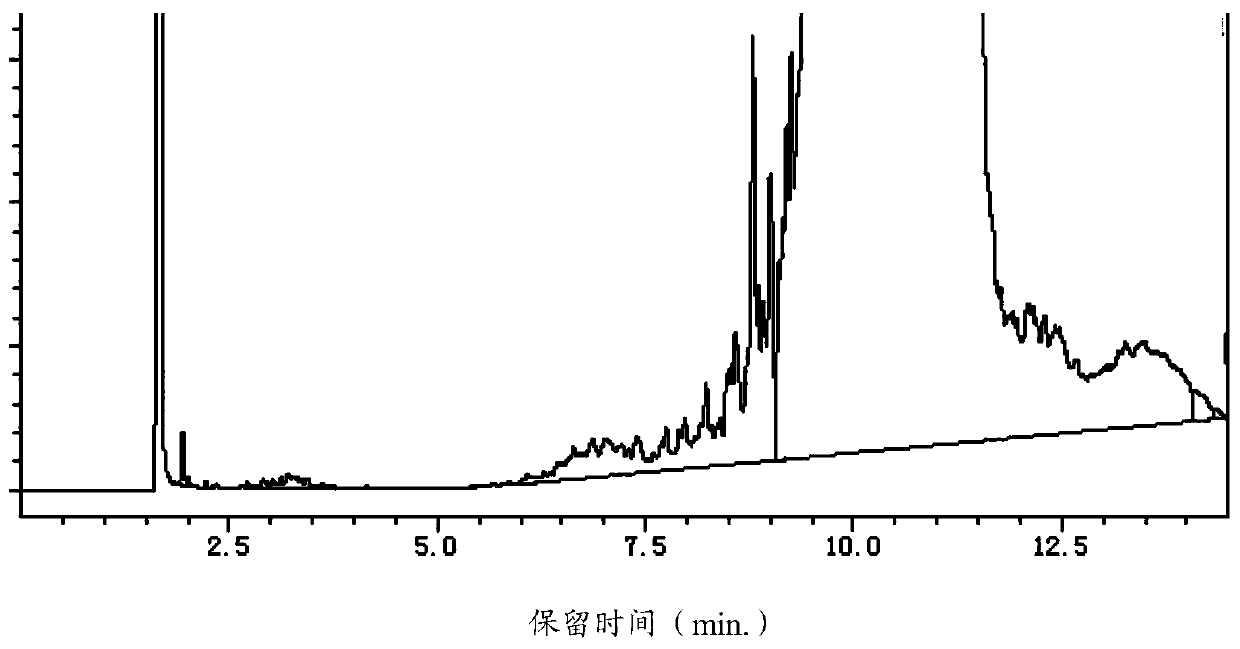

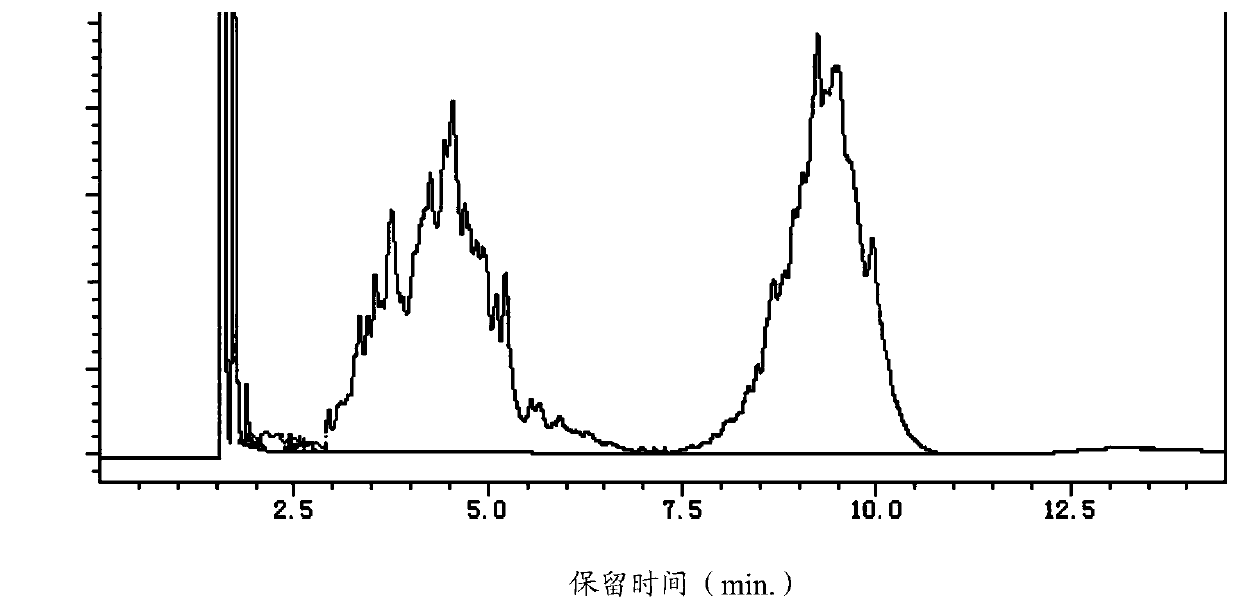

The invention relates to a preparation method of lilial. The preparation method of lilial comprises the following steps that p-tert.-butyl-benzaldehyde, methanol and caustic soda flake solutions having different concentrations are added into a reactor; n-propanal is dropwisely added into the reactor at a certain temperature and undergoes a condensation reaction and after addition of n-propanal isfinished, the condensation reaction lasts for 0.5 to 2 hours under the condition of heat preservation; acidic materials are added into the reaction system to adjust a pH value and to stop the condensation reaction; after the condensation reaction is finished, methanol is recovered by distillation and a condensation product p-tert.-butyl-alpha-methyl phenyl acrolein is obtained by film evaporator distillation; methanol, p-tert.-butyl-alpha-methyl phenyl acrolein and a hydrogenation catalyst are added into a hydrogenation reactor; hydrogen is fed into the hydrogenation reactor and the mixture in the hydrogenation reactor undergoes a hydrogen reaction; and after the hydrogen reaction is finished, the reaction products are subjected to filter pressing, solvent removal and rectification so that a finished product lilial is obtained. Lilial obtained by the preparation method is a colorless and transparent liquid, and has a refractive index (nd20) of 1.504 to 1.506, the specific gravity (25 DEG C, mg / mL) of 0.942 to 0.946, an acid value (mgKOH / g) of 2.0(max.), the GC content (determined by an area normalization method) of m-LLY less than 2.0%, p-LLY great than or equal to 97.0% and m-LLY+p-LLY great than or equal to 98.0%, and the moisture content less than or equal to 0.25%.

Owner:SUQIAN COSMOS CHEM

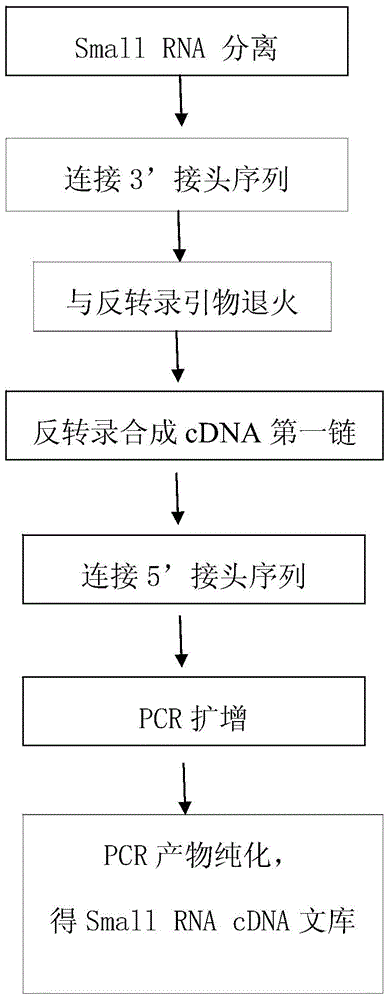

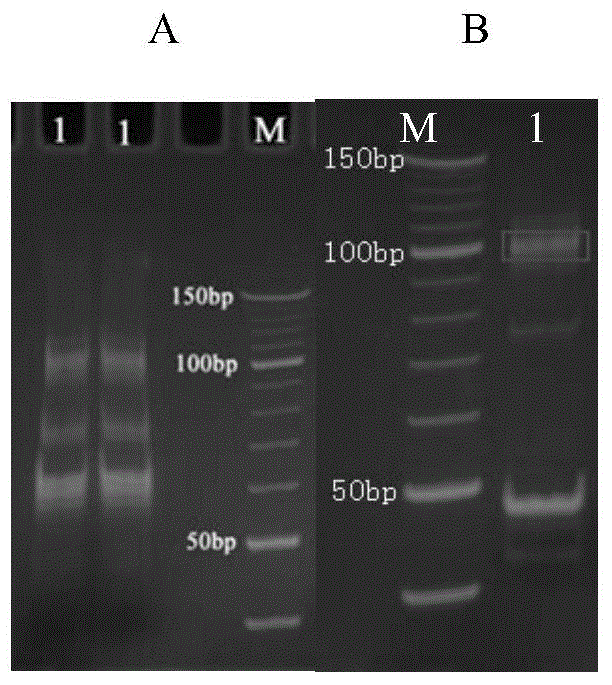

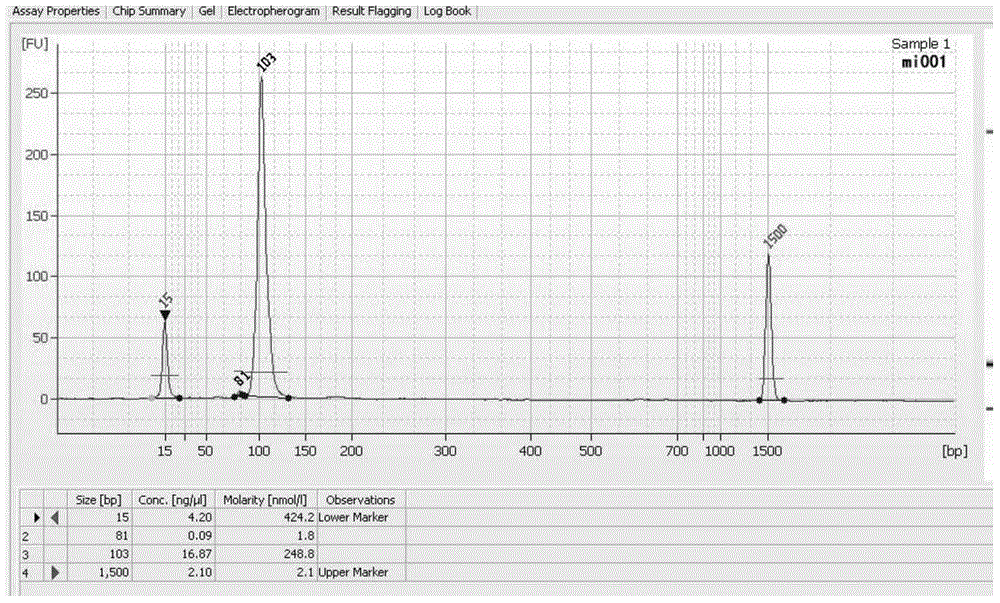

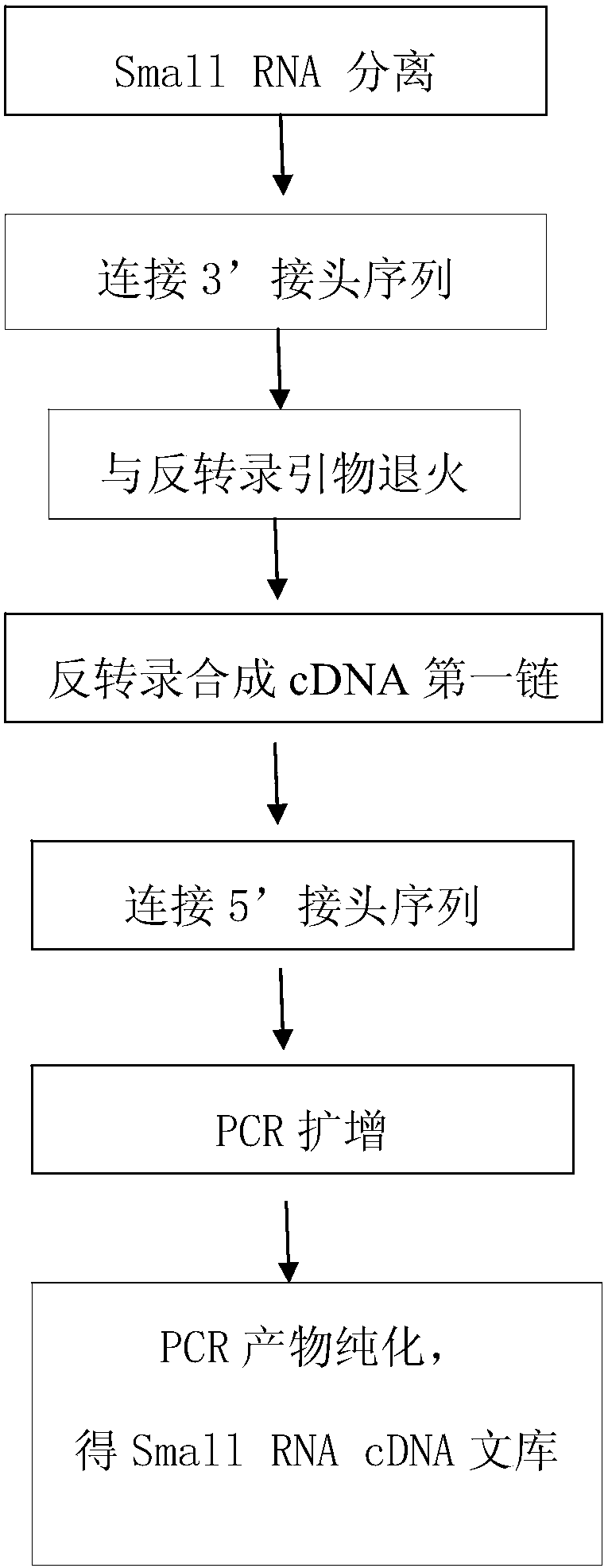

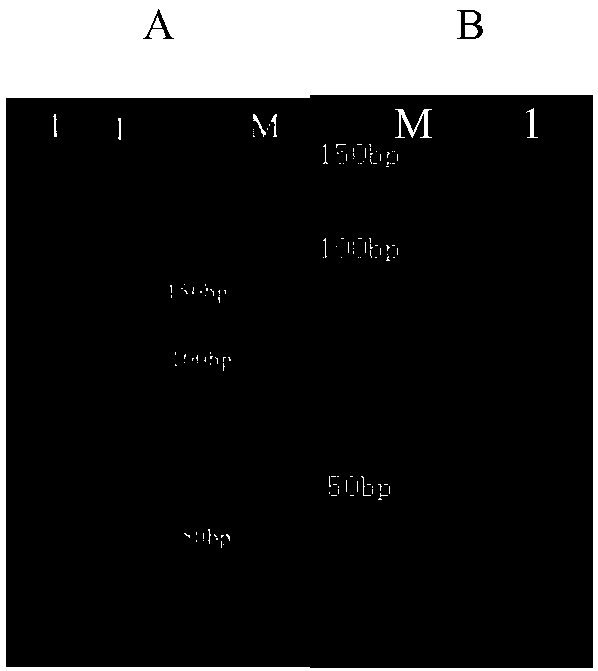

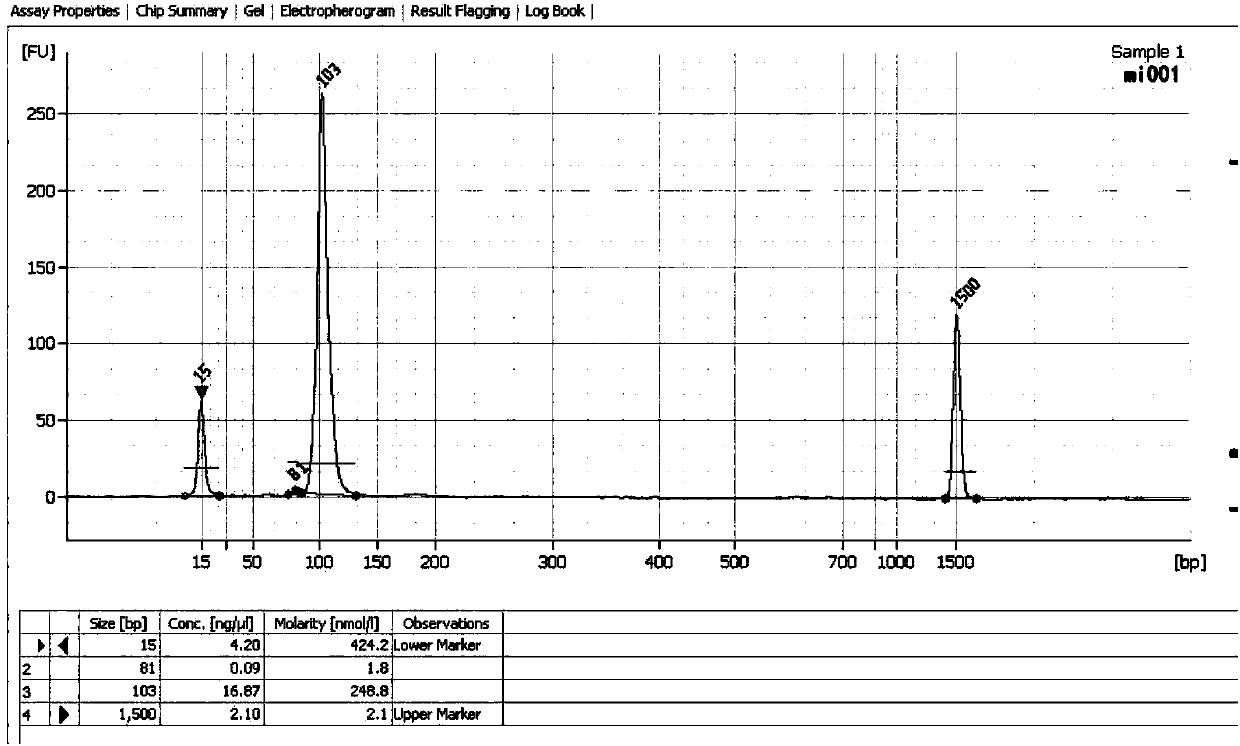

Method for constructing Small RAN cDNA library

ActiveCN104630211ALong period of separationLower success rateMicrobiological testing/measurementLibrary creationCDNA libraryGel electrophoresis

The invention discloses a method for constructing a Small RAN cDNA library. A group of DNA molecules disclosed by the invention consist of the following four kinds of molecules (1)-(4): (1) DNA molecule shown as SEQ ID No. 1; (2) DNA molecule shown as SEQ ID No. 2; (3) DNA molecule shown as SEQ ID No. 3; and (4) DNA molecule shown as SEQ ID No. 4. The Small RNA quick separation method solves the problems of long time, complicated operation, high requirement and high toxicity in acrylamide gel electrophoresis separation of Small RNA at present. Moreover, the method for constructing the Small RAN cDNA library reduces nonspecific products, improves the content of a destination product and is simple, convenient and fast compared with a traditional method.

Owner:SUZHOU GENEPHARMA

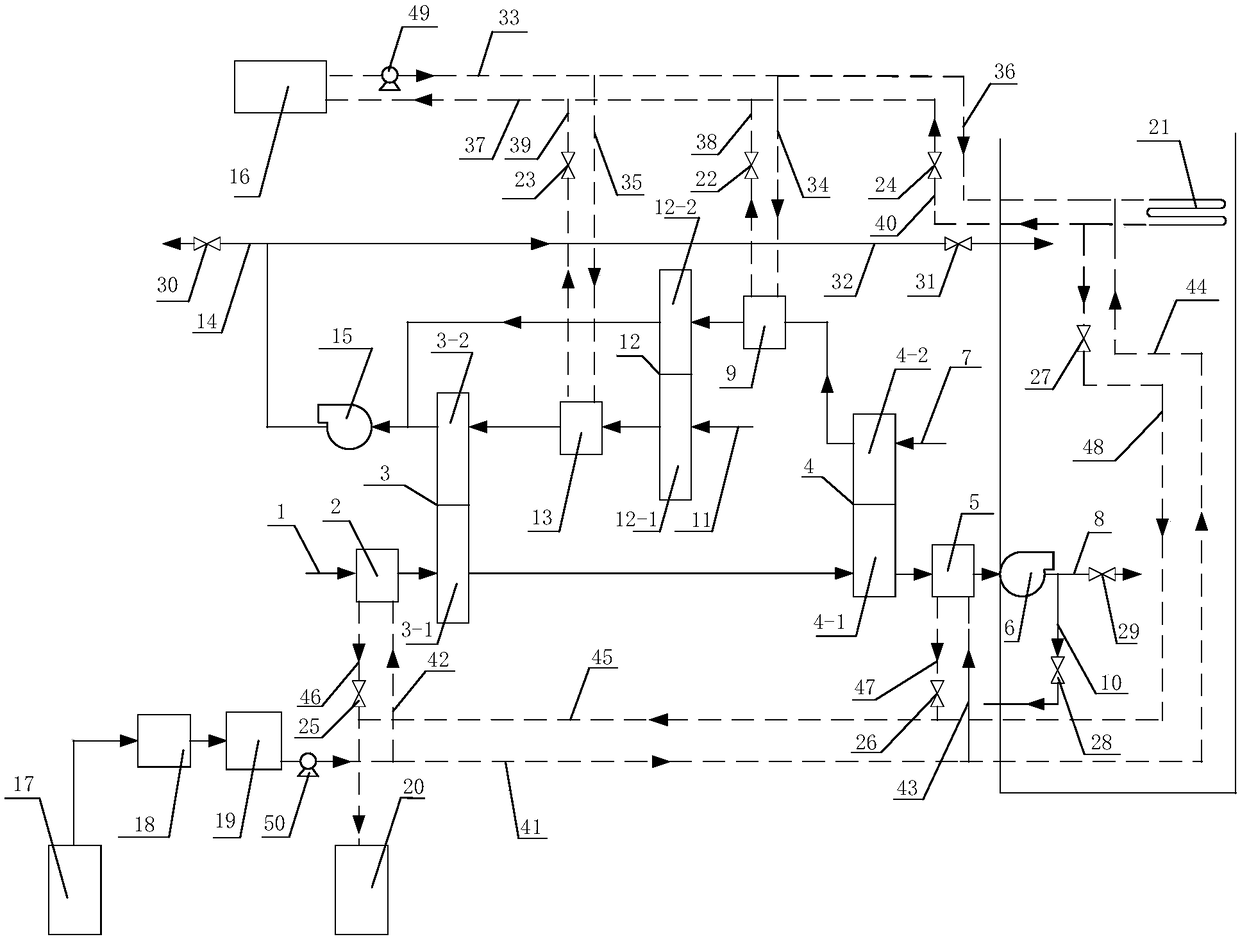

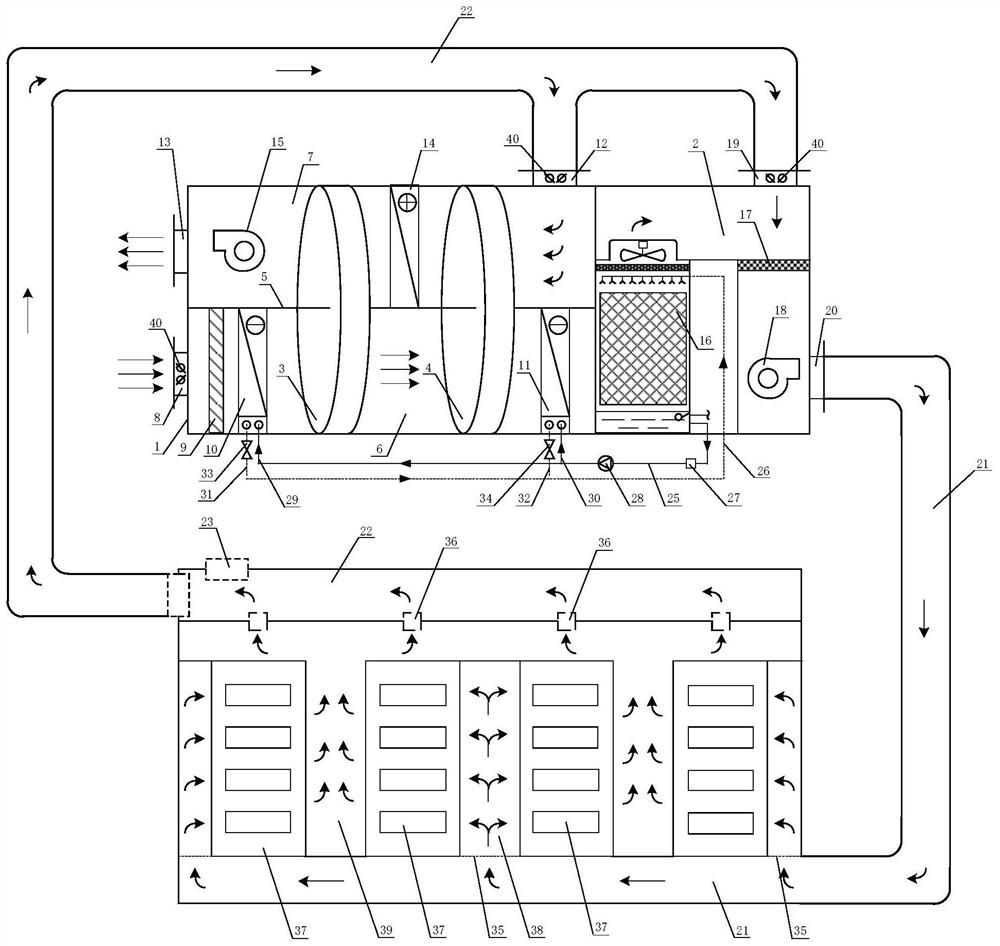

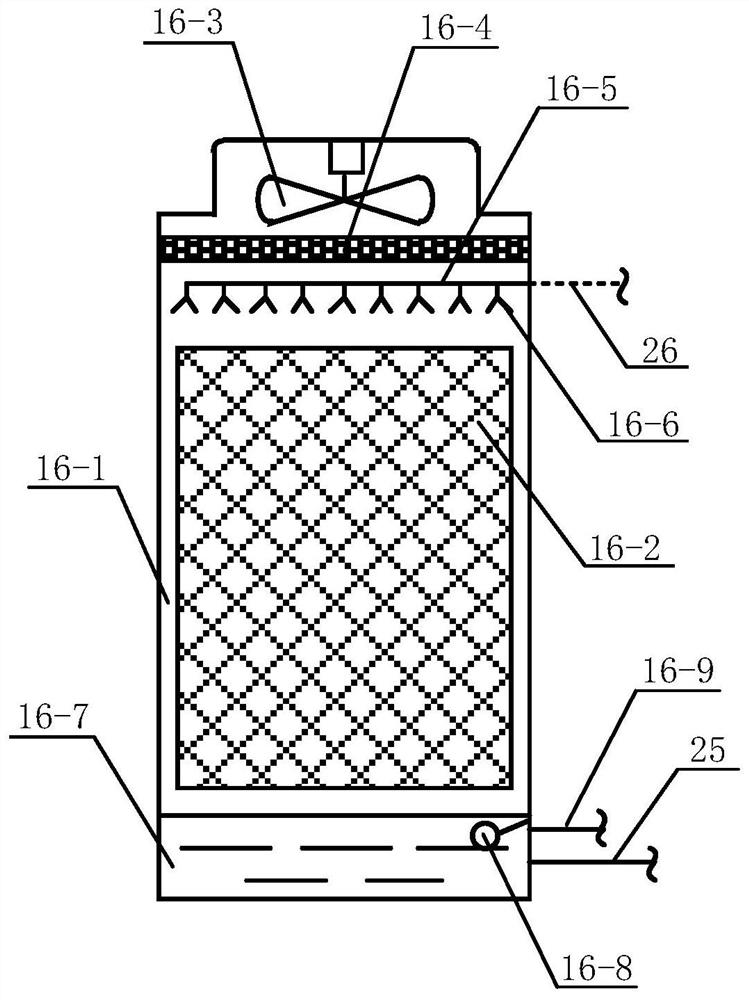

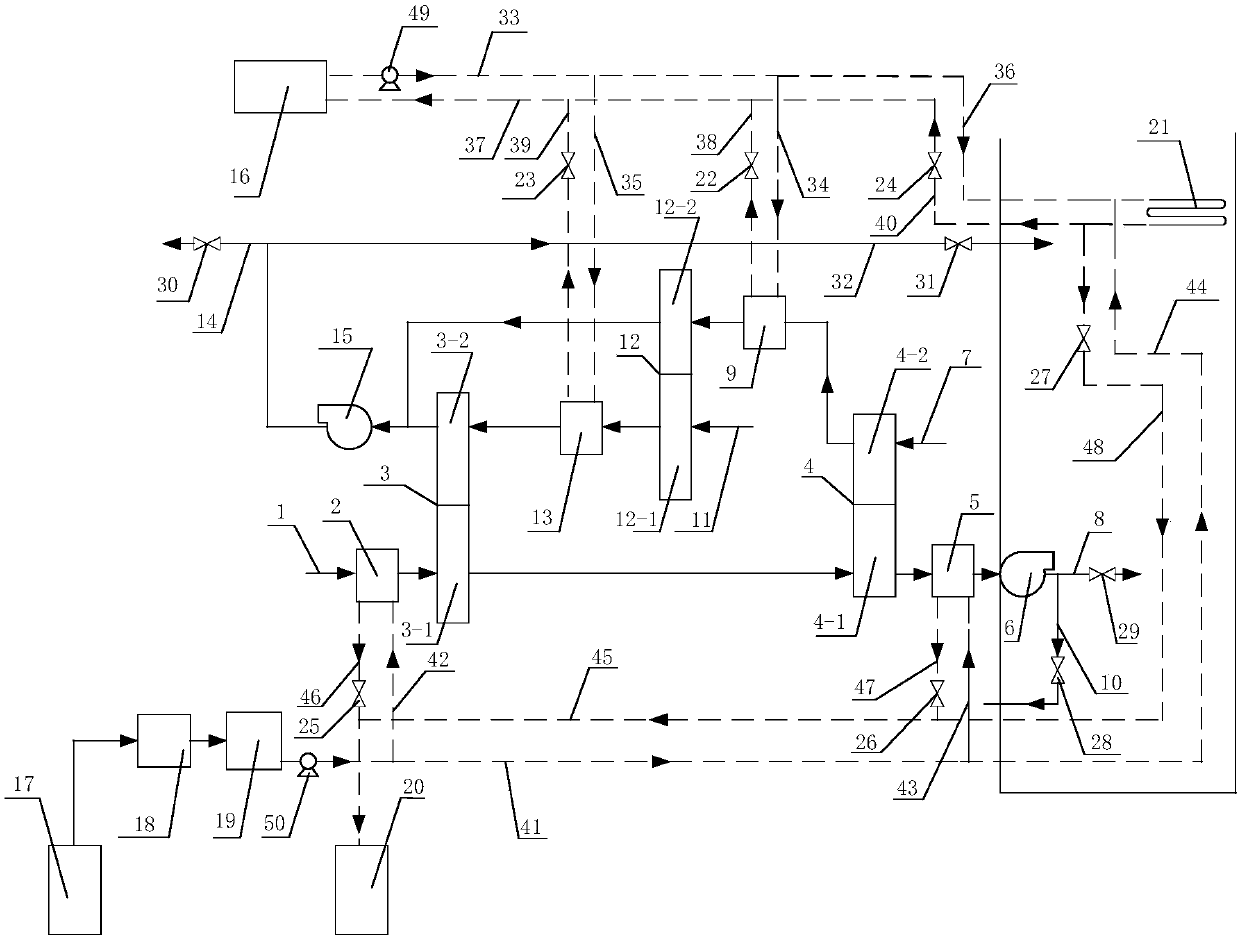

Low-temperature and low-humidity driven double-rotating-wheel dehumidification air conditioning system and air supply method thereof

ActiveCN109140610AImprove regeneration efficiencyIncrease partial pressure differenceMechanical apparatusLighting and heating apparatusWater qualityEngineering

The invention discloses a low-temperature and low-humidity driven double-rotating-wheel dehumidification air conditioning system and an air supply method thereof. The low-temperature and low-humiditydriven double-rotating-wheel dehumidification air conditioning system comprises a double-rotating-wheel dehumidification air conditioning unit, a hot water circulating system, a cold water circulatingsystem and a sensible heat air conditioning terminal device. The double-rotating-wheel dehumidification air conditioning unit comprises a first dehumidification rotating wheel, a second dehumidification rotating wheel, a plate-type heat recovery device, an air pre-cooler, an air recooler, a main air heater, an auxiliary air heater, a treatment fan and a regeneration fan. The hot water circulatingsystem comprises a low-grade energy heat collector. The cold water circulating system comprises a water return well and further comprises a water supply well, a reservoir and a water quality treatment device which are sequentially connected. The air supply method of the low-temperature and low-humidity driven double-rotating-wheel dehumidification air conditioning system comprises an air supplying method under the summer working condition and an air supplying method under the winter working condition. The low-temperature and low-humidity driven double-rotating-wheel dehumidification air conditioning system is novel and reasonable in design, low in cost, low in energy consumption, high in refrigerating and heating efficiency, free of greenhouse effect, high in practicability and high in application and popularization value.

Owner:南京丰颂机电科技有限公司

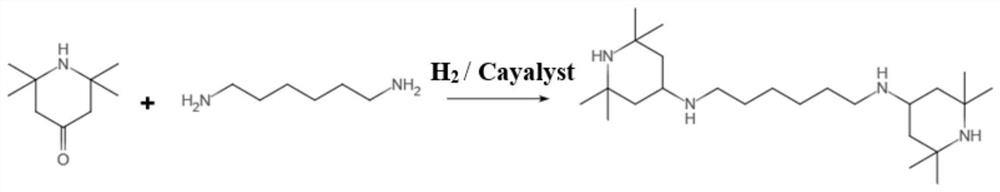

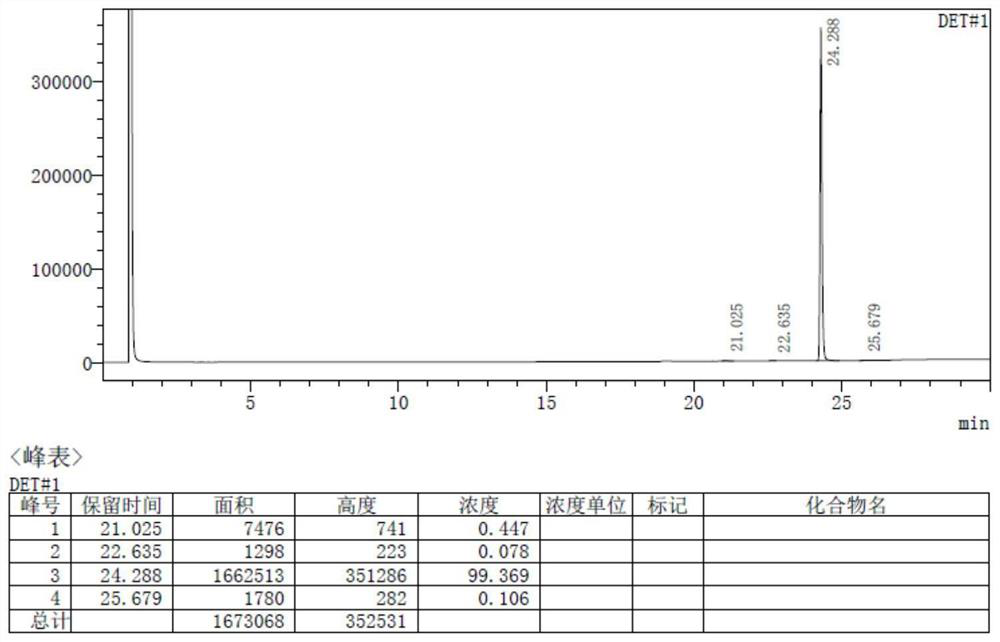

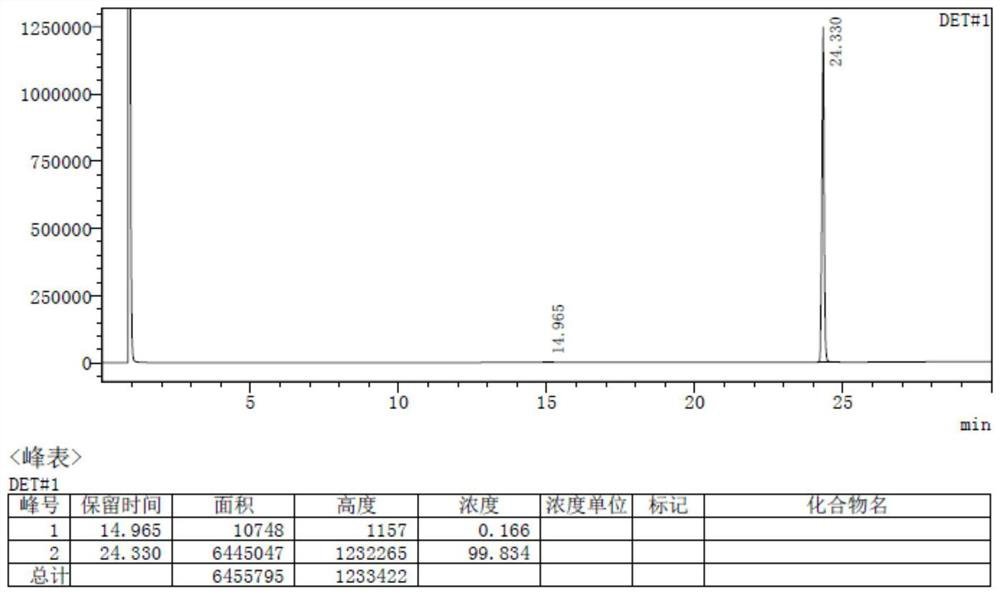

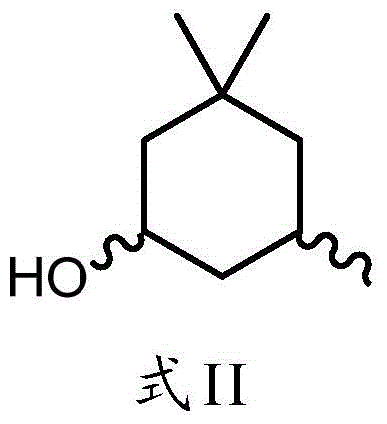

Synthesis process of hexamethylenediamine piperidine

InactiveCN111825602AReduce generationImprove responseOrganic chemistryChemical recyclingPtru catalystHexamethylenediamine

The invention relates to a synthesis process of hexamethylenediamine piperidine. The process comprises the steps of: carrying out heating dehydration reaction on 2, 2, 6, 6-tetramethyl-4-piperidone and 1, 6-hexamethylenediamine in a negative pressure environment until no water is removed from the system, and adding a water removing agent to separate the residual water from the liquid system so asto obtain an intermediate Schiff base; introducing hydrogen into the obtained Schiff base in the presence of a catalyst for hydrogenation reaction to obtain hydrogenation liquid; and filtering out thecatalyst from the hydrogenation liquid, rectifying the filtrate, and carrying out crystallization-desolvation to obtain the hexamethylenediamine piperidine finished product. According to the method,a small amount of residual water is removed by using the water removal agent, so that the Schiff base is prevented from being decomposed in the presence of trace water, the purity of the Schiff base is improved, the yield of hexamethylenediamine piperidine is increased, and few solid wastes are generated; according to the method, negative pressure reaction and crystallization treatment are innovatively adopted, so that the quality of hexamethylenediamine piperidine is high, the solvent can be continuously recycled and reused, and no organic waste liquid is generated.

Owner:江苏富比亚化学品有限公司

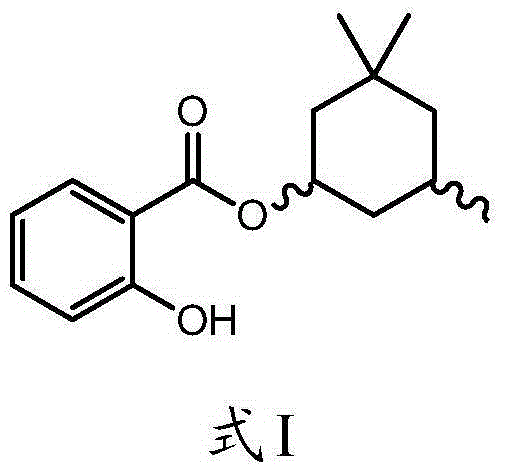

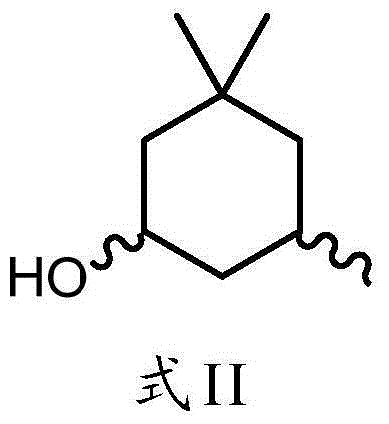

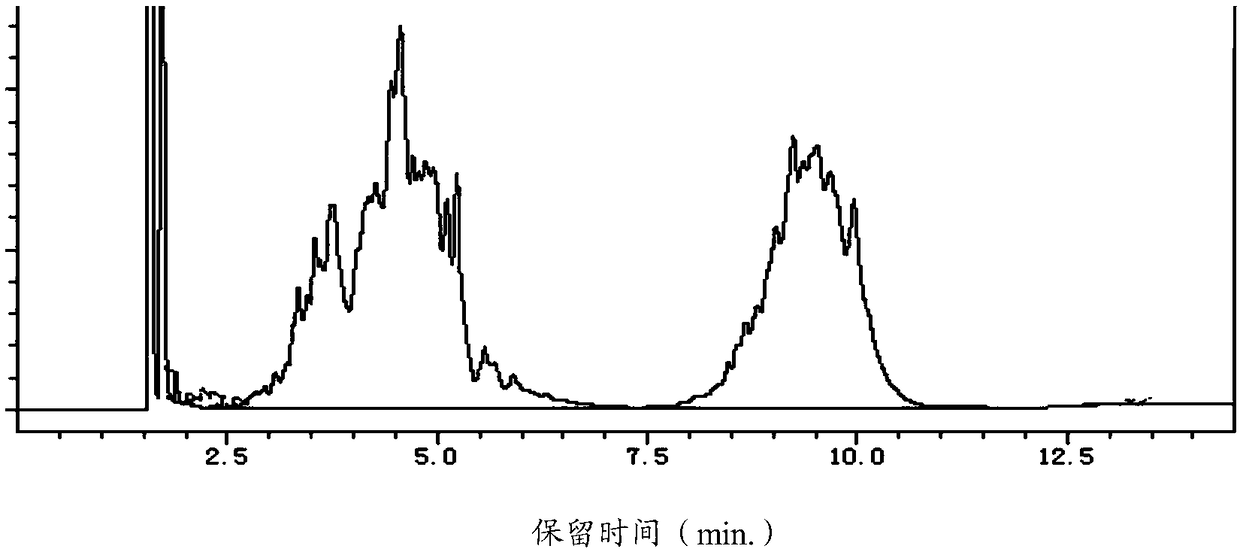

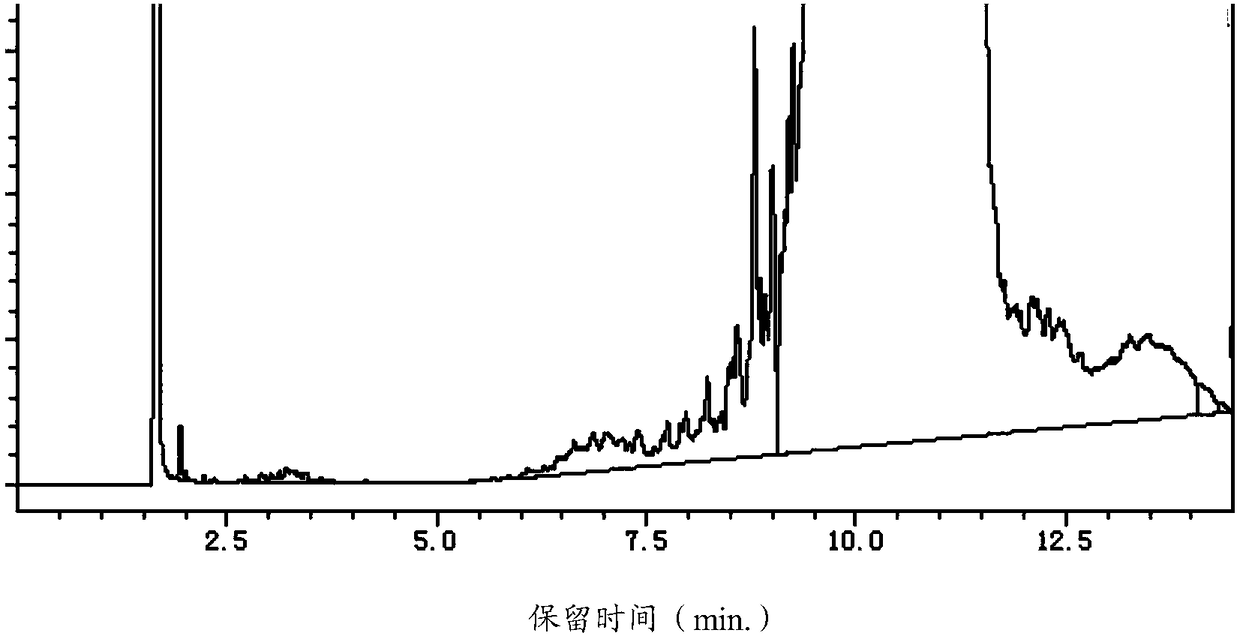

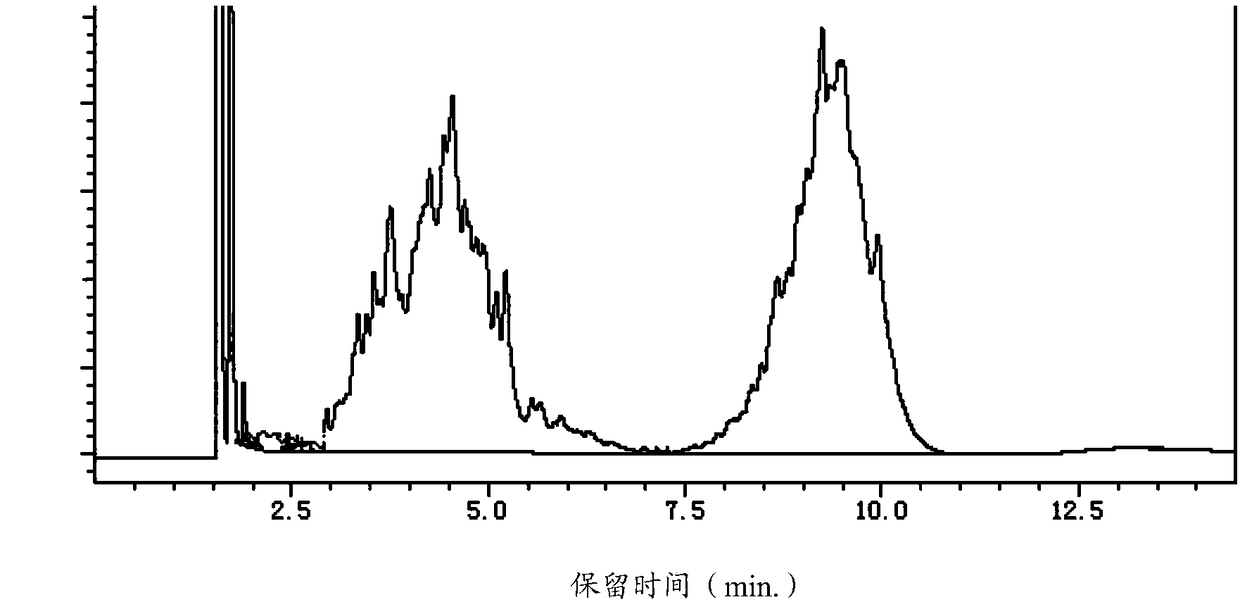

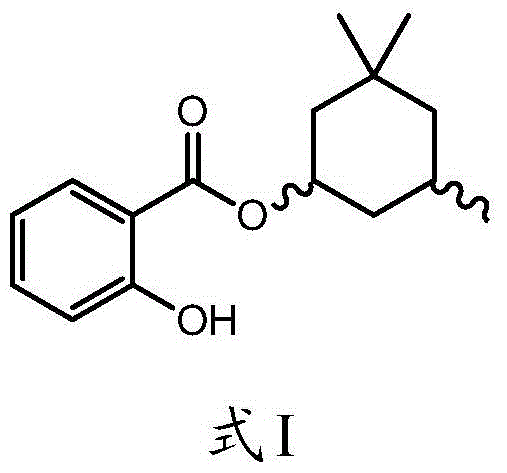

Method for preparing homosalate

ActiveCN105085273AImprove qualitySimple and fast operationOrganic compound preparationPreparation by ester-hydroxy reactionIsomerizationIsophorone

The invention provides a method for preparing homosalate. The method comprises the steps that isophorone serves as raw materials, a hydrogenation reaction is performed under the action of a catalyst, then an epimerization reaction is performed, and 3,3,5-Trimethylcyclohexanol is prepared; a transesterification reaction is performed on the prepared 3,3,5-Trimethylcyclohexanol and methyl salicylate, and finally the homosalate is prepared. The method is easy and convenient to operate, green and environmentally friendly, and the prepared homosalate is high in quality, wherein the cis form content is larger than or equal to 85.0 percent, the trans form content is smaller than or equal to 15 percent, the total content is larger than or equal to 99.0 percent, the single impurity content (GC) is smaller than or equal to 0.1 percent, and the total impurity content (GC) is smaller than or equal to 0.5 percent.

Owner:ANHUI SHENGNUOBEI CHEM TECH

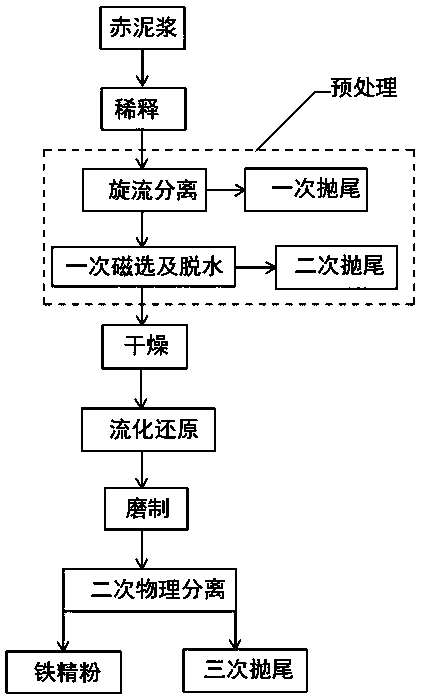

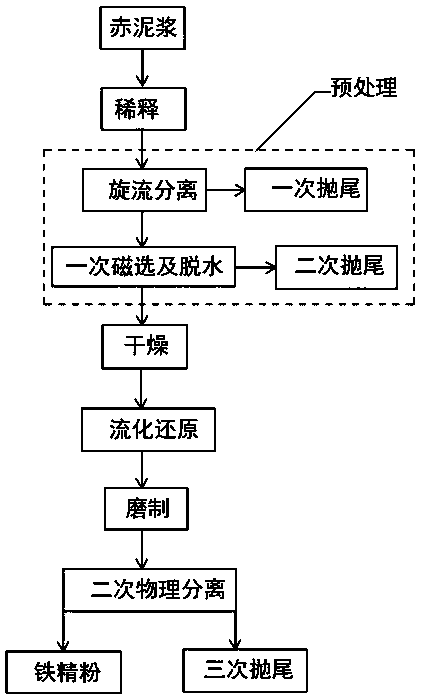

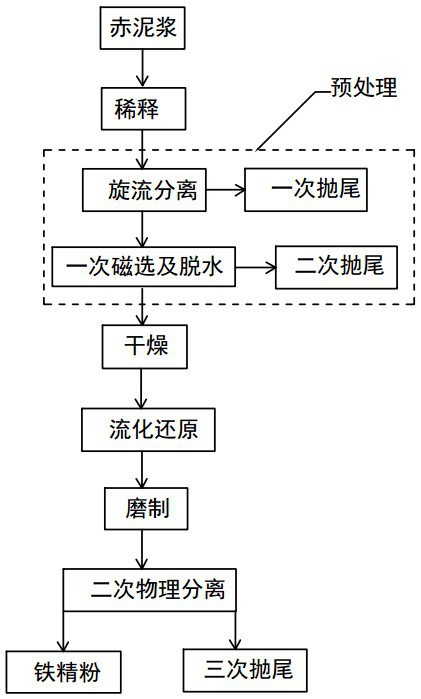

Technology for producing iron fine powder through red mud fluidized bed method

ActiveCN110004263AOvercome the defects of low product qualityOvercome the defect of low qualityFluidised-bed furnacesHearth type furnacesIron powderRed mud

The invention discloses a technology for producing iron fine powder through a red mud fluidized bed method, and belongs to the technical field of steel production. The technology is characterized by comprising the following steps that red mud grout is diluted and screened, and rough iron powder is obtained through a pretreatment manner of gravity sorting, magnetic sorting or gravity sorting and magnetic sorting combination; drying is conducted; the fluidization reducing reaction temperature of a reducing fluidized bed is controlled to range from 450 DEG C to 550 DEG C, gas with the volume ratio of CO+H2 being 40%-50% is used in the reducing fluidized bed to conduct the reducing reaction on the rough iron powder, the reducing reaction time is controlled to range from 8 min to 15 min, and reduced magnetized rough iron powder is obtained; and the reduced magnetized rough iron powder is ground to be smaller than 100 meshes, then, physical separation is conducted, and the iron fine powder with the grade being 61% or above is obtained. The technology can overcome the defect that during physical method red mud iron separating, the iron powder product quality is low, and energy consumptionduring chemical method red mud iron separating can be greatly reduced.

Owner:中铝山东工程技术有限公司

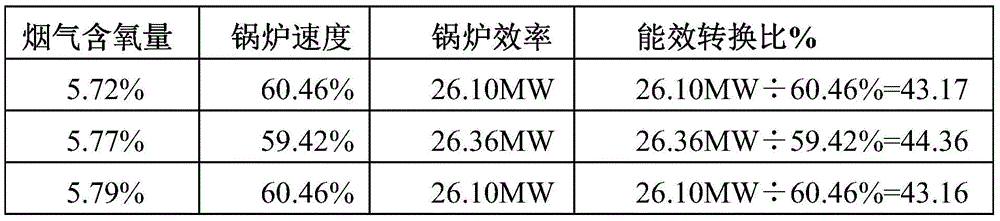

Boiler high-efficiency combustion energy-saving control method and boiler high-efficiency combustion energy-saving system

ActiveCN105716105AImprove efficiencyImprove the efficiency of pipe network operationFuel supply regulationProcess engineeringCoal

The invention provides a boiler high-efficiency combustion energy-saving control method and a boiler high-efficiency combustion energy-saving system. The boiler high-efficiency combustion energy-saving control method and the boiler high-efficiency combustion energy-saving system are used for a heating supply system. The control method comprises the steps that S1, the content of oxygen in flue gas of a boiler of the heating supply system is detected; S2, whether the detected content of oxygen in flue gas is within the set range or not is judged; and S3, if the detected content of oxygen in flue gas is not within the set range, the blast volume of an air blower and / or the coal feed quantity of a coal feeder of the heating supply system is controlled until the detection value of the content of oxygen in flue gas is within the set range. By the adoption of the boiler high-efficiency combustion energy-saving control method and the boiler high-efficiency combustion energy-saving system, the blast volume can meet the requirement for sufficient combustion of fuel, the phenomenon that the furnace box temperature is reduced due to the fact that the blast volume is excessively high cannot exist, and therefore the boiler can achieve the highest thermal efficiency.

Owner:呼和浩特市坤泰热力有限责任公司

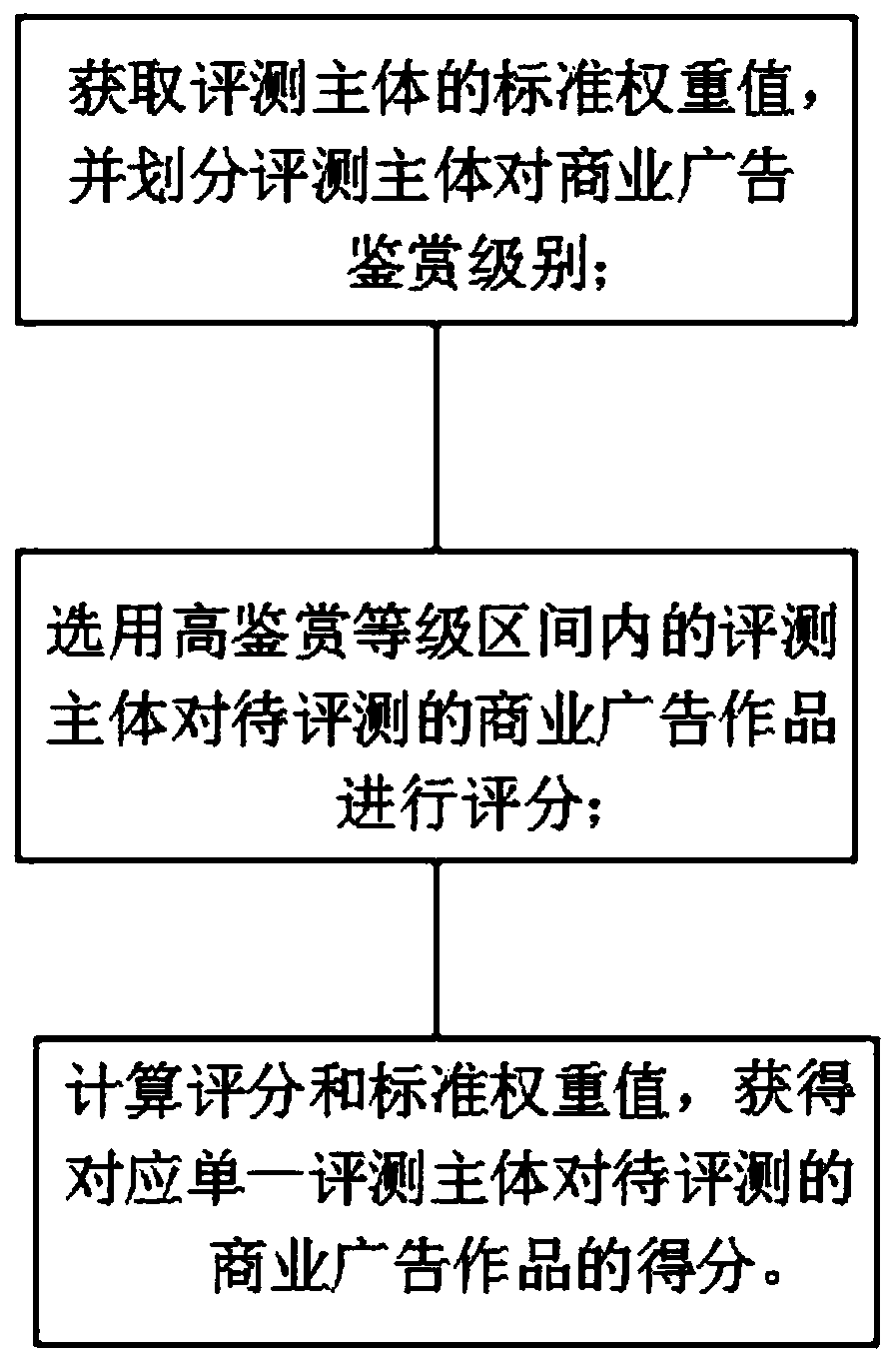

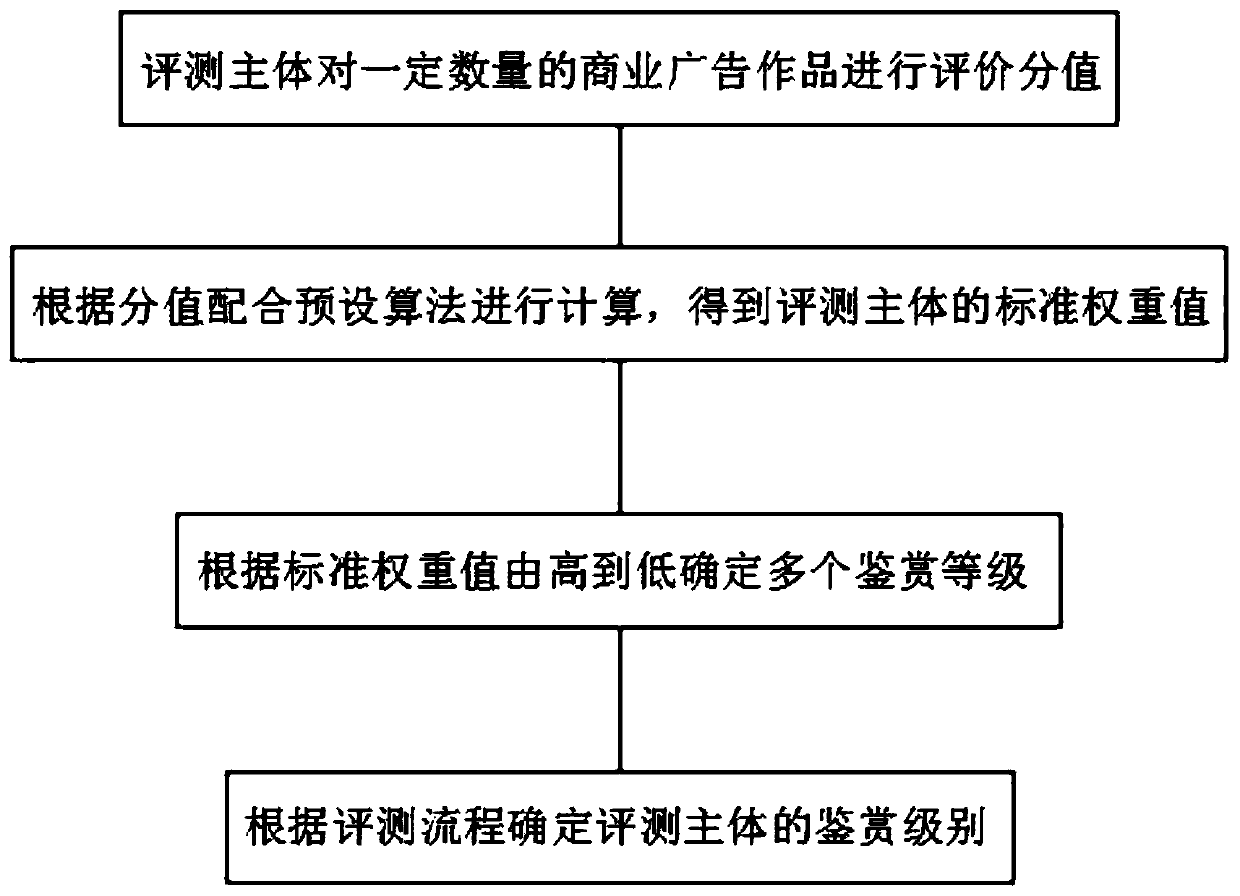

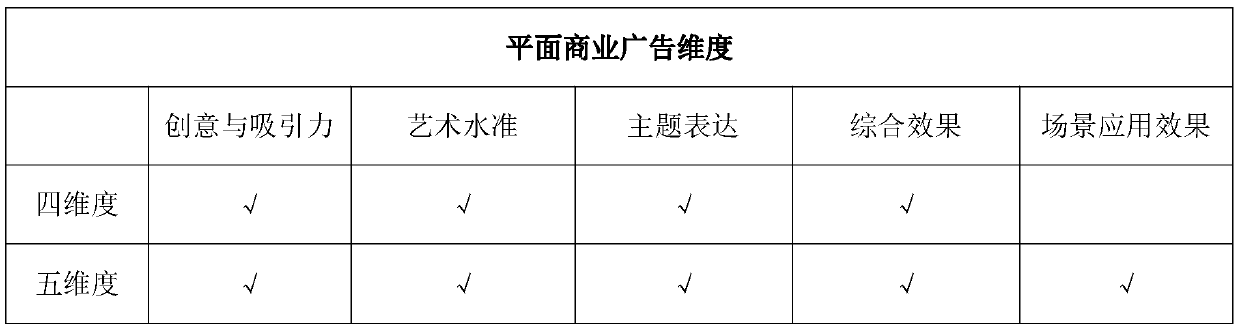

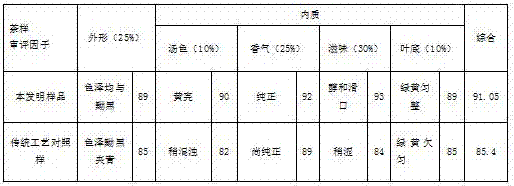

Evaluation method for plane commercial advertisement

PendingCN110135736ASolve the problem of low qualityStrong acceptanceResourcesMarketingState of artComputer science

The invention relates to the technical field of advertisement assessment, and provides an assessment method for a plane business advertisement, and the method comprises the following operation steps:obtaining the standard weight values of one or more assessment subjects, and dividing the assessment subject's appreciation level for the business advertisement according to the standard weight values; selecting an evaluation main body in a section of interval of the appreciation level to score the commercial advertising work to be evaluated; calculating the score and the standard weight value, and obtaining the score of the to-be-evaluated commercial advertising work by the corresponding single evaluation main body.The method solves the problem that a commercial advertisement evaluation modein the prior art is difficult to meet the satisfaction degree of most audience groups, so that the commercial advertisement market value is low.

Owner:上海天琥云教育科技有限公司

Preparation method of ultraviolet absorbent intermediate etocrilene (ETO)

ActiveCN103242197BHarm reductionReduce manufacturing costCarboxylic acid nitrile preparationOrganic compound preparationDistillationWater insoluble

The invention relates to a preparation method of an ultraviolet absorbent intermediate etocrilene (ETO). The preparation method comprises the following steps of: 1, adding benzophenone, ethyl cyanoacetate, a catalyst and a water-insoluble solvent into a condensation reaction kettle, carrying out backflow water distribution reaction for 12-15h, and then, cooling to 50-55 DEG C, wherein the excessive equivalent of the ethyl cyanoacetate relative to the benzophenone is 0.2-5; 2, washing the reaction liquid by using water, and separating the liquid to respectively obtain a water layer and an organic layer; distilling the recycled water at the water layer at normal pressure, dissolving distillation tailings by using a solvent same as the solvent used in the step 1, and then, replenishing a proper quantity of catalyst to obtain a product, wherein the distilled recycled water is used in the step 2, and the product is used in the step 1; and distilling the recycled solvent at the organic layer at normal pressure, and carrying out reduced pressure distillation to recycle the excessive ethyl cyanoacetate, wherein the recycled solvent and ethyl cyanoacetate are used in the step 1; 3, carrying out reduced pressure distillation on the distillation tailings, adding 75-100% of ethanol for crystallizing, and filtering to obtain the etocrilene; and 4, filtering a mother solution obtained in the step 3, recycling the ethanol at normal pressure, and carrying out reduced pressure recycle on the benzophenone and the etocrilene, wherein the recycled ethanol is used in the step 3, and the recycled benzophenone and etocrilene are used in the step 1. The preparation method has the advantages of simplicity in operation, short production period, little environment pollution, low energy consumption, realization of material recycling, and the like.

Owner:ANHUI SHENGNUOBEI CHEM TECH

A kind of construction method of small RNA cDNA library

ActiveCN104630211BSolve the problem of low qualityHigh product contentMicrobiological testing/measurementLibrary creationAgricultural scienceGenomic DNA

The invention discloses a method for constructing a Small RNA cDNA library. A group of DNA molecules disclosed by the present invention, the group of molecules is composed of four molecules as shown in (1)-(4): (1) the DNA molecule shown in SEQ ID No.1; (2) SEQ ID No. The DNA molecule shown in 2; (3) the DNA molecule shown in SEQ ID No.3; (4) the DNA molecule shown in SEQ ID No.4. The method for rapidly separating Small RNA disclosed by the invention solves the problems of long time, complicated operation, high requirements and high toxicity of the current separation of Small RNA by acrylamide gel electrophoresis. Moreover, the method for constructing a Small RNA cDNA library disclosed in the present invention reduces non-specific products and increases the content of target products, and the method is simpler and faster than traditional methods.

Owner:SUZHOU GENEPHARMA

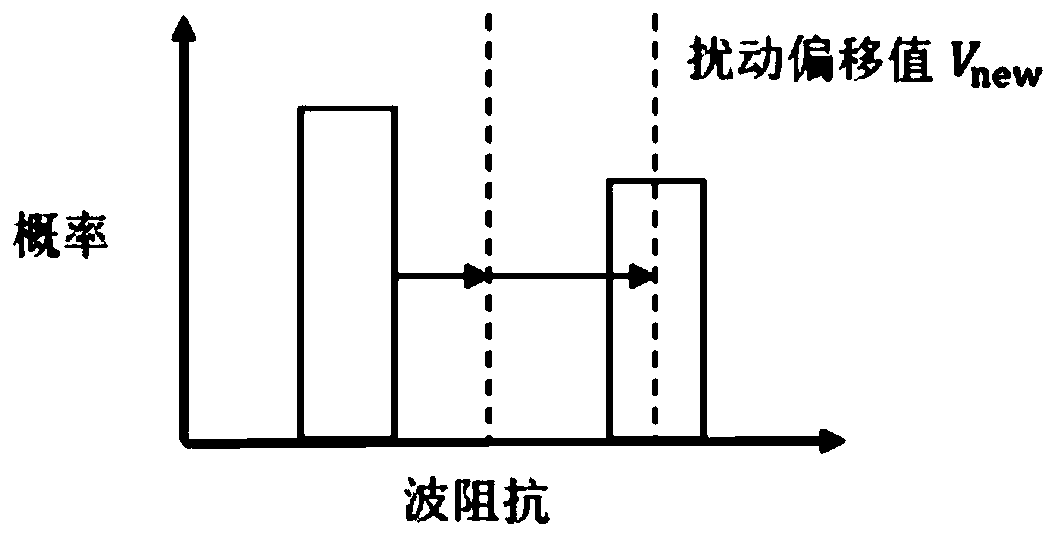

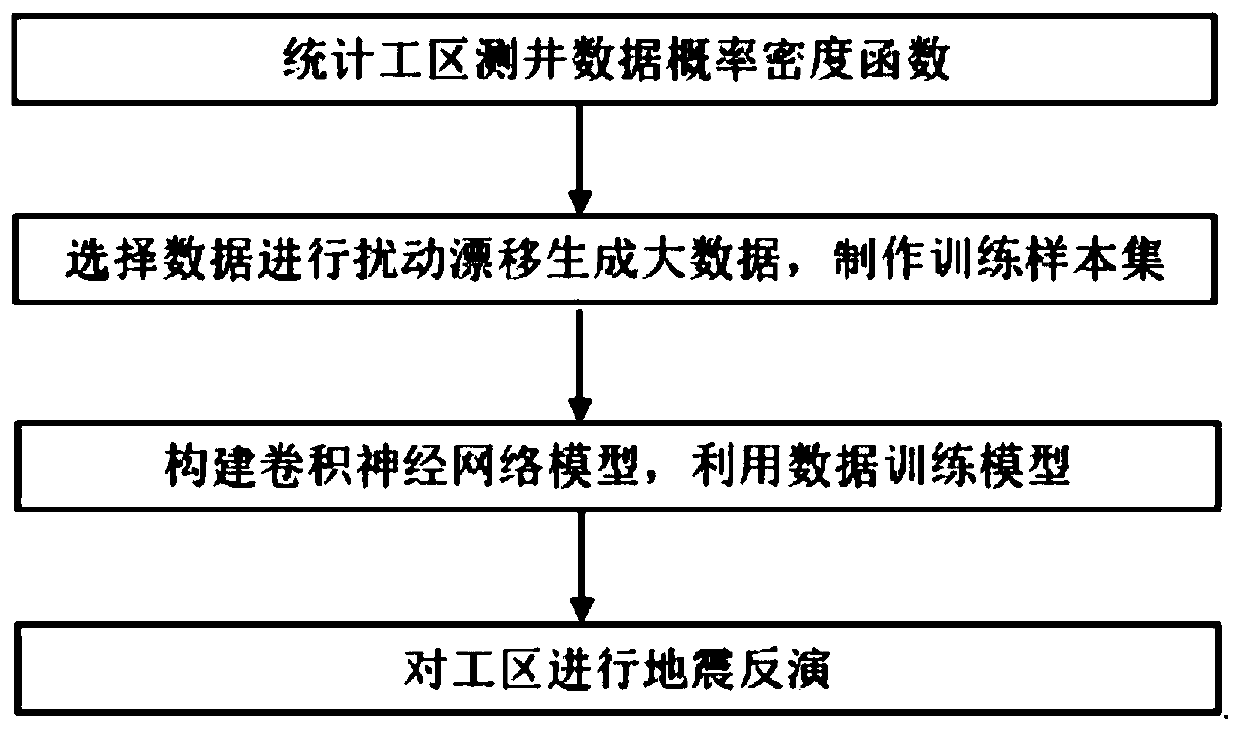

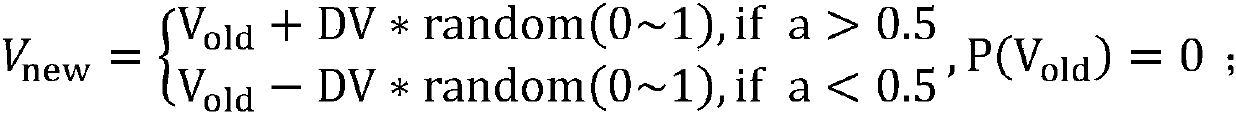

Seismic inversion big data generation method based on convolutional neural network

ActiveCN110488350ASolve the problem of low qualityLow costSeismic signal processingNeural architecturesData setSmall data

The invention discloses a seismic inversion big data generation method based on a convolutional neural network. The method is characterized in that a big data set is generated based on data statistical feature migration for realizing seismic inversion for the convolutional neural network. Artificial intelligence, geophysics, spatial statistics, information science and other multiple disciplines are integrated, a deep learning technology, a big data technology, a seismic inversion technology and the like are organically combined, big data are generated by small data for a data set required by seismic inversion, so that the problem of low quality of field exploration data is solved, the data collection cost and theexploration risk are reduced, and the defects in the prior art are overcome.

Owner:SOUTHWEST PETROLEUM UNIV

A processing process of Dayoucha

InactiveCN107094923AStrong penetrating powerHelps to penetratePre-extraction tea treatmentActive enzymeCuticle

The invention relates to a processing process of Dayoucha. The Dayoucha is prepared by process steps of withering, stacking, blending and mist spraying, fixing, rolling, deblocking, re-rolling, drying, bagging, ageing, steaming, shaping, low-temperature drying, and the like. According to the process, green tea leaves are put into a withering tank, and subjected to ventilation at 15-30 DEG C for 4-6 h; and then surfaces of the green tea leaves are wetted through mist spraying in a fixation step. In the high-temperature fixation step, water mist evaporates to form steam, the penetrating power of the steam is high and the steam can penetrate epidermis cells of tea stems to allow heat to be acted on active enzymes in the tea stems, thus deactivating the enzymes to achieve a fixation objective. In addition, the steam permeates a fixation barrel so that leaf surfaces are protected from edge coking due to fast water losing caused by overhigh temperature. The enzymes in the tea leaf stems can be completely deactivated, and leaf margin cells are protected from coking and withering and yellowing, and therefore tea leaves of the Dayoucha is uniform in fixation, the fixation quality is increased and quality is better.

Owner:LIUZHOU CITY VOCATIONAL COLLEGE

Tridemorph synthesis process

The invention relates to a tridemorph synthesis process which includes the steps: adding tridecyl alcohol and optional solvents into a reaction kettle, adding a catalyst, stirring and mixing mixture,leading into hydrogen, and heating the reaction kettle; adding 2, 6-thebaine when the temperature of the reaction kettle reaches the temperature of 200 DEG C or more, and maintaining the reaction kettle to perform reaction in a certain pressure and at a certain temperature until reaction is completed; post-processing a reactant to obtain a reactant finished product. According to the tridemorph synthesis process, the tridemorph with the purity larger than 99% is acquired under the conditions of high selectivity and high yield, and waste water, waste gas and industrial residues are greatly reduced.

Owner:江苏富比亚化学品有限公司

A kind of method for preparing protofilm loose ester

ActiveCN105085273BImprove qualitySimple and fast operationOrganic compound preparationPreparation by ester-hydroxy reactionIsomerizationIsophorone

The invention provides a method for preparing homosalate. The method comprises the steps that isophorone serves as raw materials, a hydrogenation reaction is performed under the action of a catalyst, then an epimerization reaction is performed, and 3,3,5-Trimethylcyclohexanol is prepared; a transesterification reaction is performed on the prepared 3,3,5-Trimethylcyclohexanol and methyl salicylate, and finally the homosalate is prepared. The method is easy and convenient to operate, green and environmentally friendly, and the prepared homosalate is high in quality, wherein the cis form content is larger than or equal to 85.0 percent, the trans form content is smaller than or equal to 15 percent, the total content is larger than or equal to 99.0 percent, the single impurity content (GC) is smaller than or equal to 0.1 percent, and the total impurity content (GC) is smaller than or equal to 0.5 percent.

Owner:ANHUI SHENGNUOBEI CHEM TECH

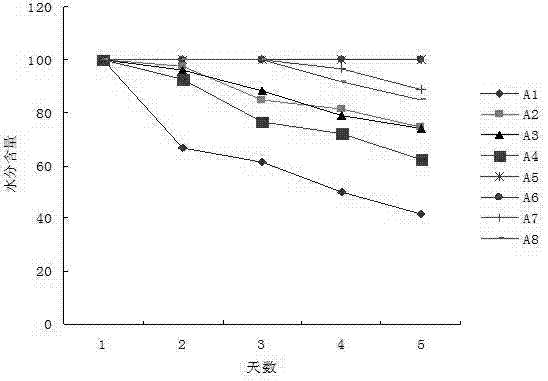

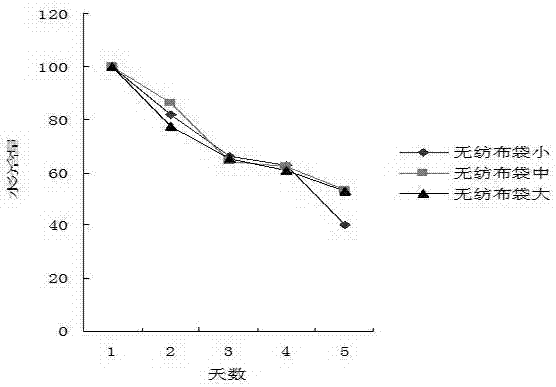

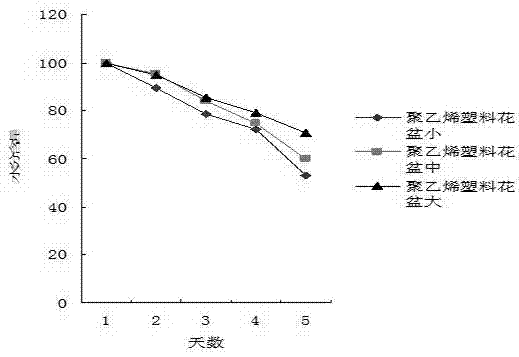

Method for breeding seedlings of grapes by using containers

InactiveCN102349430BSolve the problem of low qualityImprove survival rateCultivating equipmentsFruit treeRoot ball

The invention discloses a method for breeding seedlings of grapes by using containers and belongs to the field of fruit tree seedling raising. The method comprises the following steps of: (1) scissoring annual grape branches in winter to conserve in winter; (2) taking out the branches in late February of the next year, cutting the branches into sections of 18 to 20 cm, retaining stalks of 2 to 3 buds, and inserting into containers by cuttage, wherein nutritional soil comprises a mixture of reed residue matrix and garden soil, or a mixture of rich chaff dust and garden soil, or a mixture of the reed residue matrix, the rich chaff dust and the garden soil; and (3) inserting bamboo poles with the length of 1m into the containers to fix young sprouts when nursery stocks have 7 to 8 leaves, and pinching when the young sprouts are 80 cm. The method is not limited by season, so the defects in seedling in big lands are effectively overcome, root systems are formed in the containers and have good and complete root balls, roots are not damaged when seedlings are lifted, the seedlings are not required to be trimmed before planting, one-step forming is realized, time and labor are saved, survival rate is high after transplantation, the slow seedling stage does not exist, growth quantity is large in the initial stage, flower bud differentiation is realized in advance, high yield in early stage is realized, and quality of the nursery stocks is high.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

Preparation method of sun-screening agent iso-octyl p-methoxycinnamate

ActiveCN103242163BReduce generationReduce pressure on environmental protectionOrganic compound preparationCarboxylic acid esters preparationWater insolubleSolvent

The invention relates to a preparation method of a sun-screening agent OMC (iso-octyl P-Methoxycinnamate). The preparation method comprises the following steps of: 1, adding p-anisaldehyde, malonic acid, a catalyst I organic secondary amine substance, a catalyst II organic acid substance and a water-insoluble organic aromatic hydrocarbon solvent to a condensation reaction kettle, and carrying out reflux water diversion reaction for 4-5 hours; 2, after condensation reaction is finished, cooling to 5-15 DEG C, filtering to obtain a p-methoxycinnamic acid crude product, directly applying filter liquor to next reaction, and optionally supplementing a small quantity of catalysts and solvents to the filter liquor; 3, adding catalyst III macroporous type storng acid cation exchange resin, isooctyl alcohol, the p-methoxycinnamic acid crude product and an aromatic hydrocarbon or aliphatic hydrocarbon solvent to an esterifying reaction kettle, and carrying out reflux water diversion reaction for 2-3 hours; and 4, after esterifying reaction is finished, cooling to 65 DEG C, filtering and recovering the catalysts for mechanical application, washing the filter liquor to neutrality through a 5% sodium carbonate water solution, desolventizing, and rectifying to obtain the final product isooctyl p-methoxycinnamate. The method disclosed by the invention has the characteristics of easiness, convenience, easiness in control, industrial production, low environment pollution, low energy consumption, material recycling, high product purity, and the like.

Owner:ANHUI SHENGNUOBEI CHEM TECH

Process for synthesizing p-tert-butylbenzoic acid

ActiveCN102617335BReduce usageReduce recycling stepsOrganic compound preparationCarboxylic compound separation/purificationMoistureImpurity

The invention relates to a process for synthesizing p-tert-butylbenzoic acid. The process comprises the following steps of: adding p-tert-butyltoluene and cobalt acetate into a reaction kettle, introducing oxygen-containing gas, triggering at the temperature of between 150 and 155 DEG C, performing oxidation reaction for 0.5 to 1 hour, and continuously reacting at the temperature of between 135 and 145 DEG C for more than 5 hours to obtain a p-tert-butylbenzoic acid crude product; cooling the p-tert-butylbenzoic acid crude product to crystallize, performing centrifuge dripping, and striking and washing by using p-tert-butyltoluene to obtain a centrifugation crude product; and adding the centrifugation crude product into a dissolution kettle, adding methylbenzene, raising temperature and dissolving, filtering when a mixture is hot to remove impurities, adding water to wash, transferring materials to a recrystallization kettle, cooling to crystallize, centrifuging, striking and washing by using methylbenzene, and drying to obtain a p-tert-butylbenzoic acid finished product. The prepared p-tert-butylbenzoic acid is white crystals and does not contain mechanical impurities; and the melting point is 164.0 to 167.0 DEG C, the acid value is 312 to 316mgKOH / g, high performance liquid chromatography (HPLC) purity is more than or equal to 99.2 percent, moisture is less than or equal to 0.08 percent, and methylbenzene is less than or equal to 0.05 percent.

Owner:SUQIAN COSMOS CHEM +1

A process for producing iron concentrate powder by red mud fluidized bed method

ActiveCN110004263BSolve the problem of low qualityLow costFluidised-bed furnacesHearth type furnacesIron powderRed mud

The invention discloses a technology for producing iron fine powder through a red mud fluidized bed method, and belongs to the technical field of steel production. The technology is characterized by comprising the following steps that red mud grout is diluted and screened, and rough iron powder is obtained through a pretreatment manner of gravity sorting, magnetic sorting or gravity sorting and magnetic sorting combination; drying is conducted; the fluidization reducing reaction temperature of a reducing fluidized bed is controlled to range from 450 DEG C to 550 DEG C, gas with the volume ratio of CO+H2 being 40%-50% is used in the reducing fluidized bed to conduct the reducing reaction on the rough iron powder, the reducing reaction time is controlled to range from 8 min to 15 min, and reduced magnetized rough iron powder is obtained; and the reduced magnetized rough iron powder is ground to be smaller than 100 meshes, then, physical separation is conducted, and the iron fine powder with the grade being 61% or above is obtained. The technology can overcome the defect that during physical method red mud iron separating, the iron powder product quality is low, and energy consumptionduring chemical method red mud iron separating can be greatly reduced.

Owner:中铝山东工程技术有限公司

Air conditioning system for data center machine room in high-humidity area and using method of air conditioning system

InactiveCN113513795AReasonable structural designEasy to implementMechanical apparatusLighting and heating apparatusEvaporative coolerCold air

The invention discloses an air conditioning system for a data center machine room in a high-humidity area and a using method of the air conditioning system. The system comprises a rotating wheel dehumidification evaporative cooling unit and an air conditioning air channel; the rotating wheel dehumidification evaporative cooling unit comprises a unit shell, a channel dividing section and a mixing section are arranged in the unit shell, a rotating wheel dehumidifier, a rotating wheel heat exchanger and a baffle are arranged in the channel dividing section, the channel dividing section is divided into a treated air duct and a regenerated air duct which are arranged up and down through the baffle, a coarse filter, a precooler and a recooler are sequentially arranged in the treated air duct in the air inlet direction, an electric heater and an exhaust fan are sequentially arranged in the regenerated air duct in the exhaust direction, and a direct evaporative cooler, a medium efficiency filter and an air supply fan are arranged in the mixing section; and the air conditioning air channel comprises a cold air channel and an air return channel. The system is reasonable in structural design, can be effectively applied to data center machine rooms in medium-humidity and high-humidity areas, and is remarkable in refrigeration effect and convenient to popularize.

Owner:XIAN UNIV OF SCI & TECH

Preparation method of lilial

ActiveCN102627538BSolve the problem of low qualitySimple methodOrganic compound preparationCarbonyl compound preparationBenzaldehydeDistillation

The invention relates to a preparation method of lilial. The preparation method of lilial comprises the following steps that p-tert.-butyl-benzaldehyde, methanol and caustic soda flake solutions having different concentrations are added into a reactor; n-propanal is dropwisely added into the reactor at a certain temperature and undergoes a condensation reaction and after addition of n-propanal isfinished, the condensation reaction lasts for 0.5 to 2 hours under the condition of heat preservation; acidic materials are added into the reaction system to adjust a pH value and to stop the condensation reaction; after the condensation reaction is finished, methanol is recovered by distillation and a condensation product p-tert.-butyl-alpha-methyl phenyl acrolein is obtained by film evaporator distillation; methanol, p-tert.-butyl-alpha-methyl phenyl acrolein and a hydrogenation catalyst are added into a hydrogenation reactor; hydrogen is fed into the hydrogenation reactor and the mixture in the hydrogenation reactor undergoes a hydrogen reaction; and after the hydrogen reaction is finished, the reaction products are subjected to filter pressing, solvent removal and rectification so that a finished product lilial is obtained. Lilial obtained by the preparation method is a colorless and transparent liquid, and has a refractive index (nd20) of 1.504 to 1.506, the specific gravity (25 DEG C, mg / mL) of 0.942 to 0.946, an acid value (mgKOH / g) of 2.0(max.), the GC content (determined by an area normalization method) of m-LLY less than 2.0%, p-LLY great than or equal to 97.0% and m-LLY+p-LLY great than or equal to 98.0%, and the moisture content less than or equal to 0.25%.

Owner:SUQIAN COSMOS CHEM

A kind of synthetic technique of tridemorpholine

The invention relates to a tridemorph synthesis process which includes the steps: adding tridecyl alcohol and optional solvents into a reaction kettle, adding a catalyst, stirring and mixing mixture,leading into hydrogen, and heating the reaction kettle; adding 2, 6-thebaine when the temperature of the reaction kettle reaches the temperature of 200 DEG C or more, and maintaining the reaction kettle to perform reaction in a certain pressure and at a certain temperature until reaction is completed; post-processing a reactant to obtain a reactant finished product. According to the tridemorph synthesis process, the tridemorph with the purity larger than 99% is acquired under the conditions of high selectivity and high yield, and waste water, waste gas and industrial residues are greatly reduced.

Owner:江苏富比亚化学品有限公司

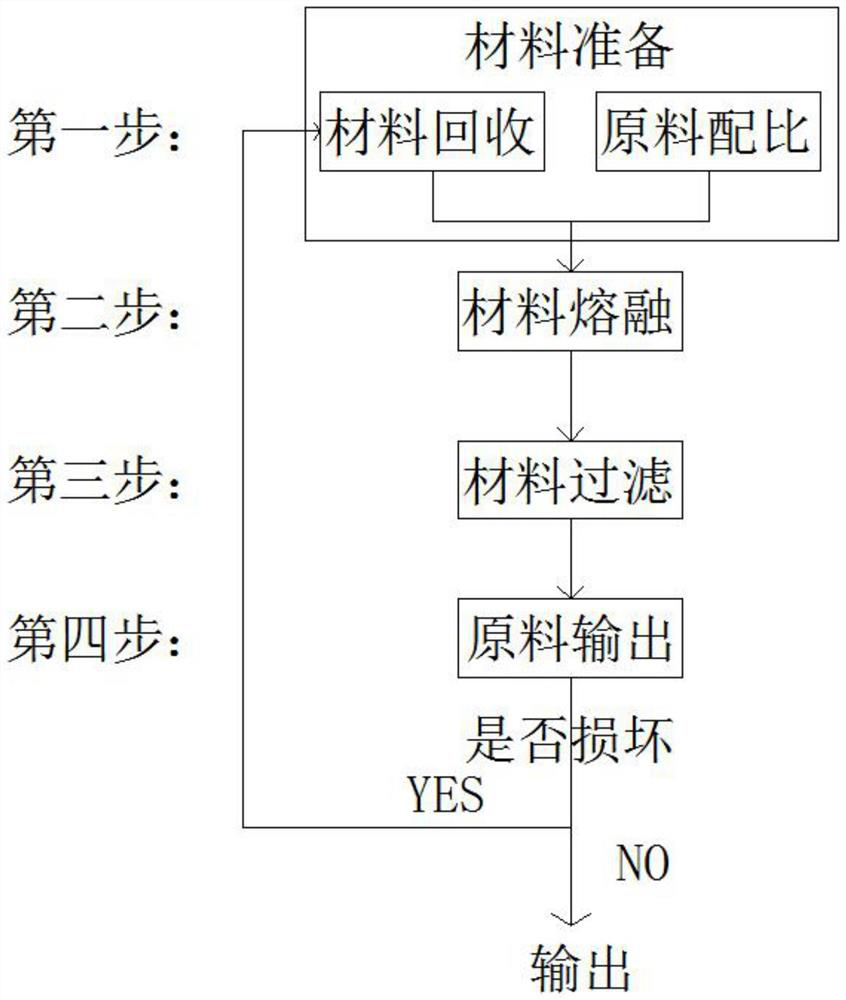

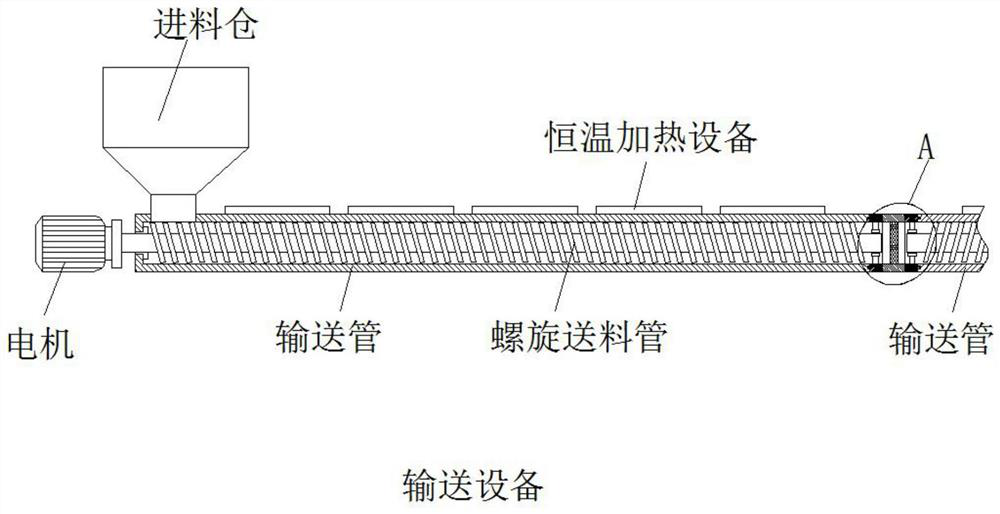

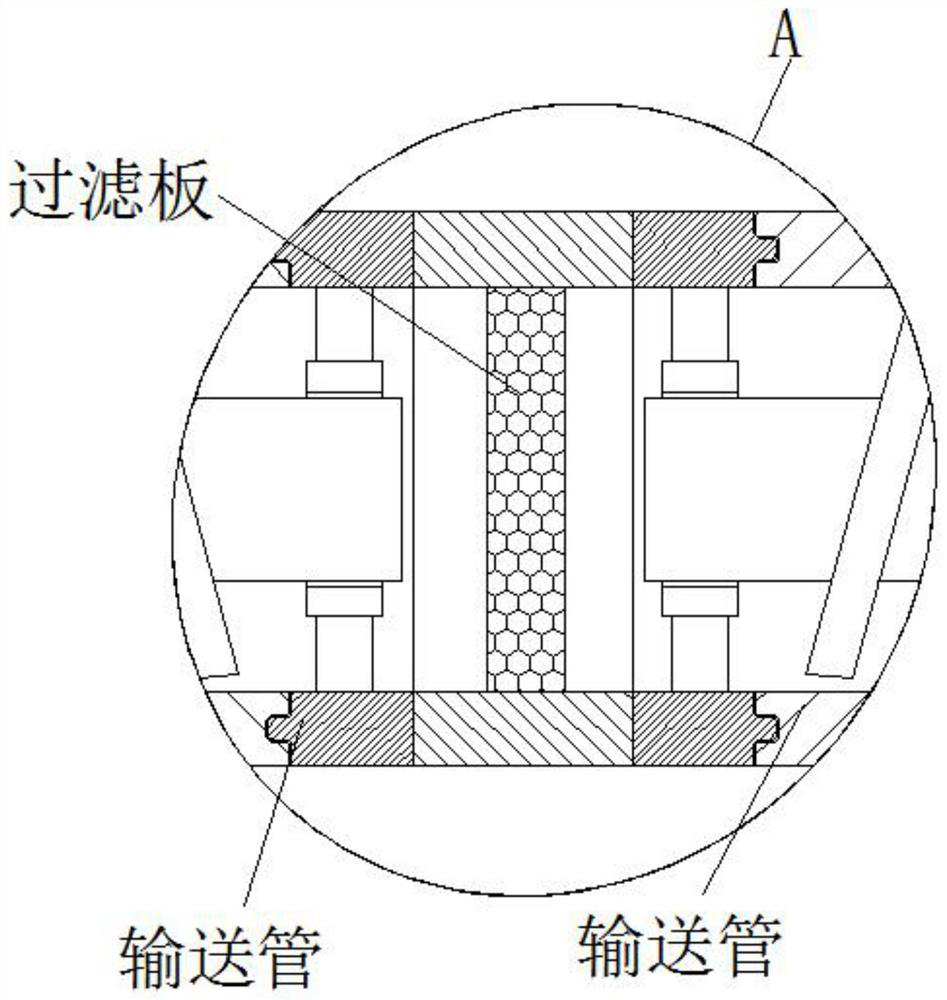

Production method of mining cable rubber sheath material

PendingCN113942140AEasy processing and recyclingReduce wastePlastic recyclingMechanical material recoveryElectric machineryComposite material

The invention discloses a production method of a mining cable rubber sheath material. The production method comprises the following steps: 1, material preparation: raw material proportioning material preparation and material recycling; 2, material melting: melting the rubber material through rubber melting equipment, and conveying the melted rubber material to the rear end; and 3, material filtering: enabling the melted material to pass through conveying equipment, and pushing rubber into a filter plate for filtering by the conveying equipment. Through cooperative use of shredding equipment, a rubber melting furnace, a feeding bin, a motor, a conveying pipe, a spiral feeding pipe and the filter plate, the problem that in the production process of an existing rubber sheath material, impurities are likely to be generated in rubber, and meanwhile, bubbles can be generated, so that the quality of the rubber sheath material becomes low is solved. The production method of the mining cable rubber sheath material has the advantages of no impurities and no bubbles, so that the market requirements are met.

Owner:QUFU HONGFEI CABLE

A dual-rotor dehumidification air conditioning system driven by low temperature and low humidity and its air supply method

ActiveCN109140610BImprove regeneration efficiencyIncrease partial pressure differenceMechanical apparatusLighting and heating apparatusWater qualityEngineering

The invention discloses a low-temperature and low-humidity driven double-rotating-wheel dehumidification air conditioning system and an air supply method thereof. The low-temperature and low-humiditydriven double-rotating-wheel dehumidification air conditioning system comprises a double-rotating-wheel dehumidification air conditioning unit, a hot water circulating system, a cold water circulatingsystem and a sensible heat air conditioning terminal device. The double-rotating-wheel dehumidification air conditioning unit comprises a first dehumidification rotating wheel, a second dehumidification rotating wheel, a plate-type heat recovery device, an air pre-cooler, an air recooler, a main air heater, an auxiliary air heater, a treatment fan and a regeneration fan. The hot water circulatingsystem comprises a low-grade energy heat collector. The cold water circulating system comprises a water return well and further comprises a water supply well, a reservoir and a water quality treatment device which are sequentially connected. The air supply method of the low-temperature and low-humidity driven double-rotating-wheel dehumidification air conditioning system comprises an air supplying method under the summer working condition and an air supplying method under the winter working condition. The low-temperature and low-humidity driven double-rotating-wheel dehumidification air conditioning system is novel and reasonable in design, low in cost, low in energy consumption, high in refrigerating and heating efficiency, free of greenhouse effect, high in practicability and high in application and popularization value.

Owner:南京丰颂机电科技有限公司

Method for preparing lilial key intermediate namely tert-butylphenol-alpha-methylbenzene acrolein

ActiveCN108658742AGood choiceAvoid it happening againOrganic compound preparationCarbonyl compound preparationBenzaldehydeAcrolein

The invention discloses a method for preparing a lilial key intermediate namely tert-butylphenol-alpha-methylbenzene acrolein. The method includes: at a set low temperature, adding propionaldehyde into p-tertbutyl benzaldehyde solution, and performing reaction under the catalytic action of potassium hydroxide; after reaction is finished, filtering to obtain a solid product namely tert-butylphenol-alpha-methylbenzene acrolein. By propionaldehyde dilution, low-temperature reaction crystallization, two-stage condensation reaction and the like, current situations including low raw material conversion rate, low yield and low purity in application of a tert-butylphenol-alpha-methylbenzene acrolein synthesis process are changed fundamentally, and the problem of low lilial quality is solved. The method has advantages of simplicity in operation, easiness in control and convenience in industrial production.

Owner:SUQIAN COSMOS CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com