A processing process of Dayoucha

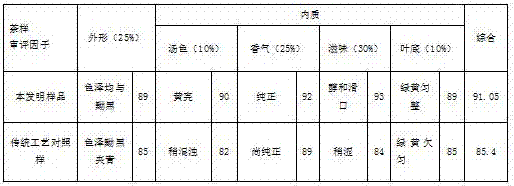

A processing technology, the technology of oil tea, which is applied in tea treatment before extraction, etc., can solve the problems of uneven greening, bitterness of tea leaves, etc., achieve the effect of strong new shoots, long internodes, and improve the quality of greening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A process for processing Camellia oleifera, comprising the following steps: A. Withering: pick the green tea leaves (tea leaves) used for Camellia oleifera and return them to the factory, then place the green tea greens in a withering tank, and ventilate at a temperature of 15-30°C 4-6h;

[0021] B. Pile up: pile up the tea greens after withering in step A, pile up into a tea pile with a pile height of 30-50cm, and pile up for 20-35min;

[0022] C. Heap spraying: Spread the tea heaps to form a tea heap with a height of 5-10cm. When the tea heaps are dispersed, water (or water mist) with a weight ratio of 1:10 to the green tea ) evenly sprayed on the surface of the tea green, turning the tea green while spraying water;

[0023] D. Finishing: Send the green tea that has been sprayed with water into a drum fixing machine or a fixing pot and stir fry for 3-7 minutes. The specific time is set according to the amount of leaves cast and the tenderness of the green tea;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com