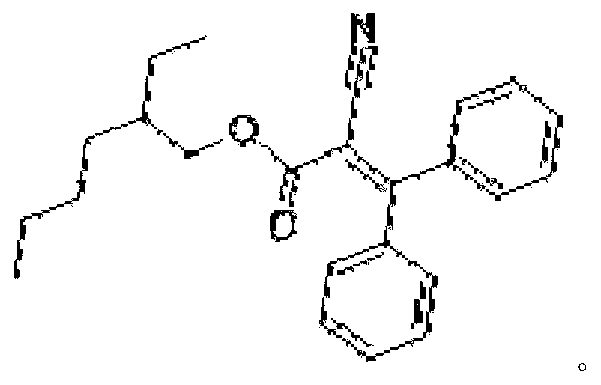

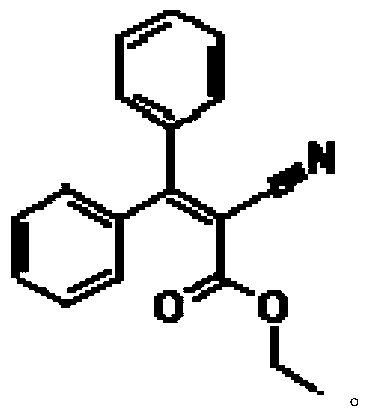

Preparation method of ultraviolet absorbent intermediate etocrilene (ETO)

The technology of an ultraviolet absorber and relying on toril is applied in the preparation of organic intermediates and in the field of preparation of sunscreen intermediates relying on toril. Achieve the effect of reducing difficulty and equipment investment, reducing amide by-products, and good separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

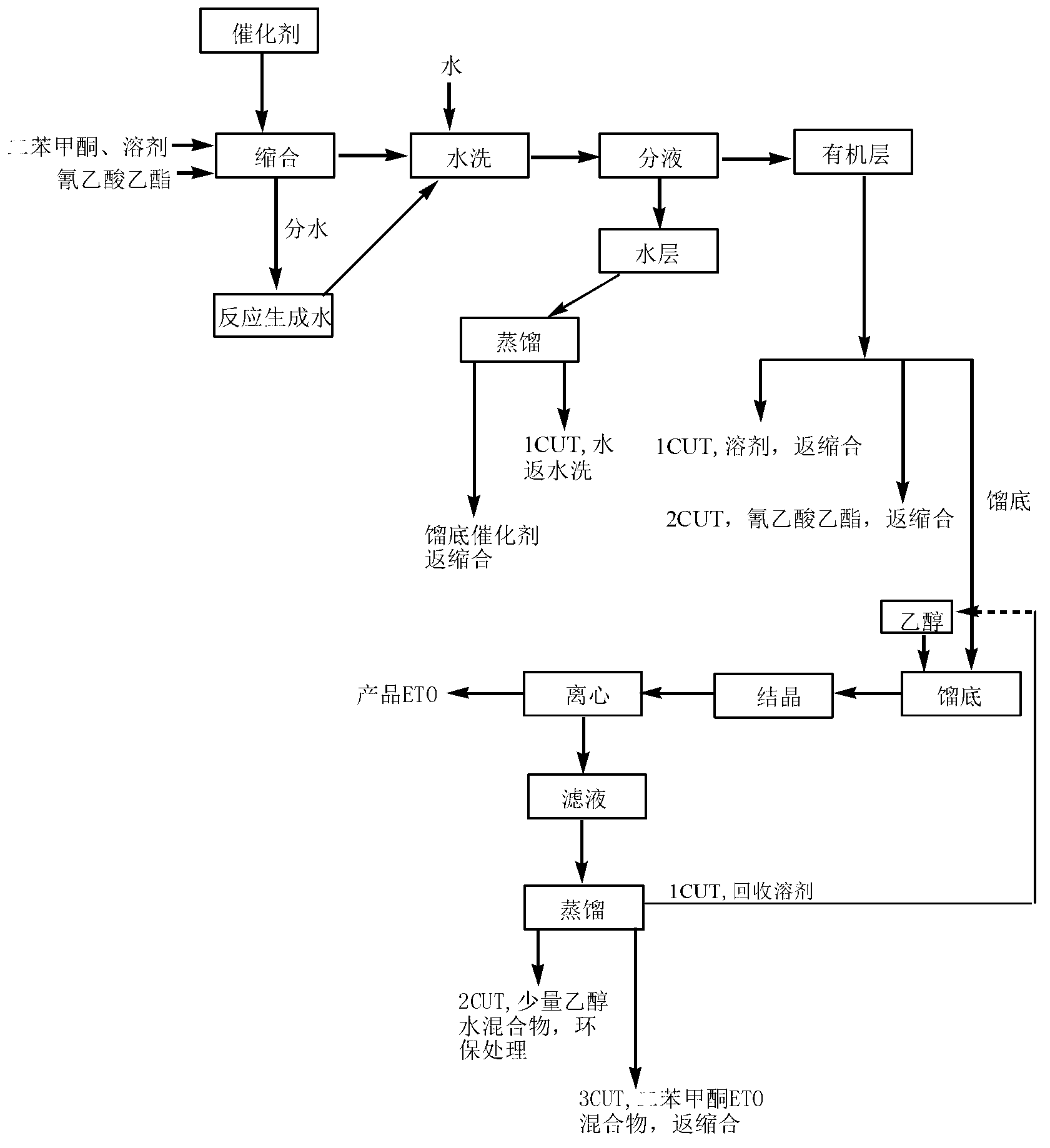

Method used

Image

Examples

Embodiment 1

[0058] Add 182kg benzophenone, 226kg ethyl cyanoacetate, 10Kg di-n-butylamine, 5.7Kg propionic acid and 273Kg cyclohexane into the reactor, heat up to reflux (reaction temperature is 85-87°C), and continuously separate the reaction Produced water, when the amount of water separated by the reaction is very small, the reaction is completed, and it takes about 14 hours to obtain 16Kg of water. Directly lower the temperature to 50-55°C, transfer 16Kg of water into the kettle, add 75Kg of preheated fresh water, stir for 15 minutes, let stand for 30 minutes, and separate the liquids to obtain 105Kg of water layer and 661.2Kg of oil layer.

[0059] Gained water layer 105Kg is simply distilled under-700mmHg vacuum until anhydrous steams out, and obtains water 73Kg, and this water can be used for embodiment 2; Distillation bottom 13.4Kg, is the catalyst of reclaiming, can be used for embodiment 2 and apply. .

[0060] The obtained oil layer was 661.2Kg, distilled at normal pressure un...

Embodiment 2

[0064] Embodiment 2 has investigated the mechanical application of each reclaimed material, to illustrate the applicability of the present invention.

[0065] Add benzophenone and ETO mixture 80Kg that reclaims in embodiment 1 in reactor, new benzophenone 132Kg; Add in embodiment 1 and reclaim ethyl cyanoacetate 138Kg, new ethyl cyanoacetate 95Kg; Add the catalyst that reclaims 13.4Kg, add new 1.5Kg di-n-butylamine and 0.8Kg propionic acid, add recovered cyclohexane 239Kg and new cyclohexane 25Kg, heat up to reflux (reaction temperature is 86-88°C), and continuously separate the reaction products When the amount of water separated by the reaction is very small, the reaction is completed, and it takes about 12 hours to obtain 21Kg of water. Directly lower the temperature to 50-55°C, transfer the separated 21Kg of water into the kettle, then add 73Kg of preheated recovered water, stir for 15 minutes, let stand for 30 minutes, and separate the liquids to obtain 106.4Kg of water l...

Embodiment 3

[0071] Add 182kg benzophenone, 226kg ethyl cyanoacetate, 6.6kg piperidine, 11.2kg n-octanoic acid and 275kg n-heptane in the reactor, heat up to reflux (reaction temperature is 99-102°C), and continuously separate the reaction products When the amount of water separated by the reaction is very small, the reaction is completed, and it takes about 13 hours to obtain 15.9kg of water. Directly lower the temperature to 52-55°C, transfer 15.9kg of water into the kettle, then add 75kg of preheated tap water, stir for 20 minutes, let stand for 40 minutes, and separate the liquids to obtain 107kg of water layer and 658kg of oil layer.

[0072] Gained water layer is simply distilled under -700mmHg vacuum until anhydrous is evaporated, and 75kg of water is obtained, which can be recycled; the distillation bottom 17.2kg is the catalyst recovered and can be recycled.

[0073] The resulting oil layer was distilled at normal pressure until the flow was cut off to obtain 265 kg of n-heptane; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com